Abstract

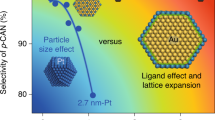

In oxidation reactions catalysed by supported metal nanoparticles with oxygen as the terminal oxidant, the rate of the oxygen reduction can be a limiting factor. This is exemplified by the oxidative dehydrogenation of alcohols, an important class of reactions with modern commercial applications1,2,3. Supported gold nanoparticles are highly active for the dehydrogenation of the alcohol to an aldehyde4 but are less effective for oxygen reduction5,6. By contrast, supported palladium nanoparticles offer high efficacy for oxygen reduction5,6. This imbalance can be overcome by alloying gold with palladium, which gives enhanced activity to both reactions7,8,9; however, the electrochemical potential of the alloy is a compromise between that of the two metals, meaning that although the oxygen reduction can be improved in the alloy, the dehydrogenation activity is often limited. Here we show that by separating the gold and palladium components in bimetallic carbon-supported catalysts, we can almost double the reaction rate compared with that achieved with the corresponding alloy catalyst. We demonstrate this using physical mixtures of carbon-supported monometallic gold and palladium catalysts and a bimetallic catalyst comprising separated gold and palladium regions. Furthermore, we demonstrate electrochemically that this enhancement is attributable to the coupling of separate redox processes occurring at isolated gold and palladium sites. The discovery of this catalytic effect—a cooperative redox enhancement—offers an approach to the design of multicomponent heterogeneous catalysts.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data that led us to understand the results presented here are available with the Article or from the corresponding author upon reasonable request. Source data are provided with this paper.

References

Mallat, T. & Baiker, A. Oxidation of alcohols with molecular oxygen on solid catalysts. Chem. Rev. 104, 3037–3058 (2004).

Ciriminna, R., Pandarus, V., Béland, F., Xu, Y. J. & Pagliaro, M. Heterogeneously catalyzed alcohol oxidation for the fine chemical industry. Org. Process Res. Dev. 19, 1554–1558 (2015).

Sheldon, R. A., Arends, I. W. C. E., Brink, G. J., Ten, & Dijksman, A. Green, catalytic oxidations of alcohols. Acc. Chem. Res. 35, 774–781 (2002).

Abad, A., Concepción, P., Corma, A. & García, H. A collaborative effect between gold and a support induces the selective oxidation of alcohols. Angew. Chem. Int. Ed. 44, 4066–4069 (2005).

Kulkarni, A., Siahrostami, S., Patel, A. & Nørskov, J. K. Understanding catalytic activity trends in the oxygen reduction reaction. Chem. Rev. 118, 2302–2312 (2018).

Nørskov, J. K. et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B 108, 17886–17892 (2004).

Zhu, X. et al. Optimising surface d charge of AuPd nanoalloy catalysts for enhanced catalytic activity. Nat. Commun. 10, 1428 (2019).

Enache, D. I. et al. Solvent-free oxidation of primary alcohols to aldehydes using Au–Pd/TiO2 catalyst. Science 311, 362–365 (2006).

Trindell, J. A., Duan, Z., Henkelman, G. & Crooks, R. M. AuxPd(300-x) alloy nanoparticles for the oxygen reduction reaction in alkaline media. ChemElectroChem 7, 3824–3831 (2020).

Hutchings, G. J. & Kiely, C. J. Strategies for the synthesis of supported gold palladium nanoparticles with controlled morphology and composition. Acc. Chem. Res. 46, 1759–1772 (2013).

Wang, A., Liu, X. Y., Mou, C. Y. & Zhang, T. Understanding the synergistic effects of gold bimetallic catalysts. J. Catal. 308, 258–271 (2013).

Wang, D., Villa, A., Porta, F., Prati, L. & Su, D. Bimetallic gold/palladium catalysts: correlation between nanostructure and synergistic effects. J. Phys. Chem. C 112, 8617–8622 (2008).

Gao, F. & Goodman, D. W. Pd–Au bimetallic catalysts: understanding alloy effects from planar models and (supported) nanoparticles. Chem. Soc. Rev. 41, 8009–8020 (2012).

Han, S. & Mullins, C. B. Catalytic reactions on Pd–Au bimetallic model catalysts. Acc. Chem. Res. 54, 379–387 (2020).

Davis, S. E., Ide, M. S. & Davis, R. J. Selective oxidation of alcohols and aldehydes over supported metal nanoparticles. Green Chem. 15, 17–45 (2013).

Parmeggiani, C., Matassini, C. & Cardona, F. A step forward towards sustainable aerobic alcohol oxidation: new and revised catalysts based on transition metals on solid supports. Green Chem. 19, 2030–2050 (2017).

Pelaez, M. et al. A review on the visible light active titanium dioxide photocatalysts for environmental applications. Appl. Catal. B 125, 331–349 (2012).

Golberg, D. et al. Boron nitride nanotubes and nanosheets. ACS Nano 4, 2979–2993 (2010).

Suo, Y., Zhuang, L. & Lu, J. First-principles considerations in the design of Pd-alloy catalysts for oxygen reduction. Angew. Chem. Int. Ed. 46, 2862–2864 (2007).

Zope, B. N., Hibbitts, D. D., Neurock, M. & Davis, R. J. Reactivity of the gold/water interface during selective oxidation catalysis. Science 330, 74–78 (2010).

Han, Y. F. et al. Au promotional effects on the synthesis of H2O2 directly from H2 and O2 on supported Pd–Au alloy catalysts. J. Phys. Chem. C 111, 8410–8413 (2007).

Chadderdon, D. J. et al. Electrocatalytic oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid on supported Au and Pd bimetallic nanoparticles. Green Chem. 16, 3778–3786 (2014).

Zhu, Y. et al. Boosting oxygen reduction reaction activity of palladium by stabilizing its unusual oxidation states in perovskite. Chem. Mater. 27, 3048–3054 (2015).

Ringeisen, B. R. et al. High power density from a miniature microbial fuel cell using Shewanella oneidensis DSP10. Environ. Sci. Technol. 40, 2629–2634 (2006).

Mackay, A. L. A dense non-crystallographic packing of equal spheres. Acta Cryst. 15, 916–918 (1962).

Siyo, B. et al. Influence of support on the aerobic oxidation of HMF into FDCA over preformed Pd nanoparticle based materials. Appl. Catal. A 478, 107–116 (2014).

Villa, A., Schiavoni, M., Campisi, S., Veith, G. M. & Prati, L. Pd-modified Au on carbon as an effective and durable catalyst for the direct oxidation of HMF to 2,5-furandicarboxylic acid. ChemSusChem 6, 609–612 (2013).

Han, X. et al. Base-free aerobic oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid over a Pt/C–O–Mg catalyst. Green Chem. 18, 1597–1604 (2016).

Zhou, C. et al. Functionalized carbon nanotubes for biomass conversion: the base‐free aerobic oxidation of 5‐hydroxymethylfurfural to 2,5‐furandicarboxylic acid over platinum supported on a carbon nanotube catalyst. ChemCatChem 7, 2853–2863 (2015).

Artz, J. & Palkovits, R. Base‐free aqueous‐phase oxidation of 5‐hydroxymethylfurfural over ruthenium catalysts supported on covalent triazine frameworks. ChemSusChem 8, 3832–3838 (2015).

Mishra, D. K. et al. MnCo2O4 spinel supported ruthenium catalyst for air-oxidation of HMF to FDCA under aqueous phase and base-free conditions. Green Chem. 19, 1619–1623 (2017).

Schade, O. et al. The influence of the gold particle size on the catalytic oxidation of 5-(hydroxymethyl)furfural. Catalysts 10, 342 (2020).

Megías‐Sayago, C. et al. Effect of gold particles size over Au/C catalyst selectivity in HMF oxidation reaction. ChemCatChem 12, 1177–1183 (2020).

Ferraz, C. P. et al. 5-Hydroxymethylfurfural and furfural base-free oxidation over AuPd embedded bimetallic nanoparticles. Catalysts 10, 75 (2020).

Yang, J. et al. Effect of the oxygen coordination environment of CaMn oxides on the catalytic performance of Pd supported catalysts for aerobic oxidation of 5-hydroxymethyl-2-furfural. Catal. Sci. Technol. 9, 6659–6668 (2019).

Liu, Y. et al. Active oxygen species promoted catalytic oxidation of 5-hydroxymethyl-2-furfural on facet-specific Pt nanocrystals. ACS Catal. 9, 8306–8315 (2019).

Megias-Sayago, C. et al. Understanding the role of the acid sites in 5-hydroxymethylfurfural oxidation to 2,5-furandicarboxylic acid reaction over gold catalysts: surface investigation on CexZr1−xO2 compounds. ACS Catal. 8, 11154–11164 (2018).

Yu, K. et al. The role of Bi-doping in promoting electron transfer and catalytic performance of Pt/3DOM-Ce1−xBixO2−δ. J. Catal. 365, 292–302 (2018).

Schade, O. R., Kalz, K. F., Neukum, D., Kleist, W. & Grunwaldt, J. D. Supported gold- and silver-based catalysts for the selective aerobic oxidation of 5-(hydroxymethyl)furfural to 2,5-furandicarboxylic acid and 5-hydroxymethyl-2-furancarboxylic acid. Green Chem. 20, 3530–3541 (2018).

Masoud, N., Donoeva, B. & de Jongh, P. E. Stability of gold nanocatalysts supported on mesoporous silica for the oxidation of 5-hydroxymethyl furfural to furan-2,5-dicarboxylic acid. Appl. Catal. A 561, 150–157 (2018).

Wan, X. et al. Base-free aerobic oxidation of 5-hydroxymethyl-furfural to 2,5-furandicarboxylic acid in water catalyzed by functionalized carbon nanotube-supported Au–Pd alloy nanoparticles. ACS Catal. 4, 2175–2185 (2014).

Bonincontro, D. et al. AuPd-nNiO as an effective catalyst for the base-free oxidation of HMF under mild reaction conditions. Green Chem. 21, 4090–4099 (2019).

Gui, Z. et al. Efficient aerobic oxidation of 5‐hydroxymethylfurfural in aqueous media with Au–Pd supported on zinc hydroxycarbonate. ChemCatChem 8, 3636–3643 (2016).

Kerdi, F. et al. Evaluation of surface properties and pore structure of carbon on the activity of supported Ru catalysts in the aqueous-phase aerobic oxidation of HMF to FDCA. Appl. Catal. A 506, 206–219 (2015).

Ait Rass, H., Essayem, N. & Besson, M. Selective aerobic oxidation of 5‐HMF into 2,5‐furandicarboxylic acid with Pt catalysts supported on TiO2‐ and ZrO2‐based supports. ChemSusChem 8, 1206–1217 (2015).

Chen, H. et al. Atomic layer deposition of Pt nanoparticles on low surface area zirconium oxide for the efficient base-free oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid. Appl. Catal. A 555, 98–107 (2018).

Acknowledgements

We thank L. Kang and R. Wang from University College London and Cardiff University for access and assistance with the electron microscopy; and the Diamond Light Source for access to beamline E01 (proposal number EM18909). C.J.K. acknowledges funding from the National Science Foundation Major Research Instrumentation programme (GR# MRI/DMR-1040229). S.M.A. thanks the Saudi Arabian government for his PhD scholarship. X.H. and Q.H. thank Cardiff University School of Chemistry for financial support. Q.H. also acknowledges the support by National Research Foundation (NRF) Singapore, under its NRF Fellowship (NRF-NRFF11-2019-0002). K.W. and L.Z. thank the Chinese Scholarship Council (CSC) for financial support. XPS data collection was performed at the EPSRC National Facility for XPS (‘HarwellXPS’), operated by Cardiff University and UCL, under contract number PR16195. We thank Cardiff University and the Max Planck Centre for Fundamental Heterogeneous Catalysis (FUNCAT) for financial support.

Author information

Authors and Affiliations

Contributions

X.H., O.A., M.D., R.J.L., S.P., P.J.M. and G.J.H. contributed to the design of the study. X.H., O.A., L.Z., I.T.D., R.J.L., K.W., J.F. and F.W. conducted experiments and data analysis. O.A. and X.H. conceived the mechanism. X.H., O.A., M.D., R.J.L., S.P., P.J.M., G.S., D.B., S.M., C.J.K. and G.J.H. provided technical support, conceptual advice and result interpretation. X.H., O.A., S.P., G.S., D.J.M., S.M.A., T.E.D., Q.H. and C.J.K. conducted catalyst characterization and corresponding data processing. M.D., O.A., D.B. and G.J.H. wrote the manuscript. X.H. wrote the Extended Data figures and tables. X.H., O.A., M.D., R.J.L., S.P., G.S., D.B., S.M., C.J.K. and G.J.H commented on and amended both documents. All authors discussed and contributed to the work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Bin Wang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Diagrammatic representation of the sol-immobilisation method used for catalyst preparation.

a, Monometallic Au/C and Pd/C. b, Au=Pd/C. c, Au@Pd/C catalysts. d, alloyed Au–Pd/C. e, Schematic representation of our reactor set-up for the thermocatalytic experiments.

Extended Data Fig. 2 Time-on-line data of aqueous HMF oxidation over series of Au/Pd catalysts and their TOF.

a, Au/C. b, Pd/C. c, Au–Pd/C alloy. d, Physical mixture of Au/C + Pd/C. e, Au@Pd/C. f, Au/C followed by the addition of Pd/C after 30 min. g, Au/C followed by the addition of C after 30 min. Reaction conditions: HMF (0.1 M); NaHCO3 (0.4 M); H2O (16 ml); Au/C: 72.1 mg; Pd/C: 71 mg; Au–Pd/C alloy: 143.1 mg; Au@Pd/C: 143.1 mg; C: 71 mg; 80 °C; pO2 = 3 bar. Key: FDCA yield (■), FFCA yield (♦), HMFCA yield (▲), HMF conversion (●), mass balance (*). Associated error bars correspond to mean ± s.d. (n = 5). h, The influence on ODH activity when various quantities of Pd/C (▲) and C (●) are added to Au/C (72.1 mg); ODH activity exhibited by various quantities of Pd/C, in the absence of Au/C, is also displayed (◂). i, The influence of oxygen pressure (0.6–3.0 bar) on ODH activity over a physical mixture of Au/C + Pd/C (▲) and Au/C (♦) is displayed. The reaction conditions used for h and i are given in Methods. j, Summary of each catalyst in terms of HMF conversion, initial rate and TOF at a 5-min reaction time. The total active sites available in each catalyst was estimated using the Mackay model, based on the presented particle size distributions25. Further information relating to how the TOFs were calculated, can be found in Methods.

Extended Data Fig. 3 Catalytic performance over Au/C, Pd/C, Au–Pd/C alloy, Au/C + Pd/C physical mixture and Au@Pd/C catalysts in series of alcohol oxidation reactions.

a, Glycerol oxidation. b, Ethanol oxidation. c, 5-Formyl-2-furancarboxylic acid (FFCA) oxidation. d, 5-Hydroxymethylfuroicacid (HMFCA) oxidation. Reaction conditions were all listed in Methods. e, Conversion values for the HMF oxidation reaction after 5 and 15 min time-on-line for the various catalysts studied in this work. Reaction conditions: HMF (0.1 M); NaHCO3 (0.4 M); H2O (16 ml); Au/(C/TiO2/BN): 72.1 mg, Pd/(C/TiO2/BN): 71 mg, Au@Pd/C, Au–Pd/(C/TiO2/BN) and Au/(C/TiO2/BN) + Pd/(C/TiO2/BN): 143.1 mg; 80 °C; pO2 = 3 bar; reaction time: 5 and 15 min. * presents the test on bare supports in HMF oxidation, HMF (0.1 M); NaHCO3 (0.4 M); H2O (16 ml); C/TiO2/BN: 60 mg; 80 °C; pO2 = 3 bar; reaction time: 30 min.

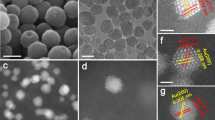

Extended Data Fig. 4 Electron microscopy analysis of Au/C + Pd/C (physical mixture) catalyst after one cycle of use in the oxidation of HMF.

a, b, Representative complementary BF- and HAADF-STEM micrographs showing metal nanoparticle size and spatial distribution. c, Atomic resolution HAADF-STEM micrograph of a C grain supporting Au particles. d, A C grain supporting Pd particles confirming that the Au and Pd remain separated under our reaction conditions. e, f, Representative XEDS spectra of individual Au particles and Pd particles in the catalyst, respectively. No evidence of Au or Pd migration or intermixing after the catalytic reaction was observed.

Extended Data Fig. 5 XPS data.

a, b, Au 4f and c, d, Pd 3d /Au 4d regions for Au/C and Pd/C monometallic catalysts before and after a typical HMF oxidation reaction as a physical mixture. Among which, a, fresh Au/C; b, used Au/C; c, fresh Pd/C; and d, used Pd/C. TPR data for the physically mixed Au/C + Pd/C catalyst and the Au@Pd/C catalyst e, before and f, after HMF oxidation.

Extended Data Fig. 6 Electrochemical and thermal catalytic oxidation of aqueous HMF over Au/Pd catalysts.

a, Correlation between the thermo- and electro-catalytic HMF oxidation over the series of catalysts. For thermocatalytic experiments, the initial rates were from a 5-min reaction. The current densities were from the maxima observed in the corresponding CV experiments (Fig. 3a). Associated error bars correspond to mean ± s.d. (n = 3). b, Aqueous HMF oxidation over the mono- and bi-metallic Au–Pd catalysts. Reaction conditions: HMF (0.1 M); NaOH (0.4 M); H2O (16 ml); 25 °C; pO2 = 3 bar; 30 min; catalyst amounts for Au@Pd/C and Au–Pd/C:143.1 mg, Au/C: 72.1 mg, Pd/C: 71 mg, carbon balance: ca 92%. c, Catalytic performance in short circuit with current density (normalized by an electrode surface area of 0.07 cm2) generated as a function of time in the single cell. Reaction conditions: 0.1 M NaOH and 0.02 M HMF in 50 ml H2O; Au (working electrode) and Pd or C (counter electrode); 25 °C; O2 flow: 50 ml min−1. d, H-type dual cell consists of Au as the anode in an N2 flow, Pd as cathode in an O2 flow. The two cells connect via an anion exchange membrane. Reaction conditions: each cell contains 0.1 M NaOH and 0.02 M HMF in 35 ml H2O; 25 °C; gas flow O2/N2: 50 ml min-1. e, Reaction conditions: i: 0.1 M NaOH and 0.02 M HMF in 50 ml H2O, 25 °C, N2 flow: 50 ml min−1; ii: same as i, except for the O2 flow: 50 ml min−1; iii: each cell contains 0.1 M NaOH and 0.02 M HMF in 35 ml H2O, 25 °C, O2/N2 flow: 50 ml min−1; iv: same as iii, except for the disconnection of Au and Pd electrodes; v- same as iii, except the mass of Pd/C is doubled.

Extended Data Fig. 7 Representative STEM-HAADF images and X-ED spectra of nanoparticles in the Au=Pd/C catalysts and its corresponding activities.

a, Lower magnification STEM-HAADF image of the Au = Pd/C catalyst. b, c, X-ED spectra obtained from individual nanoparticles, showing a Au-only and a Pd-only nanoparticle. d, STEM-HAADF image and the corresponding X-ED spectrum (inlet) of a Janus-like particle occasionally found in this Au=Pd/C catalyst. e, Activity comparison to the physical mixture f. Reaction conditions: HMF (0.1 M); NaHCO3 (0.4 M); H2O (16 ml); Au/C: 72.1 mg; Pd/C: 71 mg; Au=Pd/C: 143.1 mg; 80 °C; pO2 = 3 bar; reaction time: 30 min. Associated error bars correspond to mean ± s.d. (n = 3).

Extended Data Fig. 8 Electron microscopy analysis of Au@Pd/C catalyst after one use in the oxidation of HMF.

a, b, Representative complementary pair of BF- and HAADF-STEM micrographs showing metal nanoparticle size and spatial distribution. c–e, Atomic resolution HAADF-STEM micrographs of particles. The yellow arrows in e highlight certain atomic columns that appear lower in contrast, indicating some alloying of Pd with the Au matrix. f, A representative XEDS spectrum obtained from a typical nanoparticle, showing the presence of both Au and Pd.

Extended Data Fig. 9 Reusability data for the prepared Au/Pd catalysts in HMF oxidation reaction.

a, c, The Au@Pd/C catalyst. b, d, the physical mixture Au/C + Pd/C catalyst. Reaction conditions: HMF (0.1 M); NaHCO3 (0.4 M); H2O (16 ml); Au/C: 72.1 mg; Pd/C: 71 mg; Au@Pd/C: 143.1 mg; 80 °C; pO2 = 3 bar; reaction time: 60 min. Key: FDCA yield (■), FFCA yield (♦), HMFCA yield (▲), HMF conversion (●), mass balance (*).

Source data

Rights and permissions

About this article

Cite this article

Huang, X., Akdim, O., Douthwaite, M. et al. Au–Pd separation enhances bimetallic catalysis of alcohol oxidation. Nature 603, 271–275 (2022). https://doi.org/10.1038/s41586-022-04397-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-022-04397-7

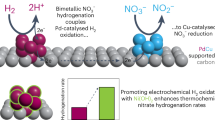

This article is cited by

-

An electrochemical approach for designing thermochemical bimetallic nitrate hydrogenation catalysts

Nature Catalysis (2024)

-

Theoretical framework for mixed-potential-driven catalysis

Communications Chemistry (2024)

-

Efficient conversion of propane in a microchannel reactor at ambient conditions

Nature Communications (2024)

-

Efficient TEMPO functionalized temperature response nanoreactors: recoverable hydrophobic pockets for aerobic oxidation of alcohols in water

Journal of Polymer Research (2024)

-

Confined Mn2+ enables effective aerobic oxidation catalysis

Science China Chemistry (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.