Abstract

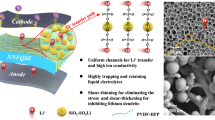

Solid-state lithium (Li)–air batteries are recognized as a next-generation solution for energy storage to address the safety and electrochemical stability issues that are encountered in liquid battery systems1,2,3,4. However, conventional solid electrolytes are unsuitable for use in solid-state Li–air systems owing to their instability towards lithium metal and/or air, as well as the difficulty in constructing low-resistance interfaces5. Here we present an integrated solid-state Li–air battery that contains an ultrathin, high-ion-conductive lithium-ion-exchanged zeolite X (LiX) membrane as the sole solid electrolyte. This electrolyte is integrated with cast lithium as the anode and carbon nanotubes as the cathode using an in situ assembly strategy. Owing to the intrinsic chemical stability of the zeolite, degeneration of the electrolyte from the effects of lithium or air is effectively suppressed. The battery has a capacity of 12,020 milliamp hours per gram of carbon nanotubes, and has a cycle life of 149 cycles at a current density of 500 milliamps per gram and at a capacity of 1,000 milliamp hours per gram. This cycle life is greater than those of batteries based on lithium aluminium germanium phosphate (12 cycles) and organic electrolytes (102 cycles) under the same conditions. The electrochemical performance, flexibility and stability of zeolite-based Li–air batteries confer practical applicability that could extend to other energy-storage systems, such as Li–ion, Na–air and Na–ion batteries.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data generated in this study are available from the corresponding authors upon reasonable request. Source data are provided with this paper.

References

Bruce, P. G., Freunberger, S. A., Hardwick, L. J. & Tarascon, J. M. Li–O2 and Li–S batteries with high energy storage. Nat. Mater. 11, 19–29 (2012).

Li, Y., Wang, X., Dong, S., Chen, X. & Cui, G. Recent advances in non-aqueous electrolyte for rechargeable Li–O2 batteries. Adv. Energy Mater. 6, 1600751 (2016).

Lu, Y.-C. et al. Lithium–oxygen batteries: bridging mechanistic understanding and battery performance. Energy Environ. Sci. 6, 750–768 (2013).

Manthiram, A., Yu, X. & Wang, S. Lithium battery chemistries enabled by solid-state electrolytes. Nat. Rev. Mater. 2, 16103 (2017).

Liu, Y., He, P. & Zhou, H. Rechargeable solid-state Li–air and Li–S batteries: materials, construction, and challenges. Adv. Energy Mater. 8, 1701602 (2018).

Freunberger, S. A. et al. Reactions in the rechargeable lithium–O2 battery with alkyl carbonate electrolytes. J. Am. Chem. Soc. 133, 8040–8047 (2011).

Asadi, M. et al. A lithium–oxygen battery with a long cycle life in an air-like atmosphere. Nature 555, 502–506 (2018).

Tarascon, J.-M. & Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 414, 359–367 (2001).

Goodenough, J. B. & Kim, Y. Challenges for rechargeable Li batteries. Chem. Mater. 22, 587–603 (2010).

Zhu, X. B., Zhao, T. S., Wei, Z. H., Tan, P. & Zhao, G. A novel solid-state Li–O2 battery with an integrated electrolyte and cathode structure. Energy Environ. Sci. 8, 2782–2790 (2015).

Famprikis, T., Canepa, P., Dawson, J. A., Islam, M. S. & Masquelier, C. Fundamentals of inorganic solid-state electrolytes for batteries. Nat. Mater. 18, 1278–1291 (2019).

Liu, Y. et al. Intensive investigation on all-solid-state Li–air batteries with cathode catalysts of single-walled carbon nanotube/RuO2. J. Power Sources 395, 439–443 (2018).

Bachman, J. C. et al. Inorganic solid-state electrolytes for lithium batteries: mechanisms and properties governing ion conduction. Chem. Rev. 116, 140–162 (2016).

Liu, Y. et al. Germanium thin film protected lithium aluminum germanium phosphate for solid-state Li batteries. Adv. Energy Mater. 8, 1702374 (2018).

Chen, R., Li, Q., Yu, X., Chen, L. & Li, H. Approaching practically accessible solid-state batteries: stability issues related to solid electrolytes and interfaces. Chem. Rev. 120, 6820–6877 (2020).

Mo, F. et al. Inside or outside: origin of lithium dendrite formation of all solid-state electrolytes. Adv. Energy Mater. 9, 1902123 (2019).

Han, F. et al. High electronic conductivity as the origin of lithium dendrite formation within solid electrolytes. Nat. Energy 4, 187–196 (2019).

Liu, W., Song, M. S., Kong, B. & Cui, Y. Flexible and stretchable energy storage: recent advances and future perspectives. Adv. Mater. 29, 1603436 (2017).

Yang, X.-Y. et al. Blood-capillary-inspired, free-standing, flexible, and low-cost super-hydrophobic N-CNTs@SS cathodes for high-capacity, high-rate, and stable Li–air batteries. Adv. Energy Mater. 8, 1702242 (2018).

Li, Y., Li, L. & Yu, J. Applications of zeolites in sustainable chemistry. Chem 3, 928–949 (2017).

Martínez, C. & Corma, A. Inorganic molecular sieves: Preparation, modification and industrial application in catalytic processes. Coord. Chem. Rev. 255, 1558–1580 (2011).

Schoonheydt, R. A. & Uytterhoeven, J. B. Dielectric study of synthetic zeolites X and Y. Adv. Chem. 101, 456–472 (1974).

Feuerstein, M. & Lobo, R. F. Mobility of Li cations in X zeolites studied by solid-state NMR spectroscopy. Solid State Ion. 118, 135–139 (1999).

Krogh Andersen, E., Krogh Andersen, I. G., Metcalf-Johansen, J., Simonsen, K. E. & Skou, E. The ionic conductivity of alkalimetal-zeolite X. Solid State Ion. 28–30, 249–253 (1988).

Kelemen, G., Lortz, W. & Schön, G. Ionic conductivity of synthetic analcime, sodalite and offretite. J. Mater. Sci. 24, 333–338 (1989).

Kelemen, G. & Schön, G. Ionic conductivity in dehydrated zeolites. J. Mater. Sci. 27, 6036–6040 (1992).

Tekin, R., Bac, N., Warzywoda, J. & Sacco, A. Effect of reaction mixture composition and silica source on size distribution of zeolite X crystals. J. Cryst. Growth 411, 45–48 (2015).

Simon, U. & Flesch, U. Cation–cation interaction in dehydrated zeolites X and Y monitored by modulus spectroscopy. J. Porous Mater. 6, 33–40 (1999).

Kamaya, N. et al. A lithium superionic conductor. Nat. Mater. 10, 682–686 (2011).

Wang, Z., Ge, Q., Shao, J. & Yan, Y. High performance zeolite LTA pervaporation membranes on ceramic hollow fibers by dipcoating-wiping seed deposition. J. Am. Chem. Soc. 131, 6910–6911 (2009).

Wang, S. et al. Fabrication of bioactive 3D printed porous titanium implants with Sr ion-incorporated zeolite coatings for bone ingrowth. J. Mater. Chem. B 6, 3254–3261 (2018).

Zhang, T. & Zhou, H. From Li–O2 to Li–air batteries: carbon nanotubes/ionic liquid gels with a tricontinuous passage of electrons, ions, and oxygen. Angew. Chem. Int. Ed. 51, 11062–11067 (2012).

Wang, C. et al. Universal soldering of lithium and sodium alloys on various substrates for batteries. Adv. Energy Mater. 8, 1701963 (2018).

Wang, Z. et al. A metal–organic-framework-based electrolyte with nanowetted interfaces for high-energy-density solid-state lithium battery. Adv. Mater. 30, 1704436 (2018).

Liu, G. et al. High air-stability and superior lithium ion conduction of Li3+3xP1−xZnxS4−xOx by aliovalent substitution of ZnO for all-solid-state lithium batteries. Energy Storage Mater. 17, 266–274 (2019).

Wang, S. et al. Ultra-fine surface solid-state electrolytes for long cycle life all-solid-state lithiumi–air batteries. J. Mater. Chem. A 6, 21248–21254 (2018).

Kim, B. G. et al. A moisture- and oxygen-impermeable separator for aprotic Li–O2 batteries. Adv. Funct. Mater. 26, 1747–1756 (2016).

Xu, J.-J., Wang, Z.-L., Xu, D., Zhang, L.-L. & Zhang, X.-B. Tailoring deposition and morphology of discharge products towards high-rate and long-life lithium–oxygen batteries. Nat. Commun. 4, 2438 (2013).

Vitillo, J. G., Ricchiardi, G., Spoto, G. & Zecchina, A. Theoretical maximal storage of hydrogen in zeolitic frameworks. Phys. Chem. Chem. Phys. 7, 3948–3954 (2005).

Baimpos, T., Kouzoudis, D., Gora, L. & Nikolakis, V. Are zeolite films flexible? Chem. Mater. 23, 1347–1349 (2011).

Wan, J. et al. Ultrathin, flexible, solid polymer composite electrolyte enabled with aligned nanoporous host for lithium batteries. Nat. Nanotechnol. 14, 705–711 (2019).

Goodenough, J. B., Hong, H. Y.-P. & Kafalas, J. A. Fast Na+-ion transport in skeleton structures. Mater. Res. Bull. 11, 203–220 (1976).

Freeman, D. C. & Stamires, D. N. Electrical conductivity of synthetic crystalline zeolites. J. Chem. Phys. 35, 799–806 (1961).

Armand, M. & Tarascon, J.-M. Building better batteries. Nature 451, 652–657 (2008).

Yoshima, K., Harada, Y. & Takami, N. Thin hybrid electrolyte based on garnet-type lithium–ion conductor Li7La3Zr2O12 for 12 V-class bipolar batteries. J. Power Sources 302, 283–290 (2016).

Ohgushi, T. & Sato, S. Cation movements in dehydrated (Ca,Na)-A zeolites. J. Solid State Chem. 87, 95–100 (1990).

Yu, H. et al. Thermal decomposition of the carbon nanotube/SiO2 precursor powders. J. Therm. Anal. Calorim. 82, 97–101 (2005).

Lin, Y. et al. Ultrahigh-capacity lithium–oxygen batteries enabled by dry-pressed holey graphene air cathodes. Nano Lett. 17, 3252–3260 (2017).

Lai, J. et al. Electrolytes for rechargeable lithium–air batteries. Angew. Chem. Int. Ed. 59, 2974–2997 (2020).

Acknowledgements

J.Y. is supported by the National Natural Science Foundation of China (grants 21621001, 21835002 and 21920102005) and the 111 Project (B17020). J.X. is supported by the National Natural Science Foundation of China (grants 21621001, 51771177 and 51972141) and Jilin Province Science and Technology Development Program (20190303104SF). M. L. is supported by the National Postdoctoral Program for Innovative Talents (BX20180119) and the China Postdoctoral Science Foundation (2019M651194).

Author information

Authors and Affiliations

Contributions

J.Y. and J.X. conceived the project. X.C., J.Y., J.X., J.D. and M.L. designed the experiments. X.C. prepared materials, performed measurements and analysed the data. P.B., L.S., X.W., F.L. and S.L. helped with some of the experiments and characterization. All authors discussed the results and commented on the manuscript. X.C. and M.L. wrote the draft, and J.X. and J.Y. revised and finalized the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature thanks the anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Characterization of SC-LiX.

a, XRD patterns and SEM image (scale bar, 20 μm) of the synthesized SC-LiX. The standard XRD pattern of the simulated FAU structure is provided for comparison. The SC-LiX displays a typical octahedral morphology with a particle size of 28 μm. b, N2 adsorption–desorption isotherms and pore-size distributions of SC-LiX (total surface area = 880 m2 g−1, micropore area = 819 m2 g−1, external surface area = 61 m2 g−1, micropore volume = 0.30 cm3 g−1). c, Photograph and micrograph of the test device used for the EIS of SC-LiX. The ionic conductivity was calculated with the formula σ = d/(R × S), in which the value of the resistance R (28,656 Ω) was obtained from the fitted Nyquist plots, the value of the diameter d (2.3 × 10−3 cm) was measured from the SEM image in the inset of a, and S (3.4 × 10−6 cm2) was the adhesion area of the silver electrode for SC-LiX, with the shape of an equilateral triangle. d, EIS spectrum of the synthesized SC-LiX.

Extended Data Fig. 2 Characterization of zeolite-based solid electrolyte.

a, XRD pattern and SEM image (scale bar, 1 μm) of the crystal seeds used in the synthesis of LiXZM. Crystal seeds display a particle size of about 800 nm. b, XRD patterns of LiXZM before and after keeping for 1 year. c, SEM image of LiXZP (scale bar, 5 μm). d, XPS spectrum and Ag 3d spectra of LiXZP after the EIS experiment. After EIS, the XPS spectrum of LiXZP was conducted after scraping off the Ag current collectors from the LiXZP. No Ag could be detected in the Ag 3d spectrum, demonstrating that Ag could not participate in ion conduction as a mobile ion. The ionic conductivities of LiXZM and LiXZP were calculated using the formula σ = d/(R × S), in which the values of R (5.9 × 106 Ω for LiXZP, 11,720 Ω for LiXZM) were obtained from the fitted Nyquist plots, the values of d (1.5 × 10−2 cm for LiXZP, 5.0 × 10−4 cm for LiXZM) were from the SEM images in Fig. 1e, f, and the values of S (7.9 × 10−1 cm2 for LiXZP, 1.6 × 10−4 cm2 for LiXZM) corresponded to the adhesion area of silver electrodes for LiXZP (circle) and LiXZM (rectangle, stripped from the smooth stainless-steel substrate). Thus, the ionic conductivities were calculated to be 3.3 × 10−9 S cm−1 for LiXZP and 2.7 × 10−4 S cm−1 for LiXZM. e, f, EIS spectra (e) and the corresponding Arrhenius conductivity plots (f) of LiXZM at 25–200 °C in the frequency range of 1 MHz–10 Hz. According to the Arrhenius equation (σ = σ0exp(−Ea/kBT))34, the activation energy of conduction (Ea) is calculated to be 6.54 kJ mol−1. g, h, Current–time curves (g) and the corresponding electronic conductivity (h) of LiXZM at 25–500 °C. i, Results of scratch and Vickers hardness tests on LiXZM and LiXZP.

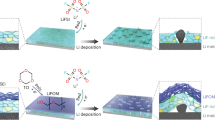

Extended Data Fig. 3 Construction of the integrated SSLAB with C-LiXZM.

a, Elemental mapping (C, N, O) of CNT-SS using EDS (scale bar, 200 μm). b, SEM image of the crystal seeds wiped on the CNT-SS (scale bar, 1 μm). c, Raman spectra of CNT-SS with 300 s plasma treatment before and after LiXZM growth. The two peaks located at 1,351 and 1,580 cm−1 arise from the D and G bands of CNT-SS. The intensity ratio of the two peaks (ID/IG) remained approximately the same after the in situ growth of LiXZM, indicating that the structural integrity of the CNTs was preserved. d, XPS survey spectrum of C-LiXZM. XPS analysis of CNT-SS demonstrates the existence of C, O, and N on the surfaces of the CNTs, whereas peaks corresponding to Si 2p, Al 2p and Li 1s are observed in the XPS spectrum of C-LiXZM owing to the presence of LiX zeolite. e, XPS spectra of C-LiXZM in the C 1s region. The peaks at 284.6, 285.2, 287.3 and 289.0 eV correspond to C–C (sp3), C–N (sp3), C=O (sp2) and O–C=O (sp2), respectively. f, XPS spectra of C-LiXZM in the N 1s region. The peaks of pyridinic N at 398.6 eV, pyrrolic N at 399.7 eV and graphitic N at 401.1 eV are identified in the N 1s spectrum of C-LiXZM. g, Thermogravimetric curve of C-LiXZM after the stainless-steel mesh substrate was removed. The dehydration of zeolites (<200 °C)46 and the thermal decomposition of CNTs (500–630 °C)47 take place in sequence as the temperature increases. h, Cross-sectional SEM image of the interface between LiXZM and Li metal anode (scale bar, 100 μm).

Extended Data Fig. 4 Construction and performance of SSLABs.

a, SEM image of the 500-mesh stainless-steel mesh as the substrate (scale bar, 50 μm). b, SEM image of LiXZM grown on the 500-mesh stainless-steel mesh (scale bar, 50 μm), which serves as the solid electrolyte for non-integrated batteries with C|LiXZM. c, XRD pattern of the commercial NASICON-type solid electrolyte of LAGP, which has a rhombohedral structure with space group36 R3c. d, The first discharge–charge curves of SSLABs with C-LiXZM, C|LiXZM and C|LAGP. The curves are additionally labelled at an areal current density of 0.065 mA cm−2 with a limited areal specific capacity of 0.13 mAh cm−2. e, Rate performances of the three SSLABs.

Extended Data Fig. 5 Stability of LAGP and LiXZM.

a, b, SEM image of LAGP before cycling (scale bar, 2 μm) (a) and after 10 cycles (scale bar, 2 μm) (b). c, d, SEM image of C-LiXZM before cycling (scale bar, 500 nm) (c) and after 100 cycles (scale bar, 500 nm) (d). The original morphology of LAGP was not maintained after cycling, whereas the outline of the crystal face of LiXZM is still clear. e, f, XRD patterns of LAGP (e) and LiXZM (f) after cycling. The crystallinity of LAGP decreased considerably, indicating the poor stability of LAGP, whereas no structural change was observed in LiXZM even after 100 cycles. g, h, Ge 3d XPS spectra of LAGP before (g) and after (h) cycling. i, j, Al 2p XPS spectra of C-LiXZM before (i) and after (j) cycling. k, l, Si 2p XPS spectra of C-LiXZM before (k) and after (l) cycling. When in contact with the Li metal surface, Ge4+ in LAGP is easily reduced, whereas no structural change occurs in LiXZM even after 100 cycles. m, n, Al 2p (m) and Si 2p (n) XPS spectra of the lithium anode before and after cycling. No Al and Si species appeared on the surface of lithium metal after cycling, which further confirmed the stability of LiXZM towards lithium metal. o, Results of scratch and Vickers hardness tests of LiXZM and LAGP.

Extended Data Fig. 6 Cycling performance of SSLABs with C-LiXZM.

a, Cycling performance of SSLAB with C-LiXZM at 200 mA g−1 and 200 mAh g−1 (top), at 500 mA g−1 and 500 mAh g−1 (middle) and at 1,000 mA g−1 and 1,000 mAh g−1 (bottom) in ambient air. The SSLABs with C-LiXZM exhibit stable discharge–recharge reactions for 1,297 cycles at 200 mA g−1 and 200 mAh g−1, 309 cycles at 500 mA g−1 and 500 mAh g−1, and 115 cycles at 1,000 mA g−1 and 1,000 mAh g−1 in ambient air, and the battery keeps operating steadily at 200 mA g−1 and 200 mAh g−1 as of the submission of this work. To our knowledge, these are the best cycling performances reported to date in SSLABs. b, Cycling performance of SSLABs with CNT mass loadings of 0.05, 0.10 and 0.15 mg cm−2 at a current density of 500 mA g−1 with a specific capacity limited to 1,000 mAh g−1. The overpotentials of the batteries display negligible change, whereas the cycle life is affected by the CNTs mass loading. Specifically, SSLABs using C-LiXZM could operate for 465, 149 and 96 cycles with CNT mass loadings of 0.05, 0.10 and 0.15 mg cm−2, respectively. The reduced cycle life for the cathode materials with increased mass loading is common in practical battery systems, because the accumulation of active substance affects mass transfer48. In the meantime, the absolute current of the battery under the same current density would increase with increased active mass loading. c, Terminal discharge voltage of the SSLAB with C-LiXZM compared with the Li–air battery with ionic liquid electrolyte (IL). The cyclic stability of the SSLAB with C-LiXZM is better than that of the Li–air battery with ionic liquid electrolyte, which operates for only 67 cycles before failure—mainly as a result of similar problems to the organic-electrolyte-based Li–air batteries, including the decomposition of the ionic liquid and growth of Li dendrites49.

Extended Data Fig. 7 Protective effect of C-LiXZM.

Time-resolved optical images of lithium metal inserted in the test devices sealed with Celgard separator (immersed with organic electrolyte), glass fibre separator (immersed with organic electrolyte), LiXZM and C-LiXZM. The lithium metal sealed with LiXZM and C-LiXZM retains its metallic lustre after 1,000 h of ageing, which demonstrates that lithium metal can be effectively protected from the erosion of air components by zeolite membranes. Notably, lithium metal sealed with C-LiXZM is brighter than that sealed with LiXZM, because the hydrophobic carbon cathode surface can further block H2O from the air.

Extended Data Fig. 8 Characterization and properties of LiXZM.

a, XRD patterns of the discharge products of batteries with C-LiXZM and the organic electrolyte after the first discharge. b, Li 1s XPS spectra of LiXZM before and after cycling. The surface of the LiXZM adjacent to the cathode side was characterized by XPS after cycling, and no discharge products of Li2O2 were detected. c, EIS spectrum of LiXZM after discharge. The ionic conductivity after discharge is 2.71 × 10−4 S cm−1, showing no notable difference from that before discharge (2.65 × 10−4 S cm−1). d, Terminal discharge voltage of the SSLABs with C-LiXZM compared with those of the Li–air batteries with organic electrolyte at 500 mA g−1, 500 mAh g−1 in ambient air (309 versus 162 cycles), and 500 mA g−1, 1,000 mAh g−1 in dry oxygen (276 versus 169 cycles). e, FTIR spectra of the discharge products in the SSLAB with C-LiXZM after 150 cycles.

Extended Data Fig. 9 The nail test on the batteries with C-LiXZM and organic electrolyte.

a, The short-circuit battery temperature observed through an infrared camera. b, The first discharge–charge curves of the batteries with organic electrolyte and C-LiXZM after the nail test. c, Terminal discharge voltage of the batteries with organic electrolyte and C-LiXZM after the nail test at a current density of 500 mA g−1 with the specific capacity limited to 1,000 mAg−1. The nail pierced the batteries containing C-LiXZM and organic electrolyte powering a red LED (Supplementary Video 1, 2). The battery with C-LiXZM was able to light up the LED immediately after the nail was removed, whereas the battery with organic electrolyte was no longer able to function. The temperature of the battery with organic electrolyte immediately increased by 2 °C after the short circuit, whereas no temperature change was observed in the case of SSLABs with C-LiXZM. It is notable that a very small button battery with an open system produced such a temperature difference. If a battery pack that contains flammable and explosive organic electrolytes is hit or damaged when used in a vehicle, a short circuit could be very dangerous.

Extended Data Fig. 10 Potential for the practical application of zeolite membranes as solid electrolytes.

a, The performance of the SSLAB with C-LiXZM under a simulated actual application state. The integrated SSLAB with C-LiXZM was operated for 20 cycles (200 mA g−1, 2,000 mAh g−1). After an interval of 40 days, the battery with C-LiXZM was able to operate steadily for 40 cycles at a different current density and specific capacity (500 mA g−1, 1,000 mAh g−1). b, Curvature test of the integrated SSLAB with C-LiXZM. The curvature radius and curvature are 3.92 mm and 2.55 × 102 m−1, respectively. c, Stress strain curve (σ–ε) of the C-LiXZM. d, A digital photograph of large LiXZMs synthesized in the laboratory.

Supplementary information

Supplementary Video 1

A nail test of the battery with C-LiXZM.

Supplementary Video 2

A nail test of the battery with organic electrolyte (OE).

Supplementary Video 3

The flexibility of the SSLAB with C-LiXZM.

Supplementary Video 4

The SSLAB with C-LiXZM providing power to drive an unmanned aerial vehicle.

Rights and permissions

About this article

Cite this article

Chi, X., Li, M., Di, J. et al. A highly stable and flexible zeolite electrolyte solid-state Li–air battery. Nature 592, 551–557 (2021). https://doi.org/10.1038/s41586-021-03410-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-021-03410-9

This article is cited by

-

The development of a novel zeolite-based assay for efficient and deep plasma proteomic profiling

Journal of Nanobiotechnology (2024)

-

A rechargeable calcium–oxygen battery that operates at room temperature

Nature (2024)

-

Pd cluster decorated free standing flexible cathode for high performance Li-oxygen batteries

Nano Research (2024)

-

Li–air batteries: air stability of lithium metal anodes

Science China Chemistry (2024)

-

Lignin-reinforced PVDF electrolyte for dendrite-free quasi-solid-state Li metal battery

Rare Metals (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.