Abstract

Two-dimensional (2D) materials, consisting of atomically thin crystal layers bound by the van der Waals force, have attracted much interest because of their potential in diverse technologies, including electronics, optoelectronics and catalysis1,2,3,4,5,6,7,8,9,10. In particular, solution-processable 2D semiconductor (such as MoS2) nanosheets are attractive building blocks for large-area thin-film electronics. In contrast to conventional zero- and one-dimensional nanostructures (quantum dots and nanowires, respectively), which are typically plagued by surface dangling bonds and associated trapping states, 2D nanosheets have dangling-bond-free surfaces. Thin films created by stacking multiple nanosheets have atomically clean van der Waals interfaces and thus promise excellent charge transport11,12,13,14,15. However, preparing high-quality solution-processable 2D semiconductor nanosheets remains a challenge. For example, MoS2 nanosheets and thin films produced using lithium intercalation and exfoliation are plagued by the presence of the metallic 1T phase and poor electrical performance (mobilities of about 0.3 square centimetres per volt per second and on/off ratios of less than 10)2,12, and materials produced by liquid exfoliation exhibit an intrinsically broad thickness distribution, which leads to poor film quality and unsatisfactory thin-film electrical performance (mobilities of about 0.4 square centimetres per volt per second and on/off ratios of about 100)14,16,17. Here we report a general approach to preparing highly uniform, solution-processable, phase-pure semiconducting nanosheets, which involves the electrochemical intercalation of quaternary ammonium molecules (such as tetraheptylammonium bromide) into 2D crystals, followed by a mild sonication and exfoliation process. By precisely controlling the intercalation chemistry, we obtained phase-pure, semiconducting 2H-MoS2 nanosheets with a narrow thickness distribution. These nanosheets were then further processed into high-performance thin-film transistors, with room-temperature mobilities of about 10 square centimetres per volt per second and on/off ratios of 106 that greatly exceed those obtained for previous solution-processed MoS2 thin-film transistors. The scalable fabrication of large-area arrays of thin-film transistors enabled the construction of functional logic gates and computational circuits, including an inverter, NAND, NOR, AND and XOR gates, and a logic half-adder. We also applied our approach to other 2D materials, including WSe2, Bi2Se3, NbSe2, In2Se3, Sb2Te3 and black phosphorus, demonstrating its potential for generating versatile solution-processable 2D materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors on reasonable request.

References

Radisavljevic, B., Radenovic, A., Brivio, J., Giacometti, V. & Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 6, 147–150 (2011).

Zeng, Z. et al. Single-layer semiconducting nanosheets: high-yield preparation and device fabrication. Angew. Chem. Int. Ed. 50, 11093–11097 (2011).

Wang, Q. H., Kalantar-Zadeh, K., Kis, A., Coleman, J. N. & Strano, M. S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 7, 699–712 (2012).

Butler, S. Z. et al. Progress, challenges, and opportunities in two-dimensional materials beyond graphene. ACS Nano 7, 2898–2926 (2013).

Kappera, R. et al. Phase-engineered low-resistance contacts for ultrathin MoS2 transistors. Nat. Mater. 13, 1128–1134 (2014).

Cheng, R. et al. Few-layer molybdenum disulfide transistors and circuits for high-speed flexible electronics. Nat. Commun. 5, 5143 (2014).

Kang, K. et al. High-mobility three-atom-thick semiconducting films with wafer-scale homogeneity. Nature 520, 656–660 (2015).

Gao, M.-R. et al. An efficient molybdenum disulfide/cobalt diselenide hybrid catalyst for electrochemical hydrogen generation. Nat. Commun. 6, 5982 (2015).

Desai, S. B. et al. MoS2 transistors with 1-nanometer gate lengths. Science 354, 99–102 (2016).

Lin, Z. et al. Scalable solution-phase epitaxial growth of symmetry-mismatched heterostructures on two-dimensional crystal soft template. Sci. Adv. 2, e1600993 (2016).

Eda, G. et al. Photoluminescence from chemically exfoliated MoS2. Nano Lett. 11, 5111–5116 (2011).

He, Q. et al. Fabrication of flexible MoS2 thin-film transistor arrays for practical gas-sensing applications. Small 8, 2994–2999 (2012).

Lin, Z. et al. Solution processable colloidal nanoplates as building blocks for high-performance electronic thin films on flexible substrates. Nano Lett. 14, 6547–6553 (2014).

Kelly, A. G. et al. All-printed thin-film transistors from networks of liquid-exfoliated nanosheets. Science 356, 69–73 (2017).

Talapin, D. V., Lee, J.-S., Kovalenko, M. V. & Shevchenko, E. V. Prospects of colloidal nanocrystals for electronic and optoelectronic applications. Chem. Rev. 110, 389–458 (2010).

Xi, Y. et al. Fabrication of MoS2 thin film transistors via selective-area solution deposition methods. J. Mater. Chem. C 3, 3842–3847 (2015).

Coleman, J. N. et al. Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 331, 568–571 (2011).

Wang, Y. et al. Structural phase transition in monolayer MoTe2 driven by electrostatic doping. Nature 550, 487–491 (2017).

Li, Y., Duerloo, K.-A. N., Wauson, K. & Reed, E. J. Structural semiconductor-to-semimetal phase transition in two-dimensional materials induced by electrostatic gating. Nat. Commun. 7, 10671 (2016).

Wang, C. et al. Monolayer atomic crystal molecular superlattices. Nature 555, 231–236 (2018).

Zheng, J. et al. High yield exfoliation of two-dimensional chalcogenides using sodium naphthalenide. Nat. Commun. 5, 2995 (2014).

O’Neill, A., Khan, U. & Coleman, J. N. Preparation of high concentration dispersions of exfoliated MoS2 with increased flake size. Chem. Mater. 24, 2414–2421 (2012).

Halim, U. et al. A rational design of cosolvent exfoliation of layered materials by directly probing liquid-solid interaction. Nat. Commun. 4, 2213 (2013).

Lee, C. et al. Anomalous lattice vibrations of single-and few-layer MoS2. ACS Nano 4, 2695–2700 (2010).

Parkin, W. M. et al. Raman shifts in electron-irradiated monolayer MoS2. ACS Nano 10, 4134–4142 (2016).

Zhao, M. et al. Large-scale chemical assembly of atomically thin transistors and circuits. Nat. Nanotechnol. 11, 954–959 (2016).

Lim, Y. R. et al. Wafer-scale, homogeneous MoS2 layers on plastic substrates for flexible visible-light photodetectors. Adv. Mater. 28, 5025–5030 (2016).

Lin, Z. et al. Cosolvent approach for solution-processable electronic thin films. ACS Nano 9, 4398–4405 (2015).

Sun, Y. & Rogers, J. A. Inorganic semiconductors for flexible electronics. Adv. Mater. 19, 1897–1916 (2007).

Park, S., Vosguerichian, M. & Bao, Z. A review of fabrication and applications of carbon nanotube film-based flexible electronics. Nanoscale 5, 1727–1752 (2013).

Amani, M. et al. Near-unity photoluminescence quantum yield in MoS2. Science 350, 1065–1068 (2015).

Yu, X., Prévot, M. S. & Sivula, K. Multiflake thin film electronic devices of solution processed 2D MoS2 enabled by sonopolymer assisted exfoliation and surface modification. Chem. Mater. 26, 5892–5899 (2014).

Li, J., Naiini, M. M., Vaziri, S., Lemme, M. C. & Östling, M. Inkjet printing of MoS2. Adv. Funct. Mater. 24, 6524–6531 (2014).

Kim, T.-Y. et al. Electrical properties of synthesized large-area MoS2 field-effect transistors fabricated with inkjet-printed contacts. ACS Nano 10, 2819–2826 (2016).

Tao, L. et al. Centimeter-scale CVD growth of highly crystalline single-layer MoS2 film with spatial homogeneity and the visualization of grain boundaries. ACS Appl. Mater. Interfaces 9, 12073–12081 (2017).

Gurarslan, A. et al. Surface-energy-assisted perfect transfer of centimeter-scale monolayer and few-layer MoS2 films onto arbitrary substrates. ACS Nano 8, 11522–11528 (2014).

Jeon, J. et al. Layer-controlled CVD growth of large-area two-dimensional MoS2 films. Nanoscale 7, 1688–1695 (2015).

Song, X. et al. A novel synthesis method for large-area MoS2 film with improved electrical contact. 2D Mater. 4, 025051 (2017).

Lee, Y. et al. Trap-induced photoresponse of solution-synthesized MoS2. Nanoscale 8, 9193–9200 (2016).

George, A. S. et al. Wafer scale synthesis and high resolution structural characterization of atomically thin MoS2 layers. Adv. Funct. Mater. 24, 7461–7466 (2014).

Liu, K.-K. et al. Growth of large-area and highly crystalline MoS2 thin layers on insulating substrates. Nano Lett. 12, 1538–1544 (2012).

Schmidt, H. et al. Transport properties of monolayer MoS2 grown by chemical vapor deposition. Nano Lett. 14, 1909–1913 (2014).

Zheng, J. et al. High-mobility multilayered MoS2 flakes with low contact resistance grown by chemical vapor deposition. Adv. Mater. 29, 1604540 (2017).

Acknowledgements

Xiangfeng Duan acknowledges support from the US Department of Energy, Office of Basic Energy Sciences, Division of Materials Science and Engineering through award DE-SC0018828. (material synthesis and structural characterizations). Y.H. acknowledges financial support from National Science Foundation grant EFRI-1433541 (thin film device fabrication and characterizations). We acknowledge the Electron Imaging Center at UCLA for TEM technical support and the Nanoelectronics Research Facility at UCLA for device fabrication technical support.

Reviewer information

Nature thanks K. Xiao and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Author information

Authors and Affiliations

Contributions

Xiangfeng Duan designed the research. Z.L. developed the intercalation–exfoliation approach, fabricated the electronic devices and analysed the results. Z.L., U.H. and Yuanyue Liu solved the structure of the intercalated crystal. Yuan Liu, M.D., Y.W., C.J., P.C. and Xidong Duan assisted with the fabrication of the electronic device, the measurements and the analysis of the results. Z.L., Y.W. and Chen Wang collected the Raman and photoluminescence spectra. Z.L., F.S., M.L. and Chengzhang Wan performed the electron microscopy analyses on the exfoliated materials. Xiangfeng Duan and Y.H. supervised the research. Xiangfeng Duan and Z.L. co-wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

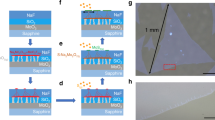

Extended Data Fig. 1 Molecular intercalation and exfoliation of MoS2 nanosheets.

a, Schematic of the electrochemical intercalation of MoS2 with THAB. b, Schematic of the intercalation and exfoliation of the MoS2 crystal to produce 2D-nanosheet ink, which can be processed further into continuous large-area thin films with broad-area plane-to-plane contacts between stacked nanosheets. c, Photographs of a thin piece of MoS2 crystal before (left) and after (right) THAB intercalation. The MoS2 crystal expands by a factor of about 20 along the (001) direction. Scale bars, 5 mm. d, Schematic of the interlayer spacing expansion from the original 6.1 Å to 22.9 Å, caused by the intercalation of THAB molecules.

Extended Data Fig. 2 XRD patterns of MoS2 crystals intercalated with various ammonium molecules.

a, XRD patterns of the THAB-intercalated (inter-MoS2) and pure MoS2. The MoS2 interlayer spacing expands from the original 6.1 Å to 22.9 Å after the electrochemical intercalation of THAB. The peaks indicated with asterisks are for the intercalated MoS2; the rest are from MoS2 itself. For XRD, the MoS2 crystal was allowed to be intercalated for a short period (about 1 min) to capture the intermediate state where the intercalation occurs but the expansion is not sufficient to cause severe shape deformation. b, XRD patterns for MoS2 crystals intercalated with various ammonium molecules. C2, C3, C4, and C10 represent tetraethylammonium bromide ((C2H5)4NBr; TEAB), tetrapropylammonium bromide ((C3H7)4NBr; TPAB), tetrabutylammonium bromide ((C4H9)4NBr; TBAB) and tetradecylammonium bromide ((C10H21)4NBr; TDAB), respectively. With the increasing molecule size (from C2 to C3, C4 and C10), the interlayer distance expansion is more substantial, ranging from 10.9 Å to 14.3 Å, 18.5 Å and 24.2 Å.

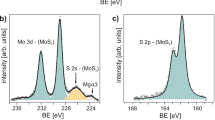

Extended Data Fig. 3 Elemental and electrical analyses on exfoliated MoS2 nanosheets.

a–c, XPS spectra for the as-deposited (black), TFSI-treated (red), and TFSI-treated and annealed (blue) MoS2 film, including the Mo 3d scan (a), S 2p scan (b) and N 1s scan (c). All three MoS2 films have the same 2H crystal structure. The absence of any N signal after TFSI treatment and thermal annealing indicates the complete removal of ammonium molecules and PVP. a.u., arbitrary units. d, SEM image of a single-nanosheet device fabricated on a 300-nm-thick SiO2/Si substrate. Electrodes are false-coloured. Scale bar, 1 μm. e, Isd–Vg transfer characteristics of the device with Vsd = 1 V. f, EDS spectrum of the intercalated THAB–exfoliated MoS2 superlattice. It shows the co-existence of Mo and S from MoS2 and that of N and Br from THAB. The atomic ratio N/Br is approximately 2% of Mo/S. During the reaction, Br2 was produced at the anode, as indicated by the emergence of the dark yellow Br2 solution. However, after the electrochemical potential was withdrawn, the highly active Br2 quickly back-reacted with the THA+–MoS2− layers to form the final MoS2–THAB superlattice structure. Consequently, N and Br elements were both detected in the THAB–exfoliated MoS2 structure.

Extended Data Fig. 4 Characterizations of MoS2 films fabricated on a substrate.

a, Photograph of the photolithographically patterned MoS2 thin film on a standard 100-mm-diameter SiO2/Si wafer. b, c, SEM image of the transistor fabricated with photolithography (b) and AFM analysis (c). Scale bars, 10 μm (b) and 2 μm (c). d, e, Cross-sectional TEM images of plane-to-plane contacts between MoS2 nanosheets; d and e show two different regions of the thin film. The red dashed boxes indicate the regions where two nanosheets exhibit a contact that is nearly indistinguishable from a van der Waals interface between atomic layers of MoS2. Scale bars, 5 nm.

Extended Data Fig. 5 Output characteristics of 50 independently measured transistors.

Vg ranges from −10 V (black) to 40 V (dark blue) in steps of 10 V.

Extended Data Fig. 6 Transfer characteristics of 50 independently measured transistors.

a, b, Isd on linear (a) and logarithmic (b) scales. Vsd = 1 V.

Extended Data Fig. 7 Isd–Vg transfer characteristics of MoS2 films annealed at various temperatures.

a, Annealed at 200 °C. b, Annealed at 400 °C. Both devices were fabricated on a 90-nm-thick SiO2/Si substrate, with Vsd = 1 V. The threshold voltage shifts to more positive values when the film is annealed at a higher temperature, suggesting a reduced carrier concentration owing to the removal of impurity doping at the higher temperature.

Extended Data Fig. 8 Constructing logic gates and computational circuits using MoS2 thin-film transistors with a local back gate.

a, Schematic of the MoS2 transistor with a local back gate (Ti/Au, 10 nm/40 nm) buried under a 30-nm-thick Al2O3 dielectric layer. b, Optical image of an individual transistor. The gate electrode was fabricated after etching the underlying Al2O3 layer. Scale bar, 20 μm. c, Isd–Vg transfer characteristics of the transistor constructed on the buried gate with a 30-nm-thick Al2O3 dielectric layer andVsd = 1 V. The device was annealed at 400 °C for 1 h. d–h, Schematics of the logic inverter (d) and the NAND (e), NOR (f), AND (g) and XOR (h) gates. GND, ground.

Extended Data Fig. 9 Exfoliation of various 2D crystals.

a–l, AFM (a–f) and TEM (g–l) images of exfoliated nanosheets of WSe2 (a, g), Bi2Se3 (b, h), NbSe2 (c, i), In2Se3 (d, j), Sb2Te3 (e, k) and black phosphorus (BP; f, l). Insets are photographs of the corresponding ink solutions. Scale bars, 1 μm (a, c, f), 500 nm (b, d, e, g, i, l) and 200 nm (h, j, k).

Rights and permissions

About this article

Cite this article

Lin, Z., Liu, Y., Halim, U. et al. Solution-processable 2D semiconductors for high-performance large-area electronics. Nature 562, 254–258 (2018). https://doi.org/10.1038/s41586-018-0574-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-018-0574-4

Keywords

This article is cited by

-

Homojunction-loaded inverters based on self-biased molybdenum disulfide transistors for sub-picowatt computing

Nature Electronics (2024)

-

Material and structural considerations for high-performance electrodes for wearable skin devices

Communications Materials (2024)

-

Quantitative analysis of printed nanostructured networks using high-resolution 3D FIB-SEM nanotomography

Nature Communications (2024)

-

Broadband nonlinear modulation of incoherent light using a transparent optoelectronic neuron array

Nature Communications (2024)

-

Metal telluride nanosheets by scalable solid lithiation and exfoliation

Nature (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.