Abstract

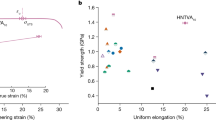

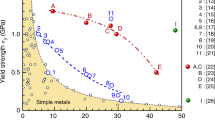

Uniform tensile ductility (UTD) is crucial for the forming/machining capabilities of structural materials. Normally, planar-slip induced narrow deformation bands localize the plastic strains and hence hamper UTD, particularly in body-centred-cubic (bcc) multi-principal element high-entropy alloys (HEAs), which generally exhibit early necking (UTD < 5%). Here we demonstrate a strategy to tailor the planar-slip bands in a Ti-Zr-V-Nb-Al bcc HEA, achieving a 25% UTD together with nearly 50% elongation-to-failure (approaching a ductile elemental metal), while offering gigapascal yield strength. The HEA composition is designed not only to enhance the B2-like local chemical order (LCO), seeding sites to disperse planar slip, but also to generate excess lattice distortion upon deformation-induced LCO destruction, which promotes elastic strains and dislocation debris to cause dynamic hardening. This encourages second-generation planar-slip bands to branch out from first-generation bands, effectively spreading the plastic flow to permeate the sample volume. Moreover, the profuse bands frequently intersect to sustain adequate work-hardening rate (WHR) to large strains. Our strategy showcases the tuning of plastic flow dynamics that turns an otherwise-undesirable deformation mode to our advantage, enabling an unusual synergy of yield strength and UTD for bcc HEAs.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in the published article and Supplementary Information and are available from the corresponding authors upon reasonable request.

Code availability

The computer codes are available from the corresponding authors upon reasonable request.

References

Yeh, J. W. et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299–303 (2004).

Cantor, B., Chang, I. T. H., Knight, P. & Vincent, A. J. B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375–377, 213–218 (2004).

Gludovatz, B. et al. A failure-resistant high-entropy alloy for cryogenic applications. Science 345, 1153–1159 (2014).

Senkov, O. N., Wilks, G. B., Scott, J. M. & Miracle, D. B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 19, 698–706 (2011).

Ko, P. et al. Discovery of a superconducting high-entropy alloy. Phys. Rev. Lett. 113, 107001 (2014).

An, Z. et al. Spinodal-modulated solid solution delivers a strong and ductile refractory high-entropy alloy. Mater. Horiz. 8, 948–955 (2021).

Zhang, R. et al. Short-range order and its impact on the CrCoNi medium-entropy alloy. Nature 581, 283–287 (2020).

Ding, Q. et al. Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature 574, 223–227 (2019).

Antillon, E., Woodward, C., Rao, S. I. & Akdim, B. Chemical short range order strengthening in BCC complex concentrated alloys. Acta Mater. 215, 117012 (2021).

Yin, S. et al. Atomistic simulations of dislocation mobility in refractory high-entropy alloys and the effect of chemical short-range order. Nat. Commun. 12, 4873 (2021).

Li, Q. J., Sheng, H. & Ma, E. Strengthening in multi-principal element alloys with local-chemical-order roughened dislocation pathways. Nat. Commun. 10, 3563 (2019).

Yin, B., Yoshida, S., Tsuji, N. & Curtin, W. A. Yield strength and misfit volumes of NiCoCr and implications for short-range-order. Nat. Commun. 11, 2507 (2020).

Ma, E. Unusual dislocation behavior in high-entropy alloys. Scr. Mater. 181, 127–133 (2020).

Bu, Y. et al. Local chemical fluctuation mediated ductility in body-centered-cubic high-entropy alloys. Mater. Today 46, 28–34 (2021).

Chen, X. et al. Direct observation of chemical short-range order in a medium-entropy alloy. Nature 592, 712–716 (2021).

Chen, S. et al. Simultaneously enhancing the ultimate strength and ductility of high-entropy alloys via short-range ordering. Nat. Commun. 12, 4953 (2021).

Arne, M. Work hardening and softening in a dislocation glide plane with precipitates. Mater. Sci. Eng. 34, 235–240 (1978).

Gerold, V. & Karnthaler, H. P. On the origin of planar slip in f.c.c. alloys. Acta Metall. 37, 2177–2183 (1989).

Chong, Y. et al. Elimination of oxygen sensitivity in α-titanium by substitutional alloying with Al. Nat. Commun. 12, 6158 (2021).

Sheikh, S. et al. Alloy design for intrinsically ductile refractory high-entropy alloys. J. Appl. Phys. 120, 164902 (2016).

Wu, Y. D. et al. A refractory Hf25Nb25Ti25Zr25 high-entropy alloy with excellent structural stability and tensile properties. Mater. Lett. 130, 277–280 (2014).

Sun, Q. Y. & Gu, H. C. Tensile and low-cycle fatigue behavior of commercially pure titanium and Ti–5Al–2.5Sn alloy at 293 and 77 K. Mater. Sci. Eng. A 316, 80–86 (2001).

Yang, P., Li, Q., Tsuru, T. & Ogata, S. Mechanism of hardening and damage initiation in oxygen embrittlement of body-centred-cubic niobium. Acta Mater. 168, 331–342 (2019).

Lei, Z. et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature 563, 546–550 (2018).

Ding, J., Yu, Q., Asta, M. & Ritchie, R. O. Tunable stacking fault energies by tailoring local chemical order in CrCoNi medium-entropy alloys. Proc. Natl Acad. Sci. USA 115, 8919–8924 (2018).

Wang, L. et al. Lightweight Zr1.2V0.8NbTixAly high-entropy alloys with high tensile strength and ductility. Mater. Sci. Eng. A 814, 141234 (2021).

Chen, Y. et al. A single-phase V0.5Nb0.5ZrTi refractory high-entropy alloy with outstanding tensile properties. Mater. Sci. Eng. A 792, 139774 (2020).

Zhou, L. et al. Atomic-scale evidence of chemical short-range order in CrCoNi medium-entropy alloy. Acta Mater. 224, 117490 (2022).

Hytch, M. J., Snoeck, E. & Kilaas, R. Quantitative measurement of displacement and strain fields from HREM micrographs. Ultramicroscopy 74, 131–146 (1998).

Williams, D. B. & Carter, C. B. Transmission Electron Microscopy: A Textbook for Materials Science (Springer, 2009).

Soni, V. et al. Phase inversion in a two-phase, BCC + B2, refractory high entropy alloy. Acta Mater. 185, 89–97 (2020).

Wu, M. et al. Dislocation glide and mechanical twinning in a ductile VNbTi medium entropy alloy. J. Mater. Sci. Technol. 110, 210–215 (2022).

Yan, X., Liaw, P. K. & Zhang, Y. Ultrastrong and ductile BCC high-entropy alloys with low-density via dislocation regulation and nanoprecipitates. J. Mater. Sci. Technol. 110, 109–116 (2022).

Wei, S. et al. Natural-mixing guided design of refractory high-entropy alloys with as-cast tensile ductility. Nat. Mater. 19, 1175–1181 (2020).

Jia, Y. et al. A lightweight refractory complex concentrated alloy with high strength and uniform ductility. Appl. Mater. Today 27, 101429 (2022).

Ma, Y. et al. Hexagonal closed-packed precipitation enhancement in a NbTiHfZr refractory high-entropy alloy. Metals 9, 485 (2019).

Wang, R. et al. Achieving high strength and ductility in nitrogen-doped refractory high-entropy alloys. Mater. Des. 213, 110356 (2022).

Huang, H. et al. On cooling rates dependence of microstructure and mechanical properties of refractory high-entropy alloys HfTaTiZr and HfNbTiZr. Scr. Mater. 211, 114506 (2022).

Wang, S. et al. Mechanical instability and tensile properties of TiZrHfNbTa high entropy alloy at cryogenic temperatures. Acta Mater. 201, 517–527 (2020).

Liao, Y. C. et al. Designing novel lightweight, high-strength and high-plasticity Tix(AlCrNb)100-x medium-entropy alloys. Intermetallics 117, 106673 (2020).

Pang, J. et al. Ductile Ti1.5ZrNbAl0.3 refractory high entropy alloy with high specific strength. Mater. Lett. 290, 129428 (2021).

Akmal, M., Woo, H. & Jin, H. Mo and Ta addition in NbTiZr medium entropy alloy to overcome tensile yield strength-ductility trade-off. J. Mater. Sci. Technol. 109, 176–185 (2022).

Liu, L. et al. Dislocation network in additive manufactured steel breaks strength – ductility trade-off. Mater. Today 21, 354–361 (2018).

Wang, L. et al. Remarkable ductility in metastable refractory high entropy alloys via BCC-FCC/α″ martensitic transformations. Appl. Phys. Lett. 119, 151902 (2021).

Jiang, S. H. et al. Strain hardening mediated by coherent nanoprecipitates in ultrahigh-strength steels. Acta Mater. 213, 116984 (2021).

Rao, S. I. et al. Modeling solution hardening in BCC refractory complex concentrated alloys: NbTiZr, Nb1.5TiZr0.5 and Nb0.5TiZr1.5. Acta Mater. 168, 222–236 (2019).

Chen, B. et al. Correlating dislocation mobility with local lattice distortion in refractory multi-principal element alloys. Scr. Mater. 222, 115048 (2023).

Ren, J. et al. Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing. Nature 608, 62–68 (2022).

Sohn, S. S. et al. Ultrastrong medium-entropy single-phase alloys designed via severe lattice distortion. Adv. Mater. 31, 1807142 (2019).

Greer, A. L., Cheng, Y. Q. & Ma, E. Shear bands in metallic glasses. Mater. Sci. Eng. R. 74, 71–132 (2013).

Hammersley, A. P., Svensson, S. & Thompson, A. Calibration and correction of spatial distortions in 2D detector systems. Nucl. Instrum. Methods Phys. Res. A 346, 312–321 (1994).

Toby, B. H. & Von Dreele, R. B. GSAS-II: the genesis of a modern open-source all purpose crystallography software package. J. Appl. Crystallogr. 46, 544–549 (2013).

Zunger, A., Wei, S., Ferreira, L. G. & Bernard, J. E. Special quasirandom structures. Phys. Rev. Lett. 65, 353–356 (1990).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558–561 (1993).

Krexner, G. & Hafner, J. Ab initio molecular-dynamics liquid-metal—amorphous-semiconductor simulation of the transition in germanium. Phys. Rev. B 49, 14251–14269 (1994).

Monkhorst, H. J. & Pack, J. D. Special points for Brillonin-zone integrations. Phys. Rev. B. 13, 5188–5192 (1976).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 11–19 (1999).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Plimpton, S. Fast parallel algorithms for short range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995).

Sadigh, B. et al. Scalable parallel Monte Carlo algorithm for atomistic simulations of precipitation in alloys. Phys. Rev. B 184203, 1–11 (2012).

Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO – the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2010).

Cowley, J. M. An approximate theory of order in alloys. Phys. Rev. 77, 669–675 (1950).

Acknowledgements

Y.X. and Liang W. acknowledge support from National Natural Science Foundation of China (grant no. U2241234). Liang W. acknowledges support from China Postdoctoral Science Foundation (grant no. 2019M660482). J.D. acknowledges support from National Natural Science Foundation of China (grant no. 12004294) and National Youth Talents Program. E.M. acknowledges National Natural Science Foundation of China (grant no. 52231001) and the 111 Project (grant no. BP2018008). E.M. and J.D. thank the support by Center for Alloy Innovation and Design (CAID) and the HPC platform of Xi’an Jiaotong University. K.J. acknowledges support from National MCF Energy R&D Program (grant no. 2022YFE03120000). Y.R. acknowledges support from City University of Hong Kong (grant no. 9610533). S.Z. acknowledges support from the Key Project of Natural Science Foundation of Tianjin (grant no. 20JCZDJC00440). The use of the Advanced Photon Source at Argonne National Laboratory was supported by the US Department of Energy (grant no. DE-AC02-06CH11357). Y.X. and Liang W. thank Yandong Wang at State Key Laboratory for Advanced Metals and Materials, University of Science and Technology Beijing, for the suggestion on material characterization and mechanism analysis, and Fang Zhang at Analysis and Testing Center, Beijing Institute of Technology, for help with aberration-corrected TEM and STEM experiments.

Author information

Authors and Affiliations

Contributions

Y.X. and E.M. conceived the ideas and supervised the project. Liang W., J.D. and Y.X. analysed the data. Liang W. and E.M. led the writing of the paper and the presentations in the figures. Liang W., S.C., J.C. and B.W. prepared the alloys and performed the mechanical property tests and scanning electron microscopy and EBSD observations. J.D. and B.C. conducted the DFT-based Monte Carlo simulations and MD simulations. Liang W., Q.Z. and K.J. performed the aberration-corrected STEM and TEM experiments on LCO and lattice distribution. Liang W., S.Z., K.M., W.L. and J.H. performed the TEM and STEM experiments on dislocation configurations. Liang W., T.L. and Y.R. conducted the SXRD and total-scattering tests. Lu W. and J.L. reaffirmed the structure characterization and mechanical properties. G.S. performed the 3D-APT experiments. All authors contributed to the discussion of the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Rajarshi Banerjee, E.-Wen Huang, M. Kramer and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–28, notes 1–5 and table 1.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, L., Ding, J., Chen, S. et al. Tailoring planar slip to achieve pure metal-like ductility in body-centred-cubic multi-principal element alloys. Nat. Mater. 22, 950–957 (2023). https://doi.org/10.1038/s41563-023-01517-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-023-01517-0

This article is cited by

-

Negative mixing enthalpy solid solutions deliver high strength and ductility

Nature (2024)

-

Harnessing instability for work hardening in multi-principal element alloys

Nature Materials (2024)

-

Novel as-cast Ti-rich refractory complex concentrated alloys with superior tensile properties

Science China Materials (2024)

-

Aging elevates chemical short-range order and twinning stress in a CrCoNi medium-entropy alloy

Science China Materials (2023)