Abstract

Pressure-driven membranes is a widely used separation technology in a range of industries, such as water purification, bioprocessing, food processing and chemical production1,2. Despite their numerous advantages, such as modular design and minimal footprint, inevitable membrane fouling is the key challenge in most practical applications3. Fouling limits membrane performance by reducing permeate flux or increasing pressure requirements, which results in higher energetic operation and maintenance costs4,5,6,7. Here we report a hydraulic-pressure-responsive membrane (PiezoMem) to transform pressure pulses into electroactive responses for in situ self-cleaning. A transient hydraulic pressure fluctuation across the membrane results in generation of current pulses and rapid voltage oscillations (peak, +5.0/−3.2 V) capable of foulant degradation and repulsion without the need for supplementary chemical cleaning agents, secondary waste disposal or further external stimuli3,8,9,10,11,12,13. PiezoMem showed broad-spectrum antifouling action towards a range of membrane foulants, including organic molecules, oil droplets, proteins, bacteria and inorganic colloids, through reactive oxygen species (ROS) production and dielectrophoretic repulsion.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data supporting the findings of this study are included within the paper and its Supplementary Information and are available from the corresponding author on request.

References

Shannon, M. A. et al. Science and technology for water purification in the coming decades. Nature 452, 301–310 (2008).

Werber, J. R., Osuji, C. O. & Elimelech, M. Materials for next-generation desalination and water purification membranes. Nat. Rev. Mater. 1, 16018 (2016).

Ronen, A., Walker, S. L. & Jassby, D. Electroconductive and electroresponsive membranes for water treatment. Rev. Chem. Eng. 32, 533–550 (2016).

Hou, X., Hu, Y. H., Grinthal, A., Khan, M. & Aizenberg, J. Liquid-based gating mechanism with tunable multiphase selectivity and antifouling behaviour. Nature 519, 70–73 (2015).

Huang, K. et al. Cation-controlled wetting properties of vermiculite membranes and its promise for fouling resistant oil–water separation. Nat. Commun. 11, 1097 (2020).

Seo, D. H. et al. Anti-fouling graphene-based membranes for effective water desalination. Nat. Commun. 9, 683 (2018).

Yu, Q. & Zhang, Y. Fouling-resistant biofilter of an anaerobic electrochemical membrane reactor. Nat. Commun. 10, 4860 (2019).

Zhu, X. & Jassby, D. Electroactive membranes for water treatment: enhanced treatment functionalities, energy considerations, and future challenges. Acc. Chem. Res. 52, 1177–1186 (2019).

Formoso, P., Pantuso, E., De Filpo, G. & Nicoletta, F. P. Electro-conductive membranes for permeation enhancement and fouling mitigation: a short review. Membranes 7, 115219 (2017).

Zhang, Q. Y. et al. Interlaced CNT electrodes for bacterial fouling reduction of microfiltration membranes. Environ. Sci. Technol. 51, 9176–9183 (2017).

Zhang, Q. Y. & Vecitis, C. D. Conductive CNT-PVDF membrane for capacitive organic fouling reduction. J. Membr. Sci. 459, 143–156 (2014).

Kuscer, D. et al. Integrated piezoelectric vibration system for fouling mitigation in ceramic filtration membranes. J. Membr. Sci. 540, 277–284 (2017).

Zhang, J. et al. Endowing piezoelectric and anti-fouling properties by directly poling β-phase PVDF membranes with green diluents. AIP Adv. 9, 115219 (2019).

Zhao, Y., Gu, Y. N. & Gao, G. D. Piezoelectricity induced by pulsed hydraulic pressure enables in situ membrane demulsification and oil/water separation. Water Res. 215, 118245 (2022).

You, Y. M. et al. An organic-inorganic perovskite ferroelectric with large piezoelectric response. Science 357, 306–309 (2017).

Wang, R., Tang, E., Yang, G. & Han, Y. Experimental research on dynamic response of PZT-5H under impact load. Ceram. Int. 46, 2868–2876 (2020).

Park, D. Y. et al. Self-powered real-time arterial pulse monitoring using ultrathin epidermal piezoelectric sensors. Adv. Mater. 29, 1702308 (2017).

Yan, Y., Zhou, J. E., Maurya, D., Wang, Y. U. & Priya, S. Giant piezoelectric voltage coefficient in grain-oriented modified PbTiO3 material. Nat. Commun. 7, 13089 (2016).

Wu, W. et al. Piezoelectricity of single-atomic-layer MoS2 for energy conversion and piezotronics. Nature 514, 470–474 (2014).

Mao, H. et al. Self-cleaning piezoelectric membrane for oil-in-water separation. ACS Appl. Mater. Interfaces 10, 18093–18103 (2018).

Xiao, B., Dong, Y., Ma, N. & Du, P. Formation of sol–gel in situ derived BTO/NZFO composite ceramics with considerable dielectric and magnetic properties. J. Am. Ceram. Soc. 96, 1240–1247 (2013).

Huan, Y., Wang, X., Fang, J. & Li, L. Grain size effects on piezoelectric properties and domain structure of BaTiO3 ceramics prepared by two-step sintering. J. Am. Ceram. Soc. 96, 3369–3371 (2013).

Ghosh, D. et al. Domain wall displacement is the origin of superior permittivity and piezoelectricity in BaTiO3 at intermediate grain sizes. Adv. Funct. Mater. 24, 885–896 (2014).

Williams, J. B., Clarkson, C., Mant, C., Drinkwater, A. & May, E. Fat, oil and grease deposits in sewers: characterisation of deposits and formation mechanisms. Water Res. 46, 6319–6328 (2012).

Zhang, R. et al. Engineering amphiphilic nanofiltration membrane surfaces with a multi-defense mechanism for improved antifouling performances. J. Mater. Chem. A 4, 7892–7902 (2016).

Liang, Z., Yan, C.-F., Rtimi, S. & Bandara, J. Piezoelectric materials for catalytic/photocatalytic removal of pollutants: recent advances and outlook. Appl. Catal. B Environ. 241, 256–269 (2019).

Yi, Q. et al. Singlet oxygen triggered by superoxide radicals in a molybdenum cocatalytic Fenton reaction with enhanced REDOX activity in the environment. Environ. Sci. Technol. 53, 9725–9733 (2019).

Saito, Y. et al. Lead-free piezoceramics. Nature 432, 84–87 (2004).

Wu, Y., Zaiden, N., Liu, X., Mukherjee, M. & Cao, B. Responses of exogenous bacteria to soluble extracellular polymeric substances in wastewater: a mechanistic study and implications on bioaugmentation. Environ. Sci. Technol. 54, 6919–6928 (2020).

Pradel, K. C., Sohn, K. & Huang, J. Cross-flow purification of nanowires. Angew. Chem. Int. Ed. 50, 3412–3416 (2011).

Asatekin, A. & Mayes, A. M. Oil industry wastewater treatment with fouling resistant membranes containing amphiphilic comb copolymers. Environ. Sci. Technol. 43, 4487–4492 (2009).

Tangsubkul, N., Parameshwaran, K., Lundie, S., Fane, A. G. & Waite, T. D. Environmental life cycle assessment of the microfiltration process. J. Membr. Sci. 284, 214–226 (2006).

Lan, Y., Groenen-Serrano, K., Coetsier, C. & Causserand, C. Nanofiltration performances after membrane bioreactor for hospital wastewater treatment: fouling mechanisms and the quantitative link between stable fluxes and the water matrix. Water Res. 146, 77–87 (2018).

Acknowledgements

This work is supported by the National Natural Science Foundation of China (21976085) and the National Key Research and Development Program of China (grant nos. 2016YFA0203104 and 2017YFE010720). G.G. thanks J.D. and C.S. for the measurement of pore size distribution and porosity, L.T.P. for their efforts in preparing the new PiezoMem to enable long-term running and Nanjing Wondux Environmental Protection Technology Corp. Ltd. for their assistance in scaling up the new PiezoMem and carrying out long-term experiments.

Author information

Authors and Affiliations

Contributions

G.G. conceived the idea, supervised this work and revised the manuscript. Y.Z. designed and carried out the experiments (not including the preparation of the redesigned and improved new PiezoMem, and its long-term and scale-up experiments) and drafted the manuscript. B.L. and Y.G simulated and verified dielectrophoresis. Y.Y. measured the morphology of PiezoMem. C.S. discussed and revised the manuscript. C.D.V. discussed the data, proposed the dielectrophoresis antifouling mechanism and revised the manuscript. J.G. and S.Z. proposed the new PiezoMem in the revision of this manuscript. All authors analysed and interpreted the results.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Suzana Nunes and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

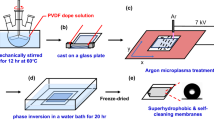

Extended Data Fig. 1 Membrane poling and periodical pressure cycling membrane filtration devices.

Devices of the membrane poling process (a–c), piezoelectricity determination (d) and the periodical pressure cycling membrane filtration (e).

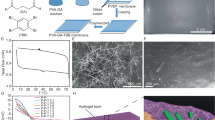

Extended Data Fig. 2 Characterization of PiezoMem.

The enhanced membrane strength of MnO/BTO PiezoMem without crack after filtration compared with the pure BTO membrane (a). Pore (b) and grain size (c) distributions of the PiezoMem after sintering. ESEM and the corresponding EDS elemental mapping images (corresponding ESEM images scale bar, 1 mm) of the PiezoMem (d). HRTEM image of the grain (e). STEM-HAADF EDS results (f) from the selected region of the MnO/BTO grain in Fig 1d. The pore size distribution measured by the mercury porosimetry method (g).

Extended Data Fig. 3 Characterization and properties of piezoelectric particles, membrane and foulants.

XRD patterns (a), underwater oil contact angle (b), permittivity (c), d33 values of the membranes (d) and the piezo outputs of the PiezoMem in response to a weight of 300 g in O/W emulsion (e). DLVO energy as a function of separation distance between O/W particle membranes (f,g) and the grain size distribution and zeta potential of foulants (h).

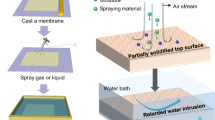

Extended Data Fig. 4 Optimization of pressure operation cycles.

The corresponding changing pressure on antifouling (a–d). PiezoMem resists the sudden and transient high content feed solution up to 5,000 ppm (e) by regulating pressure operation (f). The flux of PiezoMem under lower pressure conditions (<2 bar) (g) and corresponding antifouling properties (h). Four parallel tests under the cycle condition (70-(2-7) s, 2 bar) with a high 2,500-ppm O/W emulsion (i).

Extended Data Fig. 5 Foulants in the pores and surfaces of PiezoMem and non-PiezoMem.

ESEM images of the membranes after O/W emulsion (a), BSA (b), SiO2 (c) and Al2O3 (d) filtration. EDS elemental mapping images in a and b correspond to the cross-section ESEM images. (e), flux50 permeation of the membranes. (f), Typical element content of foulants on the membrane surface after pressure cycling filtration according to the EDX results. (Note that the content of BSA was 50 ppm, whereas those of oil, SiO2 and Al2O3 were all 2,500 ppm).

Extended Data Fig. 6 Antibacterial performance.

Images of the PiezoMem and non-PiezoMem (a–d) towards E. coli.

Extended Data Fig. 7 COMSOL simulation.

Modelling dielectrophoresis (a–e) and electrostatic interaction (f) results.

Supplementary information

Supplementary Information

This file contains the COMSOL simulation and legends for supplementary videos.

Rights and permissions

About this article

Cite this article

Zhao, Y., Gu, Y., Liu, B. et al. Pulsed hydraulic-pressure-responsive self-cleaning membrane. Nature 608, 69–73 (2022). https://doi.org/10.1038/s41586-022-04942-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-022-04942-4

This article is cited by

-

An advanced 2D/3D g-C3N4/TiO2@MnO2 multifunctional membrane for sunlight-driven sustainable water purification

Nano Research (2024)

-

Active self-assembly of piezoelectric biomolecular films via synergistic nanoconfinement and in-situ poling

Nature Communications (2023)

-

High-Value Processing and Utilization for Digested Manure Effluent Treatment: Advances and Challenges

Current Pollution Reports (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.