Abstract

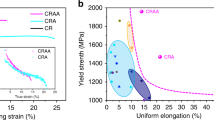

Single-phase high- and medium-entropy alloys with face-centred cubic (fcc) structure can exhibit high tensile ductility1,2 and excellent toughness2,3, but their room-temperature strengths are low1,2,3. Dislocation obstacles such as grain boundaries4, twin boundaries5, solute atoms6 and precipitates7,8,9 can increase strength. However, with few exceptions8,9,10,11, such obstacles tend to decrease ductility. Interestingly, precipitates can also hinder phase transformations12,13. Here, using a model, precipitate-strengthened, Fe–Ni–Al–Ti medium-entropy alloy, we demonstrate a strategy that combines these dual functions in a single alloy. The nanoprecipitates in our alloy, in addition to providing conventional strengthening of the matrix, also modulate its transformation from fcc-austenite to body-centred cubic (bcc) martensite, constraining it to remain as metastable fcc after quenching through the transformation temperature. During subsequent tensile testing, the matrix progressively transforms to bcc-martensite, enabling substantial increases in strength, work hardening and ductility. This use of nanoprecipitates exploits synergies between precipitation strengthening and transformation-induced plasticity, resulting in simultaneous enhancement of tensile strength and uniform elongation. Our findings demonstrate how synergistic deformation mechanisms can be deliberately activated, exactly when needed, by altering precipitate characteristics (such as size, spacing, and so on), along with the chemical driving force for phase transformation, to optimize strength and ductility.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All figures have associated raw data, available on request from Y.Y.

References

Gali, A. & George, E. P. Tensile properties of high- and medium-entropy alloys. Intermetallics 39, 74–78 (2013).

Gludovatz, B. et al. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 7, 10602 (2016).

Gludovatz, B. et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science 345, 1153–1158 (2014).

Kumar, K., Van Swygenhoven, H. & Suresh, S. Mechanical behavior of nanocrystalline metals and alloys. Acta Mater. 51, 5743–5774 (2003).

Lu, L., Chen, X., Huang, X. & Lu, K. Revealing the maximum strength in nanotwinned copper. Science 323, 607–610 (2009).

Labusch, R. A statistical theory of solid solution hardening. Phys. Status Solidi B 41, 659–669 (1970).

Gladman, T. Precipitation hardening in metals. Mater. Sci. Technol. 15, 30–36 (1999).

Jiang, S. et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 544, 460 (2017).

Yang, T. et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 362, 933–937 (2018).

He, B. et al. High dislocation density-induced large ductility in deformed and partitioned steels. Science 357, 1029–1032 (2017).

Lu, K., Lu, L. & Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 324, 349–352 (2009).

La Roca, P., Baruj, A., Sobrero, C. E., Malarria, J. A. & Sade, M. Nanoprecipitation effects on phase stability of Fe-Mn-Al-Ni alloys. J. Alloys Compd. 708, 422–427 (2017).

Luo, H., Shan, F., Huo, Y. & Wang, Y. Effect of precipitates on phase transformation behavior of Ti-49 at.% Ni film. Thin Solid Films 339, 305–308 (1999).

Kaufman, L. & Cohen, M. The martensitic transformation in the iron-nickel system. JOM 8, 1393–1401 (1956).

Liang, Y.-J. et al. High-content ductile coherent nanoprecipitates achieve ultrastrong high-entropy alloys. Nat. Commun. 9, 4063 (2018).

Raabe, D., Ponge, D., Dmitrieva, O. & Sander, B. Nanoprecipitate-hardened 1.5 GPa steels with unexpected high ductility. Scr. Mater. 60, 1141–1144 (2009).

Nishiyama, Z. X-ray investigation of the mechanism of the transformation from face centered cubic lattice to body centered cubic. Sci. Rep. Tohoku Univ. 23, 637 (1934).

Fisher, J., Hollomon, J. & Turnbull, D. Kinetics of the austenite → martensite transformation. Metals Trans. 185, 691–700 (1949).

Jimenez-Melero, E. et al. Martensitic transformation of individual grains in low-alloyed TRIP steels. Scr. Mater. 56, 421–424 (2007).

Yang, H.-S. & Bhadeshia, H. Austenite grain size and the martensite-start temperature. Scr. Mater. 60, 493–495 (2009).

Jin, S., Morris, J., Chen, Y., Thomas, G. & Jaffee, R. An investigation of transformation strengthening in precipitation-hardened Fe-Ni austenite. Metall. Trans. A 9, 1625–1633 (1978).

Wang, T. et al. Co-introduction of precipitate hardening and TRIP in a TWIP high-entropy alloy using friction stir alloying. Sci. Rep. 11, 1–10 (2021).

Kaufman, L. & Bernstein, H. Computer Calculation of Phase Diagrams. With Special Reference to Refractory Metals (Academic Press, 1970).

Cao, W. et al. PANDAT software with PanEngine, PanOptimizer and PanPrecipitation for multi-component phase diagram calculation and materials property simulation. Calphad 33, 328–342 (2009).

Yeh, J. W., Chen, Y. L., Lin, S. J. & Chen, S. K. in Materials Science Forum Vol. 560 (eds Balmori-Ramirez, H. et al.) 1–9 (Trans Tech Publ, 2007).

Cacciamani, G. et al. Critical evaluation of the Fe–Ni, Fe–Ti and Fe–Ni–Ti alloy systems. Intermetallics 14, 1312–1325 (2006).

Borgenstam, A. & Hillert, M. Massive transformation in the Fe–Ni system. Acta Mater. 48, 2765–2775 (2000).

Nishiyama, Z. Martensitic Transformation (Elsevier, 2012).

Ardell, A. J. Precipitation hardening. Metall. Trans. A 16, 2131–2165 (1985).

Gorbatov, O. I. et al. Effect of composition on antiphase boundary energy in Ni3Al-based alloys: ab initio calculations. Phys. Rev. B 93, 224106 (2016).

Rosenberg, J. & Piehler, H. Calculation of the Taylor factor and lattice rotations for bcc metals deforming by pencil glide. Metall. Trans. 2, 257–259 (1971).

Zhang, M., Li, L., Fu, R., Krizan, D. & De Cooman, B. Continuous cooling transformation diagrams and properties of micro-alloyed TRIP steels. Mater. Sci. Eng. A 438–440, 296–299 (2006).

Zhao, J.-l., Yan, X., Wen, S. & Lin, L. Microstructure and mechanical properties of high manganese TRIP steel. J. Iron Steel Res. Int. 19, 57–62 (2012).

Bouaziz, O., Zurob, H. & Huang, M. Driving force and logic of development of advanced high strength steels for automotive applications. Steel Res. Int. 84, 937–947 (2013).

Boyer, H. E. Atlas of Stress–Strain Curves (ASM International, 1987).

Morris, J., Jr. Maraging steels: Making steel strong and cheap. Nat. Mater. 16, 787 (2017).

García-Mateo, C. & Caballero, F. G. The role of retained austenite on tensile properties of steels with bainitic microstructures. Mater. Trans. 46, 1839–1846 (2005).

Kim, S.-H., Kim, H. & Kim, N. J. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Nature 518, 77–79 (2015).

De Moor, E., Speer, J. G., Matlock, D. K., Kwak, J.-H. & Lee, S.-B. Effect of carbon and manganese on the quenching and partitioning response of CMnSi steels. ISIJ Int. 51, 137–144 (2011).

Dong, X., Shen, Y., Yin, T., Misra, R. & Lin, G. Strengthening a medium-carbon steel to 2800 MPa by tailoring nanosized precipitates and the phase ratio. Mater. Sci. Eng. A 759, 725–735 (2019).

Bouaziz, O., Barbier, D., Cugy, P. & Petigand, G. Effect of process parameters on a metallurgical route providing nano‐structured single phase steel with high work-hardening. Adv. Eng. Mater. 14, 49–51 (2012).

Wang, H., Tao, N. & Lu, K. Strengthening an austenitic Fe–Mn steel using nanotwinned austenitic grains. Acta Mater. 60, 4027–4040 (2012).

Otto, F. et al. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 61, 5743–5755 (2013).

Wu, Z., Bei, H., Pharr, G. M. & George, E. P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 81, 428–441 (2014).

He, J. et al. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 102, 187–196 (2016).

Li, Z., Pradeep, K. G., Deng, Y., Raabe, D. & Tasan, C. C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 534, 227 (2016).

Wignall, G. D. et al. The 40 m general purpose small-angle neutron scattering instrument at Oak Ridge National Laboratory. J. Appl. Cryst. 45, 990–998 (2012).

Kotlarchyk, M. & Chen, S. H. Analysis of small angle neutron scattering spectra from polydisperse interacting colloids. J. Chem. Phys. 79, 2461–2469 (1983).

Thompson, K. et al. In situ site-specific specimen preparation for atom probe tomography. Ultramicroscopy 107, 131–139 (2007).

Soven, P. Coherent-potential model of substitutional disordered alloys. Phys. Rev. 156, 809 (1967).

Taylor, D. Vibrational properties of imperfect crystals with large defect concentrations. Phys. Rev. 156, 1017 (1967).

Stocks, G., Temmerman, W. & Gyorffy, B. Complete solution of the Korringa–Kohn–Rostoker coherent-potential-approximation equations: Cu–Ni alloys. Phys. Rev. Lett. 41, 339 (1978).

Ebert, H., Koedderitzsch, D. & Minar, J. Calculating condensed matter properties using the KKR–Green’s function method—recent developments and applications. Rep. Prog. Phys. 74, 096501 (2011).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Togo, A. & Tanaka, I. First principles phonon calculations in materials science. Scr. Mater. 108, 1–5 (2015).

Giannozzi, P. et al. QUANTUM ESPRESSO: a modular and open-source software project for quantum simulations of materials. J. Phys. Condens. Matter 21, 395502 (2009).

Liechtenstein, A. I., Katsnelson, M., Antropov, V. & Gubanov, V. Local spin density functional approach to the theory of exchange interactions in ferromagnetic metals and alloys. J. Magn. Magn. Mater. 67, 65–74 (1987).

Vaks, V. & Zeĭn, N. Theory of phase transitions in solid solutions. J. Exp. Theor. Phys. 40, 537 (1975).

Vaks, V. & Samolyuk, G. On accuracy of different cluster models used in describing ordering phase transitions in fcc alloys. J. Exp. Theor. Phys. 88, 89–100 (1999).

Chuang, Y.-Y., Chang, Y. A., Schmid, R. & Lin, J.-C. Magnetic contributions to the thermodynamic functions of alloys and the phase equilibria of Fe–Ni system below 1200 K. Metall. Trans. A 17, 1361–1372 (1986).

Edwards, D. The paramagnetic state of itinerant electron systems with local magnetic moments. I. Static properties. J. Phys. F Met. Phys. 12, 1789 (1982).

Rappe, A. M., Rabe, K. M., Kaxiras, E. & Joannopoulos, J. Optimized pseudopotentials. Phys. Rev. B 41, 1227 (1990).

Ramer, N. J. & Rappe, A. M. Virtual-crystal approximation that works: locating a compositional phase boundary in Pb(Zr1−xTix)O3. Phys. Rev. B 62, R743 (2000).

Kurdjumov, G. & Sachs, G. Crystallographic orientation relationship between α-and γ-Fe. Ann. Phys. 64, 325 (1930).

American Iron and Steel Institute. High-Temperature Characteristics of Stainless Steel A Designer’s Handbook Report No. 9004 (Nickel Development Institute, 1979); https://nickelinstitute.org/media/1699/high_temperaturecharacteristicsofstainlesssteel_9004_.pdf

Warlimont, H. & Martienssen, W. Springer Handbook of Materials Data (Springer, 2018).

Acknowledgements

This research was supported by the US Department of Energy, Office of Science, Basic Energy Sciences, Materials Sciences and Engineering Division (testing and analysis of mechanical properties and responsible deformation mechanisms, TEM characterization of the FNAT-4h alloy, and writing of the manuscript) and by the Laboratory Directed Research and Development programme of Oak Ridge National Laboratory (ORNL) (microstructural characterization and first-principles calculations), managed by UT-Battelle, LLC, for the US Department of Energy. Y.Y. acknowledges CompuTherm for providing the phase diagram calculation software Pandat. Resources at ORNL’s High Flux Isotope Reactor for small-angle neutron scattering, Spallation Neutron Source for neutron diffraction, and Center for Nanophase Materials Sciences for atom probe tomography were used in this study, which are US DOE Office of Science User Facilities.

Author information

Authors and Affiliations

Contributions

Y.Y. conceived the study, designed the alloy and supervised the project. T.C., A.R.L., A.B. and L.T. performed the TEM and STEM analyses. L.T. performed EBSD analysis. K.A. performed neutron diffraction and phase analysis. Y.W. performed and analysed tensile tests with DIC. J.D.P. performed the APT analysis. G.D.S. performed the first-principles calculations. K.L. performed the SANS analysis. Y.Y. and E.P.G. analysed and interpreted the mechanical properties and deformation mechanisms and wrote the manuscript. All authors reviewed and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature thanks the anonymous reviewers for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

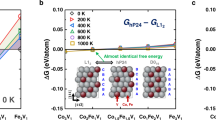

Extended Data Fig. 1 Temperature dependence of phase equilibria and composition calculated using the CALPHAD approach, and the free energy from first-principles calculations.

a, Mole fraction of equilibrium phases in FNAT. b, Compositions of elements (at%) in the fcc phase. c, Free energy of fcc and bcc phases that have the same composition (Fe-23Ni-3.5Al-0.5Ti, at%) as the matrix of FNAT.

Extended Data Fig. 2 Information for estimating yield strength of FNAT-47h.

a, Room-temperature tensile stress–strain curve of FNAT after solutionizing at 1,100 °C and water quenching showing yield strength of ~325 MPa. b, STEM bright-field image showing dislocations cutting particles (yellow arrows) in the matrix of a plastically deformed FNAT sample. c, Corresponding HAADF image of b.

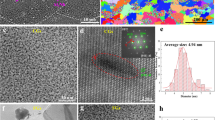

Extended Data Fig. 3 TEM/STEM analyses of interface between precipitate and matrix of the FNAT-47h alloy.

a, b, HAADF lattice images before deformation (from tab section of tensile specimen). a, A lattice image of L12/bcc interface displays the Nishiyama–Wasserman orientation \({(1\bar{1}1)}_{{{\rm{L1}}}_{2}}\parallel {(0\bar{1}1)}_{{\rm{bcc}}}\) and \({[110]}_{{{\rm{L1}}}_{2}}\parallel {[100]}_{{\rm{bcc}}}\), where the interplanar spacings, \(d{(1\bar{1}1)}_{{{\rm{L1}}}_{2}}\) = 0.2072 nm and \(d{(0\bar{1}1)}_{{\rm{bcc}}}\) = 0.2027 nm, result in a mismatch of ~2.2% and a semi-coherent interface. b, A lattice image of L12/fcc interface region exhibits full cube-on-cube lattice coherency with \({(\bar{1}11)}_{{{\rm{L1}}}_{2}}\parallel {(\bar{1}11)}_{{\rm{fcc}}}\) and \({[110]}_{{{\rm{L1}}}_{2}}\parallel {[110]}_{{\rm{fcc}}}\), where the interplanar spacings, \(d{(1\bar{1}1)}_{{{\rm{L1}}}_{2}}\) = 0.2072 nm and \(d{(1\bar{1}1)}_{{\rm{fcc}}}\) = 0.2074 nm, result in a small mismatch of ~0.1%. c–e, TEM and HAADF lattice images after deformation (from gauge section of tensile specimen). c, Dark-field TEM image showing L12 precipitates, some containing streaks (marked by arrowheads), embedded in a deformation-induced bcc grain after deformation. d, HAADF lattice image showing a stacking fault with a Burgers vector of \(\tfrac{1}{6} < 112 > \) formed in one of the L12 precipitates containing streaks. Labels A, B, C in the inset denote alternating {111} planes in the L12 structure. e, HAADF lattice image showing semi-coherent L12/bcc interface with the Kurdjumov–Sachs orientation relationship64, namely, \({(\bar{1}11)}_{{{\rm{L1}}}_{2}}\parallel {(\bar{1}10)}_{{\rm{bcc}}}\) and \({[110]}_{{{\rm{L1}}}_{2}}\parallel {[111]}_{{\rm{bcc}}}\) and a lattice mismatch of ~2.2%. The slip-transfer mechanism in c–e is common when dislocations move from fcc matrix to L12 precipitate, but is rarely seen when the matrix is bcc.

Extended Data Fig. 4 STEM HAADF image, corresponding FFT diffractogram and inverse FFT image of the as-quenched FNAT-4h alloy sample tilted to [110] zone axis condition.

a, HR STEM image. b, FFT diffractogram. c, the inverse FFT generated using the blue-circled 'extra spots' in b. The diffuse spatial distribution of the bright features in c indicates that the extra spots in b are caused by small variable local misorientations due to local internal strains as opposed to any nano-domains of a different matrix phase.

Extended Data Fig. 5 Ultimate tensile strength versus Ni or (Ni + Co) content at room temperature and 700 °C.

Open symbols, room temperature (RT); filled symbols, 700 °C. The FNAT alloy is compared with different materials whose data sources are Fe-based heat-resistant alloys including 410, 430, 302, 309, 310, 316, 321, 34765 A286 and Incoloy 80066; Ni-based super alloys66 including Inconel 706, Inconel 718, Nimonic 80A, PE 16, Inconel 625, Inconel 600, Hastelloy S, Hastelloy X, Udimet 630; and Ni–Co-based super alloys66 including Incoloy 909, Nimonic 90, Nimonic 115, Waspaloy, Udimet 720, Udimet 500, Rene 41, Rene 95, Astroloy, Inconel 617 and Haynes 230.

Extended Data Fig. 6 Textures of FNAT-47h and FNAT-m-47h after hot-rolling and annealing.

a, b, EBSD pole figures for FNAT-47h, c, d, EBSD pole figures for FNAT-m-47h. The normal direction (ND) in each case is at the centre of the circle and is either 001 or 111 as marked. TD in a–d refers to the transverse direction. e, Neutron diffraction spectra of FNAT-47h along the rolling direction (RD) and the normal direction (ND). Note that we have shifted the RD and ND spectra horizontally with respect to each other to facilitate comparison (otherwise the peaks would overlap). Both EBSD (a, b) and ND (e) results show that FNAT-47h has negligible texture.

Extended Data Fig. 7 Fracture analysis of tensile-tested FNAT-m-47h and FNAT-47h alloys.

a, FNAT-m-47h: fractograph and stress–strain curve showing considerable necking before fracture, and DIC strain maps showing strain localization in the region where fracture eventually occurs. b, FNAT-47h: fractograph and stress–strain curve showing minimal necking before fracture, and DIC strain maps showing relatively diffuse strain distribution throughout the gauge section with no evidence of localization near the fracture plane.

Rights and permissions

About this article

Cite this article

Yang, Y., Chen, T., Tan, L. et al. Bifunctional nanoprecipitates strengthen and ductilize a medium-entropy alloy. Nature 595, 245–249 (2021). https://doi.org/10.1038/s41586-021-03607-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-021-03607-y

This article is cited by

-

Harnessing instability for work hardening in multi-principal element alloys

Nature Materials (2024)

-

Compositional Dependence of the Recrystallization and Grain Growth in Strongly-distorted Pd-containing Multi-Component Equiatomic Alloys

Metals and Materials International (2024)

-

Doubled strength and ductility via maraging effect and dynamic precipitate transformation in ultrastrong medium-entropy alloy

Nature Communications (2023)

-

Trifunctional nanoprecipitates ductilize and toughen a strong laminated metastable titanium alloy

Nature Communications (2023)

-

Ultra-strong tungsten refractory high-entropy alloy via stepwise controllable coherent nanoprecipitations

Nature Communications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.