Abstract

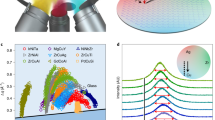

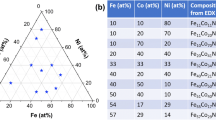

Since their discovery in 19601, metallic glasses based on a wide range of elements have been developed2. However, the theoretical prediction of glass-forming compositions is challenging and the discovery of alloys with specific properties has so far largely been the result of trial and error3,4,5,6,7,8. Bulk metallic glasses can exhibit strength and elasticity surpassing those of conventional structural alloys9,10,11, but the mechanical properties of these glasses are critically dependent on the glass transition temperature. At temperatures approaching the glass transition, bulk metallic glasses undergo plastic flow, resulting in a substantial decrease in quasi-static strength. Bulk metallic glasses with glass transition temperatures greater than 1,000 kelvin have been developed, but the supercooled liquid region (between the glass transition and the crystallization temperature) is narrow, resulting in very little thermoplastic formability, which limits their practical applicability. Here we report the design of iridium/nickel/tantalum metallic glasses (and others also containing boron) with a glass transition temperature of up to 1,162 kelvin and a supercooled liquid region of 136 kelvin that is wider than that of most existing metallic glasses12. Our Ir–Ni–Ta–(B) glasses exhibit high strength at high temperatures compared to existing alloys: 3.7 gigapascals at 1,000 kelvin9,13. Their glass-forming ability is characterized by a critical casting thickness of three millimetres, suggesting that small-scale components for applications at high temperatures or in harsh environments can readily be obtained by thermoplastic forming14. To identify alloys of interest, we used a simplified combinatorial approach6,7,8 harnessing a previously reported correlation between glass-forming ability and electrical resistivity15,16,17. This method is non-destructive, allowing subsequent testing of a range of physical properties on the same library of samples. The practicality of our design and discovery approach, exemplified by the identification of high-strength, high-temperature bulk metallic glasses, bodes well for enabling the discovery of other glassy alloys with exciting properties.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are included within the paper and available from the corresponding author on reasonable request.

References

Klement, W., Willens, R. H. & Duwez, P. Non-crystalline structure in solidified gold–silicon alloys. Nature 187, 869–870 (1960).

Greer, A. L. Metallic glasses… on the threshold. Mater. Today 12, 14–22 (2009).

Li, Y. L., Zhao, S. F., Liu, Y. H., Gong, P. & Schroers, J. How many bulk metallic glasses are there? ACS Comb. Sci. 19, 687–693 (2017).

Tsai, P. & Flores, K. M. High-throughput discovery and characterization of multicomponent bulk metallic glass alloys. Acta Mater. 120, 426–434 (2016).

Ma, D., Tan, H., Wang, D., Li, Y. & Ma, E. Strategy for pinpointing the best glass-forming alloys. Appl. Phys. Lett. 86, 191906 (2005).

Deng, Y. P. et al. A combinatorial thin film sputtering approach for synthesizing and characterizing ternary ZrCuAl metallic glasses. Intermetallics 15, 1208–1216 (2007).

Ding, S. Y. et al. Combinatorial development of bulk metallic glasses. Nat. Mater. 13, 494–500 (2014).

Li, Y., Guo, Q., Kalb, J. A. & Thompson, C. V. Matching glass-forming ability with the density of the amorphous phase. Science 322, 1816–1819 (2008).

Chen, G. et al. Polysynthetic twinned TiAl single crystals for high-temperature applications. Nat. Mater. 15, 876–881 (2016).

Inoue, A., Shen, B. L., Koshiba, H., Kato, H. & Yavari, A. R. Cobalt-based bulk glassy alloy with ultrahigh strength and soft magnetic properties. Nat. Mater. 2, 661–663 (2003).

Senkov, O. N., Wilks, G. B., Scott, J. M. & Miracle, D. B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 19, 698–706 (2011).

Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 48, 279–306 (2000).

Miracle, D. B. & Senkov, O. N. A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448–511 (2017).

Schroers, J. On the formability of bulk metallic glass in its supercooled liquid state. Acta Mater. 56, 471–478 (2008).

Nagel, S. R. & Tauc, J. Nearly-free-electron approach to theory of metallic glass alloys. Phys. Rev. Lett. 35, 380–383 (1975).

Yu, H. B., Wang, W. H. & Bai, H. Y. An electronic structure perspective on glass-forming ability in metallic glasses. Appl. Phys. Lett. 96, 081902 (2010).

Wang, L. F., Zhang, Q. D., Cui, X. & Zu, F. Q. An empirical criterion for predicting the glass-forming ability of amorphous alloys based on electrical transport properties. J. Non-Cryst. Solids 419, 51–57 (2015).

Liu, Y. H. et al. Thermodynamic origins of shear band formation and the universal scaling law of metallic glass strength. Phys. Rev. Lett. 103, 065504 (2009).

Ma, D. et al. Elastic moduli inheritance and the weakest link in bulk metallic glasses. Phys. Rev. Lett. 108, 085501 (2012).

Cao, C. R. et al. Correlation between glass transition temperature and melting temperature in metallic glasses. Mater. Des. 60, 576–579 (2014).

Collver, M. M. & Hammond, R. H. Stability of amorphous transition-metal films. J. Appl. Phys. 49, 2420–2422 (1978).

Wang, Y. M., Wang, Q., Zhao, J. J. & Dong, C. Ni–Ta binary bulk metallic glasses. Scr. Mater. 63, 178–180 (2010).

Johnson, W. L. Bulk glass-forming metallic alloys: science and technology. MRS Bull. 24, 42–56 (1999).

Hao, G. J., Lin, J. P., Zhang, Y., Chen, G. L. & Lu, Z. P. Ti–Zr–Be ternary bulk metallic glasses correlated with binary eutectic clusters. Mater. Sci. Eng. A 527, 6248–6250 (2010).

Bernard, V. B., Kuprina, V. V. & Burnasheva, V. V. Iridium–nickel–tantalum ternary alloy phase diagram ASM Alloy Phase Diagrams Database (ed. Villars, P.) (ASM International, Russel Township, 2016).

Liu, Y. H., Fujita, T., Aji, D. P. B., Matsuura, M. & Chen, M. W. Structural origins of Johari–Goldstein relaxation in a metallic glass. Nat. Commun. 5, 3238 (2014).

Turnbull, D. Under what conditions can a glass be formed? Contemp. Phys. 10, 473–488 (1969).

Lu, Z. P. & Liu, C. T. Glass formation criterion for various glass-forming systems. Phys. Rev. Lett. 91, 115505 (2003).

Kumar, G., Neibecker, P., Liu, Y. H. & Schroers, J. Critical fictive temperature for plasticity in metallic glasses. Nat. Commun. 4, 1536 (2013); corrigendum 4, 2357 (2013).

Gangopadhyay, A. K. et al. Correlation of the fragility of metallic liquids with the high temperature structure, volume, and cohesive energy. J. Chem. Phys. 146, 154506 (2017).

Ohriner, E. K. Processing of iridium and iridium alloys: methods from purification to fabrication. Platin. Met. Rev. 52, 186–197 (2008).

Rohr, L., Reimann, P., Richmond, T. & Guntherodt, H. J. Refractory metallic glasses. Mater. Sci. Eng. A 133, 715–717 (1991).

Yoshimoto, R., Nogi, Y., Tamura, R. & Takeuchi, S. Fabrication of refractory metal based metallic glasses. Mater. Sci. Eng. A 449–451, 260–263 (2007).

Acknowledgements

We thank D. Q. Zhao and D. W. Ding for experimental assistance. This work was partly supported by the National Key Research and Development programme of China (grant number 2017YFB0701900), the MOST 973 programme (grant number 2015CB856800), the NSF of China (grant numbers 11790291 and 61888102), the Key Research programme of Frontier Sciences of the Chinese Academy of Sciences (grant number QYZDY-SSW-JSC017) and the Strategic Priority Research programme of the Chinese Academy of Sciences (grant number XDB30000000). J.S. is grateful for support by NSF DMR through award number 1609391 for the combinatorial fabrication and XRD mapping. Y.H.L. acknowledges funding from the National Science Fund for Distinguished Young Scholars of the NSF of China (grant number 51825104), the Hundred Talents programme of the Chinese Academy of Sciences and the National Thousand Young Talents programme of China.

Reviewer information

Nature thanks Chain Tsuan Liu and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Author information

Authors and Affiliations

Contributions

Y.H.L. conceived and led the research. Y.H.L., J.S. and W.-H.W. supervised the project. Y.H.L. and M.-X.L. designed the experiments (with advice from P.W., H.-Y.B., M.W.C., J.S. and W.-H.W.). M.-X.L. conducted the experiments. S.-F.Z. and J.S. carried out combinatorial fabrication, XRD mapping and bending tests. Z.L., A.H. and M.W.C. conducted nanoindentation tests. M.-X.L. and Y.H.L. wrote the manuscript with input and comments from all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Oxide formation with temperature and time.

XRD characterizations on the surfaces of annealed BMG disks indicate that the oxide layer is mainly composed of Ta2O5 and NiO.

Extended Data Fig. 2 Morphologies of oxide layer.

a, b, Cross-section and surface morphology along with corresponding element distribution on disk sample annealed at 1,000 K for 1 min. c, d, Cross-section and surface morphology along with corresponding element distribution on disk sample annealed at 1,000 K for 60 min.

Rights and permissions

About this article

Cite this article

Li, MX., Zhao, SF., Lu, Z. et al. High-temperature bulk metallic glasses developed by combinatorial methods. Nature 569, 99–103 (2019). https://doi.org/10.1038/s41586-019-1145-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-019-1145-z

This article is cited by

-

Substantially enhanced homogeneous plastic flow in hierarchically nanodomained amorphous alloys

Nature Communications (2023)

-

Large magnetocaloric effect in low-cobalt-content Gd-Co-Al metallic glasses

Science China Materials (2023)

-

Electronic structure and surface morphology of multicomponent iron-based metallic glasses

Applied Nanoscience (2023)

-

Rational design and glass-forming ability prediction of bulk metallic glasses via interpretable machine learning

Journal of Materials Science (2023)

-

Study on the effects of Ag addition on the mechanical properties and oxidation resistance of Sn–Zn lead-free solder alloy by high-throughput method

Journal of Materials Science: Materials in Electronics (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.