Abstract

The use of lithium metal anodes in solid-state batteries has emerged as one of the most promising technologies for replacing conventional lithium-ion batteries1,2. Solid-state electrolytes are a key enabling technology for the safe operation of lithium metal batteries as they suppress the uncontrolled growth of lithium dendrites. However, the mechanical properties and electrochemical performance of current solid-state electrolytes do not meet the requirements for practical applications of lithium metal batteries. Here we report a class of elastomeric solid-state electrolytes with a three-dimensional interconnected plastic crystal phase. The elastomeric electrolytes show a combination of mechanical robustness, high ionic conductivity, low interfacial resistance and high lithium-ion transference number. The in situ-formed elastomer electrolyte on copper foils accommodates volume changes for prolonged lithium plating and stripping processes with a Coulombic efficiency of 100.0 per cent. Moreover, the elastomer electrolytes enable stable operation of the full cells under constrained conditions of a limited lithium source, a thin electrolyte and a high-loading LiNi0.83Mn0.06Co0.11O2 cathode at a high voltage of 4.5 volts at ambient temperature, delivering a high specific energy exceeding 410 watt-hours per kilogram of electrode plus electrolyte. The elastomeric electrolyte system presents a powerful strategy for enabling stable operation of high-energy, solid-state lithium batteries.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request. Source data are provided with this paper.

References

Armand, M. & Tarascon, J.-M. Building better batteries. Nature 451, 652–657 (2008).

Choi, J. W. & Aurbach, D. Promise and reality of post-lithium-ion batteries with high energy densities. Nat. Rev. Mater. 1, 16013 (2016).

Bai, P., Li, J., Brushett, F. R. & Bazant, M. Z. Transition of lithium growth mechanisms in liquid electrolytes. Energy Environ. Sci. 9, 3221–3229 (2016).

Lin, D. C., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 12, 194–206 (2017).

Wan, J. Y. et al. Ultrathin, flexible, solid polymer composite electrolyte enabled with aligned nanoporous host for lithium batteries. Nat. Nanotechnol. 14, 705–711 (2019).

Lee, Y.-G. et al. High-energy long-cycling all-solid-state lithium metal batteries enabled by silver-carbon composite anodes. Nat. Energy 5, 299–308 (2020).

Liu, W. et al. Enhancing ionic conductivity in composite polymer electrolytes with well-aligned ceramic nanowires. Nat. Energy 2, 17035 (2017).

Zhao, Q., Liu, X. T., Stalin, S., Khan, K. & Archer, L. A. Solid-state polymer electrolytes with in-built fast interfacial transport for secondary lithium batteries. Nat. Energy 4, 365–373 (2019).

Zhang, X. Y. et al. Long cycling life solid-state Li metal batteries with stress self-adapted Li/garnet interface. Nano Lett. 20, 2871–2878 (2020).

Zhu, Y., Cao, J., Chen, H., Yu, Q. & Li, B. High electrochemical stability of a 3D cross-linked network PEO@nano-SiO2 composite polymer electrolyte for lithium metal batteries. J. Mater. Chem. A 7, 6832–6839 (2019).

Lee, W. et al. Ceramic-salt composite electrolytes from cold sintering. Adv. Funct. Mater. 29, 1807872 (2019).

Yang, X. et al. Determining the limiting factor of the electrochemical stability window for PEO-based solid polymer electrolytes: main chain or terminal –OH group? Energy Environ. Sci. 13, 1318–1325 (2020).

Chen, R.-J. et al. Addressing the interface issues in all-solid-state bulk-type lithium ion battery via an all-composite approach. ACS Appl. Mater. Interfaces 9, 9654–9661 (2017).

Bouchet, R. et al. Single-ion BAB triblock copolymers as highly efficient electrolytes for lithium-metal batteries. Nat. Mater. 12, 452–457 (2013).

Zhou, D. et al. In situ synthesis of a hierarchical all-solid-state electrolyte based on nitrile materials for high-performance lithium-ion batteries. Adv. Energy Mater. 5, 1500353 (2015).

Jiang, T. et al. Solvent-free synthesis of thin, flexible, nonflammable garnet-based composite solid electrolyte for all-solid-state lithium batteries. Adv. Energy Mater. 10, 1903376 (2020).

Markvicka, E. J., Bartlett, M. D., Huang, X. & Majidi, C. An autonomously electrically self-healing liquid metal–elastomer composite for robust soft-matter robotics and electronics. Nat. Mater. 17, 618–624 (2018).

Pan, C. et al. A liquid-metal–elastomer nanocomposite for stretchable dielectric materials. Adv. Mater. 31, 1900663 (2019).

Kim, H. J., Chen, B., Suo, Z. & Hayward, R. C. Ionoelastomer junctions between polymer networks of fixed anions and cations. Science 367, 773–776 (2020).

Park, M. et al. Highly stretchable electric circuits from a composite material of silver nanoparticles and elastomeric fibres. Nat. Nanotechnol. 7, 803–809 (2012).

Chen, L. et al. PEO/garnet composite electrolytes for solid-state lithium batteries: From “ceramic-in-polymer” to “polymer-in-ceramic”. Nano Energy 46, 176–184 (2018).

Wang, F. et al. Progress report on phase separation in polymer solutions. Adv. Mater. 31, 1806733 (2019).

Seo, M. & Hillmyer, M. A. Reticulated nanoporous polymers by controlled polymerization-induced microphase separation. Science 336, 1422–1425 (2012).

Schulze, M. W., Mcintosh, L. D., Hilmyer, M. A. & Lodge, T. P. High-modulus, high-conductivty nanostructured polymer electrolyte membrane via polymerization-induced phase separation. Nano Lett. 14, 122–126 (2014).

Alarco, P.-J., Abu-Lebdeh, Y., Abouimrane, A. & Armand, M. The plastic-crystalline phase of succinonitrile as a universal matrix for solid-state ionic conductors. Nat. Mater. 3, 476–481 (2004).

Choi, K.-H. et al. Thin, deformable, and safety-reinforced plastic crystal polymer electrolytes for high-performance flexible lithium-ion batteries. Adv. Funct. Mater. 24, 44–52 (2014).

White, T. J., Natarajan, L. V., Tondiglia, V. P., Bunning, T. J. & Guymon, C. A. Polymerization kinetics and monomer functionality effects in thiol-ene polymer dispersed liquid crystals. Macromolecules 40, 1112–1120 (2007).

Serbutoviez, C., Kloosterboer, J. G., Boots, H. M. J. & Touwslager, F. J. Polymerization-induced phase separation. 2. Morphology of polymer-dispersed liquid crystal thin films. Macromolecules 29, 7690–7698 (1996).

Phillip, W. A. et al. Diffusion and flow across nanoporous polydicyclopentadiene-based membranes. ACS Appl. Mater. Interfaces 1, 472–480 (2009).

Watson, B. L., Rolston, N., Printz, A. D. & Dauskardt, R. H. Scaffold-reinforced perovskite compound solar cells. Energy Environ. Sci. 10, 2500–2508 (2017).

Meng, J., Chu, F., Hu, J. & Li, C. Liquid polydimethylsiloxane grafting to enable dendrite-free Li plating for highly reversible Li-metal batteries. Adv. Funct. Mater. 29, 1902220 (2019).

Albertus, P., Babinec, S., Litzelman, S. & Newman, A. Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries. Nat. Energy 3, 16–21 (2018).

Bruce, P. G., Evans, J. & Vincent, C. A. Conductivity and transference number measurements on polymer electrolytes. Solid State Ion. 28, 918–922 (1988).

Diederichsen, K. M., McShane, E. J. & McCloskey, B. D. Promising routes to a high Li+ transference number electrolyte for lithium ion batteries. ACS Energy Lett. 2, 2563–2575 (2017).

Timachova, K., Watanabe, H. & Balsara, N. P. Effect of molecular weight and salt concentration on ion transport and the transference number in polymer electrolytes. Macromolecules 48, 7882–7888 (2015).

He, M. et al. Fluorinated electrolytes for 5-V Li-ion chemistry: probing voltage stability of electrolytes with electrochemical floating test. J. Electrochem. Soc. 162, A1725–A1729 (2015).

Randau, S. et al. Benchmarking the performance of all-solid-state lithium batteries. Nat. Energy 5, 259–270 (2020).

Duan, H. et al. Extended electrochemical window of solid electrolytes via heterogeneous multilayered structure for high-voltage lithium metal batteries. Adv. Mater. 31, 1807789 (2019).

Yu, X. et al. Selectively wetted rigid-flexible coupling polymer electrolyte enabling superior stability and compatibility of high-voltage lithium metal batteries. Adv. Energy Mater. 10, 1903939 (2020).

Lopez, J. et al. A dual-crosslinking design for resilient lithium-ion conductors. Adv. Mater. 30, 1804142 (2018).

Zhang, W., Nie, J., Li, F., Wang, Z. L. & Sun, C. A durable and safe solid-state lithium battery with a hybrid electrolyte membrane. Nano Energy 45, 413–419 (2018).

Wang, C. et al. Solid-state plastic crystal electrolytes: effective protection interlayers for sulfide-based all-solid-state lithium metal batteries. Adv. Funct. Mater. 29, 1900392 (2019).

Sun, J. et al. Hierarchical composite-solid-electrolyte with high electrochemical stability and interfacial regulation for boosting ultra-stable lithium batteries. Adv. Funct. Mater. 31, 2006381 (2021).

Yao, P. et al. PVDF/palygorskite nanowire composite electrolyte for 4 V rechargeable lithium batteries with high energy density. Nano Lett. 18, 6113–6120 (2018).

Fu, C. et al. A dual-salt coupled fluoroethylene carbonate succinonitrile-based electrolyte enables Li-metal batteries. J. Mater. Chem. A 8, 2066–2073 (2020).

Mackanic, D. G. et al. Decoupling of mechanical properties and ionic conductivity in supramolecular lithium ion conductors. Nat. Commun. 10, 5384 (2019).

Fu, C. et al. Universal chemomechanical design rules for solid-ion conductors to prevent dendrite formation in lithium metal batteries. Nat. Mater. 19, 758–766 (2020).

Xia, S. et al. High-rate and large-capacity lithium metal anode enabled by volume conformal and self-healable composite polymer electrolyte. Adv. Sci. 6, 1802353 (2019).

Liu, Y. et al. Lithium-coated polymeric matrix as a minimum volume-change and dendrite-free lithium metal anode. Nat. Commun. 7, 10992 (2016).

Chen, T. et al. Ionic liquid-immobilized polymer gel electrolyte with self-healing capability, high ionic conductivity and heat resistance for dendrite-free lithium metal batteries. Nano Energy 54, 17–25 (2018).

Lu, Q. et al. Dendrite-free, high-rate, long-life lithium metal batteries with a 3D cross-linked network polymer electrolyte. Adv. Mater. 29, 1604460 (2017).

Dong, T. et al. A multifunctional polymer electrolyte enables ultra-long cycle-life in a high-voltage lithium metal battery. Energy Environ. Sci. 11, 1197–1203 (2018).

Acknowledgements

This work was performed in part at the Georgia Tech Institute for Electronics and Nanotechnology, a member of the National Nanotechnology Coordinated Infrastructure (NNCI), which is supported by the National Science Foundation (ECCS-2025462). This work was partially supported by KRICT core project (BSF20-242). J.H., Y.J.L. and B.J.K. acknowledge the support from the National Research Foundation of Korea (NRF-2019R1A2B5B03101123, 2017M3D1A1039553 and 2020RlA4A1018516).

Author information

Authors and Affiliations

Contributions

S.W.L., B.J.K., M.J.L. and J.H. conceived the ideas and designed the experiments. K.L., Y.J.L., B.G.K. and K.-N.J. were involved with the methods and characterizations of materials. S.W.L., B.J.K., M.J.L. and J.H. co-wrote the manuscript. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

S.W.L., B.J.K., M.J.L. and J.H. have filed a US provisional patent application (63/209,140) covering the materials and lithium metal battery application described in this paper.

Peer review information

Nature thanks Enrique Gomez and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer review reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

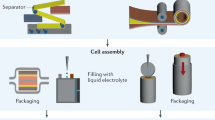

Extended Data Fig. 1 Fabrication process of in situ-polymerized PCEE within the electrochemical cell.

a, Digital photo images of a homogeneous solution consisting of BA, SN, LiTFSI, PEGDA and AIBN for built-in polymerization (left) and haze-coloured PCEE on the bottom of a glass vial after polymerization at 70 °C for 2 h (right). b, Photo image of PCEE showing mechanical elasticity. c, Schematic illustration of the built-in polymerization process. The solution was injected into the electrochemical cells and then heated in an oven for built-in polymerization.

Extended Data Fig. 2 Comparison of morphology, ion conductivity and mechanical property between polymerization induced-PCEE and blend systems.

a, Morphology of PCEE. SEM image of PCEE shows the continuously-connected SN phases within the elastomeric matrix that was uniformly developed over a large area through PIPS. b, Morphology of blend consisting of elastomeric polymer (cross-linked poly(butylacrylate) and PEGDA) and plastic crystal (SN) with LiTFSI. A blend is prepared from a mixture of elastomeric polymers and SN–LiTFSI in chloroform, followed by a drying process. The same weight ratios of BA, SN, PEGDA and LiTFSI are used for constructing the PCEE and blend systems. SEM image of blend shows a macrophase separation with a length-scale of over μm. c–d, Comparison of ionic conductivity (c) and toughness (d) between the PCEE and blend systems.

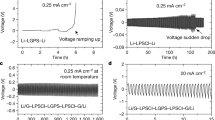

Extended Data Fig. 3 Electrochemical characterization for the symmetric Li cells with built-in PCEE.

a, Time-dependent Nyquist plots of the symmetric Li cells configured with built-in PCEE. b, Nyquist plots of the symmetric Li cells configured with built-in PCEE after 25, 75, and 100 cycles. c, Cycling performance of the symmetric Li cells configured with built-in PCEE at different current densities. d, Voltage hysteresis of Li plating/stripping for built-in PCEE compared with previously reported literature data8,12,16,38,39,47,48,49,50,51,52. e, Nyquist plots of the symmetric Li cells before and after polarization of 10 mV. f, Steady-state current measurement of the symmetric Li cells under 10 mV polarization for 10 h. EIS was measured at open-circuit voltage in the range of 105 to 10° Hz with an amplitude of 10 mV.

Extended Data Fig. 4 Characterization of the SEI components on the cycled Li metal anodes with built-in PCEE and SN100 by XPS.

The high-resolution Li 1s, C 1s, O 1s, N 1s, and F 1s XPS spectra of the Li metal anodes were measured after 100 cycles of the symmetric Li cells with built-in PCEE and SN100 at a current density of 1 mA cm–2 with a capacity of 1 mAh cm–2.

Extended Data Fig. 5 Li plating and stripping behaviour of built-in PCEE on bare Cu.

a, Cycling performance of the asymmetric Li||Cu cells at current densities of 0.5 and 1 mA cm–2, respectively. b–c, Li stripping and plating profiles for built-in PCEE at a current density of 0.5 mA cm–2 with a capacity of 1 mAh cm–2 (b), and a current density of 1 mA cm–2 with a capacity of 2 mAh cm–2 (c).

Extended Data Fig. 6 Electrochemical stability of built-in PCEE paired with high-voltage NMC-622 cathode.

a, Electrochemical floating experiment was performed using Li||NMC-622 with built-in PCEE. The cell was charged to 4.2 V at 0.2C (1 C = 180 mA g–1) and then held at gradually higher voltages for 10 h up to 4.7 V. b, Rate capability of the full cell (35-μm-thick Li anode; 25-μm-thick built-in PCEE; high-loading NMC-622 (9.7 mg cm–2) in the voltage range of 2.7–4.5 V at equal current densities. (Inset: the capacity utilization at different areal current densities). c, Cycling performance of the full cell (excess Li; 25-μm-thick built-in PCEE; NMC-622 (2.1 mg cm–2)) as a function of cycle number in the voltage range of 2.7–4.5 V. The cell maintained a high capacity of ~140 mAh g–1 (82% capacity retention) with high CEs of 99.5% for 100 cycles, confirming the stable operation at high voltage. Cells were performed at 20 °C.

Extended Data Fig. 7 Cycling performance of the Li||LiFePO4 cell at 1 C without voltage holding.

a, Capacity and Coulombic efficiency as a function of cycle number. b, Corresponding voltage profiles. 1 C = 170 mA g–1.

Extended Data Fig. 8 Electrochemical performances of the full cells with high-voltage NMC-83 cathode.

a, The charge and discharge profiles of the full cell in the voltage range of 2.7–4.3V at 0.1 mA cm–2. b, Temperature-dependent voltage profiles of the full cell charged/discharged at equal temperatures (60 to 0 °C) in the voltage range of 2.7–4.5 V. (Inset: the capacity utilization at different temperatures). All full cells were configured with 35-μm-thick Li anode; 25-μm-thick built-in PCEE; high-loading NMC-83 (>10 mg cm–2).

Supplementary information

Supplementary Figures

This file contains Supplementary Figures 1–14.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, M.J., Han, J., Lee, K. et al. Elastomeric electrolytes for high-energy solid-state lithium batteries. Nature 601, 217–222 (2022). https://doi.org/10.1038/s41586-021-04209-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-021-04209-4

This article is cited by

-

Elastic microphase separation produces robust bicontinuous materials

Nature Materials (2024)

-

An entanglement association polymer electrolyte for Li-metal batteries

Nature Communications (2024)

-

An in-situ polymerized interphase engineering for high-voltage all-solid-state lithium-metal batteries

Nano Research (2024)

-

An all-from-one strategy to flexible solid-state lithium-ion batteries with decreased interfacial resistance

Science China Materials (2024)

-

Precisely succinonitrile-functionalized PEO electrolytes toward room-temperature all-solid-state lithium batteries

Science China Materials (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.