Abstract

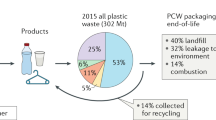

The vast majority of commodity plastics do not degrade and therefore they permanently pollute the environment. At present, less than 20% of post-consumer plastic waste in developed countries is recycled, predominately for energy recovery or repurposing as lower-value materials by mechanical recycling. Chemical recycling offers an opportunity to revert plastics back to monomers for repolymerization to virgin materials without altering the properties of the material or the economic value of the polymer. For plastic waste that is either cost prohibitive or infeasible to mechanically or chemically recycle, the nascent field of chemical upcycling promises to use chemical or engineering approaches to place plastic waste at the beginning of a new value chain. Here state-of-the-art methods are highlighted for upcycling plastic waste into value-added performance materials, fine chemicals and specialty polymers. By identifying common conceptual approaches, we critically discuss how the advantages and challenges of each approach contribute to the goal of realizing a sustainable plastics economy.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Plastics—The Facts 2019 (PlasticsEurope, 2019).

Vollmer, I. et al. Beyond mechanical recycling: giving new life to plastic waste. Angew. Chem. Int. Ed. 59, 2–24 (2020). A Review on the different recycling technologies suitable for the reuse or the valorization of plastic wastes in a circular economy perspective.

Lazarevic, D., Aoustin, E., Buclet, N. & Brandt, N. Plastic waste management in the context of a European recycling society: comparing results and uncertainties in a life cycle perspective. Resour. Conserv. Recycl. 55, 246–259 (2010).

Antelava, A. et al. Plastic solid waste (PSW) in the context of life cycle assessment (LCA) and sustainable management. Environ. Manage. 64, 230–244 (2019).

National overview: facts and figures on materials, wastes and recycling. US EPA https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials (2017).

What a Waste?: A Global Review of Solid Waste Management (World Bank, 2012); https://documents.worldbank.org/en/publication/documents-reports/documentdetail/302341468126264791/What-a-waste-a-global-review-of-solid-waste-management.

Ügdüler, S., Van Geem, K. M., Roosen, M., Delbeke, E. I. P. & De Meester, S. Challenges and opportunities of solvent-based additive extraction methods for plastic recycling. Waste Manage. 104, 148–182 (2020).

Tournier, V. et al. An engineered PET depolymerase to break down and recycle plastic bottles. Nature 580, 216–219 (2020).

Ellis, L. D. et al. Tandem heterogeneous catalysis for polyethylene depolymerization via an olefin-intermediate process. ACS Sustain. Chem. Eng. 9, 623–628 (2021).

Ellen Macarthur Foundation. The new plastic economy - catalysing action. https://ellenmacarthurfoundation.org/the-new-plastics-economy-catalysing-action (2018).

Hong, M. & Y.-X. Chen, E. Chemically recyclable polymers: a circular economy approach to sustainability. Green Chem. 19, 3692–3706 (2017).

Schneiderman, D. K. & Hillmyer, M. A. 50th anniversary perspective: there is a great future in sustainable polymers. Macromolecules 50, 3733–3749 (2017). A Perspective summarizing the most important topics for moving to more sustainable polymers: renewable monomers and degradable polymers, the development of chemical recycling strategies, new classes of reprocessable thermosets and the design of advanced catalysts.

Rahimi, A. & García, J. M. Chemical recycling of waste plastics for new materials production. Nat. Rev. Chem. 1, 0046 (2017).

Jehanno, C., Pérez-Madrigal, M. M., Demarteau, J., Sardon, H. & Dove, A. P. Organocatalysis for depolymerisation. Polym. Chem. 10, 172–186 (2018).

Coates, G. W. & Getzler, Y. D. Y. L. Chemical recycling to monomer for an ideal, circular polymer economy. Nat. Rev. Mater. 5, 501–516 (2020). A Review and point of view on the ideal design for chemical recycling to monomer considering thermodynamic and processing issues.

Ellis, L. D. et al. Chemical and biological catalysis for plastics recycling and upcycling. Nat. Catal. 4, 539–556 (2021).

Pauli, G. & Hartkemeyer, J. F. UpCycling (Chronik Verlag im Bertelsmann LEXIKON Verlag, 1999).

Eriksen, M. K., Damgaard, A., Boldrin, A. & Astrup, T. F. Quality assessment and circularity potential of recovery systems for household plastic waste. J. Ind. Ecol. 23, 156–168 (2019).

Vadenbo, C., Hellweg, S. & Astrup, T. F. Let’s be clear(er) about substitution: a reporting framework to account for product displacement in life cycle assessment. J. Ind. Ecol. 21, 1078–1089 (2017).

Geyer, B., Röhner, S., Lorenz, G. & Kandelbauer, A. Designing oligomeric ethylene terephtalate building blocks by chemical recycling of polyethylene terephtalate. J. Appl. Polym. Sci. 131, 39786–39798 (2014).

Kathalewar, M. et al. Chemical recycling of PET using neopentyl glycol: reaction kinetics and preparation of polyurethane coatings. Prog. Org. Coat. 76, 147–156 (2013).

Roy, P. K., Mathur, R., Kumar, D. & Rajagopal, C. Tertiary recycling of poly(ethylene terephthalate) wastes for production of polyurethane–polyisocyanurate foams. J. Environ. Chem. Eng. 1, 1062–1069 (2013).

Rorrer, N. A. et al. Combining reclaimed PET with bio-based monomers enables plastics upcycling. Joule 3, 1006–1027 (2019). Recyclates from PET and bio-derived monomers recombined into fibreglass reinforced plastic resulting into an upcycled material with a lower production of energy and greenhouse gas emissions.

Kim, J. G. Chemical recycling of poly(bisphenol A carbonate). Polym. Chem. 11, 1830–4849 (2020).

Jones, G. O., Yuen, A., Wojtecki, R. J., Hedrick, J. L. & García, J. M. Computational and experimental investigations of one-step conversion of poly(carbonate)s into value-added poly(aryl ether sulfone)s. Proc. Natl Acad. Sci. USA 113, 7722–7726 (2016).

Pang, C. et al. Sustainable polycarbonates from a citric acid-based rigid diol and recycled BPA-PC: from synthesis to properties. ACS Sustain. Chem. Eng. 6, 17059–17067 (2018). The synthesis of innovative amorphous polycarbonates based on a bicyclic diol from naturally occurring citric acid derivatives and recyclates of BPA-PC wastes through melt polycondensation.

Saito, K. et al. From plastic waste to polymer electrolytes for batteries through chemical upcycling of polycarbonate. J. Mater. Chem. A 8, 13921–13926 (2020).

Wu, C.-H., Chen, L.-Y., Jeng, R.-J. & Dai, S. A. 100% atom-economy efficiency of recycling polycarbonate into versatile intermediates. ACS Sustain. Chem. Eng. 6, 8964–8975 (2018).

Sohn, Y. J. et al. Recent advances in sustainable plastic upcycling and biopolymers. Biotechnol. J. 15, 1900489 (2020).

Kenny, S. T. et al. Development of a bioprocess to convert PET derived terephthalic acid and biodiesel derived glycerol to medium chain length polyhydroxyalkanoate. Appl. Microbiol. Biotechnol. 95, 623–633 (2012).

Kenny, S. T. et al. Up-cycling of PET (polyethylene terephthalate) to the biodegradable plastic PHA (polyhydroxyalkanoate). Environ. Sci. Technol. 42, 7696–7701 (2008).

Tiso, T. et al. Towards bio-upcycling of polyethylene terephthalate. Metab. Eng. 66, 167–178 (2021).

Ward, P. G., Goff, M., Donner, M., Kaminsky, W. & O’Connor, K. E. A two step chemo-biotechnological conversion of polystyrene to a biodegradable thermoplastic. Environ. Sci. Technol. 40, 2433–2437 (2006).

Wei, R. et al. Possibilities and limitations of biotechnological plastic degradation and recycling. Nat. Catal. 3, 867–871 (2020).

Geyer, R., Jambeck, J. R. & Law, K. L. Production, use, and fate of all plastics ever made. Sci. Adv. 3, e1700782 (2017).

Williamson, J. B., Lewis, S. E., Johnson, R. R. III, Manning, I. M. & Leibfarth, F. A. C−H functionalization of commodity polymers. Angew. Chem. Int. Ed. 58, 8654–8668 (2019).

Kondo, Y. et al. Rhodium-catalyzed, regiospecific functionalization of polyolefins in the melt. J. Am. Chem. Soc. 124, 1164–1165 (2002).

Bae, C. et al. Regiospecific side-chain functionalization of linear low-density polyethylene with polar groups. Angew. Chem. Int. Ed. 44, 6410–6413 (2005).

Bae, C. et al. Catalytic hydroxylation of polypropylenes. J. Am. Chem. Soc. 127, 767–776 (2005).

Williamson, J. B., Czaplyski, W. L., Alexanian, E. J. & Leibfarth, F. A. Regioselective C−H xanthylation as a platform for polyolefin functionalization. Angew. Chem. Int. Ed. 57, 6261–6265 (2018).

Williamson, J. B. et al. Chemo- and regioselective functionalization of isotactic polypropylene: a mechanistic and structure–property study. J. Am. Chem. Soc. 141, 12815–12823 (2019).

M. Plummer, C., Li, L. & Chen, Y. The post-modification of polyolefins with emerging synthetic methods. Polym. Chem. 11, 6862–6872 (2020).

Fakezas, T. J. et al. Diversification of aliphatic C–H bonds in small molecules and polyolefins through radical chain transfer. Science 375, 545–550 (2022).

Chen, L. et al. Selective, catalytic oxidations of C–H bonds in polyethylenes produce functional materials with enhanced adhesion. Chem 7, 137–145 (2021). Selective functionalization of polyethylene through ruthenium-catalysed oxidation of C–H bonds for the synthesis of processable and adhesive materials.

Röttger, M. et al. High-performance vitrimers from commodity thermoplastics through dioxaborolane metathesis. Science 356, 62–65 (2017).

Easterling, C. P., Kubo, T., Orr, Z. M., Fanucci, G. E. & Sumerlin, B. S. Synthetic upcycling of polyacrylates through organocatalyzed post-polymerization modification. Chem. Sci. 8, 7705–7709 (2017).

Lewis, S. E., Wilhelmy, B. E. & Leibfarth, F. A. Organocatalytic C–H fluoroalkylation of commodity polymers. Polym. Chem. https://doi.org/10.1039/C9PY01884K (2020).

Lewis, S. E., Wilhelmy, B. E. & Leibfarth, F. A. Upcycling aromatic polymers through C–H fluoroalkylation. Chem. Sci. 10, 6270–6277 (2019).

Sharma, P., Lochab, B., Kumar, D. & Roy, P. K. Sustainable bis-benzoxazines from cardanol and PET-derived terephthalamides. ACS Sustain. Chem. Eng. 4, 1085–1093 (2016).

Tan, J. P. K. et al. Upcycling poly(ethylene terephthalate) refuse to advanced therapeutics for the treatment of nosocomial and mycobacterial infections. Macromolecules 52, 7878–7885 (2019).

Fukushima, K. et al. Supramolecular high-aspect ratio assemblies with strong antifungal activity. Nat. Commun. 4, 2861 (2013).

Fukushima, K. et al. Advanced chemical recycling of poly(ethylene terephthalate) through organocatalytic aminolysis. Polym. Chem. 4, 1610–1616 (2013).

Fukushima, K. et al. Broad-spectrum antimicrobial supramolecular assemblies with distinctive size and shape. ACS Nano 6, 9191–9199 (2012).

Demarteau, J., O’Harra, K. E., Bara, J. E. & Sardon, H. Valorization of plastic wastes for the synthesis of imidazolium-based self-supported elastomeric ionenes. ChemSusChem 13, 3122–3126 (2020).

Kammakakam, I., O’Harra, K. E., Dennis, G. P., Jackson, E. M. & Bara, J. E. Self-healing imidazolium-based ionene-polyamide membranes: an experimental study on physical and gas transport properties. Polym. Int. 68, 1123–1129 (2019).

Iannone, F. et al. Ionic liquids/ZnO nanoparticles as recyclable catalyst for polycarbonate depolymerization. J. Mol. Catal. A 426, 107–116 (2017).

Do, T., Baral, E. R. & Kim, J. G. Chemical recycling of poly(bisphenol A carbonate): 1,5,7-triazabicyclo[4.4.0]-dec-5-ene catalyzed alcoholysis for highly efficient bisphenol A and organic carbonate recovery. Polymer 143, 106–114 (2018).

Jehanno, C. et al. Synthesis of functionalized cyclic carbonates through commodity polymer upcycling. ACS Macro Lett. 9, 443–447 (2020). Selective upcycling of BPA-PC wastes into functionalized six-member cyclic carbonates through an organocatalysed-mediated depolymerization.

Tempelaar, S., Mespouille, L., Coulembier, O., Dubois, P. & P. Dove, A. Synthesis and post-polymerisation modifications of aliphatic poly(carbonate)s prepared by ring-opening polymerisation. Chem. Soc. Rev. 42, 1312–1336 (2013).

Sardon, H. et al. Synthesis of polyurethanes using organocatalysis: a perspective. Macromolecules 48, 3153–3165 (2015).

Westhues, S., Idel, J. & Klankermayer, J. Molecular catalyst systems as key enablers for tailored polyesters and polycarbonate recycling concepts. Sci. Adv. 4, eaat9669 (2018). Catalytic depolymerization of polyesters and polycarbonates through a ruthenium catalyst-mediated hydrogenolysis, paving the way to innovative and sustainable recycling strategies.

Monsigny, L., Berthet, J.-C. & Cantat, T. Depolymerization of waste plastics to monomers and chemicals using a hydrosilylation strategy facilitated by Brookhart’s iridium(III) catalyst. ACS Sustain. Chem. Eng. 6, 10481–10488 (2018).

Zhang, F. et al. Polyethylene upcycling to long-chain alkylaromatics by tandem hydrogenolysis/aromatization. Science 370, 437–441 (2020).

Yoshida, S. et al. A bacterium that degrades and assimilates poly(ethylene terephthalate). Science 351, 1196–1199 (2016).

Kim, H. T. et al. Biological valorization of poly(ethylene terephthalate) monomers for upcycling waste PET. ACS Sustain. Chem. Eng. 7, 19396–19406 (2019).

Additive Manufacturing Market Size: Industry Report, 2020–2025 https://www.knowledge-sourcing.com/report/additive-manufacturing-market (Knowledge Sourcing Intelligence LLP, 2021).

Bäckström, E., Odelius, K. & Hakkarainen, M. Trash to treasure: microwave-assisted conversion of polyethylene to functional chemicals. Ind. Eng. Chem. Res. 56, 14814–14821 (2017).

Bäckström, E., Odelius, K. & Hakkarainen, M. Designed from recycled: turning polyethylene waste to covalently attached polylactide plasticizers. ACS Sustain. Chem. Eng. 7, 11004–11013 (2019). Microwave-assisted oxidative degradation of LDPE waste into functional chemicals (glutaric, succinic and adipic acids) for the subsequent synthesis of PLA plasticizer.

Mouawia, A., Nourry, A., Gaumont, A.-C., Pilard, J.-F. & Dez, I. Controlled metathetic depolymerization of natural rubber in ionic liquids: from waste tires to telechelic polyisoprene oligomers. ACS Sustain. Chem. Eng. 5, 696–700 (2017).

Zhang, J., Yan, B., Wan, S. & Kong, Q. Converting polyethylene waste into large scale one-dimensional Fe3O4@C composites by a facile one-pot process. Ind. Eng. Chem. Res. 52, 5708–5712 (2013).

Gong, J. et al. Upcycling waste polypropylene into graphene flakes on organically modified montmorillonite. Ind. Eng. Chem. Res. 53, 4173–4181 (2014).

Yang, R.-X., Chuang, K.-H. & Wey, M.-Y. Effects of nickel species on Ni/Al2O3 catalysts in carbon nanotube and hydrogen production by waste plastic gasification: bench- and pilot-scale tests. Energy Fuels 29, 8178–8187 (2015).

Zhao, D., Wang, X., Miller, J. B. & Huber, G. W. The chemistry and kinetics of polyethylene pyrolysis: a process to produce fuels and chemicals. ChemSusChem 13, 1764–1774 (2020).

Zhuo, C. & Levendis, Y. A. Upcycling waste plastics into carbon nanomaterials: a review. J. Appl. Polym. Sci. https://doi.org/10.1002/app.39931 (2014).

Gong, J., Chen, X. & Tang, T. Recent progress in controlled carbonization of (waste) polymers. Prog. Polym. Sci. 94, 1–32 (2019).

Gong, J. et al. Converting mixed plastics into mesoporous hollow carbon spheres with controllable diameter. Appl. Catal. B 152–153, 289–299 (2014).

Villagómez-Salas, S., Manikandan, P., Acuña Guzmán, S. F. & Pol, V. G. Amorphous carbon chips Li-ion battery anodes produced through polyethylene waste upcycling. ACS Omega 3, 17520–17527 (2018).

Kim, P. J., Fontecha, H. D., Kim, K. & Pol, V. G. Toward high-performance lithium–sulfur batteries: upcycling of LDPE plastic into sulfonated carbon scaffold via microwave-promoted sulfonation. ACS Appl. Mater. Interfaces 10, 14827–14834 (2018). Preparation of highly porous sulfonated materials from microwave-promoted sulfonation of LDPE wastes.

Mohamed, H. H., Alsanea, A. A., Alomair, N. A., Akhtar, S. & Bahnemann, D. W. ZnO@ porous graphite nanocomposite from waste for superior photocatalytic activity. Environ. Sci. Pollut. Res. 26, 12288–12301 (2019).

Ko, S., Kwon, Y. J., Lee, J. U. & Jeon, Y.-P. Preparation of synthetic graphite from waste PET plastic. J. Ind. Eng. Chem. 83, 449–458 (2019).

Koning, C., Van Duin, M., Pagnoulle, C. & Jerome, R. Strategies for compatibilization of polymer blends. Prog. Polym. Sci. 23, 707–757 (1998).

Feldman, D. Polyblend compatibilization. J. Macromol. Sci. A 42, 587–605 (2005).

Nechifor, M., Tanasă, F., Teacă, C.-A. & Zănoagă, M. Compatibilization strategies toward new polymer materials from re-/up-cycled plastics. Int. J. Polym. Anal. Charact. 23, 740–757 (2018).

Santana, R. M. C. & Manrich, S. Studies on morphology and mechanical properties of PP/HIPS blends from postconsumer plastic waste. J. Appl. Polym. Sci. 87, 747–751 (2003).

Equiza, N., Yave, W., Quijada, R. & Yazdani‐Pedram, M. Use of SEBS/EPR and SBR/EPR as binary compatibilizers for PE/PP/PS/HIPS blends: a work oriented to the recycling of thermoplastic wastes. Macromol. Mater. Eng. 292, 1001–1011 (2007).

Pracella, M., Rolla, L., Chionna, D. & Galeski, A. Compatibilization and properties of poly(ethylene terephthalate)/polyethylene blends based on recycled materials. Macromol. Chem. Phys. 203, 1473–1485 (2002).

Pawlak, A., Morawiec, J., Pazzagli, F., Pracella, M. & Galeski, A. Recycling of postconsumer poly(ethylene terephthalate) and high-density polyethylene by compatibilized blending. J. Appl. Polym. Sci. 86, 1473–1485 (2002).

Ragaert, K., Delva, L. & Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manage. 69, 24–58 (2017).

Eagan, J. M. et al. Combining polyethylene and polypropylene: enhanced performance with PE/iPP multiblock polymers. Science 355, 814–816 (2017).

Xu, J. et al. Compatibilization of isotactic polypropylene (iPP) and high-density polyethylene (HDPE) with iPP–PE multiblock copolymers. Macromolecules 51, 8585–8596 (2018).

Washiyama, J., Kramer, E. J. & Hui, C. Y. Fracture mechanisms of polymer interfaces reinforced with block copolymers: transition from chain pullout to crazing. Macromolecules 26, 2928–2934 (1993).

Galloway, J. A., Jeon, H. K., Bell, J. R. & Macosko, C. W. Block copolymer compatibilization of cocontinuous polymer blends. Polymer 46, 183–191 (2005).

Macosko, C. W., Jeon, H. K. & Hoye, T. R. Reactions at polymer–polymer interfaces for blend compatibilization. Prog. Polym. Sci. 30, 939–947 (2005).

Sundararaj, U. & Macosko, C. W. Drop breakup and coalescence in polymer blends: the effects of concentration and compatibilization. Macromolecules 28, 2647–2657 (1995).

Saleem, M. & Baker, W. E. In situ reactive compatibilization in polymer blends: effects of functional group concentrations. J. Appl. Polym. Sci. 39, 655–678 (1990).

Hettema, R., Pasman, J. & Janssen, L. P. B. M. Reactive extrusion of recycled bottle waste material. Polym. Eng. Sci. 42, 665–680 (2002).

Hlavatá, D., Kruliš, Z., Horák, Z., Lednický, F. & Hromádková, J. The role of lubricants in reactive compatibilization of polyolefin blends. Macromol. Symp. 176, 93–106 (2001).

Ghose, A., Pizzol, M. & McLaren, S. J. Consequential LCA modelling of building refurbishment in New Zealand-—an evaluation of resource and waste management scenarios. J. Clean. Prod. 165, 119–133 (2017).

Buyle, M., Galle, W., Debacker, W. & Audenaert, A. Sustainability assessment of circular building alternatives: consequential LCA and LCC for internal wall assemblies as a case study in a Belgian context. J. Clean. Prod. 218, 141–156 (2019).

Prosman, E. J. & Sacchi, R. New environmental supplier selection criteria for circular supply chains: lessons from a consequential LCA study on waste recovery. J. Clean. Prod. 172, 2782–2792 (2018).

Civancik-Uslu, D. et al. Moving from linear to circular household plastic packaging in Belgium: prospective life cycle assessment of mechanical and thermochemical recycling. Resour. Conserv. Recycl. 171, 105633 (2021).

De Meester, S., Nachtergaele, P., Debaveye, S., Vos, P. & Dewulf, J. Using material flow analysis and life cycle assessment in decision support: a case study on WEEE valorization in Belgium. Resour. Conserv. Recycl. 142, 1–9 (2019).

Moraga, G. et al. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 146, 452–461 (2019).

Britt, P. et al. Report of the Basic Energy Sciences Roundtable on Chemical Upcycling of Polymers (2019).

Plastic upcycling. Nat. Catal. 2, 945–946 (2019).

Shi, C. et al. Design principles for intrinsically circular polymers with tunable properties. Chem. 7, 2896–2912 (2021)

Liu, X., Hong, M., Falivene, L., Cavallo, L. & Chen, E. Y.-X. Closed-loop polymer upcycling by installing property-enhancing comonomer sequences and recyclability. Macromolecules 52, 4570–4578 (2019).

Christensen, P. R., Scheuermann, A. M., Loeffler, K. E. & Helms, B. A. Closed-loop recycling of plastics enabled by dynamic covalent diketoenamine bonds. Nat. Chem. 11, 442 (2019).

Science to Enable Sustainable Plastics https://www.rsc.org/globalassets/22-new-perspectives/sustainability/progressive-plastics/c19_tl_sustainability_cs3_whitepaper_a4_web_final.pdf (Royal Society of Chemistry, 2020).

Anastas, P. T. & Warner, J. C. In Green Chemistry: Theory and Practice 30 (Univ. Press, 1998).

Anastas, P. T. & Zimmerman, J. B. Design through the 12 principles of green engineering. Environ. Sci. Technol. 37, 94A–101A (2003).

Nicholson, S. R., Rorrer, N. A., Carpenter, A. C. & Beckham, G. T. Manufacturing energy and greenhouse gas emissions associated with plastics consumption. Joule 5, 673–686 (2021).

Acknowledgements

C.J. and H.S. thank the Spanish Ministry for the excellence Grant POLYCE and the Basque University for the EHUrOPE grant. F.A.L. and J.W.A. acknowledge support from the Air Force Office of Scientific Research award number 17RT0487 under the Young Investigator Program. S.D.M. and M.R. acknowledge support from VLAIO and the Catalisti Moonshot programme through the PREFER project (The plastics refinery: No more waste - HBC20202609) and the European Regional Development Fund (ERDF) via the PSYCHE project (Interreg France-Wallonie-Vlaanderen) with co-financing from the provinces of East-Flanders and West-Flanders. E.Y.-X.C. acknowledges support from the BOTTLE Consortium funded by the US Department of Energy, Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office and Bioenergy Technologies Office under contract number DE-AC36-08GO28308 with the National Renewable Energy Laboratory, operated by Alliance for Sustainable Energy. A.P.D. acknowledges the financial support from the University of Birmingham.

Author information

Authors and Affiliations

Contributions

C.J. and J.W.A. wrote the initial manuscript under the supervision of and with contributions from H.S. and F.A.L. S.D.M. and M.R. performed the calculations for the quantification of carbon footprint and wrote the ‘Quantifying the sustainability of upcycling’ section. All authors have contributed to the discussion of the content and have revised and edited the manuscript. C.J. realized the figures.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Edward Kosior, Tomonori Saito and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

This file contains Supplementary Information, including Supplementary Figs. 1–6, Tables 1–3 and references.

Rights and permissions

About this article

Cite this article

Jehanno, C., Alty, J.W., Roosen, M. et al. Critical advances and future opportunities in upcycling commodity polymers. Nature 603, 803–814 (2022). https://doi.org/10.1038/s41586-021-04350-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-021-04350-0

This article is cited by

-

Tandem catalysis enables chlorine-containing waste as chlorination reagents

Nature Chemistry (2024)

-

Closed-loop recycling of sulfur-rich polymers with tunable properties spanning thermoplastics, elastomers, and vitrimers

Nature Communications (2024)

-

A general strategy for recycling polyester wastes into carboxylic acids and hydrocarbons

Nature Communications (2024)

-

Designing a circular carbon and plastics economy for a sustainable future

Nature (2024)

-

Complete hydrogenolysis of mixed plastic wastes

Nature Chemical Engineering (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.