Abstract

The integration of various two-dimensional (2D) materials on wafers enables a more-than-Moore approach for enriching the functionalities of devices1,2,3. On the other hand, the additive growth of 2D materials to form heterostructures allows construction of materials with unconventional properties. Both may be achieved by materials transfer, but often suffer from mechanical damage or chemical contamination during the transfer. The direct growth of high-quality 2D materials generally requires high temperatures, hampering the additive growth or monolithic incorporation of different 2D materials. Here we report a general approach of growing crystalline 2D layers and their heterostructures at a temperature below 400 °C. Metal iodide (MI, where M = In, Cd, Cu, Co, Fe, Pb, Sn and Bi) layers are epitaxially grown on mica, MoS2 or WS2 at a low temperature, and the subsequent low-barrier-energy substitution of iodine with chalcogens enables the conversion to at least 17 different 2D crystalline metal chalcogenides. As an example, the 2D In2S3 grown on MoS2 at 280 °C exhibits high photoresponsivity comparable with that of the materials grown by conventional high-temperature vapour deposition (~700–1,000 °C). Multiple 2D materials have also been sequentially grown on the same wafer, showing a promising solution for the monolithic integration of different high-quality 2D materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Additional data related to this paper are available from the corresponding authors upon reasonable request.

References

Badaroglu, M. et al. More Moore. In 2021 IEEE International Roadmap for Devices and Systems Outbriefs 1–38 (IEEE, 2020).

Liu, Y. et al. Promises and prospects of two-dimensional transistors. Nature 591, 43–53 (2021).

Li, M.-Y., Su, S.-K., Wong, H.-S. P. & Li, L.-J. How 2D semiconductors could extend Moore’s law. Nature 567, 169–170 (2019).

Akinwande, D. et al. Graphene and two-dimensional materials for silicon technology. Nature 573, 507–518 (2019).

Chen, S. et al. Wafer-scale integration of two-dimensional materials in high-density memristive crossbar arrays for artificial neural networks. Nat. Electron. 3, 638–645 (2020).

Liu, C. et al. Two-dimensional materials for next-generation computing technologies. Nat. Nanotechnol. 15, 545–557 (2020).

Rogée, L. et al. Ferroelectricity in untwisted heterobilayers of transition metal dichalcogenides. Science 376, 973–978 (2022).

Migliato Marega, G. et al. Logic-in-memory based on an atomically thin semiconductor. Nature 587, 72–77 (2020).

Zhu, K. et al. The development of integrated circuits based on two-dimensional materials. Nat. Electron. 4, 775–785 (2021).

Liu, C. et al. A semi-floating gate memory based on van der Waals heterostructures for quasi-non-volatile applications. Nat. Nanotechnol. 13, 404–410 (2018).

Jiang, J. et al. Rational design of Al2O3/2D perovskite heterostructure dielectric for high performance MoS2 phototransistors. Nat. Commun. 11, 4266 (2020).

Meng, W. et al. Three-dimensional monolithic micro-LED display driven by atomically thin transistor matrix. Nat. Nanotechnol. 16, 1231–1236 (2021).

Wu, L. et al. Atomically sharp interface enabled ultrahigh-speed non-volatile memory devices. Nat. Nanotechnol. 16, 882–887 (2021).

Hwangbo, S., Hu, L., Hoang, A. T., Choi, J. Y. & Ahn, J.-H. Wafer-scale monolithic integration of full-colour micro-LED display using MoS2 transistor. Nat. Nanotechnol. 17, 500–506 (2022).

Li, N. et al. Large-scale flexible and transparent electronics based on monolayer molybdenum disulfide field-effect transistors. Nat. Electron. 3, 711–717 (2020).

Du, Z. et al. Conversion of non-van der Waals solids to 2D transition-metal chalcogenides. Nature 577, 492–496 (2020).

Wang, J. et al. Dual-coupling-guided epitaxial growth of wafer-scale single-crystal WS2 monolayer on vicinal a-plane sapphire. Nat. Nanotechnol. 17, 33–38 (2022).

Zhou, J. et al. A library of atomically thin metal chalcogenides. Nature 556, 355–359 (2018).

Kang, K. et al. High-mobility three-atom-thick semiconducting films with wafer-scale homogeneity. Nature 520, 656–660 (2015).

Choi, S. H. et al. Large-scale synthesis of graphene and other 2D materials towards industrialization. Nat. Commun. 13, 1484 (2022).

Jiang, J., Parto, K., Cao, W. & Banerjee, K. Ultimate monolithic-3D integration with 2D materials: rationale, prospects, and challenges. IEEE J. Electron Devices Soc. 7, 878–887 (2019).

Batude, P. et al. 3D sequential integration: application-driven technological achievements and guidelines. In 2017 IEEE International Electron Devices Meeting (IEDM) 3.1.1–3.1.4 (IEEE, 2017).

Das, S. et al. Transistors based on two-dimensional materials for future integrated circuits. Nat. Electron. 4, 786–799 (2021).

Cao, Y. et al. Unconventional superconductivity in magic-angle graphene superlattices. Nature 556, 43–50 (2018).

Frolov, S. M., Manfra, M. J. & Sau, J. D. Topological superconductivity in hybrid devices. Nat. Phys. 16, 718–724 (2020).

Regan, E. C. et al. Mott and generalized Wigner crystal states in WSe2/WS2 moiré superlattices. Nature 579, 359–363 (2020).

Tong, Q. et al. Topological mosaics in moiré superlattices of van der Waals heterobilayers. Nat. Phys. 13, 356–362 (2017).

Zhao, C. et al. Enhanced valley splitting in monolayer WSe2 due to magnetic exchange field. Nat. Nanotechnol. 12, 757–762 (2017).

Norden, T. et al. Giant valley splitting in monolayer WS2 by magnetic proximity effect. Nat. Commun. 10, 4163 (2019).

Tran, K. et al. Evidence for moiré excitons in van der Waals heterostructures. Nature 567, 71–75 (2019).

Andrei, E. Y. et al. The marvels of moiré materials. Nat. Rev. Mater. 6, 201–206 (2021).

Zhang, K. et al. Visualizing van der Waals epitaxial growth of 2D heterostructures. Adv. Mater. 33, 2105079 (2021).

Niu, L. et al. Van der Waals template-assisted low-temperature epitaxial growth of 2D atomic crystals. Adv. Funct. Mater. 32, 2202580 (2022).

Li, J. et al. General synthesis of two-dimensional van der Waals heterostructure arrays. Nature 579, 368–374 (2020).

Liu, Y., Huang, Y. & Duan, X. Van der Waals integration before and beyond two-dimensional materials. Nature 567, 323–333 (2019).

Bian, M. et al. Dative epitaxy of commensurate monocrystalline covalent van der Waals moiré supercrystal. Adv. Mater. 34, 2200117 (2022).

Yun, S. J. et al. Telluriding monolayer MoS2 and WS2 via alkali metal scooter. Nat. Commun. 8, 2163 (2017).

Guo, Y. et al. Designing artificial two-dimensional landscapes via atomic-layer substitution. Proc. Natl Acad. Sci. USA 118, e2106124118 (2021).

Acknowledgements

This research was supported by the National Natural Science Foundation of China (52002080, 51920105004, 52072272). Z. Luo acknowledges support from the RGC (16304421), Research Fund of Guangdong-Hong Kong-Macao Joint Laboratory for Intelligent Micro-Nano Optoelectronic Technology (no. 2020B1212030010) and Shenzhen Special Fund for Central Guiding the Local Science and Technology Development (2021Szvup136). We thank K.-L. Xu, Sichuan University, and S.-Y. Wu, University of Electronic Science and Technology of China, for their help with the Vienna ab initio simulation package and Materials Studio calculations. L.-J.L. acknowledges support from the Jockey Club Hong Kong to the JC STEM lab of 3DIC, and the Research Grant of Council of Hong Kong (CRS_PolyU502/22).

Author information

Authors and Affiliations

Contributions

K.Z., L.Z. and S.H. designed the research. Y.S., M.Z. and K.Z. synthesized the materials and performed the OM, AFM, XRD and Raman characterizations; device fabrication; and electrical measurements. X.C. performed the planar and cross-sectional HAADF–STEM characterizations. C.D. carried out the theoretical calculations. Z. Liu, Y.S., M.Z. and H.L. performed the TEM characterizations. W.Z. and J.M. performed the photodetection imaging measurements. L.-J.L. provided the large-area TMD films. Z. Luo and S.H. contributed to the data analysis. K.Z. and L.-J.L. drafted and revised the manuscript with input from all the authors. All the authors discussed the results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Nanotechnology thanks Feng Ding, Jiangtao Wang, Hao Zeng and Zhengwei Zhang for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

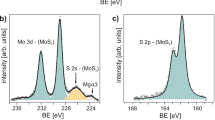

Extended Data Fig. 1 Synthesis of 2D MCs.

(a) Schematic illustration of the growth of 2D MCs. (b) Time vs temperature profile for the growth of 2D MCs. A quartz boat containing MIs powders was placed in the centre of a tube furnace. The TMD (WS2 or MoS2) substrates were placed near the MIs precursors (or face down cover the MIs assisted by a holder). Another quartz boat containing S (Se or Te) powder was placed in the upstream side of the tube furnace. Argon was used as the carrier gas. Firstly, the furnace was heated to the growth temperature (T1) and held at that temperature for the growth of 2D MIs. Then, the furnace was cooled down to substitution temperature (T2), and the boat with S (Se or Te) was pushed into the hot zone, while then the boat with MIs precursor powders was pulled out of the hot zone. After the substitution reaction, the furnace was naturally cooled down to room temperature under the Ar atmosphere. Detailed synthetic recipes and reaction conditions are summarized in Extended Data Fig. 3.

Extended Data Fig. 2 AFM images of 2D In2S3 grown on WS2.

(a-e) The AFM images of 2D-In2S3 crystals with different thicknesses grown on monolayer WS2 substrates. (f-g) The statistical histograms of the In2S3 nanoflakes thickness (measured on 50*50 μm2 WS2 templates). The thickness of In2S3 crystals can be controlled by tuning of the evaporation of InI sources. For the growth of 1 nm In2S3, 10 mg InI was used as the precursor. The growth temperature of 280 °C was held for 6 min under 60 sccm Ar. The thickness of In2S3 flakes increases with more InI precursors in the growth process. For the growth of 2–4 nm In2S3, 15–25 mg InI sources and 55-15 sccm Ar were used for growth 8 min. For the growth of more than 10 nm of In2S3, 30 mg InI sources and 20 sccm Ar were used to maintain 10 min in the growth process. The panels f-g show the static distribution of In2S3 nanoflakes thickness in two growth conditions (measured on 50*50 μm2 TMD templates). The statistical results of MC nanoflakes suggest that the thickness of MC can be modulated by adjusting the deposition parameters.

Extended Data Fig. 3 Detailed reaction conditions in our experiments.

Eight MIs powders were used as metallic compound precursors. They can be vaporized below melting points. Then, the deposited 2D MIs flakes will transform to 2D MCs in the environments with heated chalcogen (S, Se and Te) vapour. The blue color represents a layered structure, and the purple color represents a non-layered structure. The CH3NH3PbI3 perovskites were obtained by replacing the chalcogen resource with CH3NH3PbI3 by using the same low-temperature strategy. It is noticed that many difficulties exist in the I-to-Te conversion due to the higher melting point of tellurium powder and the lower activity of Te atoms with metals compared to sulfur or selenium atoms. Therefore, most of the tellurides were not successfully synthesized using this approach. Although the SnTe and Bi2Te3 were successfully synthesized, they need more reaction time than sulfurization and selenization. In addition, the 2D crystal morphology of converted PbS cannot be preserved from PbI2 precursors. We believe the quickly centralized release of strain easily leads to broken PbS. Thus, we think the epitaxial substitution is unsuitable for synthesizing 2D PbS.

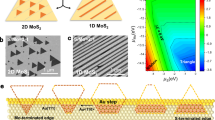

Extended Data Fig. 4 Epitaxial relationship of SnI2/WS2, SnS2/WS2 and SnTe/WS2.

The statistical histograms of the twist angles and representative SAED patterns for SnI2/WS2 (a, b), SnS2/WS2 (c, d) and SnTe/WS2 (e, f), respectively. Scale bars, 3 nm−1. (30 samples were measured for each group). The statistical results of SAED showed that the preferred orientation alignment of layered hexagonal SnI2 (100) and SnS2 (100) on the WS2 (100) templates is observed. However, the non-layered cubic SnTe leads to the loss of orientational alignment to WS2.

Extended Data Fig. 5 The calculated exchange energy barriers for 16 kinds substitutional reactions.

The calculations indicate that a barrier smaller than 0.5 eV is required for the 16 kinds of direct substitution of I by chalcogen atoms (S, Se or Te) in perfect MI lattices.

Extended Data Fig. 6 Detailed DFT studies of the nucleation of SnS2 in SnI2.

(a-c) Geometry optimization of the nucleation process of SnS2 at the I vacancy site in SnI2. (d, e) Energy barriers for S substitution at I sites around inserted S atom and SnS2 nucleus, respectively. After the insertion of the first S atom, the exchange energy barrier of the nearest I atoms is reduced from 0.4 eV to 0.276 eV (marked blue in panel d) and 0.294 eV (marked red in panel d), which indicates the SnS2 nuclei could be formed through the continuous substituted reaction in the enrichment of S precursors. In panel e, the substitutional energy barrier of the I atoms around the SnS2 nucleus is reduced to 0.217 eV from 0.4 eV. The lower substitutional energy barriers indicated the thermodynamic conversion process would gradually proceed toward around the SnS2 nucleus.

Extended Data Fig. 7 HAADF–STEM images of the underlying TMD templates in MCs/TMD heterostructures.

Schematic illustration of individual TMD (a), MCs/TMD heterostructures before (b) and after (c) sliding MCs by AFM. OM images of individual monolayer WS2 (d), MC/TMD heterostructures before (e) and after (f) sliding the MC by AFM. In-situ AFM images of MC/TMD heterostructures before (g) and after (h) sliding the MC. The area marked in panel h is corresponding to the location in panel g. (i) STEM image of individual monolayer WS2. (j) STEM image of In2S3/WS2 after sliding away the MCs by AFM. The enlargement of the highlighted area is shown in Fig. 3b. (k) STEM image of SnSe2/WS2 after sliding away the SnSe2 by AFM. (l) Enlargement of the monolayer WS2 area marked in panel i. The underlying TMD templates were exposed by sliding the MCs by AFM. The HAADF–STEM images of individual monolayer WS2 (i), underlying monolayer WS2 in In2S3/WS2 (Fig. 3b) and SnSe2/WS2 (l) show the perfect WS2 crystal structure (Fig. 3c). The grown MCs domains usually with varying shapes on TMD templates due to the kinetically controlled MIs domain shape at low temperatures.

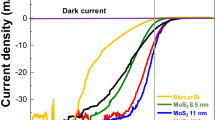

Extended Data Fig. 8 Schematic of reflection 2D passive scanning imaging system.

A scanning imaging system (a) and bridge structured detector with integrating pre-amplifier (b). The imaging system consists of a scanning swing planar mirror, a concave mirror, a preamplifier, and the imaging control module. The visible to near infrared light enters the optical system beam from about 100 cm away. The hexagonal two-dimensional scanning swing mirror sized about 800 cm2 has a Φ 30 mm circular hole in the center to allow the focused light to pass through. The aperture and the focal length of the concave mirror are both 250 mm. The position of the detector can be adjusted by using the linear XYZ platform which is located behind the scanning swing mirror. The focused light can be reflected by the swing mirror and the concave mirror before the detector finally receives it. A bridge structured detector and the integrating pre-amplifier are shown in panel b. The electrical signal of the photodetector can be read and amplified by the pre-amplifier and output to the imaging control module. By controlling the two-dimensional swing of the scanning mirror, the radiation signals at different positions of the target can be detected. The total imaging time is estimated to be about 600 seconds for the scanning of 128*128 = 16384 pixels.

Extended Data Fig. 9 Single-pixel visible and infrared imaging measurement.

(a, d; b, e) Optical photograph of front and side view of two imaging scenes. (c, f) Results of two imaging operating at room temperature, corresponding to the scenes a and d, respectively. The incandescent lamp is used as the infrared radiation source (broad emission ranges from visible to near-infrared), and the LED surface light source with a university logo is used as the visible light radiation source. The target is imaged by the two-dimensional scanning imaging device. The band of incident light can be changed by setting visible light filter (850 nm high pass). In the first test scene, the incandescent lamp and LED were imaged at the same time, where the images of the both are very legible. (panel c). In the second test scene, the incandescent lamp was covered with a visible light filter, only the near-infrared (λ ≥ 850 nm) light can pass the filter. The imaging of the logo (visible) and the incandescent lamp that filters out the visible light were also both realized (panel f). The results indicated that the response wave band of the detector covers both visible and near infrared.

Extended Data Fig. 10 OM images and Raman (PL) mapping of MCs arrays.

(a) High-magnification OM images, Raman (peak with 384 cm−1) and PL (peak with 670 nm) intensity mapping of 4 × 4 MoS2. OM images and Raman intensity mapping of 4 × 4 SnS2/MoS2 (b), CdSe/MoS2 (c), In2S3/MoS2 (d), SnSe2/MoS2 (e), and CH3NH3PbI3/MoS2 (f) arrays with resonant peaks at 384 cm−1 (MoS2), 312 cm−1 (SnS2), 201 cm−1 (CdSe), 308 cm−1 (In2S3), 186 cm−1 (SnSe2) and 110 cm−1 (CH3NH3PbI3) respectively. Scale bars, 20 μm.

Supplementary information

Supplementary Information

Supplementary Figs. 1–32, Tables 1–3 and references.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, K., She, Y., Cai, X. et al. Epitaxial substitution of metal iodides for low-temperature growth of two-dimensional metal chalcogenides. Nat. Nanotechnol. 18, 448–455 (2023). https://doi.org/10.1038/s41565-023-01326-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41565-023-01326-1

This article is cited by

-

Synthesis and Modulation of Low-Dimensional Transition Metal Chalcogenide Materials via Atomic Substitution

Nano-Micro Letters (2024)

-

Moore must go on

Nature Nanotechnology (2023)

-

Direct synthesis of MoS2 films on flexible substrates at low temperature

Nature Nanotechnology (2023)

-

Low-temperature growth of MoS2 on polymer and thin glass substrates for flexible electronics

Nature Nanotechnology (2023)

-

Vapour-phase deposition of two-dimensional layered chalcogenides

Nature Reviews Materials (2023)