Abstract

Transitioning from fossil fuels to renewable energy sources is a critical global challenge; it demands advances — at the materials, devices and systems levels — for the efficient harvesting, storage, conversion and management of renewable energy. Energy researchers have begun to incorporate machine learning (ML) techniques to accelerate these advances. In this Perspective, we highlight recent advances in ML-driven energy research, outline current and future challenges, and describe what is required to make the best use of ML techniques. We introduce a set of key performance indicators with which to compare the benefits of different ML-accelerated workflows for energy research. We discuss and evaluate the latest advances in applying ML to the development of energy harvesting (photovoltaics), storage (batteries), conversion (electrocatalysis) and management (smart grids). Finally, we offer an overview of potential research areas in the energy field that stand to benefit further from the application of ML.

Similar content being viewed by others

Introduction

The combustion of fossil fuels, used to fulfill approximately 80% of the world’s energy needs, is the largest single source of rising greenhouse gas emissions and global temperature1. The increased use of renewable sources of energy, notably solar and wind power, is an economically viable path towards meeting the climate goals of the Paris Agreement2. However, the rate at which renewable energy has grown has been outpaced by ever-growing energy demand, and as a result the fraction of total energy produced by renewable sources has remained constant since 2000 (ref.3). It is thus essential to accelerate the transition towards sustainable sources of energy4. Achieving this transition requires energy technologies, infrastructure and policies that enable and promote the harvest, storage, conversion and management of renewable energy.

In sustainable energy research, suitable material candidates (such as photovoltaic materials) must first be chosen from the combinatorial space of possible materials, then synthesized at a high enough yield and quality for use in devices (such as solar panels). The time frame of a representative materials discovery process is 15–20 years5,6, leaving considerable room for improvement. Furthermore, the devices have to be optimized for robustness and reproducibility to be incorporated into energy systems (such as in solar farms)7, where management of energy usage and generation patterns is needed to further guarantee commercial success.

Here we explore the extent to which machine learning (ML) techniques can help to address many of these challenges8,9,10. ML models can be used to predict specific properties of new materials without the need for costly characterization; they can generate new material structures with desired properties; they can understand patterns in renewable energy usage and generation; and they can help to inform energy policy by optimizing energy management at both device and grid levels.

In this Perspective, we introduce Acc(X)eleration Performance Indicators (XPIs), which can be used to measure the effectiveness of platforms developed for accelerated energy materials discovery. Next, we discuss closed-loop ML frameworks and evaluate the latest advances in applying ML to the development of energy harvesting, storage and conversion technologies, as well as the integration of ML into a smart power grid. Finally, we offer an overview of energy research areas that stand to benefit further from ML.

Performance indicators

Because many reports discuss ML-accelerated approaches for materials discovery and energy systems management, we posit that there should be a consistent baseline from which these reports can be compared. For energy systems management, performance indicators at the device, plant and grid levels have been reported11,12, yet there are no equivalent counterparts for accelerated materials discovery.

The primary goal in materials discovery is to develop efficient materials that are ready for commercialization. The commercialization of a new material requires intensive research efforts that can span up to two decades: the goal of every accelerated approach should be to accomplish commercialization an order-of-magnitude faster. The materials science field can benefit from studying the case of vaccine development. Historically, new vaccines take 10 years from conception to market13. However, after the start of the COVID-19 pandemic, several companies were able to develop and begin releasing vaccines in less than a year. This achievement was in part due to an unprecedented global research intensity, but also to a shift in the technology: after a technological breakthrough in 2008, the cost of sequencing DNA began decreasing exponentially14,15, enabling researchers to screen orders-of-magnitude more vaccines than was previously possible.

ML for energy technologies has much in common with ML for other fields like biomedicine, sharing the same methodology and principles. However, in practice, ML models for different technologies are exposed to additional unique requirements. For example, ML models for medical applications usually have complex structures that take into account regulatory oversight and ensure the safe development, use and monitoring of systems, which usually does not happen in the energy field16. Moreover, data availability varies substantially from field to field; biomedical researchers can work with a relatively large amount of data that energy researchers usually lack. This limited data accessibility can constrain the usage of sophisticated ML models (such as deep learning models) in the energy field. However, adaptation has been quick in all energy subfields, with a rapidly increased number of groups recognizing the importance of statistical methods and starting to use them for various problems. We posit that the use of high-throughput experimentation and ML in materials discovery workflows can result in breakthroughs in accelerating development, but the field first needs a set of metrics with which ML models can be evaluated and compared.

Accelerated materials discovery methods should be judged based on the time it takes for a new material to be commercialized. We recognize that this is not a useful metric for new platforms, nor is it one that can be used to decide quickly which platform is best suited for a particular scenario. We therefore propose here XPIs that new materials discovery platforms should report.

Acceleration factor of new materials, XPI-1

This XPI is evaluated by dividing the number of new materials that are synthesized and characterized per unit time with the accelerated platform by the number of materials that are synthesized and characterized with traditional methods. For example, an acceleration factor of ten means that for a given time period, the accelerated platform can evaluate ten times more materials than a traditional platform. For materials with multiple target properties, researchers should report the rate-limiting acceleration factor.

Number of new materials with threshold performance, XPI-2

This XPI tracks the number of new materials discovered with an accelerated platform that have a performance greater than the baseline value. The selection of this baseline value is critical: it should be something that fairly captures the standard to which new materials need to be compared. As an example, an accelerated platform that seeks to discover new perovskite solar cell materials should track the number of devices made with new materials that have a better performance than the best existing solar cell17.

Performance of best material over time, XPI-3

This XPI tracks the absolute performance — whether it is Faradaic efficiency, power conversion efficiency or other — of the best material as a function of time. For the accelerated framework, the evolution of the performance should increase faster than the performance obtained by traditional methods18.

Repeatability and reproducibility of new materials, XPI-4

This XPI seeks to ensure that the new materials discovered are consistent and repeatable: this is a key consideration to screen out materials that would fail at the commercialization stage. The performance of a new material should not vary by more than x% of its mean value (where x is the standard error): if it does, this material should not be included in either XPI-2 (number of new materials with threshold performance) or XPI-3 (performance of best material over time).

Human cost of the accelerated platform, XPI-5

This XPI reports the total costs of the accelerated platform. This should include the total number of researcher hours needed to design and order the components for the accelerated system, develop the programming and robotic infrastructure, develop and maintain databases used in the system and maintain and run the accelerated platform. This metric would provide researchers with a realistic estimate of the resources required to adapt an accelerated platform for their own research.

Use of the XPIs

Each of these XPIs can be measured for computational, experimental or integrated accelerated systems. Consistently reporting each of these XPIs as new accelerated platforms are developed will allow researchers to evaluate the growth of these platforms and will provide a consistent metric by which different platforms can be compared. As a demonstration, we applied the XPIs to evaluate the acceleration performance of several typical platforms: Edisonian-like trial-test, robotic photocatalysis development19 and design of a DNA-encoded-library-based kinase inhibitor20 (Table 1). To obtain a comprehensive performance estimate, we define one overall acceleration score S adhering to the following rules. The dependent acceleration factors (XPI-1 and XPI-2), which function in a synergetic way, are added together to reflect their contribution as a whole. The independent acceleration factors (XPI-3, XPI-4 and XPI-5), which may function in a reduplicated way, are multiplied together to value their contributions respectively. As a result, the overall acceleration score can be calculated as S = (XPI-1 + XPI-2) × XPI-3 × XPI-4 ÷ XPI-5. As the reference, the Edisonian-like approach has a calculated overall XPIs score of around 1, whereas the most advanced method, the DNA-encoded-library-based drug design, exhibits an overall XPIs score of 107. For the sustainability field, the robotic photocatalysis platform has an overall XPIs score of 105.

For energy systems, the most frequently reported XPI is the acceleration factor, in part because it is deterministic, but also because it is easy to calculate at the end of the development of a workflow. In most cases, we expect that authors report the acceleration factor only after completing the development of the platform. Reporting the other suggested XPIs will provide researchers with a better sense of both the time and human resources required to develop the platform until it is ready for publication. Moving forward, we hope that other researchers adopt the XPIs — or other similar metrics — to allow for fair and consistent comparison between the different methods and algorithms that are used to accelerate materials discovery.

Closed-loop ML for materials discovery

The traditional approach to materials discovery is often Edisonian-like, relying on trial and error to develop materials with specific properties. First, a target application is identified, and a starting pool of possible candidates is selected (Fig. 1a). The materials are then synthesized and incorporated into a device or system to measure their properties. These results are then used to establish empirical structure–property relationships, which guide the next round of synthesis and testing. This slow process goes through as many iterations as required and each cycle can take several years to complete.

a | Traditional Edisonian-like approach, which involves experimental trial and error. b | High-throughput screening approach involving a combination of theory and experiment. c | Machine learning (ML)-driven approach whereby theoretical and experimental results are used to train a ML model for predicting structure–property relationships. d | ML-driven approach for property-directed and automatic exploration of the chemical space using optimization ML (such as genetic algorithms or generative models) that solve the ‘inverse’ design problem.

A computation-driven, high-throughput screening strategy (Fig. 1b) offers a faster turnaround. To explore the overall vast chemical space (~1060 possibilities), human intuition and expertise can be used to create a library with a substantial number of materials of interest (~104). Theoretical calculations are carried out on these candidates and the top performers (~102 candidates) are then experimentally verified. With luck, the material with the desired functionality is ‘discovered’. Otherwise, this process is repeated in another region of the chemical space. This approach can still be very time-consuming and computationally expensive and can only sample a small region of the chemical space.

ML can substantially increase the chemical space sampled, without costing extra time and effort. ML is data-driven, screening datasets to detect patterns, which are the physical laws that govern the system. In this case, these laws correspond to materials structure–property relationships. This workflow involves high-throughput virtual screening (Fig. 1c) and begins by selecting a larger region (~106) of the chemical space of possibilities using human intuition and expertise. Theoretical calculations are carried out on a representative subset (~104 candidates) and the results are used for training a discriminative ML model. The model can then be used to make predictions on the other candidates in the overall selected chemical space9. The top ~102 candidates are experimentally verified, and the results are used to improve the predictive capabilities of the model in an iterative loop. If the desired material is not ‘discovered’, the process is repeated on another region of the chemical space.

An improvement on the previous approaches is a framework that requires limited human intuition or expertise to direct the chemical space search: the automated virtual screening approach (Fig. 1d). To begin with, a region of the chemical space is picked at random to initiate the process. Thereafter, this process is similar to the previous approach, except that the computational and experimental data is also used to train a generative learning model. This generative model solves the ‘inverse’ problem: given a required property, the goal is to predict an ideal structure and composition in the chemical space. This enables a directed, automated search of the chemical space, towards the goal of ‘discovering’ the ideal material8.

ML for energy

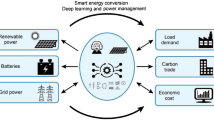

ML has so far been used to accelerate the development of materials and devices for energy harvesting (photovoltaics), storage (batteries) and conversion (electrocatalysis), as well as to optimize power grids. Besides all the examples discussed here, we summarize the essential concepts in ML (Box 1), the grand challenges in sustainable materials research (Box 2) and the details of key studies (Table 2).

Photovoltaics

ML is accelerating the discovery of new optoelectronic materials and devices for photovoltaics, but major challenges are still associated with each step.

Photovoltaics materials discovery

One materials class for which ML has proved particularly effective is perovskites, because these materials have a vast chemical space from which the constituents may be chosen. Early representations of perovskite materials for ML were atomic-feature representations, in which each structure is encoded as a fixed-length vector comprised of an average of certain atomic properties of the atoms in the crystal structure21,22. A similar technique was used to predict new lead-free perovskite materials with the proper bandgap for solar cells23 (Fig. 2a). These representations allowed for high accuracy but did not account for any spatial relation between atoms24,25. Materials systems can also be represented as images26 or as graphs27, enabling the treatment of systems with diverse number of atoms. The latter representation is particularly compelling, as perovskites, particularly organic–inorganic perovskites, have crystal structures that incorporate a varying number of atoms, and the organic molecules can vary in size.

Although bandgap prediction is an important first step, this parameter alone is not sufficient to indicate a useful optoelectronic material; other parameters, including electronic defect density and stability, are equally important. Defect energies are addressable with computational methods, but the calculation of defects in structures is extremely computationally expensive, which inhibits the generation of a dataset of defect energies from which an ML model can be trained. To expedite the high-throughput calculation of defect energies, a Python toolkit has been developed28 that will be pivotal in building a database of defect energies in semiconductors. Researchers can then use ML to predict both the formation energy of defects and the energy levels of these defects. This knowledge will ensure that the materials selected from high-throughput screening will not only have the correct bandgap but will also either be defect-tolerant or defect-resistant, finding use in commercial optoelectronic devices.

Even without access to a large dataset of experimental results, ML can accelerate the discovery of optoelectronic materials. Using a self-driving laboratory approach, the number of experiments required to optimize an organic solar cell can be reduced from 500 to just 60 (ref.29). This robotic synthesis method accelerates the learning rate of the ML models and drastically reduces the cost of the chemicals needed to run the optimization.

Solar device structure and fabrication

Photovoltaic devices require optimization of layers other than the active layer to maximize performance. One component is the top transparent conductive layer, which needs to have both high optical transparency and high electronic conductivity30,31. A genetic algorithm that optimized the topology of a light-trapping structure enabled a broadband absorption efficiency of 48.1%, which represents a more than threefold increase over the Yablonovitch limit, the 4n2 factor (where n is the refractive index of the material) theoretical limit for light trapping in photovoltaics32.

A universal standard irradiance spectrum is usually used by researchers to determine optimal bandgaps for solar cell operation33. However, actual solar irradiance fluctuates based on factors such as the position of the Sun, atmospheric phenomena and the season. ML can reduce yearly spectral sets into a few characteristic spectra33, allowing for the calculation of optimal bandgaps for real-world conditions.

To optimize device fabrication, a CNN was used to predict the current–voltage characteristics of as-cut Si wafers based on their photoluminescence images34. Additionally, an artificial neural network was used to predict the contact resistance of metallic front contacts for Si solar cells, which is critical for the manufacturing process35.

Although successful, these studies appear to be limited to optimizing structures and processes that are already well established. We suggest that, in future work, ML could be used to augment simulations, such as the multiphysics models for solar cells. Design of device architecture could begin from such simulation models, coupled with ML in an iterative process to quickly optimize design and reduce computational time and cost. In addition, optimal conditions for the scaling-up of device area and fabrication processes are likely to be very different from those for laboratory-scale demonstrations. However, determining these optimal conditions could be expensive in terms of materials cost and time, owing to the need to construct much larger devices. In this regard, ML, together with the strategic design of experiments, could greatly accelerate the optimization of process conditions (such as the annealing temperatures and solvent choice).

Electrochemical energy storage

Electrochemical energy storage is an essential component in applications such as electric vehicles, consumer electronics and stationary power stations. State-of-the-art electrochemical energy storage solutions have varying efficacy in different applications: for example, lithium-ion batteries exhibit excellent energy density and are widely used in electronics and electric vehicles, whereas redox flow batteries have drawn substantial attention for use in stationary power storage. ML approaches have been widely employed in the field of batteries, including for the discovery of new materials such as solid-state ion conductors36,37,38 (Fig. 2b) and redox active electrolytes for redox flow batteries39. ML has also aided battery management, for example, through state-of-charge determination40, state-of-health evaluation41,42 and remaining-life prediction43,44.

Electrode and electrolyte materials design

Layered oxide materials, such as LiCoO2 or LiNixMnyCo1-x-yO2, have been used extensively as cathode materials for alkali metal-ion (Li/Na/K) batteries. However, developing new Li-ion battery materials with higher operating voltages, enhanced energy densities and longer lifetimes is of paramount interest. So far, universal design principles for new battery materials remain undefined, and hence different approaches have been explored. Data from the Materials Project have been used to model the electrode voltage profile diagrams for different materials in alkali metal-ion batteries (Na and K)45, leading to the proposition of 5,000 different electrode materials with appropriate moderate voltages. ML was also employed to screen 12,000 candidates for solid Li-ion batteries, resulting in the discovery of ten new Li-ion conducting materials46,47.

Flow batteries consist of active materials dissolved in electrolytes that flow into a cell with electrodes that facilitate redox reactions. Organic flow batteries are of particular interest. In flow batteries, the solubility of the active material in the electrolyte and the charge/discharge stability dictate performance. ML methods have explored the chemical space to find suitable electrolytes for organic redox flow batteries48,49. Furthermore, a multi-kernel-ridge regression method accelerated the discovery of active organic molecules using multiple feature training48. This method also helped in predicting the solubility dependence of anthraquinone molecules with different numbers and combinations of sulfonic and hydroxyl groups on pH. Future opportunities lie in the exploration of large combinatorial spaces for the inverse design of high-entropy electrodes50 and high-voltage electrolytes51. To this end, deep generative models can assist the discovery of new materials based on the simplified molecular input line entry system (SMILES) representation of molecules52.

Battery device and stack management

A combination of mechanistic and semi-empirical models is currently used to estimate capacity and power loss in lithium-ion batteries. However, the models are applicable only to specific failure mechanisms or situations and cannot predict the lifetimes of batteries at the early stages of usage. By contrast, mechanism-agnostic models based on ML can accurately predict battery cycle life, even at an early stage of a battery’s life43. A combined early-prediction and Bayesian optimization model has been used to rapidly identify the optimal charging protocol with the longest cycle life44. ML can be used to accelerate the optimization of lithium-ion batteries for longer lifetimes53, but it remains to be seen whether these models can be generalized to different battery chemistries54.

ML methods can also predict important properties of battery storage facilities. A neural network was used to predict the charge/discharge profiles in two types of stationary battery systems, lithium iron phosphate and vanadium redox flow batteries55. Battery power management techniques must also consider the uncertainty and variability that arise from both the environment and the application. An iterative Q-learning (reinforcement learning) method was also designed for battery management and control in smart residential environments56. Given the residential load and the real-time electricity rate, the method is effective at optimizing battery charging/discharging/idle cycles. Discriminative neural network-based models can also optimize battery usage in electric vehicles57.

Although ML is able to predict the lifetime of batteries, the underlying degradation mechanisms are difficult to identify and correlate to the state of health and lifetime. To this end, incorporation of domain knowledge into a hybrid physics-based ML model can provide insight and reduce overfitting53. However, incorporating the physics of battery degradation processes into a hybrid model remains challenging; representation of electrode materials that encode both compositional and structural information is far from trivial. Validation of these models also requires the development of operando characterization techniques, such as liquid-phase transmission electron microscopy and ambient-pressure X-ray absorption spectroscopy (XAS), that reflect true operating conditions as closely as possible54. Ideally, these characterization techniques should be carried out in a high-throughput manner, using automated sample changers, for example, in order to generate large datasets for ML.

Electrocatalysts

Electrocatalysis enables the conversion of simple feedstocks (such as water, carbon dioxide and nitrogen) into valuable chemicals and/or fuels (such as hydrogen, hydrocarbons and ammonia), using renewable energy as an input58. The reverse reactions are also possible in a fuel cell, and hydrogen can be consumed to produce electricity59. Active and selective electrocatalysts must be developed to improve the efficiency of these reactions60,61. ML has been used to accelerate electrocatalyst development and device optimization.

Electrocatalyst materials discovery

The most common descriptor of catalytic activity is the adsorption energy of intermediates on a catalyst61,62. Although these adsorption energies can be calculated using density functional theory (DFT), catalysts possess multiple surface binding sites, each with different adsorption energies63. The number of possible sites increases dramatically if alloys are considered, and thus becomes intractable with conventional means64.

DFT calculations are critical for the search of electrocatalytic materials65 and efforts have been made to accelerate the calculations and to reduce their computational cost by using surrogate ML models66,67,68,69. Complex reaction mechanisms involving hundreds of possible species and intermediates can also be simplified using ML, with a surrogate model predicting the most important reaction steps and deducing the most likely reaction pathways70. ML can also be used to screen for active sites across a random, disordered nanoparticle surface71,72. DFT calculations are performed on only a few representative sites, which are then used to train a neural network to predict the adsorption energies of all active sites.

Catalyst development can benefit from high-throughput systems for catalyst synthesis and performance evaluation73,74. An automatic ML-driven framework was developed to screen a large intermetallic chemical space for CO2 reduction and H2 evolution75. The model predicted the adsorption energy of new intermetallic systems and DFT was automatically performed on the most promising candidates to verify the predictions. This process went on iteratively in a closed feedback loop. 131 intermetallic surfaces across 54 alloys were ultimately identified as promising candidates for CO2 reduction. Experimental validation76 with Cu–Al catalysts yielded an unprecedented Faradaic efficiency of 80% towards ethylene at a high current density of 400 mA cm–2 (Fig. 2c).

Because of the large number of properties that electrocatalysts may possess (such as shape, size and composition), it is difficult to do data mining on the literature77. Electrocatalyst structures are complex and difficult to characterize completely; as a result, many properties may not be fully characterized by research groups in their publications. To avoid situations in which potentially promising compositions perform poorly as a result of non-ideal synthesis or testing conditions, other factors (such as current density, particle size and pH value) that affect the electrocatalyst performance must be kept consistent. New approaches such as carbothermal shock synthesis78,79 may be a promising avenue, owing to its propensity to generate uniformly sized and shaped alloy nanoparticles, regardless of composition.

XAS is a powerful technique, especially for in situ measurements, and has been widely employed to gain crucial insight into the nature of active sites and changes in the electrocatalyst over time80. Because the data analysis relies heavily on human experience and expertise, there has been interest in developing ML tools for interpreting XAS data81. Improved random forest models can predict the Bader charge (a good approximation of the total electronic charge of an atom) and nearest-neighbour distances, crucial factors that influence the catalytic properties of the material82. The extended X-ray absorption fine structure (EXAFS) region of XAS spectra is known to contain information on bonding environments and coordination numbers. Neural networks can be used to automatically interpret EXAFS data83, permitting the identification of the structure of bimetallic nanoparticles using experimental XAS data, for example84. Raman and infrared spectroscopy are also important tools for the mechanistic understanding of electrocatalysis. Together with explainable artificial intelligence (AI), which can relate the results to underlying physics, these analyses could be used to discover descriptors hidden in spectra that could lead to new breakthroughs in electrocatalyst discovery and optimization.

Fuel cell and electrolyser device management

A fuel cell is an electrochemical device that can be used to convert the chemical energy of a fuel (such as hydrogen) into electrical energy. An electrolyser transforms electrical energy into chemical energy (such as in water splitting to generate hydrogen). ML has been used to optimize and manage their performance, predict degradation and device lifetime as well as detect and diagnose faults. Using a hybrid method consisting of an extreme learning machine, genetic algorithms and wavelet analysis, the degradation in proton-exchange membrane fuel cells has been predicted85,86. Electrochemical impedance measurements used as input for an artificial neural network have enabled fault detection and isolation in a high-temperature stack of proton-exchange membrane fuel cells87,88.

ML approaches can also be employed to diagnose faults, such as fuel and air leakage issues, in solid oxide fuel cell stacks. Artificial neural networks can predict the performance of solid oxide fuel cells under different operating conditions89. In addition, ML has been applied to optimize the performance of solid oxide electrolysers, for CO2/H2O reduction90, and chloralkali electrolysers91.

In the future, the use of ML for fuel cells could be combined with multiscale modelling to improve their design, for example to minimize Ohmic losses and optimize catalyst loading. For practical applications, fuel cells may be subject to fluctuations in energy output requirements (for example, when used in vehicles). ML models could be used to determine the effects of such fluctuations on the long-term durability and performance of fuel cells, similar to what has been done for predicting the state of health and lifetime for batteries. Furthermore, it remains to be seen whether the ML techniques for fuel cells can be easily generalized to electrolysers and vice versa, using transfer learning for example, given that they are essentially reactions in reverse.

Smart power grids

A power grid is responsible for delivering electrical energy from producers (such as power plants and solar farms) to consumers (such as homes and offices). However, energy fluctuations from intermittent renewable energy generators can render the grid vulnerable92. ML algorithms can be used to optimize the automatic generation control of power grids, which controls the power output of multiple generators in an energy system. For example, when a relaxed deep learning model was used as a unified timescale controller for the automatic generation control unit, the total operational cost was reduced by up to 80% compared with traditional heuristic control strategies93 (Fig. 2d). A smart generation control strategy based on multi-agent reinforcement learning was found to improve the control performance by around 10% compared with other ML algorithms94.

Accurate demand and load prediction can support decision-making operations in energy systems for proper load scheduling and power allocation. Multiple ML methods have been proposed to precisely predict the demand load: for example, long short-term memory was used to successfully and accurately predict hourly building load95. Short-term load forecasting of diverse customers (such as retail businesses) using a deep neural network and cross-building energy demand forecasting using a deep belief network have also been demonstrated effectively96,97.

Demand-side management consists of a set of mechanisms that shape consumer electricity consumption by dynamically adjusting the price of electricity. These include reducing (peak shaving), increasing (load growth) and rescheduling (load shifting) the energy demand, which allows for flexible balancing of renewable electricity generation and load98. A reinforcement-learning-based algorithm resulted in substantial cost reduction for both the service provider and customer99. A decentralized learning-based residential demand scheduling technique successfully shifted up to 35% of the energy demand to periods of high wind availability, substantially saving power costs compared with the unscheduled energy demand scenario100. Load forecasting using a multi-agent approach integrates load prediction with reinforcement learning algorithms to shift energy usage (for example, to different electrical devices in a household) for its optimization101. This approach reduced peak usage by more than 30% and increased off-peak usage by 50%, reducing the cost and energy losses associated with energy storage.

Opportunities for ML in renewable energy

ML provides the opportunity to enable substantial further advances in different areas of the energy materials field, which share similar materials-related challenges (Fig. 3). There are also grand challenges for ML application in smart grid and policy optimization.

a | Energy materials present additional modelling challenges. Machine learning (ML) could help in the representation of structurally complex structures, which can include disordering, dislocations and amorphous phases. b | Flexible models that scale efficiently with varied dataset sizes are in demand, and ML could help to develop robust predictive models. The yellow dots stand for the addition of unreliable datasets that could harm the prediction accuracy of the ML model. c | Synthesis route prediction remains to be solved for the design of a novel material. In the ternary phase diagram, the dots stand for the stable compounds in that corresponding phase space and the red dot for the targeted compound. Two possible synthesis pathways are compared for a single compound. The score obtained would reflect the complexity, cost and so on of one synthesis pathway. d | ML-aided phase degradation prediction could boost the development of materials with enhanced cyclability. The shaded region represents the rocksalt phase, which grows inside the layered phase. The arrow marks the growth direction. e | The use of ML models could help in optimizing energy generation and energy consumption. Automating the decision-making processes associated with dynamic power supplies using ML will make the power distribution more efficient. f | Energy policy is the manner in which an entity (for example, a government) addresses its energy issues, including conversion, distribution and utilization, where ML could be used to optimize the corresponding economy.

Materials with novel geometries

A ML representation is effective when it captures the inherent properties of the system (such as its physical symmetries) and can be utilized in downstream ancillary tasks, such as transfer learning to new predictive tasks, building new knowledge using visualization or attribution and generating similar data distributions with generative models102.

For materials, the inputs are molecules or crystal structures whose physical properties are modelled by the Schrödinger equation. Designing a general representation of materials that reflects these properties is an ongoing research problem. For molecular systems, several representations have been used successfully, including fingerprints103, SMILES104, self-referencing embedded strings (SELFIES)105 and graphs106,107,108. Representing crystalline materials has the added complexity of needing to incorporate periodicity in the representation. Methods like the smooth overlap of atomic positions109, Voronoi tessellation110,111, diffraction images112, multi-perspective fingerprints113 and graph-based algorithms27,114 have been suggested, but typically lack the capability for structure reconstruction.

Complex structural systems found in energy materials present additional modelling challenges (Fig. 3a): a large number of atoms (such as in reticular frameworks or polymers), specific symmetries (such as in molecules with a particular space group and for reticular frameworks belonging to a certain topology), atomic disordering, partial occupancy, or amorphous phases (leading to an enormous combinatorial space), defects and dislocations (such as interfaces and grain boundaries) and low-dimensionality materials (as in nanoparticles). Reduction approximations alleviate the first issue (using, for example, RFcode for reticular framework representation)8, but the remaining several problems warrant intensive future research efforts.

Self-supervised learning, which seeks to lever large amounts of synthetic labels and tasks to continue learning without experimental labels115, multi-task learning116, in which multiple material properties can be modelled jointly to exploit correlation structure between properties, and meta-learning117, which looks at strategies that allow models to perform better in new datasets or in out-of-distribution data, all offer avenues to build better representations. On the modelling front, new advances in attention mechanisms118,119, graph neural networks120 and equivariant neural networks121 expand our range of tools with which to model interactions and expected symmetries.

Robust predictive models

Predictive models are the first step when building a pipeline that seeks materials with desired properties. A key component for building these models is training data; more data will often translate into better-performing models, which in turn will translate into better accuracy in the prediction of new materials. Deep learning models tend to scale more favourably with dataset size than traditional ML approaches (such as random forests). Dataset quality is also essential. However, experiments are usually conducted under diverse conditions with large variation in untracked variables (Fig. 3b). Additionally, public datasets are more likely to suffer from publication bias, because negative results are less likely to be published even though they are just as important as positive results when training statistical models122.

Addressing these issues require transparency and standardization of the experimental data reported in the literature. Text and natural language processing strategies could then be employed to extract data from the literature77. Data should be reported with the belief that it will eventually be consolidated in a database, such as the MatD3 database123. Autonomous laboratory techniques will help to address this issue19,124. Structured property databases such as the Materials Project122 and the Harvard Clean Energy Project125 can also provide a large amount of data. Additionally, different energy fields — energy storage, harvesting and conversion — should converge upon a standard and uniform way to report data. This standard should be continuously updated; as researchers continue to learn about the systems they are studying, conditions that were previously thought to be unimportant will become relevant.

New modelling approaches that work in low-data regimes, such as data-efficient models, dataset-building strategies (active sampling)126 and data-augmentation techniques, are also important127. Uncertainty quantification, data efficiency, interpretability and regularization are important considerations that improve the robustness of ML models. These considerations relate to the notion of generalizability: predictions should generalize to a new class of materials that is out of the distribution of the original dataset. Researchers can attempt to model how far away new data points are from the training set128 or the variability in predicted labels with uncertainty quantification129. Neural networks are a flexible model class, and often models can be underspecified130. Incorporating regularization, inductive biases or priors can boost the credibility of a model. Another way to create trustable models could be to enhance the interpretability of ML algorithms by deriving feature relevance and scoring their importance131. This strategy could help to identify potential chemically meaningful features and form a starting point for understanding latent factors that dominate material properties. These techniques can also identify the presence of model bias and overfitting, as well as improving generalization and performance132,133,134.

Stable and synthesizable new materials

The formation energy of a compound is used to estimate its stability and synthesizability135,136. Although negative values usually correspond to stable or synthesizable compounds, slightly positive formation energies below a limit lead to metastable phases with unclear synthesizability137,138. This is more apparent when investigating unexplored chemical spaces with undetermined equilibrium ground states; yet often the metastable phases exhibit superior properties, as seen in photovoltaics136,139 and ion conductors140, for example. It is thus of interest to develop a method to evaluate the synthesizability of metastable phases (Fig. 3c). Instead of estimating the probability that a particular phase can be synthesized, one can instead evaluate its synthetic complexity using ML. In organic chemistry, synthesis complexity is evaluated according to the accessibility of the phases’ synthesis route141 or precedent reaction knowledge142. Similar methodologies can be applied to the inorganic field with the ongoing design of automated synthesis-planning algorithms for inorganic materials143,144.

Synthesis and evaluation of a new material alone does not ensure that material will make it to market; material stability is a crucial property that takes a long time to evaluate. Degradation is a generally complex process that occurs through the loss of active matter or growth of inactive phases (such as the rocksalt phases formed in layered Li-ion battery electrodes145 (Fig. 3d) or the Pt particle agglomeration in fuel cells146) and/or propagation of defects (such as cracks in cycled battery electrode147). Microscopies such as electron microscopy148 and simulations such as continuum mechanics modelling149 are often used to investigate growth and propagation dynamics (that is, phase boundary and defect surface movements versus time). However, these techniques are usually expensive and do not allow rapid degradation prediction. Deep learning techniques such as convolutional neural networks and recurrent neural networks may be able to predict the phase boundary and/or defect pattern evolution under certain conditions after proper training150. Similar models can then be built to understand multiple degradation phenomena and aid the design of materials with improved cycle life.

Optimized smart power grids

A promising prospect of ML in smart grids is automating the decision-making processes that are associated with dynamic power supplies to distribute power most efficiently (Fig. 3e). Practical deployment of ML technologies into physical systems remains difficult because of data scarcity and the risk-averse mindset of policymakers. The collection of and access to large amounts of diverse data is challenging owing to high cost, long delays and concerns over compliance and security151. For instance, to capture the variation of renewable resources owing to peak or off-peak and seasonal attributes, long-term data collections are implemented for periods of 24 hours to several years152. Furthermore, although ML algorithms are ideally supposed to account for all uncertainties and unpredictable situations in energy systems, the risk-adverse mindset in the energy management industry means that implementation still relies on human decision-making153.

An ML-based framework that involves a digital twin of the physical system can address these problems154,155. The digital twin represents the digitalized cyber models of the physical system and can be constructed from physical laws and/or ML models trained using data sampled from the physical system. This approach aims to accurately simulate the dynamics of the physical system, enabling relatively fast generation of large amounts of high-quality synthetic data at low cost. Notably, because ML model training and validation is performed on the digital twin, there is no risk to the actual physical system. Based on the prediction results, suitable actions can be suggested and then implemented in the physical system to ensure stability and/or improve system operation.

Policy optimization

Finally, research is generally focused on one narrow aspect of a larger problem; we argue that energy research needs a more integrated approach156 (Fig. 3f). Energy policy is the manner in which an entity, such as the government, addresses its energy issues, including conversion, distribution and utilization. ML has been used in the fields of energy economics finance for performance diagnostics (such as for oil wells), energy generation (such as wind power) and consumption (such as power load) forecasts and system lifespan (such as battery cell life) and failure (such as grid outage) prediction157. They have also been used for energy policy analysis and evaluation (for example, for estimating energy savings). A natural extension of ML models is to use them for policy optimization158,159, a concept that has not yet seen widespread use. We posit that the best energy policies — including the deployment of the newly discovered materials — can be improved and augmented with ML and should be discussed in research reporting accelerated energy technology platforms.

Conclusions

To summarize, ML has the potential to enable breakthroughs in the development and deployment of sustainable energy techniques. There have been remarkable achievements in many areas of energy technology, from materials design and device management to system deployment. ML is particularly well suited to discovering new materials, and researchers in the field are expecting ML to bring up new materials that may revolutionize the energy industry. The field is still nascent, but there is conclusive evidence that ML is at least able to expose the same trends that human researchers have noticed over decades of research. The ML field itself is still seeing rapid development, with new methodologies being reported daily. It will take time to develop and adopt these methodologies to solve specific problems in materials science. We believe that for ML to truly accelerate the deployment of sustainable energy, it should be deployed as a tool, similar to a synthesis procedure, characterization equipment or control apparatus. Researchers using ML to accelerate energy technology discovery should judge the success of the method primarily on the advances it enables. To this end, we have proposed the XPIs and some areas in which we hope to see ML deployed.

References

Davidson, D. J. Exnovating for a renewable energy transition. Nat. Energy 4, 254–256 (2019).

Horowitz, C. A. Paris agreement. Int. Leg. Mater. 55, 740–755 (2016).

International Energy Agency 2018 World Energy Outlook: Executive Summary https://www.iea.org/reports/world-energy-outlook-2018 (OECD/IEA, 2018).

Chu, S., Cui, Y. & Liu, N. The path towards sustainable energy. Nat. Mater. 16, 16–22 (2017).

Maine, E. & Garnsey, E. Commercializing generic technology: the case of advanced materials ventures. Res. Policy 35, 375–393 (2006).

De Luna, P., Wei, J., Bengio, Y., Aspuru-Guzik, A. & Sargent, E. Use machine learning to find energy materials. Nature 552, 23–27 (2017).

Wang, H., Lei, Z., Zhang, X., Zhou, B. & Peng, J. A review of deep learning for renewable energy forecasting. Energy Convers. Manag. 198, 111799–111814 (2019).

Yao, Z. et al. Inverse design of nanoporous crystalline reticular materials with deep generative models. Nat. Mach. Intell. 3, 76–86 (2021).

Rosen, A. S. et al. Machine learning the quantum-chemical properties of metal–organic frameworks for accelerated materials discovery. Matter 4, 1578–1597 (2021).

Jordan, M. I. & Mitchell, T. M. Machine learning: trends, perspectives, and prospects. Science 349, 255–260 (2015).

Personal, E., Guerrero, J. I., Garcia, A., Peña, M. & Leon, C. Key performance indicators: a useful tool to assess Smart Grid goals. Energy 76, 976–988 (2014).

Helmus, J. & den Hoed, R. Key performance indicators of charging infrastructure. World Electr. Veh. J. 8, 733–741 (2016).

Struck, M.-M. Vaccine R&D success rates and development times. Nat. Biotechnol. 14, 591–593 (1996).

Moore, G. E. Cramming more components onto integrated circuits. Electronics 38, 114–116 (1965).

Wetterstrand, K. A. DNA sequencing costs: data. NHGRI Genome Sequencing Program (GSP) www.genome.gov/sequencingcostsdata (2020).

Rajkomar, A., Dean, J. & Kohane, I. Machine learning in medicine. N. Engl. J. Med. 380, 1347–1358 (2019).

Jeong, J. et al. Pseudo-halide anion engineering for α-FAPbI3 perovskite solar cells. Nature 592, 381–385 (2021).

NREL. Best research-cell efficiency chart. NREL https://www.nrel.gov/pv/cell-efficiency.html (2021).

Burger, B. et al. A mobile robotic chemist. Nature 583, 237–241 (2020).

Clark, M. A. et al. Design, synthesis and selection of DNA-encoded small-molecule libraries. Nat. Chem. Biol. 5, 647–654 (2009).

Pilania, G., Gubernatis, J. E. & Lookman, T. Multi-fidelity machine learning models for accurate bandgap predictions of solids. Comput. Mater. Sci. 129, 156–163 (2017).

Pilania, G. et al. Machine learning bandgaps of double perovskites. Sci. Rep. 6, 19375 (2016).

Lu, S. et al. Accelerated discovery of stable lead-free hybrid organic-inorganic perovskites via machine learning. Nat. Commun. 9, 3405 (2018).

Askerka, M. et al. Learning-in-templates enables accelerated discovery and synthesis of new stable double perovskites. J. Am. Chem. Soc. 141, 3682–3690 (2019).

Jain, A. & Bligaard, T. Atomic-position independent descriptor for machine learning of material properties. Phys. Rev. B 98, 214112 (2018).

Choubisa, H. et al. Crystal site feature embedding enables exploration of large chemical spaces. Matter 3, 433–448 (2020).

Xie, T. & Grossman, J. C. Crystal graph convolutional neural networks for an accurate and interpretable prediction of material properties. Phys. Rev. Lett. 120, 145301–145306 (2018).

Broberg, D. et al. PyCDT: a Python toolkit for modeling point defects in semiconductors and insulators. Comput. Phys. Commun. 226, 165–179 (2018).

Roch, L. M. et al. ChemOS: an orchestration software to democratize autonomous discovery. PLoS ONE 15, 1–18 (2020).

Wei, L., Xu, X., Gurudayal, Bullock, J. & Ager, J. W. Machine learning optimization of p-type transparent conducting films. Chem. Mater. 31, 7340–7350 (2019).

Schubert, M. F. et al. Design of multilayer antireflection coatings made from co-sputtered and low-refractive-index materials by genetic algorithm. Opt. Express 16, 5290–5298 (2008).

Wang, C., Yu, S., Chen, W. & Sun, C. Highly efficient light-trapping structure design inspired by natural evolution. Sci. Rep. 3, 1025 (2013).

Ripalda, J. M., Buencuerpo, J. & García, I. Solar cell designs by maximizing energy production based on machine learning clustering of spectral variations. Nat. Commun. 9, 5126 (2018).

Demant, M., Virtue, P., Kovvali, A., Yu, S. X. & Rein, S. Learning quality rating of As-Cut mc-Si wafers via convolutional regression networks. IEEE J. Photovolt. 9, 1064–1072 (2019).

Musztyfaga-Staszuk, M. & Honysz, R. Application of artificial neural networks in modeling of manufactured front metallization contact resistance for silicon solar cells. Arch. Metall. Mater. 60, 1673–1678 (2015).

Sendek, A. D. et al. Holistic computational structure screening of more than 12000 candidates for solid lithium-ion conductor materials. Energy Environ. Sci. 10, 306–320 (2017).

Ahmad, Z., Xie, T., Maheshwari, C., Grossman, J. C. & Viswanathan, V. Machine learning enabled computational screening of inorganic solid electrolytes for suppression of dendrite formation in lithium metal anodes. ACS Cent. Sci. 4, 996–1006 (2018).

Zhang, Y. et al. Unsupervised discovery of solid-state lithium ion conductors. Nat. Commun. 10, 5260 (2019).

Doan, H. A. et al. Quantum chemistry-informed active learning to accelerate the design and discovery of sustainable energy storage materials. Chem. Mater. 32, 6338–6346 (2020).

Chemali, E., Kollmeyer, P. J., Preindl, M. & Emadi, A. State-of-charge estimation of Li-ion batteries using deep neural networks: a machine learning approach. J. Power Sources 400, 242–255 (2018).

Richardson, R. R., Osborne, M. A. & Howey, D. A. Gaussian process regression for forecasting battery state of health. J. Power Sources 357, 209–219 (2017).

Berecibar, M. et al. Online state of health estimation on NMC cells based on predictive analytics. J. Power Sources 320, 239–250 (2016).

Severson, K. A. et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 4, 383–391 (2019).

Attia, P. M. et al. Closed-loop optimization of fast-charging protocols for batteries with machine learning. Nature 578, 397–402 (2020).

Joshi, R. P. et al. Machine learning the voltage of electrode materials in metal-ion batteries. ACS Appl. Mater. Interf. 11, 18494–18503 (2019).

Cubuk, E. D., Sendek, A. D. & Reed, E. J. Screening billions of candidates for solid lithium-ion conductors: a transfer learning approach for small data. J. Chem. Phys. 150, 214701 (2019).

Sendek, A. D. et al. Machine learning-assisted discovery of solid Li-ion conducting materials. Chem. Mater. 31, 342–352 (2019).

Kim, S., Jinich, A. & Aspuru-Guzik, A. MultiDK: a multiple descriptor multiple kernel approach for molecular discovery and its application to organic flow battery electrolytes. J. Chem. Inf. Model. 57, 657–668 (2017).

Jinich, A., Sanchez-Lengeling, B., Ren, H., Harman, R. & Aspuru-Guzik, A. A mixed quantum chemistry/machine learning approach for the fast and accurate prediction of biochemical redox potentials and its large-scale application to 315000 redox reactions. ACS Cent. Sci. 5, 1199–1210 (2019).

Sarkar, A. et al. High entropy oxides for reversible energy storage. Nat. Commun. 9, 3400 (2018).

Choudhury, S. et al. Stabilizing polymer electrolytes in high-voltage lithium batteries. Nat. Commun. 10, 3091 (2019).

Sanchez-Lengeling, B. & Aspuru-Guzik, A. Inverse molecular design using machine learning: generative models for matter engineering. Science 361, 360–365 (2018).

Ng, M.-F., Zhao, J., Yan, Q., Conduit, G. J. & Seh, Z. W. Predicting the state of charge and health of batteries using data-driven machine learning. Nat. Mach. Intell. 2, 161–170 (2020).

Steinmann, S. N. & Seh, Z. W. Understanding electrified interfaces. Nat. Rev. Mater. 6, 289–291 (2021).

Kandasamy, N., Badrinarayanan, R., Kanamarlapudi, V., Tseng, K. & Soong, B.-H. Performance analysis of machine-learning approaches for modeling the charging/discharging profiles of stationary battery systems with non-uniform cell aging. Batteries 3, 18 (2017).

Wei, Q., Liu, D. & Shi, G. A novel dual iterative Q-learning method for optimal battery management in smart residential environments. IEEE Trans. Ind. Electron. 62, 2509–2518 (2015).

Murphey, Y. L. et al. Intelligent hybrid vehicle power control — Part II: online intelligent energy management. IEEE Trans. Vehicular Technol. 62, 69–79 (2013).

Seh, Z. W. et al. Combining theory and experiment in electrocatalysis: insights into materials design. Science 355, eaad4998 (2017).

Staffell, I. et al. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 12, 463–491 (2019).

Montoya, J. H. H. et al. Materials for solar fuels and chemicals. Nat. Mater. 16, 70–81 (2017).

Pérez-Ramírez, J. & López, N. Strategies to break linear scaling relationships. Nat. Catal. 2, 971–976 (2019).

Shi, C., Hansen, H. A., Lausche, A. C. & Norskov, J. K. Trends in electrochemical CO2 reduction activity for open and close-packed metal surfaces. Phys. Chem. Chem. Phys. 16, 4720–4727 (2014).

Calle-Vallejo, F., Loffreda, D., Koper, M. T. M. & Sautet, P. Introducing structural sensitivity into adsorption-energy scaling relations by means of coordination numbers. Nat. Chem. 7, 403–410 (2015).

Ulissi, Z. W. et al. Machine-learning methods enable exhaustive searches for active bimetallic facets and reveal active site motifs for CO2 reduction. ACS Catal. 7, 6600–6608 (2017).

Nørskov, J. K., Studt, F., Abild-Pedersen, F. & Bligaard, T. Activity and selectivity maps. In Fundamental Concepts in Heterogeneous Catalysis 97–113 (John Wiley, 2014).

Garijo del Río, E., Mortensen, J. J. & Jacobsen, K. W. Local Bayesian optimizer for atomic structures. Phys. Rev. B 100, 104103 (2019).

Jørgensen, M. S., Larsen, U. F., Jacobsen, K. W. & Hammer, B. Exploration versus exploitation in global atomistic structure optimization. J. Phys. Chem. A 122, 1504–1509 (2018).

Jacobsen, T. L., Jørgensen, M. S. & Hammer, B. On-the-fly machine learning of atomic potential in density functional theory structure optimization. Phys. Rev. Lett. 120, 026102 (2018).

Peterson, A. A. Acceleration of saddle-point searches with machine learning. J. Chem. Phys. 145, 074106 (2016).

Ulissi, Z. W., Medford, A. J., Bligaard, T. & Nørskov, J. K. To address surface reaction network complexity using scaling relations machine learning and DFT calculations. Nat. Commun. 8, 14621 (2017).

Huang, Y., Chen, Y., Cheng, T., Wang, L.-W. & Goddard, W. A. Identification of the selective sites for electrochemical reduction of CO to C2+ products on copper nanoparticles by combining reactive force fields, density functional theory, and machine learning. ACS Energy Lett. 3, 2983–2988 (2018).

Chen, Y., Huang, Y., Cheng, T. & Goddard, W. A. Identifying active sites for CO2 reduction on dealloyed gold surfaces by combining machine learning with multiscale simulations. J. Am. Chem. Soc. 141, 11651–11657 (2019).

Lai, Y., Jones, R. J. R., Wang, Y., Zhou, L. & Gregoire, J. M. Scanning electrochemical flow cell with online mass spectroscopy for accelerated screening of carbon dioxide reduction electrocatalysts. ACS Comb. Sci. 21, 692–704 (2019).

Lai, Y. et al. The sensitivity of Cu for electrochemical carbon dioxide reduction to hydrocarbons as revealed by high throughput experiments. J. Mater. Chem. A 7, 26785–26790 (2019).

Tran, K. & Ulissi, Z. W. Active learning across intermetallics to guide discovery of electrocatalysts for CO2 reduction and H2 evolution. Nat. Catal. 1, 696–703 (2018).

Zhong, M. et al. Accelerated discovery of CO2 electrocatalysts using active machine learning. Nature 581, 178–183 (2020).

Tshitoyan, V. et al. Unsupervised word embeddings capture latent knowledge from materials science literature. Nature 571, 95–98 (2019).

Yao, Y. et al. Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science 359, 1489–1494 (2018).

Yao, Y. et al. High-throughput, combinatorial synthesis of multimetallic nanoclusters. Proc. Natl Acad. Sci. USA 117, 6316–6322 (2020).

Timoshenko, J. & Roldan Cuenya, B. In situ/operando electrocatalyst characterization by X-ray absorption spectroscopy. Chem. Rev. 121, 882–961 (2021).

Zheng, C., Chen, C., Chen, Y. & Ong, S. P. Random forest models for accurate identification of coordination environments from X-ray absorption near-edge structure. Patterns 1, 100013–100023 (2020).

Torrisi, S. B. et al. Random forest machine learning models for interpretable X-ray absorption near-edge structure spectrum-property relationships. npj Comput. Mater. 6, 109 (2020).

Timoshenko, J. et al. Neural network approach for characterizing structural transformations by X-ray absorption fine structure spectroscopy. Phys. Rev. Lett. 120, 225502 (2018).

Marcella, N. et al. Neural network assisted analysis of bimetallic nanocatalysts using X-ray absorption near edge structure spectroscopy. Phys. Chem. Chem. Phys. 22, 18902–18910 (2020).

Chen, K., Laghrouche, S. & Djerdir, A. Degradation model of proton exchange membrane fuel cell based on a novel hybrid method. Appl. Energy 252, 113439–113447 (2019).

Ma, R. et al. Data-driven proton exchange membrane fuel cell degradation predication through deep learning method. Appl. Energy 231, 102–115 (2018).

Jeppesen, C. et al. Fault detection and isolation of high temperature proton exchange membrane fuel cell stack under the influence of degradation. J. Power Sources 359, 37–47 (2017).

Liu, J. et al. Sequence fault diagnosis for PEMFC water management subsystem using deep learning with t-SNE. IEEE Access. 7, 92009–92019 (2019).

Ansari, M. A., Rizvi, S. M. A. & Khan, S. Optimization of electrochemical performance of a solid oxide fuel cell using artificial neural network. in 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT) 4230–4234 (IEEE, 2016).

Zhang, C. et al. Modelling of solid oxide electrolyser cell using extreme learning machine. Electrochim. Acta 251, 137–144 (2017).

Esche, E., Weigert, J., Budiarto, T., Hoffmann, C. & Repke, J.-U. Optimization under uncertainty based on a data-driven model for a chloralkali electrolyzer cell. Computer-aided Chem. Eng. 46, 577–582 (2019).

Siddaiah, R. & Saini, R. P. A review on planning, configurations, modeling and optimization techniques of hybrid renewable energy systems for off grid applications. Renew. Sustain. Energy Rev. 58, 376–396 (2016).

Yin, L., Yu, T., Zhang, X. & Yang, B. Relaxed deep learning for real-time economic generation dispatch and control with unified time scale. Energy 149, 11–23 (2018).

Yu, T., Wang, H. Z., Zhou, B., Chan, K. W. & Tang, J. Multi-agent correlated equilibrium Q(λ) learning for coordinated smart generation control of interconnected power grids. IEEE Trans. Power Syst. 30, 1669–1679 (2015).

Marino, D. L., Amarasinghe, K. & Manic, M. Building energy load forecasting using deep neural networks. in IECON Proceedings (Industrial Electronics Conference) 7046–7051 (IECON, 2016).

Ryu, S., Noh, J. & Kim, H. Deep neural network based demand side short term load forecasting. in 2016 IEEE International Conference on Smart Grid Communications (SmartGridComm 2016) 308–313 (IEEE, 2016).

Mocanu, E., Nguyen, P. H., Kling, W. L. & Gibescu, M. Unsupervised energy prediction in a Smart Grid context using reinforcement cross-building transfer learning. Energy Build. 116, 646–655 (2016).

Lund, P. D., Lindgren, J., Mikkola, J. & Salpakari, J. Review of energy system flexibility measures to enable high levels of variable renewable electricity. Renew. Sustain. Energy Rev. 45, 785–807 (2015).

Kim, B. G., Zhang, Y., Van Der Schaar, M. & Lee, J. W. Dynamic pricing and energy consumption scheduling with reinforcement learning. IEEE Trans. Smart Grid 7, 2187–2198 (2016).

Dusparic, I., Taylor, A., Marinescu, A., Cahill, V. & Clarke, S. Maximizing renewable energy use with decentralized residential demand response. in 2015 IEEE 1st International Smart Cities Conference (ISC2 2015) 1–6 (IEEE, 2015).

Dusparic, I., Harris, C., Marinescu, A., Cahill, V. & Clarke, S. Multi-agent residential demand response based on load forecasting. in 2013 1st IEEE Conference on Technologies for Sustainability (SusTech 2013) 90–96 (IEEE, 2013).

Bengio, Y., Courville, A. & Vincent, P. Representation learning: a review and new perspectives. IEEE Transactions on Pattern Analysis and Machine Intelligence 35, 1798–1828 (2013).

Duvenaud, D. et al. Convolutional networks on graphs for learning molecular fingerprints. in Advances In Neural Information Processing Systems 2224–2232 (NIPS, 2015).

Gómez-Bombarelli, R. et al. Automatic chemical design using a data-driven continuous representation of molecules. ACS Cent. Sci. 4, 268–276 (2018).

Krenn, M., Hase, F., Nigam, A., Friederich, P. & Aspuru-Guzik, A. Self-referencing embedded strings (SELFIES): a 100% robust molecular string representation. Mach. Learn. Sci. Technol. 1, 045024–045031 (2020).

Jin, W., Barzilay, R. & Jaakkola, T. Junction tree variational autoencoder for molecular graph generation. Mach. Learn. 5, 3632–3648 (2018).

You, J., Liu, B., Ying, R., Pande, V. & Leskovec, J. Graph convolutional policy network for goal-directed molecular graph generation. Adv. Neural Inf. Process. Syst. 31, 6412–6422 (2018).

Liu, Q., Allamanis, M., Brockschmidt, M. & Gaunt, A. L. Constrained graph variational autoencoders for molecule design. in Proceedings of the 32nd International Conference on Neural Information Processing Systems (NIPS’18) 7806–7815 (Curran Associates Inc., 2018).

Bartók, A. P., Kondor, R. & Csányi, G. On representing chemical environments. Phys. Rev. B 87, 184115 (2013).

Ward, L. et al. Including crystal structure attributes in machine learning models of formation energies via Voronoi tessellations. Phys. Rev. B 96, 024104 (2017).

Isayev, O. et al. Universal fragment descriptors for predicting properties of inorganic crystals. Nat. Commun. 8, 15679 (2017).

Ziletti, A., Kumar, D., Scheffler, M. & Ghiringhelli, L. M. Insightful classification of crystal structures using deep learning. Nat. Commun. 9, 2775 (2018).

Ryan, K., Lengyel, J. & Shatruk, M. Crystal structure prediction via deep learning. J. Am. Chem. Soc. 140, 10158–10168 (2018).

Park, C. W. & Wolverton, C. Developing an improved crystal graph convolutional neural network framework for accelerated materials discovery. Phys. Rev. Mater. 4, 063801 (2020).

Liu, X. et al. Self-Supervised Learning: Generative or Contrastive (IEEE, 2020).

Ruder, S. An overview of multi-task learning in deep neural networks. Preprint at https://doi.org/10.48550/arXiv.1706.05098 (2017).

Hospedales, T., Antoniou, A., Micaelli, P. & Storkey, A. Meta-learning in neural networks: a survey. IEEE Transactions on Pattern Analysis & Machine Intelligence 44, 5149–5169 (2020).

Vaswani, A. et al. Attention is all you need. in Proceedings of the 31st International Conference on Neural Information Processing Systems (NIPS’17) 6000–6010 (Curran Associates Inc., 2017).

Veličković, P. et al. Graph attention networks. Preprint at https://doi.org/10.48550/arXiv.1710.10903 (2017).

Battaglia, P. W. et al. Relational inductive biases, deep learning, and graph networks. Preprint at https://doi.org/10.48550/arXiv.1806.01261 (2018).

Satorras, V. G., Hoogeboom, E. & Welling, M. E(n) equivariant graph neural networks. Preprint at https://doi.org/10.48550/arXiv.2102.09844 (2021).

Jain, A. et al. Commentary: The Materials Project: a materials genome approach to accelerating materials innovation. Apl. Mater. 1, 011002–011012 (2013).

Laasner, R. et al. MatD3: a database and online presentation package for research data supporting materials discovery, design, and dissemination. J. Open Source Softw. 5, 1945–1947 (2020).

Coley, C. W. et al. A robotic platform for flow synthesis of organic compounds informed by AI planning. Science 365, 557 (2019).

Hachmann, J. et al. The harvard clean energy project: large-scale computational screening and design of organic photovoltaics on the world community grid. J. Phys. Chem. Lett. 2, 2241–2251 (2011).

Bıyık, E., Wang, K., Anari, N. & Sadigh, D. Batch active learning using determinantal point processes. Preprint at https://doi.org/10.48550/arXiv.1906.07975 (2019).

Hoffmann, J. et al. Machine learning in a data-limited regime: augmenting experiments with synthetic data uncovers order in crumpled sheets. Sci. Adv. 5, eaau6792 (2019).

Liu, J. Z. et al. Simple and principled uncertainty estimation with deterministic deep learning via distance awareness. Adv. Neural Inf. Process Syst. 33, 7498–7512 (2020).

Lakshminarayanan, B., Pritzel, A. & Blundell, C. Simple and scalable predictive uncertainty estimation using deep ensembles. In Proceedings of the 31st International Conference on Neural Information Processing Systems (NIPS’17) 6405–6416 (Curran Associates Inc., 2017).

D’Amour, A. et al. Underspecification presents challenges for credibility in modern machine learning. Preprint at https://doi.org/10.48550/arXiv.2011.03395 (2020).

Barredo Arrieta, A. et al. Explainable artificial intelligence (XAI): concepts, taxonomies, opportunities and challenges toward responsible AI. Inf. Fusion. 58, 82–115 (2020).

Ribeiro, M. T., Singh, S. & Guestrin, C. “Why should I trust you?” Explaining the predictions of any classifier. in Proceedings of the ACM SIGKDD International Conference on Knowledge Discovery and Data Mining 1135–1144 (2016).

Lundberg, S. & Lee, S.-I. An unexpected unity among methods for interpreting model predictions. Preprint at https://arxiv.org/abs/1611.07478 (2016).

Bach, S. et al. On pixel-wise explanations for non-linear classifier decisions by layer-wise relevance propagation. PLoS ONE 10, e0130140 (2015).

Sun, W. et al. The thermodynamic scale of inorganic crystalline metastability. Sci. Adv. 2, e1600225 (2016).

Aykol, M., Dwaraknath, S. S., Sun, W. & Persson, K. A. Thermodynamic limit for synthesis of metastable inorganic materials. Sci. Adv. 4, eaaq0148 (2018).

Wei, J. N., Duvenaud, D. & Aspuru-Guzik, A. Neural networks for the prediction of organic chemistry reactions. ACS Cent. Sci. 2, 725–732 (2016).

Coley, C. W. et al. A graph-convolutional neural network model for the prediction of chemical reactivity. Chem. Sci. 10, 370–377 (2019).

Nagabhushana, G. P., Shivaramaiah, R. & Navrotsky, A. Direct calorimetric verification of thermodynamic instability of lead halide hybrid perovskites. Proc. Natl Acad. Sci. USA 113, 7717–7721 (2016).

Sanna, S. et al. Enhancement of the chemical stability in confined δ-Bi2O3. Nat. Mater. 14, 500–504 (2015).

Podolyan, Y., Walters, M. A. & Karypis, G. Assessing synthetic accessibility of chemical compounds using machine learning methods. J. Chem. Inf. Model. 50, 979–991 (2010).

Coley, C. W., Rogers, L., Green, W. H. & Jensen, K. F. SCScore: synthetic complexity learned from a reaction corpus. J. Chem. Inf. Model. 58, 252–261 (2018).

Kim, E. et al. Inorganic materials synthesis planning with literature-trained neural networks. J. Chem. Inf. Model. 60, 1194–1201 (2020).

Huo, H. et al. Semi-supervised machine-learning classification of materials synthesis procedures. npj Comput. Mater. 5, 62 (2019).

Tian, C., Lin, F. & Doeff, M. M. Electrochemical characteristics of layered transition metal oxide cathode materials for lithium ion batteries: surface, bulk behavior, and thermal properties. Acc. Chem. Res. 51, 89–96 (2018).

Guilminot, E., Corcella, A., Charlot, F., Maillard, F. & Chatenet, M. Detection of Ptz+ ions and Pt nanoparticles inside the membrane of a used PEMFC. J. Electrochem. Soc. 154, B96 (2007).

Pender, J. P. et al. Electrode degradation in lithium-ion batteries. ACS Nano 14, 1243–1295 (2020).

Li, Y. et al. Atomic structure of sensitive battery materials and interfaces revealed by cryo-electron microscopy. Science 358, 506–510 (2017).

Wang, H. Numerical modeling of non-planar hydraulic fracture propagation in brittle and ductile rocks using XFEM with cohesive zone method. J. Pet. Sci. Eng. 135, 127–140 (2015).

Hsu, Y.-C., Yu, C.-H. & Buehler, M. J. Using deep learning to predict fracture patterns in crystalline solids. Matter 3, 197–211 (2020).

Wuest, T., Weimer, D., Irgens, C. & Thoben, K. D. Machine learning in manufacturing: advantages, challenges, and applications. Prod. Manuf. Res. 4, 23–45 (2016).

De Jong, P., Sánchez, A. S., Esquerre, K., Kalid, R. A. & Torres, E. A. Solar and wind energy production in relation to the electricity load curve and hydroelectricity in the northeast region of Brazil. Renew. Sustain. Energy Rev. 23, 526–535 (2013).

Zolfani, S. H. & Saparauskas, J. New application of SWARA method in prioritizing sustainability assessment indicators of energy system. Eng. Econ. 24, 408–414 (2013).

Tao, F., Zhang, M., Liu, Y. & Nee, A. Y. C. Digital twin driven prognostics and health management for complex equipment. CIRP Ann. 67, 169–172 (2018).

Yun, S., Park, J. H. & Kim, W. T. Data-centric middleware based digital twin platform for dependable cyber-physical systems. in International Conference on Ubiquitous and Future Networks (ICUFN) 922–926 (2017).

Boretti, A. Integration of solar thermal and photovoltaic, wind, and battery energy storage through AI in NEOM city. Energy AI 3, 100038–100045 (2021).

Ghoddusi, H., Creamer, G. G. & Rafizadeh, N. Machine learning in energy economics and finance: a review. Energy Econ. 81, 709–727 (2019).

Asensio, O. I., Mi, X. & Dharur, S. Using machine learning techniques to aid environmental policy analysis: a teaching case regarding big data and electric vehicle charging infrastructure. Case Stud. Environ. 4, 961302 (2020).

Zheng, S., Trott, A., Srinivasa, S., Parkes, D. C. & Socher, R. The AI economist: taxation policy design via two-level deep multiagent reinforcement learning. Sci. Adv. 8, eabk2607 (2022).

Sun, S. et al. A data fusion approach to optimize compositional stability of halide perovskites. Matter 4, 1305–1322 (2021).

Sun, W. et al. Machine learning — assisted molecular design and efficiency prediction for high-performance organic photovoltaic materials. Sci. Adv. 5, eaay4275 (2019).

Sun, S. et al. Accelerated development of perovskite-inspired materials via high-throughput synthesis and machine-learning diagnosis. Joule 3, 1437–1451 (2019).

Kirman, J. et al. Machine-learning-accelerated perovskite crystallization. Matter 2, 938–947 (2020).

Langner, S. et al. Beyond ternary OPV: high-throughput experimentation and self-driving laboratories optimize multicomponent systems. Adv. Mater. 32, 1907801 (2020).

Hartono, N. T. P. et al. How machine learning can help select capping layers to suppress perovskite degradation. Nat. Commun. 11, 4172 (2020).

Odabaşı, Ç. & Yıldırım, R. Performance analysis of perovskite solar cells in 2013–2018 using machine-learning tools. Nano Energy 56, 770–791 (2019).

Fenning, D. P. et al. Darwin at high temperature: advancing solar cell material design using defect kinetics simulations and evolutionary optimization. Adv. Energy Mater. 4, 1400459 (2014).

Allam, O., Cho, B. W., Kim, K. C. & Jang, S. S. Application of DFT-based machine learning for developing molecular electrode materials in Li-ion batteries. RSC Adv. 8, 39414–39420 (2018).

Okamoto, Y. & Kubo, Y. Ab initio calculations of the redox potentials of additives for lithium-ion batteries and their prediction through machine learning. ACS Omega 3, 7868–7874 (2018).

Takagishi, Y., Yamanaka, T. & Yamaue, T. Machine learning approaches for designing mesoscale structure of Li-ion battery electrodes. Batteries 5, 54 (2019).

Tan, Y., Liu, W. & Qiu, Q. Adaptive power management using reinforcement learning. in IEEE/ACM International Conference on Computer-Aided Design, Digest of Technical Papers (ICCAD) 461–467 (IEEE, 2009).

Ermon, S., Xue, Y., Gomes, C. & Selman, B. Learning policies for battery usage optimization in electric vehicles. Mach. Learn. 92, 177–194 (2013).

Schmidt, J., Marques, M. R. G., Botti, S. & Marques, M. A. L. Recent advances and applications of machine learning in solid-state materials science. npj Comput. Mater. 5, 83 (2019).

Pilania, G. Machine learning in materials science: from explainable predictions to autonomous design. Comput. Mater. Sci. 193, 110360 (2021).

Butler, K. T., Davies, D. W., Cartwright, H., Isayev, O. & Walsh, A. Machine learning for molecular and materials science. Nature 559, 547–555 (2018).

Kaufmann, K. et al. Crystal symmetry determination in electron diffraction using machine learning. Science 367, 564–568 (2020).

Chen, C., Zuo, Y., Ye, W., Li, X. & Ong, S. P. Learning properties of ordered and disordered materials from multi-fidelity data. Nat. Comput. Sci. 1, 46–53 (2021).

Liu, M., Yan, K., Oztekin, B. & Ji, S. GraphEBM: molecular graph generation with energy-based models. Preprint at https://doi.org/10.48550/arXiv.2102.00546 (2021).

Segler, M. H. S., Preuss, M. & Waller, M. P. Planning chemical syntheses with deep neural networks and symbolic AI. Nature 555, 604–610 (2018).

Granda, J. M., Donina, L., Dragone, V., Long, D.-L. & Cronin, L. Controlling an organic synthesis robot with machine learning to search for new reactivity. Nature 559, 377–381 (2018).

Epps, R. W. et al. Artificial chemist: an autonomous quantum dot synthesis bot. Adv. Mater. 32, 2001626 (2020).

MacLeod, B. P. et al. Self-driving laboratory for accelerated discovery of thin-film materials. Sci. Adv. 6, eaaz8867 (2020).