Abstract

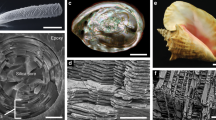

Next-generation structural materials are expected to be lightweight, high-strength and tough composites with embedded functionalities to sense, adapt, self-repair, morph and restore. This Review highlights recent developments and concepts in bioinspired nanocomposites, emphasizing tailoring of the architecture, interphases and confinement to achieve dynamic and synergetic responses. We highlight cornerstone examples from natural materials with unique mechanical property combinations based on relatively simple building blocks produced in aqueous environments under ambient conditions. A particular focus is on structural hierarchies across multiple length scales to achieve multifunctionality and robustness. We further discuss recent advances, trends and emerging opportunities for combining biological and synthetic components, state-of-the-art characterization and modelling approaches to assess the physical principles underlying nature-inspired design and mechanical responses at multiple length scales. These multidisciplinary approaches promote the synergetic enhancement of individual materials properties and an improved predictive and prescriptive design of the next era of structural materials at multilength scales for a wide range of applications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Wegst, U. G. K., Bai, H., Saiz, E., Tomsia, A. P. & Ritchie, R. O. Bioinspired structural materials. Nat. Mater. 14, 23–36 (2015).

Liu, Z. Q., Meyers, M. A., Zhang, Z. F. & Ritchie, R. O. Functional gradients and heterogeneities in biological materials: design principles, functions, and bioinspired applications. Prog. Mater. Sci. 88, 467–498 (2017).

Clancy, A. J., Anthony, D. B. & De Luca, F. Metal mimics: lightweight, strong, and tough nanocomposites and nanomaterial assemblies. ACS Appl. Mater. Interfaces 12, 15955–15975 (2020).

Ritchie, R. O. The conflicts between strength and toughness. Nat. Mater. 10, 817–822 (2011).

Kotov, N. A., Dekany, I. & Fendler, J. H. Ultrathin graphite oxide–polyelectrolyte composites prepared by self-assembly: transition between conductive and non-conductive states. Adv. Mater. 8, 637–641 (1996).

Huang, W. et al. Multiscale toughening mechanisms in biological materials and bioinspired designs. Adv. Mater. 31, 1901561 (2019).

Tadepalli, S., Slocik, J. M., Gupta, M. K., Naik, R. R. & Singamaneni, S. Bio-optics and bio-inspired optical materials. Chem. Rev. 117, 12705–12763 (2017).

Wang, B., Yang, W., McKittrick, J. & Meyers, M. A. Keratin: structure, mechanical properties, occurrence in biological organisms, and efforts at bioinspiration. Prog. Mater. Sci. 76, 229–318 (2016).

Huang, W. et al. A natural energy absorbent polymer composite: the equine hoof wall. Acta Biomater. 90, 267–277 (2019).

Chen, M. L. et al. The hierarchical structure and mechanical performance of a natural nanocomposite material: the turtle shell. Colloids Surf. A 520, 97–104 (2017).

Hieronymus, T. L., Witmer, L. M. & Ridgely, R. C. Structure of white rhinoceros (Ceratotherium simum) horn investigated by X-ray computed tomography and histology with implications for growth and external form. J. Morphol. 267, 1172–1176 (2006).

Chon, M. J. et al. Lamellae spatial distribution modulates fracture behavior and toughness of African pangolin scales. J. Mech. Behav. Biomed. Mater. 76, 30–37 (2017).

Teyssier, J., Saenko, S. V., van der Marel, D. & Milinkovitch, M. C. Photonic crystals cause active colour change in chameleons. Nat. Commun. 6, 6368 (2015).

Ren, J. et al. Biological material interfaces as inspiration for mechanical and optical material designs. Chem. Rev. 119, 12279–12336 (2019).

Morits, M. et al. Toughness and fracture properties in nacre-mimetic clay/polymer nanocomposites. Adv. Funct. Mater. 27, 1605378 (2017).

Natarajan, B. & Gilman, J. Bioinspired bouligand cellulose nanocrystal composites: a review of mechanical properties. Phil. Trans. A 376, 20170050 (2018).

Zhao, Q. L., Wang, Y. L., Cui, H. Q. & Du, X. M. Bio-inspired sensing and actuating materials. J. Mater. Chem. C 7, 6493–6511 (2019).

de Espinosa, L. M., Meesorn, W., Moatsou, D. & Weder, C. Bioinspired polymer systems with stimuli-responsive mechanical properties. Chem. Rev. 117, 12851–12892 (2017).

Egan, P., Sinko, R., LeDuc, P. R. & Keten, S. The role of mechanics in biological and bio-inspired systems. Nat. Commun. 6, 7418 (2015).

Gladman, A. S., Matsumoto, E. A., Nuzzo, R. G., Mahadevan, L. & Lewis, J. A. Biomimetic 4D printing. Nat. Mater. 15, 413–418 (2016).

Ye, C. H. et al. Bimorph silk microsheets with programmable actuating behavior: experimental analysis and computer simulations. ACS Appl. Mater. Interfaces 8, 17694–17706 (2016).

Zhang, Y. H. et al. A mechanically driven form of Kirigami as a route to 3D mesostructures in micro/nanomembranes. Proc. Natl Acad. Sci. USA 112, 11757–11764 (2015).

Lee, J. H., Lee, J. S., Kim, D. K., Park, C. H. & Lee, H. R. Clinical outcomes of silk patch in acute tympanic membrane perforation. Clin. Exp. Otorhinolaryngol. 8, 117–122 (2015).

Zhao, C. et al. Layered nanocomposites by shear-flow-induced alignment of nanosheets. Nature 580, 210–215 (2020).

Podsiadlo, P. et al. Ultrastrong and stiff layered polymer nanocomposites. Science 318, 80–83 (2007).

Bonderer, L. J., Studart, A. R. & Gauckler, L. J. Bioinspired design and assembly of platelet reinforced polymer films. Science 319, 1069–1073 (2008).

Grossman, M. et al. Mineral nano-interconnectivity stiffens and toughens nacre-like composite materials. Adv. Mater. 29, 1605039 (2017).

Bai, H. et al. Bioinspired hdroxyapatite/poly(methyl methacrylate) composite with a nacre-mimetic architecture by a bidirectional freezing method. Adv. Mater. 28, 50–56 (2016).

Tan, G. Q. et al. Nature-inspired nacre-like composites combining human tooth-matching elasticity and hardness with exceptional damage tolerance. Adv. Mater. 31, 1904603 (2019).

Mao, L. B. et al. Synthetic nacre by predesigned matrix-directed mineralization. Science 354, 107–110 (2016).

Das, P. et al. Nacre-mimetics with synthetic nanoclays up to ultrahigh aspect ratios. Nat. Commun. 6, 5967 (2015).

Heinz, H. & Ramezani-Dakhel, H. Simulations of inorganic–bioorganic interfaces to discover new materials: insights, comparisons to experiment, challenges, and opportunities. Chem. Soc. Rev. 45, 412–448 (2016).

Tan, Y. P. et al. Infiltration of chitin by protein coacervates defines the squid beak mechanical gradient. Nat. Chem. Biol. 11, 488–495 (2015).

Gim, J. et al. Nanoscale deformation mechanics reveal resilience in nacre of Pinna nobilis shell. Nat. Commun. 10, 4822 (2019).

Zeng, F. Z. et al. A bioinspired ultratough multifunctional mica-based nanopaper with 3D aramid nanofiber framework as an electrical insulating material. ACS Nano 14, 611–619 (2020).

Yin, Z., Hannard, F. & Barthelat, F. Impact-resistant nacre-like transparent materials. Science 364, 1260–1263 (2019).

Weaver, J. C. et al. The stomatopod dactyl club: a formidable damage-tolerant biological hammer. Science 336, 1275–1280 (2012).

Grunenfelder, L. K. et al. Bio-inspired impact-resistant composites. Acta Biomater. 10, 3997–4008 (2014).

Yang, W. et al. Protective role of Arapaima gigas fish scales: structure and mechanical behavior. Acta Biomater. 10, 3599–3614 (2014).

Huang, W. et al. A natural impact-resistant bicontinuous composite nanoparticle coating. Nat. Mater. 19, 1236–1243 (2020).

Yaraghi, N. A. et al. A sinusoidally architected helicoidal biocomposite. Adv. Mater. 28, 6835–6844 (2016).

Gansel, J. K. et al. Gold helix photonic metamaterial as broadband circular polarizer. Science 325, 1513–1515 (2009).

Urban, M. J. et al. Chiral plasmonic nanostructures enabled by bottom-up approaches. Annu. Rev. Phys. Chem. 70, 275–299 (2019).

Ling, S. J., Kaplan, D. L. & Buehler, M. J. Nanofibrils in nature and materials engineering. Nat. Rev. Mater. 3, 18016 (2018).

Nikolov, S. et al. Revealing the design principles of high-performance biological composites using ab initio and multiscale simulations: the example of lobster cuticle. Adv. Mater. 22, 519–526 (2010).

Cherpak, V. et al. Robust chiral organization of cellulose nanocrystals in capillary confinement. Nano Lett. 18, 6770–6777 (2018).

Guo, J. Q. et al. Biodegradable laser arrays self-assembled from plant resources. Adv. Mater. 32, 2002332 (2020).

Lin, Y. S., Wei, C. T., Olevsky, E. A. & Meyers, M. A. Mechanical properties and the laminate structure of Arapaima gigas scales. J. Mech. Behav. Biomed. Mater. 4, 1145–1156 (2011).

Yazawa, K., Malay, A. D., Masunaga, H., Norma-Rashid, Y. & Numata, K. Simultaneous effect of strain rate and humidity on the structure and mechanical behavior of spider silk. Commun. Mater. 1, 10 (2020).

Fu, C. J. et al. Cryogenic toughness of natural silk and a proposed structure–function relationship. Mater. Chem. Front. 3, 2507–2513 (2019).

Tung, S. O., Ho, S., Yang, M., Zhang, R. L. & Kotov, N. A. A dendrite-suppressing composite ion conductor from aramid nanofibres. Nat. Commun. 6, 6152 (2015).

Gupta, N., Alred, J. M., Penev, E. S. & Yakobson, B. I. Universal strength scaling in carbon nanotube bundles with frictional load transfer. ACS Nano 15, 1342–1350 (2021).

Guo, C. C. et al. Thermoplastic moulding of regenerated silk. Nat. Mater. 19, 102–108 (2020).

Chang, H., Luo, J., Gulgunje, P. V. & Kumar, S. Structural and functional fibers. Ann. Rev. Mater. Res. 47, 1–13.29 (2017).

Pramanik, C., Gissinger, J. R., Kumar, S. & Heinz, H. Carbon nanotube dispersion in solvents and polymer solutions: mechanisms, assembly, and preferences. ACS Nano 11, 12805–12816 (2017).

Davijani, A. A. B. & Kumar, S. Ordered wrapping of poly(methyl methacrylate) on single wall carbon nanotubes. Polymer 70, 278–281 (2015).

Bakhtiary Davijani, A. A., Chang, H., Liu, H. C., Luo, J. & Kumar, S. Stress transfer in nanocomposites enabled by poly(methyl methacrylate) wrapping of carbon nanotubes. Polymer 130, 191–198 (2017).

Eyckens, D. J. et al. Fiber with butterfly wings: creating colored carbon fibers with increased strength, adhesion, and reversible malleability. ACS Appl. Mater. Interfaces 11, 41617–41625 (2019).

Asai, M., Zhao, D. & Kumar, S. K. Role of grafting mechanism on the polymer coverage and self-assembly of hairy nanoparticles. ACS Nano 11, 7028–7035 (2017).

Heinz, H. et al. Nanoparticle decoration with surfactants: molecular interactions, assembly, and applications. Surf. Sci. Rep. 72, 1–58 (2017).

Hansoge, N. K. et al. Materials by design for stiff and tough hairy nanoparticle assemblies. ACS Nano 12, 7946–7958 (2018).

Xu, H. et al. Obtaining high mechanical performance silk fibers by feeding purified carbon nanotube/lignosulfonate composite to silkworms. RSC Adv. 9, 3558–3569 (2019).

Praprotnik, M., Site, L. D. & Kremer, K. Multiscale simulation of soft matter: from scale bridging to adaptive resolution. Annu. Rev. Phys. Chem. 59, 545–571 (2008).

Lu, J. X., Luo, M. & Yakobson, B. I. Glass composites reinforced with silicon-doped carbon nanotubes. Carbon 128, 231–236 (2018).

Tsafack, T. et al. Exploring the interface between single-walled carbon nanotubes and epoxy resin. Carbon 105, 600–606 (2016).

Heinz, H., Lin, T.-J., Mishra, R. K. & Emami, F. S. Thermodynamically consistent force fields for the assembly of inorganic, organic, and biological nanostructures: the INTERFACE force field. Langmuir 29, 1754–1765 (2013).

Mason, J. A. et al. Contraction and expansion of stimuli-responsive DNA bonds in flexible colloidal crystals. J. Am. Chem. Soc. 138, 8722–8725 (2016).

Samanta, D. et al. Multivalent cation-induced actuation of DNA-mediated colloidal superlattices. J. Am. Chem. Soc. 141, 19973–19977 (2019).

Gissinger, J. R., Pramanik, C., Newcomb, B., Kumar, S. & Heinz, H. Nanoscale structure–property relationships of polyacrylonitrile/CNT composites as a function of polymer crystallinity and CNT diameter. ACS Appl. Mater. Interfaces 10, 1017–1027 (2018).

Zhao, H. et al. NanoMine schema: an extensible data representation for polymer nanocomposites. APL Mater. 6, 111108 (2018).

Gooneie, A., Schuschnigg, S. & Holzer, C. A review of multiscale computational methods in polymeric materials. Polymers 9, 16 (2017).

Ha, Y. & Bobaru, F. Studies of dynamic crack propagation and crack branching with peridynamics. Int. J. Fract. 162, 229–244 (2010).

Wang, B., Oterkus, S. & Oterkus, E. Determination of horizon size in state-based peridynamics. Continuum Mech. Thermodyn. https://doi.org/10.1007/s00161-020-00896-y (2020).

Vassaux, M., Sinclair, R. C., Richardson, R. A., Suter, J. L. & Coveney, P. V. The role of graphene in enhancing the material properties of thermosetting polymers. Adv. Theory Simul. 2, 1800168 (2019).

Guarin-Zapata, N., Gomez, J., Kisailus, D. & Zavattieri, P. D. Bandgap tuning in bioinspired helicoidal composites. J. Mech. Phys. Solids 131, 344–357 (2019).

Kronqvist, N. et al. Efficient protein production inspired by how spiders make silk. Nat. Commun. 8, 15504 (2017).

Valois, E., Mirshafian, R. & Waite, J. H. Phase-dependent redox insulation in mussel adhesion. Sci. Adv. 6, eaaz6486 (2020).

Wang, C. Y., Xia, K. L., Zhang, Y. Y. & Kaplan, D. L. Silk-based advanced materials for soft electronics. Acc. Chem. Res. 52, 2916–2927 (2019).

Gu, G. X., Chen, C. T., Richmond, D. J. & Buehler, M. J. Bioinspired hierarchical composite design using machine learning: simulation, additive manufacturing, and experiment. Mater. Horiz. 5, 939–945 (2018).

Wu, Z. et al. A comprehensive survey on graph neural networks. IEEE Trans. Neural Netw. Learn. Syst. 32, 4–24 (2021).

Wang, M. Q. et al. Biomorphic structural batteries for robotics. Sci. Robot. 5, eaba1912 (2020).

Yu, C. H., Qin, Z., Martin-Martinez, F. J. & Buehler, M. J. A self-consistent sonification method to translate amino acid sequences into musical compositions and application in protein design using artificial intelligence. ACS Nano 13, 7471–7482 (2019).

Jin, W., Barzilay, R. & Jaakkola, T. Hierarchical generation of molecular graphs using structural motifs. In Proc. 37th International Conference on Machine Learning (eds Hal, D. III & Aarti, S.) 119, 4839–4848 (PMLR, 2020).

Lossada, F., Jiao, D., Hoenders, D. & Walther, A. Recyclable and light-adaptive vitrimer-based nacre-mimetic nanocomposites. ACS Nano 15, 5043–5055 (2021).

Xin, A. et al. Growing living composites with ordered microstructures and exceptional mechanical properties. Adv. Mater. 33, 2006946 (2021).

Svagan, A. J., Samir, M. A. S. A. & Berglund, L. A. Biomimetic foams of high mechanical performance based on nanostructured cell walls reinforced by native cellulose nanofibrils. Adv. Mater. 20, 1263–1269 (2008).

Podsiadlo, P., Tang, Z., Shim, B. S. & Kotov, N. A. Counterintuitive effect of molecular strength and role of molecular rigidity on mechanical properties of layer-by-layer assembled nanocomposites. Nano Lett. 7, 1224–1231 (2007).

Jiang, C. et al. Mechanical properties of robust ultrathin silk fibroin films. Adv. Funct. Mater. 17, 2229–2237 (2007).

Cheng, Q., Jiang, L. & Tang, Z. Bioinspired layered materials with superior mechanical performance. Acc. Chem. Res. 47, 1256–1266 (2014).

Gao, H. L. et al. Mass production of bulk artificial nacre with excellent mechanical properties. Nat. Commun. 8, 287 (2017).

Zhang, Y. et al. Bioinspired, graphene-enabled Ni composites with high strength and toughness. Sci. Adv. 5, eaav5577 (2019).

Xiong, R. et al. Ultrarobust transparent cellulose nanocrystal-graphene membranes with high electrical conductivity. Adv. Mater. 28, 1501–1509 (2016).

Raut, H. K. et al. Tough and strong: cross-lamella design imparts multifunctionality to biomimetic nacre. ACS Nano 14, 9771–9779 (2020).

Vollick, B., Kuo, P. Y., Therien-Aubin, H., Yan, N. & Kumacheva, E. Composite cholesteric nanocellulose films with enhanced mechanical properties. Chem. Mater. 29, 789–795 (2017).

Gu, M., Jiang, C., Liu, D., Prempeh, N. & Smalyukh, I. I. Cellulose nanocrystal/poly(ethylene glycol) composite as an iridescent coating on polymer substrates: structure-color and interface adhesion. ACS Appl. Mater. Interfaces 8, 32565–32573 (2016).

Wang, B. & Walther, A. Self-assembled, iridescent, crustacean-mimetic nanocomposites with tailored periodicity and layered cuticular structure. ACS Nano 9, 10637–10646 (2015).

Sachs, C., Fabritius, H. & Raabe, D. Influence of microstructure on deformation anisotropy of mineralized cuticle from the lobster Homarus americanus. J. Struct. Biol. 161, 120–132 (2008).

Chen, P.-Y., Lin, A. Y.-M., McKittrick, J. & Meyers, M. A. Structure and mechanical properties of crab exoskeletons. Acta Biomater. 4, 587–596 (2008).

Ayutsede, J. et al. Carbon nanotube reinforced Bombyx mori silk nanofibers by the electrospinning process. Biomacromolecules 7, 208–214 (2006).

Munch, E. et al. Tough, bio-inspired hybrid materials. Science 322, 1516–1520 (2008).

Hu, K., Gupta, M. K., Kulkarni, D. D. & Tsukruk, V. V. Ultra-robust graphene oxide-silk fibroin nanocomposite membranes. Adv. Mater. 25, 2301–2307 (2013).

Wang, J., Cheng, Q., Lin, L. & Jiang, L. Synergistic toughening of bioinspired poly(vinyl alcohol)–clay–nanofibrillar cellulose artificial nacre. ACS Nano 8, 2739–2745 (2014).

Watanabe, K. et al. Highly transparent and tough filler composite elastomer inspired by the cornea. ACS Mater. Lett. 2, 325–330 (2020).

Lönnberg, H., Larsson, K., Lindström, T., Hult, A. & Malmström, E. Synthesis of polycaprolactone-grafted microfibrillated cellulose for use in novel bionanocomposites—influence of the graft length on the mechanical properties. ACS Appl. Mater. Interfaces 3, 1426–1433 (2011).

Yang, J., Han, C.-R., Zhang, X.-M., Xu, F. & Sun, R.-C. Cellulose nanocrystals mechanical reinforcement in composite hydrogels with multiple cross-links: correlations between dissipation properties and deformation mechanisms. Macromolecules 47, 4077–4086 (2014).

Pan, H. et al. Significantly reinforced composite fibers electrospun from silk fibroin/carbon nanotube aqueous solutions. Biomacromolecules 13, 2859–2867 (2012).

Scaffaro, R. & Maio, A. Integrated ternary bionanocomposites with superior mechanical performance via the synergistic role of graphene and plasma treated carbon nanotubes. Composites B 168, 550–559 (2019).

Ashby, M. F. Overview no. 80: on the engineering properties of materials. Acta Metall. 37, 1273–1293 (1989).

CES EduPack (Granta Design, 2009).

Dalton, A. B. et al. Super-tough carbon-nanotube fibres—these extraordinary composite fibres can be woven into electronic textiles. Nature 423, 703–703 (2003).

Grant, A. M. et al. Silk fibroin–substrate interactions at heterogeneous nanocomposite interfaces. Adv. Funct. Mater. 26, 6380–6392 (2016).

Wang, Q. et al. Observations of 3 nm silk nanofibrils exfoliated from natural silkworm silk fibers. ACS Mater. Lett. 2, 153–160 (2020).

Shao, Z. Z. & Vollrath, F. Surprising strength of silkworm silk. Nature 418, 741 (2002).

Guarin-Zapata, N., Gomez, J., Yaraghi, N., Kisailus, D. & Zavattieri, P. D. Shear wave filtering in naturally-occurring Bouligand structures. Acta Biomater. 23, 11–20 (2015).

Adamcik, J. et al. Measurement of intrinsic properties of amyloid fibrils by the peak force QNM method. Nanoscale 4, 4426–4429 (2012).

Feng, W. C. et al. Assembly of mesoscale helices with near-unity enantiomeric excess and light–matter interactions for chiral semiconductors. Sci. Adv. 3, e1601159 (2017).

Adstedt, K. et al. Chiral cellulose nanocrystals with intercalated amorphous polysaccharides for controlled iridescence and enhanced mechanics. Adv. Funct. Mater. 30, 2003597 (2020).

Cao, Y. P., Bolisetty, S., Wolfisberg, G., Adamcik, J. & Mezzenga, R. Amyloid fibril-directed synthesis of silica core–shell nanofilaments, gels, and aerogels. Proc. Natl Acad. Sci. USA 116, 4012–4017 (2019).

Mittal, N. et al. Multiscale control of nanocellulose assembly: transferring remarkable nanoscale fibril mechanics to macroscale fibers. ACS Nano 12, 6378–6388 (2018).

Ling, S. et al. Polymorphic regenerated silk fibers assembled through bioinspired spinning. Nat. Commun. 8, 1387 (2017).

Jolowsky, C., Sweat, R., Park, J. G., Hao, A. & Liang, R. Microstructure evolution and self-assembling of CNT networks during mechanical stretching and mechanical properties of highly aligned CNT composites. Compos. Sci. Tech. 166, 125–130 (2018).

Huang, Y., Sasano, T., Tsujii, Y. & Ohno, K. Well-defined polymer-brush-coated rod-shaped particles: synthesis and formation of liquid crystals. Macromolecules 49, 8430–8439 (2016).

Liu, Z., Xu, Z., Hu, X. & Gao, C. Lyotropic liquid crystal of polyacrylonitrile-grafted graphene oxide and its assembled continuous strong nacre-mimetic fibers. Macromolecules 46, 6931–6941 (2013).

Naguib, M. Multifunctional pure MXene fiber from liquid crystals of only water and MXene. ACS Cent. Sci. 6, 344–346 (2020).

Djumas, L., Molotnikov, A., Simon, G. P. & Estrin, Y. Enhanced mechanical performance of bio-inspired hybrid structures utilising topological interlocking geometry. Sci. Rep. 6, 26706 (2016).

Alred, J. M., Bets, K. V., Xie, Y. & Yakobson, B. I. Machine learning electron density in sulfur crosslinked carbon nanotubes. Compos. Sci. Technol. 166, 3–9 (2018).

Acknowledgements

We acknowledge support from multiple sources: D.N., the Air Force Office of Scientific Research (AFSOR), 18RXCOR060 and 22RXCOR014; K.D., ONR, N00014-18-1-2528; M.R.B., AFOSR, FA8650-19-2-5209; M.J.B., AFOSR, FATE MURI FA9550-15-1-0514; L.C.H., Office of Naval Research Global, N62909-18-1-2024; S.Keten, PECASE Award ONR, N00014-16-1-3175; G.C.S., Center for Bio-Inspired Energy Sciences (CBES), an Energy Frontiers Research Center (EFRC), under DE-SC0000989; V.V.T., Air Force Research Laboratory, FA8650-16-D-5404, AFOSR, FA9550-20-1-0305 and NSF-ECCS 2203806; L.C.B., AFOSR, FA9550-18-1-0381; J.A.E., NSF Career Award, CMMI 1454072; P.V.C., Engineering and Physical Sciences Research Council, EP/R029598/1; H.H., NSF CMMI 1940335, NSF OAC 1931587, and NASA Space Technology Research Institute, STRI-NNX17AJ32G.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Lars Berglund, Ali Miserez, Andreas Walther and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nepal, D., Kang, S., Adstedt, K.M. et al. Hierarchically structured bioinspired nanocomposites. Nat. Mater. 22, 18–35 (2023). https://doi.org/10.1038/s41563-022-01384-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-022-01384-1

This article is cited by

-

Bioinspired structural hydrogels with highly ordered hierarchical orientations by flow-induced alignment of nanofibrils

Nature Communications (2024)

-

Biomimetic Bouligand chiral fibers array enables strong and superelastic ceramic aerogels

Nature Communications (2024)

-

Machine intelligence-accelerated discovery of all-natural plastic substitutes

Nature Nanotechnology (2024)

-

Mechanical communication within the microtubule through network-based analysis of tubulin dynamics

Biomechanics and Modeling in Mechanobiology (2024)

-

Insights into Nano- and Micro-Structured Scaffolds for Advanced Electrochemical Energy Storage

Nano-Micro Letters (2024)