Abstract

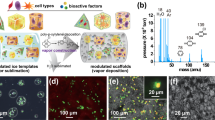

Structures that are periodic on a microscale in three dimensions are abundant in nature, for example, in the cellular arrays that make up living tissue. Such structures can also be engineered, appearing in smart materials1,2,3,4, photonic crystals5, chemical reactors6, and medical7 and biomimetic8 technologies. Here we report that fluid–fluid interfacial energy drives three-dimensional (3D) structure emergence in a micropillar scaffold. This finding offers a rapid and scalable way of transforming a simple pillar scaffold into an intricate 3D structure that is periodic on a microscale, comprising a solid microscaffold, a dispersed fluid and a continuous fluid. Structures generated with this technique exhibit a set of unique features, including a stationary internal liquid–liquid interface. Using this approach, we create structures with an internal liquid surface in a regime of interest for liquid–liquid catalysis. We also synthesize soft composites in solid, liquid and gas combinations that have previously not been shown, including actuator materials with temperature-tunable microscale pores. We further demonstrate the potential of this method for constructing 3D materials that mimic tissue with an unprecedented level of control, and for microencapsulating human cells at densities that address an unresolved challenge in cell therapy.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the plots within this paper and other findings of this study are available from the corresponding author upon reasonable request. Source data are provided with this paper.

Code availability

The code for the simulation study is available from the corresponding author upon reasonable request.

References

Schaedler, T. A. & Carter, W. B. Architected cellular materials. Annu. Rev. Mater. Res. 46, 187–210 (2016).

Schaedler, T. A. et al. Ultralight metallic microlattices. Science 334, 962–965 (2011).

Evans, A. G. et al. Concepts for enhanced energy absorption using hollow micro-lattices. Int. J. Impact Eng. 37, 947–959 (2010).

Lee, J. H., Singer, J. P. & Thomas, E. L. Micro-/nanostructured mechanical metamaterials. Adv. Mater. 24, 4782–4810 (2012).

Soukoulis, C. M. & Wegener, M. Past achievements and future challenges in the development of three-dimensional photonic metamaterials. Nat. Photon. 5, 523–530 (2011).

Hatch, A. C., Fisher, J. S., Pentoney, S. L., Yang, D. L. & Lee, A. P. Tunable 3D droplet self-assembly for ultra-high-density digital micro-reactor arrays. Lab Chip 11, 2509–2517 (2011).

McHugh, K. J. et al. Fabrication of fillable microparticles and other complex 3D microstructures. Science 357, 1138–1142 (2017).

Limmahakhun, S., Oloyede, A., Sitthiseripratip, K., Xiao, Y. & Yan, C. 3D-printed cellular structures for bone biomimetic implants. Addit. Manuf. 15, 93–101 (2017).

Whitesides, G. M. & Grzybowski, B. Self-assembly at all scales. Science 295, 2418–2421 (2002).

Yasuga, H., Kamiya, K., Takeuchi, S. & Miki, N. Self-generation of two-dimensional droplet array using oil–water immiscibility and replacement. Lab Chip 18, 1130–1137 (2018).

Pardon, G., Haraldsson, T. & van der Wijngaart, W. Simultaneous replication of hydrophilic and superhydrophobic micropatterns through area-selective monomers self-assembly. Adv. Mater. Interfaces 3, 1600404 (2016).

Decrop, D. et al. Single-step imprinting of femtoliter microwell arrays allows digital bioassays with attomolar limit of detection. ACS Appl. Mater. Interfaces 9, 10418–10426 (2017).

Weyer, F., Lismont, M., Dreesen, L. & Vandewalle, N. Compound droplet manipulations on fiber arrays. Soft Matter 11, 7086–7091 (2015).

Amselem, G., Brun, P. T., Gallaire, F. & Baroud, C. N. Breaking anchored droplets in a microfluidic Hele–Shaw cell. Phys. Rev. Appl. 3, 054006 (2015).

Vitor, M. T., Sart, S., Barizien, A., Torre, L. G. D. La & Baroud, C. N. Tracking the evolution of transiently transfected individual cells in a microfluidic platform. Sci. Rep. 8, 1225 (2018).

Yuan, R. et al. Designable 3D microshapes fabricated at the intersection of structured flow and optical fields. Small 14, 1803585 (2018).

Dendukuri, D., Hatton, T. A. & Doyle, P. S. Synthesis and self-assembly of amphiphilic polymeric microparticles. Langmuir 23, 4669–4674 (2007).

Kim, E. Two- and three-dimensional crystallization of polymeric microspheres by micromolding in capillaries. Adv. Mater. 8, 245–247 (1996).

Hansson, J., Yasuga, H., Haraldsson, T. & Van Der Wijngaart, W. Synthetic microfluidic paper: high surface area and high porosity polymer micropillar arrays. Lab Chip 16, 298–304 (2016).

Jacobsen, A. J., Barvosa-Carter, W. & Nutt, S. Micro-scale truss structures formed from self-propagating photopolymer waveguides. Adv. Mater. 19, 3892–3896 (2007).

Jacobsen, A. J., Barvosa-Carter, W. & Nutt, S. Micro-scale truss structures with three-fold and six-fold symmetry formed from self-propagating polymer waveguides. Acta Mater. 56, 2540–2548 (2008).

Song, L. et al. Facile microstructuring of organic semiconducting polymers by the breath figure method: hexagonally ordered bubble arrays in rigid-rod polymers. Adv. Mater. 16, 115–118 (2004).

Man, P. F., Mastrangelo, C. H., Burns, M. A. & Burke, D. T. Microfabricated capillarity-driven stop valve and sample injector. In Proc. IEEE Micro Electro Mechanical Systems (MEMS) 45–50 (IEEE, 1998); https://doi.org/10.1109/memsys.1998.659727

Carlborg, C. F., Haraldsson, T., Öberg, K., Malkoch, M. & Van Der Wijngaart, W. Beyond PDMS: off-stoichiometry thiol-ene (OSTE) based soft lithography for rapid prototyping of microfluidic devices. Lab Chip 11, 3136–3147 (2011).

Schwartz, H. A. Gesammelte Mathematische Abhandlungen (Springer, 1890)

Datta, S. S., Dupin, J. B. & Weitz, D. A. Fluid breakup during simultaneous two-phase flow through a three-dimensional porous medium. Phys. Fluids 26, 062004 (2014).

Garstecki, P., Stone, H. A. & Whitesides, G. M. Mechanism for flow-rate controlled breakup in confined geometries: a route to monodisperse emulsions. Phys. Rev. Lett. 94, 164501 (2005).

Takeuchi, S., Garstecki, P., Weibel, D. B. & Whitesides, G. M. An axisymmetric flow-focusing microfluidic device. Adv. Mater. 17, 1067–1072 (2005).

Kawakatsu, T., Komori, H., Nakajima, M., Kikuchi, Y. & Yonemoto, T. Production of monodispersed oil-in-water emulsion using crossflow-type silicon microchannel plate. J. Chem. Eng. Jpn 32, 241–244 (1999).

Kobayashi, I., Nakajima, M., Chun, K., Kikuchi, Y. & Fujita, H. Silicon array of elongated through-holes for monodisperse emulsion droplets. AIChE J. 48, 1639–1644 (2002).

Chiu, Y. L. et al. Synthesis of fluorosurfactants for emulsion-based biological applications. ACS Nano 8, 3913–3920 (2014).

Courtois, F. et al. Controlling the retention of small molecules in emulsion microdroplets for use in cell-based assays. Anal. Chem. 81, 3008–3016 (2009).

Bai, Y. et al. A double droplet trap system for studying mass transport across a droplet–droplet interface. Lab Chip 10, 1281–1285 (2010).

Solans, C., Morales, D. & Homs, M. Spontaneous emulsification. Curr. Opin. Colloid Interface Sci. 22, 88–93 (2016).

Villar, G., Graham, A. D. & Bayley, H. A tissue-like printed material. Science 340, 48–52 (2013).

Deamer, D. W. & Branton, D. Characterization of nucleic acids by nanopore analysis. Acc. Chem. Res. 35, 817–825 (2002).

Tsuji, Y. et al. Droplet split-and-contact method for high-throughput transmembrane electrical recording. Anal. Chem. 85, 10913–10919 (2013).

Löhr, M. et al. Microencapsulated cell-mediated treatment of inoperable pancreatic carcinoma. Lancet 357, 1591–1592 (2001).

Zhou, X. C. et al. Human cell encapsulation in gel microbeads with cosynthesized concentric nanoporous solid shells. Adv. Funct. Mater. 28, 1707129 (2018).

Headen, D. M., García, J. R. & García, A. J. Parallel droplet microfluidics for high throughput cell encapsulation and synthetic microgel generation. Microsyst. Nanoeng. 4, 1–9 (2018).

Mazloomi, M. A., Chikatamarla, S. S. & Karlin, I. V. Entropic lattice Boltzmann method for multiphase flows. Phys. Rev. Lett. 114, 174502 (2015).

Kupershtokh, A. L., Medvedev, D. A. & Karpov, D. I. On equations of state in a lattice Boltzmann method. Comput. Math. Appl. 58, 965–974 (2009).

Krüger, T. et al. The Lattice Boltzmann Method (Springer, 2017).

Chikatamarla, S. S. & Karlin, I. V. Entropic lattice Boltzmann method for turbulent flow simulations: boundary conditions. Phys. A Stat. Mech. Appl. 392, 1925–1930 (2013).

Mazloomi, M. A., Chikatamarla, S. S. & Karlin, I. V. Entropic lattice Boltzmann method for multiphase flows: fluid–solid interfaces. Phys. Rev. E 92, 023308 (2015).

Carlson, A., Do-Quang, M. & Amberg, G. Modeling of dynamic wetting far from equilibrium. Phys. Fluids 21, 1–4 (2009).

Cummings, B. S. & Schnellmann, R. G. Measurement of cell death in mammalian cells. Curr. Protoc. Pharmacol. 25, 12.8.1–12.8.22 (2004).

Acknowledgements

E.I. was funded through the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement no. 675412. H.Y. was funded through the Grant in Aid for JSPS Research Fellows (grant no. JP16J06211), the Keio University Research Grant for Young Researcher’s Program, Keio University Doctorate Student Grant-in-Aid Program and Grant for Basic Science Research Projects from The Sumitomo Foundation. X.W. was funded through the Swedish Childhood Cancer Foundation (grant no. MT2017-0024). A.H. and P.N. were funded through the Wallenberg Academy Fellows Program (grant no. KAW 2015.0178). J.S. and S. Bagheri were funded through the Knut and Alice Wallenberg Foundation (grant no. KAW 2016.0255). We thank Mercene Labs for their donation of the OSTE precursor. We thank K. Okumura, Ochanomizu University for providing a place for experiments. We thank Y. Hirata, The University of Tokyo, K. Kasahara and H. Onoe, Keio University for supporting confocal microscopy.

Author information

Authors and Affiliations

Contributions

H.Y. discovered the phenomenon of capillary trap emergence. W.v.d.W., H.Y. and E.I. performed the geometric analysis of the phenomenon. For the parametric study of the different material properties and filling conditions, H.Y., E.I. and W.v.d.W. designed the experiments, H.Y. fabricated the samples and experimental set-up and performed the measurements, and H.Y., E.I., N.M. and W.v.d.W. analysed the data. J.S. and S. Bagheri performed all fluid simulations. For the realization of all state of matter combinations of dispersed and continuous phases, H.Y., E.I., N.M. and W.v.d.W. designed the experiments and analysed the data, and H.Y. and E.I. fabricated the samples and measured their performance. For the tunable porous material, E.I., K. Kaya, G.D.D. and W.v.d.W. designed the materials and experimental set-up and analysed the results, and K. Kaya and G.D.D. fabricated the samples and measured their behaviour. For the cell microencapsulation, E.I., S. Buchmann, X.W., A.H. and W.v.d.W. designed the materials and experimental set-up, E.I. and X.W. synthesized the microcapsules, P.N., X.W. and A.H. performed the microscopy, and E.I., P.N., S. Buchmann, X.W. and A.H. analysed the data. For the DIB networks, H.Y., T.O., K. Kamiya, S.T. and N.M. designed the experiments and analysed the data, and H.Y. fabricated the samples and performed the experiments. W.v.d.W., E.I., H.Y., A.H., S. Bagheri and N.M. wrote the manuscript with input from all authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests

Additional information

Peer review information Nature Physics thanks Ana Jaklenec and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Schematic illustration of scaffolds S, S’ and S’’ and the polygon necks in their unit lattice cells.

Schematic perspective views of 3×3×3 unit lattice cells of scaffold geometries S (A), S’ (B), S’’ (C). (D) Close-up of a square cuboid unit lattice cell of scaffold S, indicated with dashed lines, containing micropillars that form polygons RP and RS, indicated with red lines. One Schwartz P minimal surface, bounded by a skewed rhomb RS, is illustrated by red shading. The white dashed lines indicate the geodesics on the Schwartz surface, and s is the saddle point at their intersection. (E) Close-up of a square cuboid unit lattice cell of scaffold S’’, indicated with dashed lines, containing micropillars that form polygons RP, SQ and T, indicated with red lines. One triangular surface, bounded by T, is illustrated by red shading.

Extended Data Fig. 2 Simulation video captions for three different states.

Blue surface is the interface between two liquids. (A) Diamond particle emerged. (Parameters: μ2 /μ1 = 1.2, cos(θ) = −0.37, Ca = 0.0068). (B) Spherical particle emerged. (Parameters: μ2 /μ1 = 1.2, cos(θ) = −0.62, Ca = 0.0068). (C) Only secondary fluid retained. (Parameters: μ2 /μ1 = 1.2, cos(θ) = −0.69, Ca = 0.0023).

Extended Data Fig. 3 Triple-phase ordered composites of gas, liquid, and solid microparticles in a gas, liquid, or solid continuous matrix inside a micropillar scaffold.

Scale bars are 1 mm.

Extended Data Fig. 4 Particles released from the scaffold.

Photographs of released blue-dyed water with an average radius of 204 ± 20 μm (sd, n=33) (A) and alginate particles with the length and the width of the gel particles as 755 ± 55 μm and 565 ± 65 μm (sd, n=50), respectively (B) and (C,D) their respective size distribution. The scale bars of (A) and (B) are 1500 µm and 500 µm, respectively.

Extended Data Fig. 5 Droplet patterning and stacking droplet arrays.

(A) Design of photomask. (B) A device for electrical measurement. (C) Procedure for DIB measurement. i) Stacking of particle arrays and arrangement of Ag/AgCl electrodes. ii) Stacked arrays of particles. iii) A photograph showing inserted electrodes. iv) Focused-on three particles in contact. v) Expected droplet interface bilayers. (D) Procedure for measurement of DIBs in series. i) Stacking of particle arrays and arrangement of Ag/AgCl electrodes. ii) Stacked arrays of particles. iii) A photograph showing 5 connected particles. iv) Focused-on three particles in contact. (E) & (F) Measured time course of current and histogram of calculated conductance for a network in (C) and (D). t0 is time when the first step and largest step was observed, respectively.

Extended Data Fig. 6 Droplet patterning and stacking particle arrays.

(A) Printing red and blue dye solution pattern into particles in an array by directly getting them into contact with a pillar array. (B) Three layers of particle arrays with differently injected samples. (C) Schematic images showing stacked two layers of a particle array and morphology of 5 contacting particles.

Supplementary information

Supplementary Information

Supplementary Materials, methods and experimental details, Text, Figs. 1–8, Tables 1–8 and captions for Supplementary Videos 1–5.

Supplementary Video 1

Top-view video of the fluid–fluid interfacial energy driven 3D structure emergence in a microscaffold (FLUID3EAMS), forming a droplet array with 1 mm periodicity of alginate-gel precursor solution of glycerol (blue dyed) in mineral oil with 1 mg ml−1 Span 80 (transparent).

Supplementary Video 2

Side-view video of the fluid–fluid interfacial energy driven 3D structure emergence in a microscaffold (FLUID3EAMS), forming a 3D droplet array with 1 mm lateral periodicity of 50% aqueous solution of glycerol (blue dyed) in mineral oil with 1 mg ml−1 Span 80 (transparent).

Supplementary Video 3

Animation videos for the fluid–fluid interfacial energy driven 3D structure emergence in a microscaffold (FLUID3EAMS) under three different fluidic conditions: 1, diamond-shaped particle is created (parameters: μ2/μ1 = 1.2, cos(θ) = −0.37, Ca = 0.0068); 2, spherical particle (parameters: μ2/μ1 = 1.2, cos(θ) = −0.62, Ca = 0.0068); 3, only secondary fluid retained (parameters: μ2/μ1 = 1.2, cos(θ) = −0.69, Ca = 0.0023). Blue surface in the video is the interface between primary and secondary liquid.

Supplementary Video 4

Perspective-view video of droplets release by lateral flow diagonal to the lattice of the scaffold.

Supplementary Video 5

Top-view video of printing pattern of colored dye solutions into a droplet array by directly getting droplets into contact with a pillar in which a tiny amount of dye solution is adhered.

Source data

Source Data Fig. 2

Numerical data of experiments and simulations in 3D plot.

Source Data Fig. 3

Numerical data obtained from electrical measurements for Fig. 3b, top.

Source Data Extended Data Fig. 4

Numerical data obtained from dimension measurements for Extended Data Figs. 4c,d.

Source Data Extended Data Fig. 5

Numerical data obtained from electrical measurements for Extended Data Fig. 5e.

Source Data Extended Data Fig. 5

Numerical data obtained from electrical measurements for Extended Data Fig. 5f.

Rights and permissions

About this article

Cite this article

Yasuga, H., Iseri, E., Wei, X. et al. Fluid interfacial energy drives the emergence of three-dimensional periodic structures in micropillar scaffolds. Nat. Phys. 17, 794–800 (2021). https://doi.org/10.1038/s41567-021-01204-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41567-021-01204-4

This article is cited by

-

Reconfigurable liquid devices from liquid building blocks

Nature Chemical Engineering (2024)

-

Endless forms fabricated

Nature Physics (2021)