Abstract

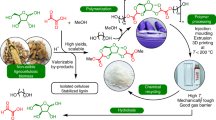

A central feature of most lignocellulosic-biomass-valorization strategies is the depolymerization of all its three major constituents: cellulose and hemicellulose to simple sugars, and lignin to phenolic monomers. However, reactive intermediates, generally resulting from dehydration reactions, can participate in undesirable condensation pathways during biomass deconstruction, which have posed fundamental challenges to commercial biomass valorization. Thus, new strategies specifically aim to suppress condensations of reactive intermediates, either avoiding their formation by functionalizing the native structure or intermediates or selectively transforming these intermediates into stable derivatives. These strategies have provided unforeseen upgrading pathways, products and process solutions. In this Review, we outline the molecular driving forces that shape the deconstruction landscape and describe the strategies for chemical functionalization. We then offer an outlook on further developments and the potential of these strategies to sustainably produce renewable-platform chemicals.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Muradov, N. in Liberating Energy from Carbon: Introduction to Decarbonization (ed. Muradov, N.) 141–184 (Springer, 2014).

Luterbacher, J. S., Alonso, D. M. & Dumesic, J. A. Targeted chemical upgrading of lignocellulosic biomass to platform molecules. Green Chem. 16, 4816–4838 (2014).

Schutyser, W. et al. Chemicals from lignin: an interplay of lignocellulose fractionation, depolymerisation, and upgrading. Chem. Soc. Rev. 47, 852–908 (2018).

Heinze, T. in Cellulose Chemistry and Properties: Fibers, Nanocelluloses and Advanced Materials (ed. Rojas, O. J.) 1–52 (Springer, 2016).

Rojas, O. J. (ed.) Cellulose Chemistry and Properties: Fibers, Nanocelluloses and Advanced Materials (Springer, 2016).

Nishiyama, Y., Langan, P. & Chanzy, H. Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron X-ray and neutron fiber diffraction. J. Am. Chem. Soc. 124, 9074–9082 (2002).

Nishiyama, Y., Sugiyama, J., Chanzy, H. & Langan, P. Crystal structure and hydrogen bonding system in cellulose Iα from synchrotron X-ray and neutron fiber diffraction. J. Am. Chem. Soc. 125, 14300–14306 (2003).

Azizi Samir, M. A. S., Alloin, F. & Dufresne, A. Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6, 612–626 (2005).

Scheller, H. V. & Ulvskov, P. Hemicelluloses. Annu. Rev. Plant. Biol. 61, 263–289 (2010).

Gírio, F. M. et al. Hemicelluloses for fuel ethanol: a review. Bioresour. Technol. 101, 4775–4800 (2010).

Wilkie, K. C. B. in Advances in Carbohydrate Chemistry and Biochemistry Vol. 36 (eds Tipson, R. S. & Horton, D.) 215–264 (Academic, 1979).

Jones, D., Ormondroyd, G. O., Curling, S. F., Popescu, C.-M. & Popescu, M.-C. in Advanced High Strength Natural Fibre Composites in Construction (eds Fan, M. & Fu, F.) 23–58 (Woodhead, 2017).

Ralph, J., Lapierre, C. & Boerjan, W. Lignin structure and its engineering. Curr. Opin. Biotechnol. 56, 240–249 (2019).

Zakzeski, J., Bruijnincx, P. C. A., Jongerius, A. L. & Weckhuysen, B. M. The catalytic valorization of lignin for the production of renewable chemicals. Chem. Rev. 110, 3552–3599 (2010).

Bajpai, P. Pretreatment of Lignocellulosic Biomass for Biofuel Production (Springer, 2016).

Werpy, T. & Petersen, G. Top value added chemicals from biomass: volume I — Results of screening for potential candidates from sugars and synthesis gas (US Department of Energy, 2004).

Holladay, J. E., White, J. F., Bozell, J. J. & Johnson, D. Top value-added chemicals from biomass: volume II — Results of screening for potential candidates from biorefinery lignin (US Department of Energy, 2007).

van Putten, R.-J. et al. Hydroxymethylfurfural, a versatile platform chemical made from renewable resources. Chem. Rev. 113, 1499–1597 (2013).

Rinaldi, R. et al. Paving the way for lignin valorisation: recent advances in bioengineering, biorefining and catalysis. Angew. Chem. Int. Ed. 55, 8164–8215 (2016).

Putro, J. N., Soetaredjo, F. E., Lin, S.-Y., Ju, Y.-H. & Ismadji, S. Pretreatment and conversion of lignocellulose biomass into valuable chemicals. RSC Adv. 6, 46834–46852 (2016).

Questell-Santiago, Y. M., Zambrano-Varela, R., Amiri, M. T. & Luterbacher, J. S. Carbohydrate stabilization extends the kinetic limits of chemical polysaccharide depolymerization. Nat. Chem. 10, 1222–1228 (2018).

Lee, Y. Y., Iyer, P. & Torget, R. W. in Recent Progress in Bioconversion of Lignocellulosics (ed. Tsao, G. T.) 93–115 (Springer, 1999).

Carvalheiro, F., Silva-Fernandes, T., Duarte, L. C. & Gírio, F. M. Wheat straw autohydrolysis: process optimization and products characterization. Appl. Biochem. Biotechnol. 153, 84–93 (2009).

Bobleter, O. Hydrothermal degradation of polymers derived from plants. Prog. Polym. Sci. 19, 797–841 (1994).

Loerbroks, C., Rinaldi, R. & Thiel, W. The electronic nature of the 1,4-β-glycosidic bond and its chemical environment: DFT insights into cellulose chemistry. Chem. Eur. J. 19, 16282–16294 (2013).

van Zandvoort, I. et al. Formation, molecular structure, and morphology of humins in biomass conversion: influence of feedstock and processing conditions. ChemSusChem 6, 1745–1758 (2013).

Guadix-Montero, S. & Sankar, M. Review on catalytic cleavage of C–C inter-unit linkages in lignin model compounds: towards lignin depolymerisation. Top. Catal. 61, 183–198 (2018).

Moriarty, K. L., Milbrandt, A. R., Warner, E., Lewis, J. E. & Schwab, A. A. 2016 bioenergy industry status report (US Department of Energy, 2018).

Renders, T., Van den Bosch, S., Koelewijn, S.-F., Schutyser, W. & Sels, B. F. Lignin-first biomass fractionation: the advent of active stabilisation strategies. Energy Environ. Sci. 10, 1551–1557 (2017).

Shuai, L., Talebi Amiri, M. & Luterbacher, J. S. The influence of interunit carbon–carbon linkages during lignin upgrading. Curr. Opin. Green Sustain. Chem. 2, 59–63 (2016).

Phongpreecha, T. et al. Predicting lignin depolymerization yields from quantifiable properties using fractionated biorefinery lignins. Green Chem. 19, 5131–5143 (2017).

Talebi Amiri, M., Bertella, S., Questell-Santiago, Y. M. & Luterbacher, J. S. Establishing lignin structure-upgradeability relationships using quantitative 1H–13C heteronuclear single quantum coherence nuclear magnetic resonance (HSQC-NMR) spectroscopy. Chem. Sci. 10, 8135–8142 (2019).

Yan, N. et al. Selective degradation of wood lignin over noble-metal catalysts in a two-step process. ChemSusChem 1, 626–629 (2008).

Shuai, L. et al. Formaldehyde stabilization facilitates lignin monomer production during biomass depolymerization. Science 354, 329–333 (2016).

Lan, W. & Luterbacher, J. S. Preventing lignin condensation to facilitate aromatic monomer production. Chimia 73, 591–598 (2019).

Kim, S. et al. Computational study of bond dissociation enthalpies for a large range of native and modified lignins. J. Phys. Chem. Lett. 2, 2846–2852 (2011).

Rinaldi, R. in Lignin Valorization: Emerging Approaches (ed. Beckham, G. T.) 108–127 (Royal Society of Chemistry, 2018).

Sturgeon, M. R. et al. A mechanistic investigation of acid-catalyzed cleavage of aryl-ether linkages: implications for lignin depolymerization in acidic environments. ACS Sustain. Chem. Eng. 2, 472–485 (2014).

Parthasarathi, R., Romero, R. A., Redondo, A. & Gnanakaran, S. Theoretical study of the remarkably diverse linkages in lignin. J. Phys. Chem. Lett. 2, 2660–2666 (2011).

Miles-Barrett, D. M. et al. The synthesis and analysis of lignin-bound Hibbert ketone structures in technical lignins. Org. Biomol. Chem. 14, 10023–10030 (2016).

Shi, S. Fundamental Study on Kinetics of Hemicellulose Hydrolysis and Bioconversion of Hemicellulose Hydrolysate Mixture into Lactic Acid. Thesis, Auburn Univ. (2015).

Chum, H. L., Johnson, D. K., Black, S. K. & Overend, R. P. Pretreatment-catalyst effects and the combined severity parameter. Appl. Biochem. Biotechnol. 24, 1 (1990).

Shimada, K., Hosoya, S. & Ikeda, T. Condensation reactions of softwood and hardwood lignin model compounds under organic acid cooking conditions. J. Wood Chem. Technol. 17, 57–72 (1997).

Lan, W., Amiri, M. T., Hunston, C. M. & Luterbacher, J. S. Protection group effects during α,γ-diol lignin stabilization promote high-selectivity monomer production. Angew. Chem. Int. Ed. 57, 1356–1360 (2018).

Li, N. et al. An uncondensed lignin depolymerized in the solid state and isolated from lignocellulosic biomass: a mechanistic study. Green Chem. 20, 4224–4235 (2018).

Renders, T. et al. Influence of acidic (H3PO4) and alkaline (NaOH) additives on the catalytic reductive fractionation of lignocellulose. ACS Catal. 6, 2055–2066 (2016).

Ouyang, X., Huang, X., Hendriks, B. M. S., Boot, M. D. & Hensen, E. J. M. Coupling organosolv fractionation and reductive depolymerization of woody biomass in a two-step catalytic process. Green Chem. 20, 2308–2319 (2018).

Deuss, P. J. et al. Metal triflates for the production of aromatics from lignin. ChemSusChem 9, 2974–2981 (2016).

Deuss, P. J. et al. Phenolic acetals from lignins of varying compositions via iron(iii) triflate catalysed depolymerisation. Green Chem. 19, 2774–2782 (2017).

Parsell, T. et al. A synergistic biorefinery based on catalytic conversion of lignin prior to cellulose starting from lignocellulosic biomass. Green Chem. 17, 1492–1499 (2015).

Talebi Amiri, M., Dick, G. R., Questell-Santiago, Y. M. & Luterbacher, J. S. Fractionation of lignocellulosic biomass to produce uncondensed aldehyde-stabilized lignin. Nat. Protoc. 14, 921–954 (2019).

Chesi, C., de Castro, I. B. D., Clough, M. T., Ferrini, P. & Rinaldi, R. The influence of hemicellulose sugars on product distribution of early-stage conversion of lignin oligomers catalysed by Raney nickel. ChemCatChem 8, 2079–2088 (2016).

Wan, G. & Frazier, C. E. Lignin acidolysis predicts formaldehyde generation in pine wood. ACS Sustain. Chem. Eng. 5, 4830–4836 (2017).

Luterbacher, J. S. et al. Lignin monomer production integrated into the γ-valerolactone sugar platform. Energy Environ. Sci. 8, 2657–2663 (2015).

Yokoyama, T. Revisiting the mechanism of β-O-4 bond cleavage during acidolysis of lignin. Part 6: A review. J. Wood Chem. Technol. 35, 27–42 (2015).

Lan, W., de Bueren, J. B. & Luterbacher, J. S. Highly selective oxidation and depolymerization of α,γ-diol-protected lignin. Angew. Chem. Int. Ed. 58, 2649–2654 (2019).

Anderson, E. M. et al. Flowthrough reductive catalytic fractionation of biomass. Joule 1, 613–622 (2017).

Kumaniaev, I. et al. Lignin depolymerization to monophenolic compounds in a flow-through system. Green Chem. 19, 5767–5771 (2017).

Zhou, H. et al. Rapid flow-through fractionation of biomass to preserve labile aryl ether bonds in native lignin. Green Chem. 21, 4625–4632 (2019).

Wijaya, Y. P. et al. Comparative study on two-step concentrated acid hydrolysis for the extraction of sugars from lignocellulosic biomass. Bioresour. Technol. 164, 221–231 (2014).

Timell, T. E. The acid hydrolysis of glycosides: I. General conditions and the effect of the nature of the aglycone. Can. J. Chem. 42, 1456–1472 (1964).

Esteghlalian, A., Hashimoto, A. G., Fenske, J. J. & Penner, M. H. Modeling and optimization of the dilute-sulfuric-acid pretreatment of corn stover, poplar and switchgrass. Bioresour. Technol. 59, 129–136 (1997).

Jin, Q., Zhang, H., Yan, L., Qu, L. & Huang, H. Kinetic characterization for hemicellulose hydrolysis of corn stover in a dilute acid cycle spray flow-through reactor at moderate conditions. Biomass Bioenerg. 35, 4158–4164 (2011).

Fagan, R. D., Grethlein, H. E., Converse, A. O. & Porteous, A. Kinetics of the acid hydrolysis of cellulose found in paper refuse. Environ. Sci. Technol. 5, 545–547 (1971).

Saeman, J. F. Kinetics of wood saccharification - hydrolysis of cellulose and decomposition of sugars in dilute acid at high temperature. Ind. Eng. Chem. 37, 43–52 (1945).

Wyman, C. E. & Yang, B. in Hydrothermal Processing in Biorefineries (eds Ruiz H. A., Hedegaard Thomsen, M. & Trajano, H. L.) 161–180 (Springer, 2017).

Patil, S. K. R., Heltzel, J. & Lund, C. R. F. Comparison of structural features of humins formed catalytically from glucose, fructose, and 5-hydroxymethylfurfuraldehyde. Energy Fuels 26, 5281–5293 (2012).

Chiang, Y. et al. Separation and purification of furans from n-butanol by zeolitic imidazole frameworks: multicomponent adsorption behavior and simulated moving bed process design. ACS Sustain. Chem. Eng. 7, 16560–16568 (2019).

Metkar, P. S. et al. Reactive distillation process for the production of furfural using solid acid catalysts. Green Chem. 17, 1453–1466 (2015).

Hoang, T. M. C., Lefferts, L. & Seshan, K. Valorization of humin-based byproducts from biomass processing - a route to sustainable hydrogen. ChemSusChem 6, 1651–1658 (2013).

Kang, S. et al. Valorization of humins by phosphoric acid activation for activated carbon production. Biomass Convers. Biorefin. 8, 889–897 (2018).

Rogalinski, T., Liu, K., Albrecht, T. & Brunner, G. Hydrolysis kinetics of biopolymers in subcritical water. J. Supercrit. Fluids 46, 335–341 (2008).

Peterson, A. A. et al. Thermochemical biofuel production in hydrothermal media: a review of sub- and supercritical water technologies. Energy Environ. Sci. 1, 32–65 (2008).

Sasaki, M., Fang, Z., Fukushima, Y., Adschiri, T. & Arai, K. Dissolution and hydrolysis of cellulose in subcritical and supercritical water. Ind. Eng. Chem. Res. 39, 2883–2890 (2000).

Cantero, D. A., Bermejo, M. D. & Cocero, M. J. Kinetic analysis of cellulose depolymerization reactions in near critical water. J. Supercrit. Fluids 75, 48–57 (2013).

Kilambi, S. & Kadam, K. L. Production of fermentable sugars and lignin from biomass using supercritical fluids. US patent US9359651B2 (2018).

Wagemann, K. & Tippkötter, N. in Biorefineries (eds Wagemann, K. & Tippkötter, N.) 1–11 (Springer, 2019).

Stuart, E. Advanced biorefinery process. European patent EP2069406A2 (2010).

Genta, M. et al. Biomass hydrothermal decomposition apparatus and method. US patent US9238827B2 (2010).

South, C. R., Wyman, C. E. & Martin, R. L. Two-stage method for pretreatment of lignocellulosic biomass. US patent US20100279361A1 (2010).

Nguyen, Q. A., Keller, F. A. & Tucker, M. P. Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics. US patent US20030199049A1 (2003).

Tao, L. et al. NREL 2012 achievement of ethanol cost targets: biochemical ethanol fermentation via dilute-acid pretreatment and enzymatic hydrolysis of corn stover (US Department of Energy, 2014).

Luterbacher, J. S. et al. Nonenzymatic sugar production from biomass using biomass-derived γ-valerolactone. Science 343, 277–280 (2014).

Shuai, L., Questell-Santiago, Y. M. & Luterbacher, J. S. A mild biomass pretreatment using γ-valerolactone for concentrated sugar production. Green Chem. 18, 937–943 (2016).

Ghosh, A., Bai, X. & Brown, R. C. Solubilized carbohydrate production by acid-catalyzed depolymerization of cellulose in polar aprotic solvents. ChemistrySelect 3, 4777–4785 (2018).

Shuai, L. & Luterbacher, J. Organic solvent effects in biomass conversion reactions. ChemSusChem 9, 133–155 (2016).

Mellmer, M. A. et al. Solvent-enabled control of reactivity for liquid-phase reactions of biomass-derived compounds. Nat. Catal. 1, 199–207 (2018).

Mellmer, M. A. et al. Effects of chloride ions in acid-catalyzed biomass dehydration reactions in polar aprotic solvents. Nat. Commun. 10, 1132 (2019).

Mellmer, M. A. et al. Solvent effects in acid-catalyzed biomass conversion reactions. Angew. Chem. Int. Ed. 53, 11872–11875 (2014).

Mellmer, M. A., Alonso, D. M., Luterbacher, J. S., Gallo, J. M. R. & Dumesic, J. A. Effects of γ-valerolactone in hydrolysis of lignocellulosic biomass to monosaccharides. Green Chem. 16, 4659–4662 (2014).

Motagamwala, A. H., Won, W., Maravelias, C. T. & Dumesic, J. A. An engineered solvent system for sugar production from lignocellulosic biomass using biomass derived γ-valerolactone. Green Chem. 18, 5756–5763 (2016).

Borand, M. N. & Karaosmanoğlu, F. Effects of organosolv pretreatment conditions for lignocellulosic biomass in biorefinery applications: a review. J. Renew. Sustain. Energy 10, 033104 (2018).

Han, J., Luterbacher, J. S., Alonso, D. M., Dumesic, J. A. & Maravelias, C. T. A lignocellulosic ethanol strategy via nonenzymatic sugar production: process synthesis and analysis. Bioresour. Technol. 182, 258–266 (2015).

Alonso, D. M. et al. Increasing the revenue from lignocellulosic biomass: maximizing feedstock utilization. Sci. Adv. 3, e1603301 (2017).

Jérôme, F., Marinkovic, S. & Estrine, B. Transglycosylation: a key reaction to access alkylpolyglycosides from lignocellulosic biomass. ChemSusChem 11, 1395–1409 (2018).

Panovic, I., Lancefield, C. S., Phillips, D., Gronnow, M. J. & Westwood, N. J. Selective primary alcohol oxidation of lignin streams from butanol-pretreated agricultural waste biomass. ChemSusChem 12, 542–548 (2019).

Yu, F. et al. Fast catalytic conversion of recalcitrant cellulose into alkyl levulinates and levulinic acid in the presence of soluble and recoverable sulfonated hyperbranched poly(arylene oxindole)s. Green Chem. 19, 153–163 (2017).

Deng, W., Liu, M., Zhang, Q., Tan, X. & Wang, Y. Acid-catalysed direct transformation of cellulose into methyl glucosides in methanol at moderate temperatures. Chem. Commun. 46, 2668–2670 (2010).

Kanchanalai, P., Temani, G., Kawajiri, Y. & Realff, M. J. Reaction kinetics of concentrated-acid hydrolysis for cellulose and hemicellulose and effect of crystallinity. BioResources 11, 1672–1689 (2016).

Moe, S. T. et al. Saccharification of lignocellulosic biomass for biofuel and biorefinery applications - a renaissance for the concentrated acid hydrolysis? Energy Procedia 20, 50–58 (2012).

Cuzens, J. E. & Farone, W. A. Method of strong acid hydrolysis. US patent US5562777A (1998).

Liu, Z.-S., Wu, X.-L., Kida, K. & Tang, Y.-Q. Corn stover saccharification with concentrated sulfuric acid: Effects of saccharification conditions on sugar recovery and by-product generation. Bioresour. Technol. 119, 224–233 (2012).

Ioelovich, M. Study of cellulose interaction with concentrated solutions of sulfuric acid. Int. Sch. Res. Notices 2012, 428974 (2012).

Braconnot, H. Action de l’acide sulfurique sur la sciure de bois de charme. Ann. Chim. Phys. 12, 172–195 (1819).

Stern, A. L. X. - Contributions to the chemistry of cellulose. I. Cellulose-sulphuric acid, and the products of its hydrolysis. J. Chem. Soc. Trans. 67, 74–90 (1895).

Binder, J. B. & Raines, R. T. Fermentable sugars by chemical hydrolysis of biomass. Proc. Natl Acad. Sci. USA 107, 4516–4521 (2010).

Swatloski, R. P., Spear, S. K., Holbrey, J. D. & Rogers, R. D. Dissolution of cellose with ionic liquids. J. Am. Chem. Soc. 124, 4974–4975 (2002).

Samayam, I. P., Hanson, B. L., Langan, P. & Schall, C. A. Ionic-liquid induced changes in cellulose structure associated with enhanced biomass hydrolysis. Biomacromolecules 12, 3091–3098 (2011).

Dee, S. J. & Bell, A. T. A study of the acid-catalyzed hydrolysis of cellulose dissolved in ionic liquids and the factors influencing the dehydration of glucose and the formation of humins. ChemSusChem 4, 1166–1173 (2011).

Bergius, F. Conversion of wood to carbohydrates. Ind. Eng. Chem. 29, 247–253 (1937).

Shahbazi, A. & Zhang, B. in Bioalcohol Production (ed. Waldron, K. W.) 143–158 (Woodhead, 2010).

BlueFire Renewables. Our technology. BlueFire https://bfreinc.com/our-technology/ (2011).

van Groenestijn, J. W., Hazewinkel, J. H. O. & Bakker, R. R. Pre-treatment of ligno-cellulose with biological acid recycling (the Biosulfurol process). Int. Sugar J. 110, 689–692 (2008).

Gschwend, F. J. V., Brandt-Talbot, A., Chambon, C. L. & Hallett, J. P. in Ionic Liquids: Current State and Future Directions Vol. 1250 (eds Shiflett, M. B. & Scurto, A. M.) 209–223 (American Chemical Society, 2017).

Zhou, J. et al. Recovery and purification of ionic liquids from solutions: a review. RSC Adv. 8, 32832–32864 (2018).

Konda, N. M. et al. Understanding cost drivers and economic potential of two variants of ionic liquid pretreatment for cellulosic biofuel production. Biotechnol. Biofuels 7, 86 (2014).

Davies, G. & Henrissat, B. Structures and mechanisms of glycosyl hydrolases. Structure 3, 853–859 (1995).

Jeoh, T., Cardona, M. J., Karuna, N., Mudinoor, A. R. & Nill, J. Mechanistic kinetic models of enzymatic cellulose hydrolysis - a review. Biotechnol. Bioeng. 114, 1369–1385 (2017).

Moreira, L. R. S. & Filho, E. X. F. Insights into the mechanism of enzymatic hydrolysis of xylan. Appl. Microbiol. Biotechnol. 100, 5205–5214 (2016).

Luterbacher, J. S., Parlange, J.-Y. & Walker, L. P. A pore-hindered diffusion and reaction model can help explain the importance of pore size distribution in enzymatic hydrolysis of biomass. Biotechnol. Bioeng. 110, 127–136 (2013).

Singh, N. et al. Overview of the process of enzymatic transformation of biomass. IntechOpen https://doi.org/10.5772/intechopen.85036 (2019).

Galkin, M. V. & Samec, J. S. M. Lignin valorization through catalytic lignocellulose fractionation: a fundamental platform for the future biorefinery. ChemSusChem 9, 1544–1558 (2016).

Sun, Z., Fridrich, B., de Santi, A., Elangovan, S. & Barta, K. Bright side of lignin depolymerization: toward new platform chemicals. Chem. Rev. 118, 614–678 (2018).

Huang, X. et al. Selective production of mono-aromatics from lignocellulose over Pd/C catalyst: the influence of acid co-catalysts. Faraday Discuss. 202, 141–156 (2017).

Renders, T. et al. Catalytic lignocellulose biorefining in n-butanol/water: a one-pot approach toward phenolics, polyols, and cellulose. Green Chem. 20, 4607–4619 (2018).

De Santi, A., Galkin, M. V., Lahive, C. W., Deuss, P. J. & Barta, K. Lignin-first fractionation of softwood lignocellulose using a mild dimethyl carbonate and ethylene glycol organosolv process. ChemSusChem https://doi.org/10.1002/cssc.201903526 (2020).

Li, S., Lundquist, K. & Westermark, U. Cleavage of arylglycerol β-aryl ethers under neutral and acid conditions. Nord. Pulp Pap. Res. J. 15, 292–299 (2000).

Nimz, H. A new type of rearrangement in the lignin field. Angew. Chem. Int. Ed. 5, 843 (1966).

Kishimoto, T. & Sano, Y. Delignification mechanism during high-boiling solvent pulping. IV. Effect of a reducing sugar on the degradation of guaiacylglycerol-β-guaiacyl ether. J. Wood Chem. Technol. 23, 233–248 (2003).

Sano, Y. & Kishimoto, T. Delignification mechanism during high-boiling solvent pulping. V. Reaction of nonphenolic β-O-4 model compounds in the presence and absence of glucose. J. Wood Chem. Technol. 23, 279–292 (2003).

Omori, S., Aoyama, M. & Sakakibara, A. Hydrolysis of lignin with dioxane–water XIX. Reaction of β-O-4 lignin model compounds in the presence of carbohydrates. Holzforschung 52, 391–397 (1998).

Zijlstra, D. S. et al. Extraction of lignin with high β-O-4 content by mild ethanol extraction and its effect on the depolymerization yield. J. Vis. Exp. 143, e58575 (2019).

Jasiukaitytė-Grojzdek, E., Kunaver, M. & Crestini, C. Lignin structural changes during liquefaction in acidified ethylene glycol. J. Wood Chem. Technol. 32, 342–360 (2012).

Li, H. & Song, G. Ru-catalyzed hydrogenolysis of lignin: base-dependent tunability of monomeric phenols and mechanistic study. ACS Catal. 9, 4054–4064 (2019).

Nichols, J. M., Bishop, L. M., Bergman, R. G. & Ellman, J. A. Catalytic C–O bond cleavage of 2-aryloxy-1-arylethanols and its application to the depolymerization of lignin-related polymers. J. Am. Chem. Soc. 132, 12554–12555 (2010).

He, J., Zhao, C. & Lercher, J. A. Ni-catalyzed cleavage of aryl ethers in the aqueous phase. J. Am. Chem. Soc. 134, 20768–20775 (2012).

Jiang, L., Guo, H., Li, C., Zhou, P. & Zhang, Z. Selective cleavage of lignin and lignin model compounds without external hydrogen, catalyzed by heterogeneous nickel catalysts. Chem. Sci. 10, 4458–4468 (2019).

Anderson, E. M. et al. Differences in S/G ratio in natural poplar variants do not predict catalytic depolymerization monomer yields. Nat. Commun. 10, 2033 (2019).

Anderson, E. M., Stone, M. L., Hülsey, M. J., Beckham, G. T. & Román-Leshkov, Y. Kinetic studies of lignin solvolysis and reduction by reductive catalytic fractionation decoupled in flow-through reactors. ACS Sustain. Chem. Eng. 6, 7951–7959 (2018).

Sarkanen, K. V. & Hoo, L. H. Kinetics of hydrolysis of erythro-guaiacylglycerol β-(2-methoxyphenyl) ether and its veratryl analogue using Hc1 and aluminum chloride as catalysts. J. Wood Chem. Technol. 1, 11–27 (1981).

Li, Y. et al. Kinetic and mechanistic insights into hydrogenolysis of lignin to monomers in a continuous flow reactor. Green Chem. 21, 3561–3572 (2019).

Anderson, E. M. et al. Reductive catalytic fractionation of corn stover lignin. ACS Sustain. Chem. Eng. 4, 6940–6950 (2016).

Schutyser, W. et al. Influence of bio-based solvents on the catalytic reductive fractionation of birch wood. Green Chem. 17, 5035–5045 (2015).

Galkin, M. V. et al. Hydrogen-free catalytic fractionation of woody biomass. ChemSusChem 9, 3280–3287 (2016).

Liao, Y. et al. A sustainable wood biorefinery for low–carbon footprint chemicals production. Science 367, 1385–1390 (2020).

Guo, H. et al. Unravelling the enigma of ligninOX: can the oxidation of lignin be controlled? Chem. Sci. 9, 702–711 (2018).

Vangeel, T., Schutyser, W., Renders, T. & Sels, B. F. Perspective on lignin oxidation: advances, challenges, and future directions. Top. Curr. Chem. 376, 30 (2018).

Dawange, M., Galkin, M. V. & Samec, J. S. M. Selective aerobic benzylic alcohol oxidation of lignin model compounds: route to aryl ketones. ChemCatChem 7, 401–404 (2015).

Mottweiler, J., Rinesch, T., Besson, C., Buendia, J. & Bolm, C. Iron-catalysed oxidative cleavage of lignin and β-O-4 lignin model compounds with peroxides in DMSO. Green Chem. 17, 5001–5008 (2015).

Zhang, Z., Lahive, C. W., Zijlstra, D. S., Wang, Z. & Deuss, P. J. Sequential catalytic modification of the lignin α-ethoxylated β-O-4 motif to facilitate C–O bond cleavage by ruthenium-Xantphos catalyzed hydrogen transfer. ACS Sustain. Chem. Eng. 7, 12105–12116 (2019).

Rahimi, A., Ulbrich, A., Coon, J. J. & Stahl, S. S. Formic-acid-induced depolymerization of oxidized lignin to aromatics. Nature 515, 249–252 (2014).

Qu, S., Dang, Y., Song, C., Guo, J. & Wang, Z.-X. Depolymerization of oxidized lignin catalyzed by formic acid exploits an unconventional elimination mechanism involving 3c–4e bonding: a DFT mechanistic study. ACS Catal. 5, 6386–6396 (2015).

Zhang, C. et al. Promoting lignin depolymerization and restraining the condensation via an oxidation–hydrogenation strategy. ACS Catal. 7, 3419–3429 (2017).

Rahimi, A., Azarpira, A., Kim, H., Ralph, J. & Stahl, S. S. Chemoselective metal-free aerobic alcohol oxidation in lignin. J. Am. Chem. Soc. 135, 6415–6418 (2013).

Bosque, I., Magallanes, G., Rigoulet, M., Kärkäs, M. D. & Stephenson, C. R. J. Redox catalysis facilitates lignin depolymerization. ACS Cent. Sci. 3, 621–628 (2017).

Dabral, S., Hernández, J. G., Kamer, P. C. J. & Bolm, C. Organocatalytic chemoselective primary alcohol oxidation and subsequent cleavage of lignin model compounds and lignin. ChemSusChem 10, 2707–2713 (2017).

Lancefield, C. S., Teunissen, L. W., Weckhuysen, B. M. & Bruijnincx, P. C. A. Iridium-catalysed primary alcohol oxidation and hydrogen shuttling for the depolymerisation of lignin. Green Chem. 20, 3214–3221 (2018).

Magallanes, G. et al. Selective C–O bond cleavage of lignin systems and polymers enabled by sequential palladium-catalyzed aerobic oxidation and visible-light photoredox catalysis. ACS Catal. 9, 2252–2260 (2019).

Lancefield, C. S., Ojo, O. S., Tran, F. & Westwood, N. J. Isolation of functionalized phenolic monomers through selective oxidation and C–O bond cleavage of the β-O-4 linkages in lignin. Angew. Chem. Int. Ed. 54, 258–262 (2015).

Galkin, M. V., Dahlstrand, C. & Samec, J. S. M. Mild and robust redox-neutral Pd/C-catalyzed lignol β-O-4′ bond cleavage through a low-energy-barrier pathway. ChemSusChem 8, 2187–2192 (2015).

Li, H. et al. NH2OH-mediated lignin conversion to isoxazole and nitrile. ACS Sustain. Chem. Eng. 6, 3748–3753 (2018).

Guo, H. et al. Is oxidation–reduction a real robust strategy for lignin conversion? A comparative study on lignin and model compounds. Green Chem. 21, 803–811 (2019).

Muurinen, E. Organosolv Pulping: A Review and Distillation Study Related to Peroxyacid Pulping. Thesis, Univ. Oulu (2000).

Lancefield, C. S., Panovic, I., Deuss, P. J., Barta, K. & Westwood, N. J. Pre-treatment of lignocellulosic feedstocks using biorenewable alcohols: towards complete biomass valorisation. Green Chem. 19, 202–214 (2017).

Deuss, P. J. et al. Aromatic monomers by in situ conversion of reactive intermediates in the acid-catalyzed depolymerization of lignin. J. Am. Chem. Soc. 137, 7456–7467 (2015).

Lahive, C. W. et al. Advanced model compounds for understanding acid-catalyzed lignin depolymerization: identification of renewable aromatics and a lignin-derived solvent. J. Am. Chem. Soc. 138, 8900–8911 (2016).

Dong, C. et al. Diol pretreatment to fractionate a reactive lignin in lignocellulosic biomass biorefineries. Green Chem. 21, 2788–2800 (2019).

Zhang, C. et al. Cleavage of the lignin β-O-4 ether bond via a dehydroxylation–hydrogenation strategy over a NiMo sulfide catalyst. Green Chem. 18, 6545–6555 (2016).

Constant, S. et al. New insights into the structure and composition of technical lignins: a comparative characterisation study. Green Chem. 18, 2651–2665 (2016).

Mu, X., Han, Z., Liu, C. & Zhang, D. Mechanistic Insights into formaldehyde-blocked lignin condensation: a DFT study. J. Phys. Chem. C 123, 8640–8648 (2019).

Greene, T. W. & Wuts, P. G. M. Protective Groups in Organic Synthesis 3rd edn (Wiley, 1999).

Kaiho, A., Kogo, M., Sakai, R., Saito, K. & Watanabe, T. In situ trapping of enol intermediates with alcohol during acid-catalysed de-polymerisation of lignin in a nonpolar solvent. Green Chem. 17, 2780–2783 (2015).

Miljković, M. in Carbohydrates: Synthesis, Mechanisms, and Stereoelectronic Effects (ed. Miljkovic, M.) 143–167 (Springer, 2009).

Robyt, J. F. Essentials of Carbohydrate Chemistry (Springer, 1998).

Pétursson, S. Protecting groups in carbohydrate chemistry. J. Chem. Educ. 74, 1297–1303 (1997).

Adkins, H. & Broderick, A. E. Hemiacetal formation and the refractive indices and densities of mixtures of certain alcohols and aldehydes. J. Am. Chem. Soc. 50, 499–503 (1928).

Lewis, E. S. (ed.) Investigation of Rates and Mechanisms of Reactions. Part I. General Considerations and Reactions at Conventional Rates 3rd edn (Wiley, 1974).

Agirre, I. et al. Glycerol acetals, kinetic study of the reaction between glycerol and formaldehyde. Biomass Bioenerg. 35, 3636–3642 (2011).

Batalha, N. et al. Gasoline from biomass through refinery-friendly carbohydrate-based bio-oil produced by ketalization. ChemSusChem 7, 1627–1636 (2014).

Paszner, L. & Chang, P.-C. Organosolv delignification and saccharification process for lignocellulosic plant materials. US patent US4409032A (1983).

Chernyavskaya, N. A. Method of continuous acid hydrolysis of cellulose containing substances. Patent WO2009116885A1 (2009).

Questell-Santiago, Y. M., Yeap, J. H., Talebi Amiri, M., Le Monnier, B. P. & Luterbacher, J. S. Catalyst evolution enhances production of xylitol from acetal-stabilized xylose. ACS Sustain. Chem. Eng. 8, 1709–1714 (2020).

Anastas, P. T. & Warner, J. C. Green Chemistry: Theory and Practice (Oxford Univ. Press, 2000).

Fiorani, G., Perosa, A. & Selva, M. Dimethyl carbonate: a versatile reagent for a sustainable valorization of renewables. Green Chem. 20, 288–322 (2018).

Scott, M., Deuss, P. J., de Vries, J. G., Prechtl, M. H. G. & Barta, K. New insights into the catalytic cleavage of the lignin β-O-4 linkage in multifunctional ionic liquid media. Catal. Sci. Technol. 6, 1882–1891 (2016).

Van den Bosch, S. et al. Integrating lignin valorization and bio-ethanol production: on the role of Ni-Al2O3 catalyst pellets during lignin-first fractionation. Green Chem. 19, 3313–3326 (2017).

Ferrini, P. & Rinaldi, R. Catalytic biorefining of plant biomass to non-pyrolytic lignin bio-oil and carbohydrates through hydrogen transfer reactions. Angew. Chem. Int. Ed. 53, 8634–8639 (2014).

Sun, Z. et al. Complete lignocellulose conversion with integrated catalyst recycling yielding valuable aromatics and fuels. Nat. Catal. 1, 82–92 (2018).

Iffland, K. et al. Definition, calculation and comparison of the “biomass utilization efficiency (BUE)” of various bio-based chemicals, polymers and fuels (nova-Institut, 2015).

Pandey, M. P. & Kim, C. S. Lignin depolymerization and conversion: a review of thermochemical methods. Chem. Eng. Technol. 34, 29–41 (2011).

Koelewijn, S.-F. et al. Sustainable bisphenols from renewable softwood lignin feedstock for polycarbonates and cyanate ester resins. Green Chem. 19, 2561–2570 (2017).

Koelewijn, S.-F. et al. Promising bulk production of a potentially benign bisphenol a replacement from a hardwood lignin platform. Green Chem. 20, 1050–1058 (2018).

Feghali, E. et al. Thermosetting polymers from lignin model compounds and depolymerized lignins. Top. Curr. Chem. 376, 32 (2018).

Zhao, S. & Abu-Omar, M. M. Biobased epoxy nanocomposites derived from lignin-based monomers. Biomacromolecules 16, 2025–2031 (2015).

van de Pas, D. J. & Torr, K. M. Biobased epoxy resins from deconstructed native softwood lignin. Biomacromolecules 18, 2640–2648 (2017).

François, C. et al. Diglycidylether of iso-eugenol: a suitable lignin-derived synthon for epoxy thermoset applications. RSC Adv. 6, 68732–68738 (2016).

Kaiho, A. et al. Construction of the di(trimethylolpropane) cross linkage and the phenylnaphthalene structure coupled with selective β-O-4 bond cleavage for synthesizing lignin-based epoxy resins with a controlled glass transition temperature. Green Chem. 18, 6526–6535 (2016).

Peng, Y., Nicastro, K. H., Epps, T. H. & Wu, C. Evaluation of estrogenic activity of novel bisphenol A alternatives, four bioinspired bisguaiacol F specimens, by in vitro assays. J. Agric. Food Chem. 66, 11775–11783 (2018).

Elangovan, S. et al. From wood to tetrahydro-2-benzazepines in three waste-free steps: modular synthesis of biologically active lignin-derived scaffolds. ACS Cent. Sci. 5, 1707–1716 (2019).

Tobisu, M. & Chatani, N. in Organometallics for Green Catalysis (eds Dixneuf, P. H. & Soulé, J.-F.) 103–140 (Springer, 2019).

Deuss, P. J. & Barta, K. From models to lignin: transition metal catalysis for selective bond cleavage reactions. Coord. Chem. Rev. 306, 510–532 (2016).

Bender, T. A., Dabrowski, J. A. & Gagné, M. R. Homogeneous catalysis for the production of low-volume, high-value chemicals from biomass. Nat. Rev. Chem. 2, 35–46 (2018).

Blondiaux, E. et al. Bio-based aromatic amines from lignin-derived monomers. ACS Sustain. Chem. Eng. 7, 6906–6916 (2019).

Lie, Y., Ortiz, P., Vendamme, R., Vanbroekhoven, K. & Farmer, T. J. BioLogicTool: a simple visual tool for assisting in the logical selection of pathways from biomass to products. Ind. Eng. Chem. Res. 58, 15945–15957 (2019).

Orazov, M. & Davis, M. E. Catalysis by framework zinc in silica-based molecular sieves. Chem. Sci. 7, 2264–2274 (2016).

Song, S., Zhang, J., Gözaydın, G. & Yan, N. Production of terephthalic acid from corn stover lignin. Angew. Chem. 131, 4988–4991 (2019).

Eerhart, A. J. J. E., Faaij, A. P. C. & Patel, M. K. Replacing fossil based PET with biobased PEF; process analysis, energy and GHG balance. Energy Environ. Sci. 5, 6407–6422 (2012).

Choudhary, V., Sandler, S. I. & Vlachos, D. G. Conversion of xylose to furfural using Lewis and Brønsted acid catalysts in aqueous media. ACS Catal. 2, 2022–2028 (2012).

Rinaldi, R. & Schüth, F. Acid hydrolysis of cellulose as the entry point into biorefinery schemes. ChemSusChem 2, 1096–1107 (2009).

Tan-Soetedjo, J. N. M. et al. Experimental and kinetic modeling studies on the conversion of sucrose to levulinic acid and 5-hydroxymethylfurfural using sulfuric acid in water. Ind. Eng. Chem. Res. 56, 13228–13239 (2017).

Huang, J.-b et al. Theoretical study of bond dissociation energies for lignin model compounds. J. Fuel Chem. Technol. 43, 429–436 (2015).

Elder, T. Bond dissociation enthalpies of a pinoresinol lignin model compound. Energy Fuels 28, 1175–1182 (2014).

Younker, J. M., Beste, A. & Buchanan, A. C. Computational study of bond dissociation enthalpies for lignin model compounds: β-5 arylcoumaran. Chem. Phys. Lett. 545, 100–106 (2012).

Elder, T., Berstis, L., Beckham, G. T. & Crowley, M. F. Density functional theory study of spirodienone stereoisomers in lignin. ACS Sustain. Chem. Eng. 5, 7188–7194 (2017).

Elder, T. Bond dissociation enthalpies of a dibenzodioxocin lignin model compound. Energy Fuels 27, 4785–4790 (2013).

Dusselier, M., Mascal, M. & Sels, B. F. in Selective Catalysis for Renewable Feedstocks and Chemicals (ed. Nicholas, K. M.) 1–40 (Springer, 2014).

Acknowledgements

J.S.L. and Y.M.Q.-S. acknowledge support from the Swiss Competence Center for Energy Research: Biomass for Swiss Energy Future through the Swiss Commission for Technology and Innovation grant KTI.2014.0116, and by EPFL. K.B. and M.V.G. are grateful for financial support from the European Research Council, ERC Starting Grant 2015 (CatASus) 638076. This work is part of the research programme Talent Scheme (Vidi) with project number 723.015.005 (K.B.), which is partly financed by the Netherlands Organisation for Scientific Research (NWO).

Author information

Authors and Affiliations

Contributions

J.S.L. and K.B. designed the review. Y.M.Q.-S. and M.V.G. wrote initial drafts of the document and prepared initial figures. All authors edited the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare competing interests. J.S.L. is an inventor on European patent applications (EP16165180, EP19203000 and EP19202957) and has co-founded a spin-off company (Bloom Biorenewables) that seeks to produce lignin and sugars using methods described in this Review.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Questell-Santiago, Y.M., Galkin, M.V., Barta, K. et al. Stabilization strategies in biomass depolymerization using chemical functionalization. Nat Rev Chem 4, 311–330 (2020). https://doi.org/10.1038/s41570-020-0187-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41570-020-0187-y

This article is cited by

-

Polyamides go circular

Nature Sustainability (2024)

-

Carbon–carbon bond cleavage for a lignin refinery

Nature Chemical Engineering (2024)

-

Catalytic carbon–carbon bond cleavage in lignin via manganese–zirconium-mediated autoxidation

Nature Communications (2024)

-

Performance polyamides built on a sustainable carbohydrate core

Nature Sustainability (2024)

-

Conversion of lignocellulosic biomass-derived compounds to 2-ethylhexanol: a review

Environmental Chemistry Letters (2024)