Abstract

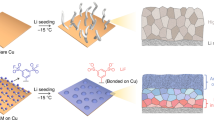

Rechargeable Li-metal batteries using high-voltage cathodes can deliver the highest possible energy densities among all electrochemistries. However, the notorious reactivity of metallic lithium as well as the catalytic nature of high-voltage cathode materials largely prevents their practical application. Here, we report a non-flammable fluorinated electrolyte that supports the most aggressive and high-voltage cathodes in a Li-metal battery. Our battery shows high cycling stability, as evidenced by the efficiencies for Li-metal plating/stripping (99.2%) for a 5 V cathode LiCoPO4 (~99.81%) and a Ni-rich LiNi0.8Mn0.1Co0.1O2 cathode (~99.93%). At a loading of 2.0 mAh cm−2, our full cells retain ~93% of their original capacities after 1,000 cycles. Surface analyses and quantum chemistry calculations show that stabilization of these aggressive chemistries at extreme potentials is due to the formation of a several-nanometre-thick fluorinated interphase.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Change history

04 October 2018

In the version of this Article originally published, in the first paragraph of the Methods, HFE was incorrectly given as 2,2,2-Trifluoroethyl-3ʹ,3ʹ,3ʹ,2ʹ,2ʹ-pentafluoropropyl ether; it should have been 1,1,2,2-tetrafluoroethyl-2ʹ,2ʹ,2ʹ-trifluoroethyl ether. This has now been corrected in the online versions of the Article.

References

Armand, M. & Tarascon, J. M. Building better batteries. Nature 451, 652–657 (2008).

Dunn, B., Kamath, H. & Tarascon, J. M. Electrical energy storage for the grid: a battery of choices. Science 334, 928–935 (2011).

Etacheri, V., Marom, R., Elazari, R., Salitra, G. & Aurbach, D. Challenges in the development of advanced Li-ion batteries: a review. Energy Environ. Sci. 4, 3243–3262 (2011).

Choi, J. W. & Aurbach, D. Promise and reality of post-lithium-ion batteries with high energy densities. Nat. Rev. Mater. 1, 16013 (2016).

Goodenough, J. B. & Kim, Y. Challenges for rechargeable Li batteries. Chem. Mater. 22, 587–603 (2009).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotech. 12, 194–206 (2017).

Lu, Y., Tu, Z. & Archer, L. A. Stable lithium electrodeposition in liquid and nanoporous solid electrolytes. Nat. Mater. 13, 961–969 (2014).

Choudhury, S., Mangal, R., Agrawal, A. & Archer, L. A. A highly reversible room-temperature lithium metal battery based on crosslinked hairy nanoparticles. Nat. Commun. 6, 10101 (2015).

Aurbach, D., Zinigrad, E., Cohen, Y. & Teller, H. A short review of failure mechanisms of lithium metal and lithiated graphite anodes in liquid electrolyte solutions. Solid State Ion. 148, 405–416 (2002).

Ding, F. et al. Effects of carbonate solvents and lithium salts on morphology and Coulombic efficiency of lithium electrode. J. Electrochem. Soc. 160, A1894–A1901 (2013).

Jeong, S. K. et al. Suppression of dendritic lithium formation by using concentrated electrolyte solutions. Electrochem. Commun. 10, 635–638 (2008).

Xu, W. et al. Lithium metal anodes for rechargeable batteries. Energy Environ. Sci. 7, 513–537 (2014).

Xu, K. Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 104, 4303–4418 (2004).

Li, W. et al. The synergetic effect of lithium polysulfide and lithium nitrate to prevent lithium dendrite growth. Nat. Commun. 6, 7436 (2015).

Xu, K. Electrolytes and interphases in Li-ion batteries and beyond. Chem. Rev. 114, 11503–11618 (2014).

Qian, J. et al. High rate and stable cycling of lithium metal anode. Nat. Commun. 6, 6362 (2015).

Cheng, X. B. et al. Dendrite-free lithium deposition induced by uniformly distributed lithium-ions for efficient lithium metal batteries. Adv. Mater. 28, 2888–2895 (2016).

Erickson, E. M. et al. Review—development of advanced rechargeable batteries: a continuous challenge in the choice of suitable electrolyte solutions. J. Electrochem. Soc. 162, A2424–A2438 (2015).

Li, J., Downie, L. E., Ma, L., Qiu, W. & Dahn, J. R. Study of the failure mechanisms of LiNi0.8Mn0.1Co0.1O2 cathode material for lithium ion batteries. J. Electrochem. Soc. 162, A1401–A1408 (2015).

Ma, J., Hu, P., Cui, G. & Chen, L. Surface and interface issues in spinel LiNi0.5Mn1.5O4: insights into a potential cathode material for high energy density lithium ion batteries. Chem. Mater. 28, 3578–3606 (2016).

Arumugam, R. S. et al. Special synergy between electrolyte additives and positive electrode surface coating to enhance the performance of Li[Ni0.6Mn0.2Co0.2]O2/graphite cells. J. Electrochem. Soc. 163, A2531–A2538 (2016).

Bramnik, N. N., Nikolowski, K., Baehtz, C. K., Bramnik, G. & Ehrenberg, H. Phase transitions occurring upon lithium insertion–extraction of LiCoPO4. Chem. Mater. 19, 908–915 (2007).

Duncan, H., Abu-Lebdeh, Y. & Davidson, I. J. Study of the cathode–electrolyte interface of LiMn1.5Ni0.5O4 synthesized by a sol–gel method for Li-ion batteries. J. Electrochem. Soc. 157, A528–A535 (2010).

Zhang, X. Q., Cheng, X. B., Chen, X., Yan, C. & Zhang, Q. Fluoroethylene carbonate additives to render uniform Li deposits in lithium metal batteries. Adv. Funct. Mater. 27, 1605989 (2017).

Fan, X. et al. Highly fluorinated interphases enable high-voltage Li-metal batteries. Chem 4, 174–185 (2018).

Suo, L. et al. Fluorine-donating electrolytes enable highly reversible 5-V-class Li metal batteries. Proc. Natl Acad. Sci. USA 115, 1156–1161 (2018).

Wang, J. et al. Fire-extinguishing organic electrolytes for safe batteries. Nat. Energy 3, 22–29 (2018).

Zhang, Z. et al. Fluorinated electrolytes for 5 V lithium-ion battery chemistry. Energy Environ. Sci. 6, 1806–1810 (2013).

Xia, J. et al. Fluorinated electrolyte for 4.5 V Li(Ni0.4Mn0.4Co0.2)O2/graphite Li-ion cells. J. Power Sources 307, 340–350 (2016).

Li, J. et al. The impact of electrolyte additives and upper cut-off voltage on the formation of a rocksalt surface layer in LiNi0.8Mn0.1Co0.1O2 electrodes. J. Electrochem. Soc. 164, A655–A665 (2017).

Liu, W. et al. Nickel-rich layered lithium transition-metal oxide for high-energy lithium-ion batteries. Angew. Chem. Int. Ed. 54, 4440–4457 (2015).

Myung, S. T. et al. Nickel-rich layered cathode materials for automotive lithium-ion batteries: achievements and perspectives. ACS Energy Lett. 2, 196–223 (2017).

Wolfenstine, J., Lee, U., Poese, B. & Allen, J. L. Effect of oxygen partial pressure on the discharge capacity of LiCoPO4. J. Power Sources 144, 226–230 (2005).

Liu, J. et al. Spherical nanoporous LiCoPO4/C composites as high performance cathode materials for rechargeable lithium-ion batteries. J. Mater. Chem. 21, 9984–9987 (2011).

Sharabi, R. et al. Electrolyte solution for the improved cycling performance of LiCoPO4/C composite cathodes. Electrochem. Commun. 28, 20–23 (2013).

Leung, K., Soto, F., Hankins, K., Balbuena, P. B. & Harrison, K. L. Stability of solid electrolyte interphase components on lithium metal and reactive anode material surfaces. J. Phys. Chem. C 120, 6302–6313 (2016).

Tasaki, K. et al. Solubility of lithium salts formed on the lithium-ion battery negative electrode surface in organic solvents. J. Electrochem. Soc. 156, A1019–A1027 (2009).

Cheng, X. B. et al. A review of solid electrolyte interphases on lithium metal anode. Adv. Sci. 3, 1500213 (2015).

Markevich, E., Salitra, G., Chesneau, F., Schmidt, M. & Aurbach, D. Very stable lithium metal stripping–plating at a high rate and high areal capacity in fluoroethylene carbonate-based organic electrolyte solution. ACS Energy Lett. 2, 1321–1326 (2017).

Zhang, Q. et al. Synergetic effects of inorganic components in solid electrolyte interphase on high cycle efficiency of lithium ion batteries. Nano Lett. 16, 2011–2016 (2016).

Leung, K. Electronic structure modeling of electrochemical reactions at electrode/electrolyte interfaces in lithium ion batteries. J. Phys. Chem. C 117, 1539–1547 (2013).

Liu, Z. et al. Interfacial study on solid electrolyte interphase at Li metal anode: implication for Li dendrite growth. J. Electrochem. Soc. 163, A592–A598 (2016).

Borodin, O., Olguin, M., Spear, C. E., Leiter, K. & Knap, J. Towards high throughput screening of electrochemical stability of battery electrolytes. Nanotechnology 26, 354003 (2015).

Kumar, N., Leung, K. & Siegel, D. J. Crystal surface and state of charge dependencies of electrolyte decomposition on LiMn2O4 cathode. J. Electrochem. Soc. 161, E3059–E3065 (2014).

Giordano, L. et al. Chemical reactivity descriptor for the oxide–electrolyte interface in Li-ion batteries. J. Phys. Chem. Lett. 8, 3881–3887 (2017).

Leung, K. First-principles modeling of Mn(ii) migration above and dissolution from LixMn2O4 (001) surfaces. Chem. Mater. 29, 2550–2562 (2017).

Xu, K., Zhang, S., Allen, J. L. & Jow, T. R. Nonflammable electrolytes for Li-ion batteries based on a fluorinated phosphate. J. Electrochem. Soc. 149, A1079–A1082 (2002).

Nagasubramanian, G. & Orendorff, C. J. Hydrofluoroether electrolytes for lithium-ion batteries: reduced gas decomposition and nonflammable. J. Power Sources 196, 8604–8609 (2011).

Sun, Y. K. et al. Nanostructured high-energy cathode materials for advanced lithium batteries. Nat. Mater. 11, 942–947 (2012).

Delp, S. A. et al. Importance of reduction and oxidation stability of high voltage electrolytes and additives. Electrochim. Acta 209, 498–510 (2016).

Allen, J. L., Jow, T. R. & Wolfenstine, J. Improved cycle life of Fe-substituted LiCoPO4. J. Power Sources 196, 8656–8661 (2011).

Frisch, M. J. et al. Gaussian 09, Revision C (Gaussian, Inc., 2010).

Borodin, O., Behl, W. & Jow, T. R. Oxidative stability and initial decomposition reactions of carbonate, sulfone, and alkyl phosphate-based electrolytes. J. Phys. Chem. C 117, 8661–8682 (2013).

Borodin, O. in Electrolytes for Lithium and Lithium-Ion Batteries Vol. 58 (eds Jow, T. R. et al.) Ch. 8 (Springer, New York, NY, 2014).

Gomer, R. & Tryson, G. An experimental determination of absolute half-cell emf’s and single ion free energies of solvation. J. Chem. Phys. 66, 4413–4424 (1977).

Trasatti, S. The absolute electrode potential—an explanatory note (Recommendations 1986). Pure Appl. Chem. 58, 955–966 (1986).

Lin, C. Y., Hodgson, J. L., Namazian, M. & Coote, M. L. Comparison of G3 and G4 theories for radical addition and abstraction reactions. J. Phys. Chem. A 113, 3690–3697 (2009).

Curtiss, L. A., Redfern, P. C. & Raghavachari, K. G n theory. WIRES Comput. Mol. Sci. 1, 810–825 (2011).

Zhao, Y. & Truhlar, D. G. The M06 suite of density functionals for main group thermochemistry, thermochemical kinetics, noncovalent interactions, excited states, and transition elements: two new functionals and systematic testing of four M06-class functionals and 12 other functionals. Theor. Chem. Acc. 120, 215–241 (2008).

Barnes, T. A., Kaminski, J. W., Borodin, O. & Miller, T. F. Ab initio characterization of the electrochemical stability and solvation properties of condensed-phase ethylene carbonate and dimethyl carbonate mixtures. J. Phys. Chem. C 119, 3865–3880 (2015).

Marenich, A. V., Cramer, C. J. & Truhlar, D. G. Universal solvation model based on solute electron density and on a continuum model of the solvent defined by the bulk dielectric constant and atomic surface tensions. J. Phys. Chem. B 113, 6378–6396 (2009).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Furthmuller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Paier, J., Marsman, M. & Kresse, G. Why does the B3LYP hybrid functional fail for metals?. J. Chem. Phys. 127, 024103 (2007).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple (vol. 77, p. 3865, 1996). Phys. Rev. Lett. 78, 1396–1396 (1997).

Johannes, M., Hoang, D. K., Allen, J. L. & Gaskell, K. Hole polaron formation and migration in olivine phosphate materials. Phys. Rev. B 85, 115106 (2012).

Zhou, F., Cococcioni, M., Marianetti, C. A., Morgan, D. & Ceder, G. First-principles prediction of redox potentials in transition-metal compounds with LDA+U. Phys. Rev. B 70, 235121 (2004).

Wang, L., Zhou, F., Meng, Y. S. & Ceder, G. First-principles study of surface properties of LiFePO4: surface energy, structure, Wulff shape, and surface redox potential. Phys. Rev. B 76, 165435 (2007).

Acknowledgements

This work was supported by the US Department of Energy (DOE) under award no. DEEE0008202 and DEEE0008200. The support of the Maryland NanoCenter and its AIM Lab is acknowledged. The authors thank K. Pupek and G. Krumdick for providing one of the fluorinated solvents, and B. Dunn for constructive discussions.

Author information

Authors and Affiliations

Contributions

X.F. and L.C designed the experiments and analysed data. O.B. conducted the calculations. X.F., L.C., X.J., J.C., S.H., T.D., J.Z. and C.Y. conducted electrochemical experiments. X.F. and S.-C.L. performed the TEM analysis. K.A., K.X. and C.W. conceived and supervised the project. All authors contributed to interpretation of the results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figures 1–39; Supplementary Tables 1–3; Supplementary Notes 1–2

Supplementary Video 1

Flammable test for the electrolyte of 1 M LiFSI-DME

Supplementary Video 2

Flammable test for the electrolyte of 1 M LiPF6-EC/DMC

Supplementary Video 3

Flammable test for the electrolyte of 1 M LiPF6-FEC/DMC

Supplementary Video 4

Flammable test for the electrolyte of 1 M LiPF6-FEC/FEMC/HFE

Rights and permissions

About this article

Cite this article

Fan, X., Chen, L., Borodin, O. et al. Non-flammable electrolyte enables Li-metal batteries with aggressive cathode chemistries. Nature Nanotech 13, 715–722 (2018). https://doi.org/10.1038/s41565-018-0183-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41565-018-0183-2

This article is cited by

-

Alkaline-based aqueous sodium-ion batteries for large-scale energy storage

Nature Communications (2024)

-

Methylation enables high-voltage ether electrolytes for lithium metal batteries

Nature Chemistry (2024)

-

Single-phase local-high-concentration solid polymer electrolytes for lithium-metal batteries

Nature Energy (2024)

-

High voltage electrolytes for lithium-ion batteries with micro-sized silicon anodes

Nature Communications (2024)

-

Methylation enables the use of fluorine-free ether electrolytes in high-voltage lithium metal batteries

Nature Chemistry (2024)