Abstract

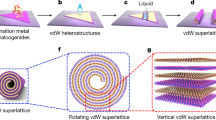

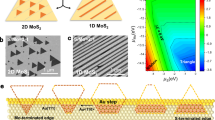

Two-dimensional van der Waals heterostructures (vdWHs) have attracted considerable interest1,2,3,4. However, most vdWHs reported so far are created by an arduous micromechanical exfoliation and manual restacking process5, which—although versatile for proof-of-concept demonstrations6,7,8,9,10,11,12,13,14,15,16 and fundamental studies17,18,19,20,21,22,23,24,25,26,27,28,29,30—is clearly not scalable for practical technologies. Here we report a general synthetic strategy for two-dimensional vdWH arrays between metallic transition-metal dichalcogenides (m-TMDs) and semiconducting TMDs (s-TMDs). By selectively patterning nucleation sites on monolayer or bilayer s-TMDs, we precisely control the nucleation and growth of diverse m-TMDs with designable periodic arrangements and tunable lateral dimensions at the predesignated spatial locations, producing a series of vdWH arrays, including VSe2/WSe2, NiTe2/WSe2, CoTe2/WSe2, NbTe2/WSe2, VS2/WSe2, VSe2/MoS2 and VSe2/WS2. Systematic scanning transmission electron microscopy studies reveal nearly ideal vdW interfaces with widely tunable moiré superlattices. With the atomically clean vdW interface, we further show that the m-TMDs function as highly reliable synthetic vdW contacts for the underlying WSe2 with excellent device performance and yield, delivering a high ON-current density of up to 900 microamperes per micrometre in bilayer WSe2 transistors. This general synthesis of diverse two-dimensional vdWH arrays provides a versatile material platform for exploring exotic physics and promises a scalable pathway to high-performance devices.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the plots within this paper and other findings of this study are available from the corresponding authors upon reasonable request.

References

Geim, A. K. & Grigorieva, I. V. Van der Waals heterostructures. Nature 499, 419–425 (2013).

Novoselov, K., Mishchenko, A., Carvalho, A. & Neto, A. C. 2D materials and van der Waals heterostructures. Science 353, aac9439 (2016).

Liu, Y. et al. Van der Waals heterostructures and devices. Nat. Rev. Mater. 1, 16042 (2016).

Liu, Y., Huang, Y. & Duan, X. F. Van der Waals integration before and beyond two-dimensional materials. Nature 567, 323–333 (2019).

Dean, C. R. et al. Boron nitride substrates for high-quality graphene electronics. Nat. Nanotechnol. 5, 722–726 (2010).

Britnell, L. et al. Field-effect tunneling transistor based on vertical graphene heterostructures. Science 335, 947–950 (2012).

Yu, W. J. et al. Vertically stacked multi-heterostructures of layered materials for logic transistors and complementary inverters. Nat. Mater. 12, 246–252 (2013).

Yu, W. J. et al. Highly efficient gate-tunable photocurrent generation in vertical heterostructures of layered materials. Nat. Nanotechnol. 8, 952–958 (2013).

Lee, C.-H. et al. Atomically thin p–n junctions with van der Waals heterointerfaces. Nat. Nanotechnol. 9, 676–681 (2014).

Fang, H. et al. Strong interlayer coupling in van der Waals heterostructures built from single-layer chalcogenides. Proc. Natl Acad. Sci. USA 111, 6198–6202 (2014).

Cheng, R. et al. Electroluminescence and photocurrent generation from atomically sharp WSe2/MoS2 heterojunction p–n diodes. Nano Lett. 14, 5590–5597 (2014).

Liu, Y. et al. Toward barrier free contact to molybdenum disulfide using graphene electrodes. Nano Lett. 15, 3030–3034 (2015).

Cui, X. et al. Multi-terminal transport measurements of MoS2 using a van der Waals heterostructure device platform. Nat. Nanotechnol. 10, 534–540 (2015).

Withers, F. et al. Light-emitting diodes by band-structure engineering in van der Waals heterostructures. Nat. Mater. 14, 301–306 (2015).

Wang, C. et al. Monolayer atomic crystal molecular superlattices. Nature 555, 231–236 (2018).

Liu, Y. et al. Approaching the Schottky–Mott limit in van der Waals metal–semiconductor junctions. Nature 557, 696–700 (2018).

Hong, X. et al. Ultrafast charge transfer in atomically thin MoS2/WS2 heterostructures. Nat. Nanotechnol. 9, 682–686 (2014).

Rivera, P. et al. Valley-polarized exciton dynamics in a 2D semiconductor heterostructure. Science 351, 688–691 (2016).

Xu, W. et al. Correlated fluorescence blinking in two-dimensional semiconductor heterostructures. Nature 541, 62–67 (2017).

Zhang, C. et al. Interlayer couplings, moiré patterns, and 2D electronic superlattices in MoS2/WSe2 hetero-bilayer. Sci. Adv. 3, e1601459 (2017).

Huang, B. et al. Layer-dependent ferromagnetism in a van der Waals crystal down to the monolayer limit. Nature 546, 270–273 (2017).

Gong, C. et al. Discovery of intrinsic ferromagnetism in two-dimensional van der Waals crystals. Nature 546, 265–269 (2017).

Song, T. et al. Giant tunneling magnetoresistance in spin-filter van der Waals heterostructures. Science 360, 1214–1218 (2018).

Unuchek, D. et al. Room-temperature electrical control of exciton flux in a van der Waals heterostructure. Nature 560, 340–344 (2018).

Cao, Y. et al. Unconventional superconductivity in magic-angle graphene superlattices. Nature 556, 43–50 (2018).

Cao, Y. et al. Correlated insulator behaviour at half-filling in magic-angle graphene superlattices. Nature 556, 80–84 (2018).

Seyler, K. L. et al. Signatures of moiré-trapped valley excitons in MoSe2/WSe2 heterobilayers. Nature 567, 66–70 (2019).

Tran, K. et al. Evidence for moiré excitons in van der Waals heterostructures. Nature 567, 71–75 (2019).

Jin, C. H. et al. Observation of moiré excitons in WSe2/WS2 heterostructure superlattices. Nature 567, 76–80 (2019); correction 569, E7 (2019).

Alexeev, E. M. et al. Resonantly hybridized excitons in moiré superlattices in van der Waals heterostructures. Nature 567, 81–86 (2019); correction 572, E8 (2019).

Han, G. H. et al. Seeded growth of highly crystalline molybdenum disulphide monolayers at controlled locations. Nat. Commun. 6, 6128 (2015).

Kang, K. et al. Layer-by-layer assembly of two-dimensional materials into wafer-scale heterostructures. Nature 550, 229–233 (2017).

Chen, P., Zhang, Z. W., Duan, X. D. & Duan, X. F. Chemical synthesis of two-dimensional atomic crystals, heterostructures and superlattices. Chem. Soc. Rev. 47, 3129–3151 (2018).

Huang, C. et al. Lateral heterojunctions within monolayer MoSe2–WSe2 semiconductors. Nat. Mater. 13, 1096–1101 (2014).

Gong, Y. et al. Vertical and in-plane heterostructures from WS2/MoS2 monolayers. Nat. Mater. 13, 1135–1142 (2014).

Duan, X. D. et al. Lateral epitaxial growth of two-dimensional layered semiconductor heterojunctions. Nat. Nanotechnol. 9, 1024–1030 (2014).

Li, M.-Y. et al. Epitaxial growth of a monolayer WSe2–MoS2 lateral p–n junction with an atomically sharp interface. Science 349, 524–528 (2015).

Chen, J. et al. Lateral epitaxy of atomically sharp WSe2/WS2 heterojunctions on silicon dioxide substrates. Chem. Mater. 28, 7194–7197 (2016).

Mahjouri-Samani, M. et al. Patterned arrays of lateral heterojunctions within monolayer two-dimensional semiconductors. Nat. Commun. 6, 7749 (2015).

Zhao, M. et al. Large-scale chemical assembly of atomically thin transistors and circuits. Nat. Nanotechnol. 11, 954–959 (2016).

Zhang, Z. et al. Robust epitaxial growth of two-dimensional heterostructures, multiheterostructures, and superlattices. Science 357, 788–792 (2017).

Sahoo, P. K., Memaran, S., Xin, Y., Balicas, L. & Gutiérrez, H. R. One-pot growth of two-dimensional lateral heterostructures via sequential edge-epitaxy. Nature 553, 63–67 (2018).

Xie, S. et al. Coherent, atomically thin transition-metal dichalcogenide superlattices with engineered strain. Science 359, 1131–1136 (2018).

Zhang, Y. et al. Edge-epitaxial growth of 2D NbS2–WS2 lateral metal–semiconductor heterostructures. Adv. Mater. 30, 1803665 (2018).

Ai, R. Q. et al. Growth of Single-crystalline cadmium iodide nanoplates, CdI2/MoS2 (WS2, WSe2) van der Waals heterostructures, and patterned arrays. ACS Nano 11, 3413–3419 (2017).

Yang, T. et al. Van der Waals epitaxial growth and optoelectronics of large-scale WSe2/SnS2 vertical bilayer p–n junctions. Nat. Commun. 8, 1906 (2017).

Zhang, Z. et al. Epitaxial growth of two-dimensional metal–semiconductor transition-metal dichalcogenide vertical stacks (VSe2/MX2) and their band alignments. ACS Nano 13, 885–893 (2019).

Wu, R. et al. Van der Waals epitaxial growth of atomically thin 2D metals on dangling-bond-free WSe2 and WS2. Adv. Funct. Mater. 29, 1806611 (2019).

Yu, H. et al. Wafer-scale growth and transfer of highly-oriented monolayer MoS2 continuous film. ACS Nano 11, 12001–12007 (2017).

Gao, Y. et al. Ultrafast growth of high-quality monolayer WSe2 on Au. Adv. Mater. 29, 1700990 (2017).

Zhang, Z. W. et al. Ultrafast growth of large single crystals of monolayer WS2 and WSe2. Natl Sci. Rev. https://academic.oup.com/nsr/advance-article/doi/10.1093/nsr/nwz223/5698323 (2020).

Clark, S. J. et al. First principles methods using CASTEP. Z. Kristallogr. 220, 567–570 (2005).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Hasnip, P. J. & Pickard, C. J. Electronic energy minimisation with ultrasoft pseudopotentials. Comput. Phys. Commun. 174, 24–29 (2006).

Perdew, J. P. et al. Atoms, molecules, solids, and surfaces: applications of the generalized gradient approximation for exchange and correlation. Phys. Rev. B 46, 6671–6687 (1992).

Head, J. D. & Zerner, M. C. A Broyden–Fletcher–Goldfarb–Shanno optimization procedure for molecular geometries. Chem. Phys. Lett. 122, 264–270 (1985).

Acknowledgements

The authors at Hunan University acknowledge the support from National Natural Science Foundation of China (grant numbers 51991340, 51991343 and 51872086), and the Hunan Key Laboratory of Two-Dimensional Materials (grant number 2018TP1010). The planar TEM studies were conducted at the Center for Electron Microscopy at Tianjin University of Technology. The cross-sectional STEM experiments were conducted using the facilities in the Irvine Materials Research Institute (IMRI) at the University of California, Irvine. The work at University of California, Irvine was supported by the Department of Energy (DOE), Office of Basic Energy Sciences, Division of Materials Sciences and Engineering under grant DE-SC0014430.

Author information

Authors and Affiliations

Contributions

Xidong Duan conceived and designed the research. J. Li, X. Yang, Yang Liu and B. Huang contributed equally to this work. J. Li developed the defect-induced nucleation and synthesized a series of metal–semiconductor vertical heterostructure arrays. J. Li and X. Yang performed device fabrication and electrical measurements. Yang Liu and Xiangfeng Duan contributed to data analysis. X. Yang and Z.Z. participated in the investigation of growth mechanism and TEM characterizations. B. Huang conducted the theoretical calculations and wrote the related discussions with support from M.Z.S.; B.Z. and H.M. participated in the materials growth. R.W. and W.D. participated in the fabrication of field-effect transistors. Z.W. and G.Z. provided large-area materials on sapphire substrates. K.W. and J. Luo performed planar TEM studies. Z.Y.L., X. Yan and X.P. performed the cross-sectional HAADF-STEM characterizations. B. Li performed the Raman and AFM measurements. Yuan Liu and Y.H. contributed to discussions. J. Li, X. Yang, Yang Liu, Xidong Duan and Xiangfeng Duan co-wrote the manuscript with input from all of the authors. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Laser-patterned nucleation sites.

a, Optical microscopy image of WSe2 with periodically patterned defects. b, AFM image of WSe2 with patterned defects. c, The height profile of the white circle region in b, exhibiting a depth of about 0.3 nm.

Extended Data Fig. 2 Raman and photoluminescence spectra of VSe2 and VSe2/WSe2.

Raman spectra of VSe2 on SiO2/Si (a) and VSe2/WSe2 vertical heterostructure (b). c, Photoluminescence spectra of the bare WSe2 and the overlapping VSe2/WSe2 vertical heterostructure.

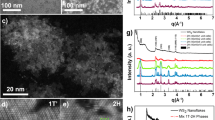

Extended Data Fig. 3 HAADF-STEM analysis of VSe2 and WSe2.

Atomic-resolution HAADF-STEM image of VSe2 (a) and the corresponding intensity profile of V (b). c, d, Atomic-resolution HAADF-STEM image of WSe2 (c) and the corresponding intensity profile of W (d).

Extended Data Fig. 4 High-resolution view of simulated moiré structures.

Zoom-in view of four locations of moiré structures marked in Fig. 4c (i, ii, iii, i), showing three distinct atomic arrangements, corresponding to the single V atom arrangement (i), V stacking over Se (ii), and V stacking over W (iii). The two panels labelled ‘i’ are identical. The red, blue and yellow spheres correspond to V, W and Se, respectively.

Extended Data Fig. 5 General synthesis of m-TMD/WSe2 vdWH arrays.

Optical microscopy images of the NbTe2/WSe2 vdWH arrays (a) and the VS2/WSe2 vdWH arrays (b).

Extended Data Fig. 6 Large-scale VSe2/MoS2 vdWH arrays on continuous monolayer MoS2 thin film.

a, Typical photograph of highly oriented monolayer MoS2 continuous films grown on 2-inch sapphire wafer. b, c, Optical microscopy images of large-scale periodic VSe2/MoS2 vdWH arrays grown on continuous MoS2 thin films taken with ×10 magnification objective (b) and ×20 magnification objective (c). d–g, High-magnification optical microscopy images of periodic VSe2/MoS2 vdWH arrays collected in different regions of b, suggesting highly uniform growth of VSe2/MoS2 vdWH arrays.

Extended Data Fig. 7 Characterizations of VSe2/WS2 vdWH arrays.

a, Typical optical microscopy image of a VSe2/WS2 vdWH array. b, Raman spectra of the bare WS2 and the overlapping VSe2/WS2 vertical heterostructure. c, d, Raman intensity mapping image of VSe2/WSe2 vdWH arrays at resonant peaks of 353 cm−1 (WS2; c) and 206 cm−1 (VSe2; d). e, Photoluminescence spectra of the bare WS2 and the overlapping VSe2/WS2 vertical heterostructure. f, Photoluminescence intensity mapping image at 658 nm (WS2 emission).

Extended Data Fig. 8 Electrical characterization of a bilayer WSe2 transistors with synthetic vdW contacts.

a, b, Output (a) and transfer (b) curves of a typical device with synthetic VSe2 vdW contacts on 285-nm SiO2/Si. The channel length is about 2.0 μm.

Rights and permissions

About this article

Cite this article

Li, J., Yang, X., Liu, Y. et al. General synthesis of two-dimensional van der Waals heterostructure arrays. Nature 579, 368–374 (2020). https://doi.org/10.1038/s41586-020-2098-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-020-2098-y

This article is cited by

-

Phase-engineered synthesis of atomically thin te single crystals with high on-state currents

Nature Communications (2024)

-

Van der Waals epitaxy of tunable moirés enabled by alloying

Nature Materials (2024)

-

The study of spin- and valley-dependent electron transport properties in silicene modulated by metallic gates

Indian Journal of Physics (2024)

-

Optical and electrical anisotropy regulation engineering of low-dimensional materials toward polarized detection and imaging applications

Rare Metals (2024)

-

Pyro-layered heterostructured nanosheet membrane for hydrogen separation

Nature Communications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.