Abstract

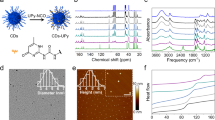

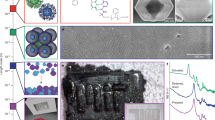

Nanolattices exhibit attractive mechanical, energy conversion and optical properties, but it is challenging to fabricate large nanolattices while maintaining the dense regular nanometre features that enable their properties. Here we report a crack-free self-assembly approach for fabricating centimetre-scale nickel nanolattices with much larger crack-free areas than prior self-assembled nanolattices and many more unit cells than three-dimensionally printed nanolattices. These nickel nanolattices have a feature size of 100 nm, a grain size of 30 nm and a tensile strength of 260 MPa, which approaches the theoretical strength limit for porous nickel. The self-assembly method and porous metal mechanics reported in this work may advance the fabrication and applications of high-strength multifunctional porous materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Zhao, B. et al. A review on metallic porous materials: pore formation, mechanical properties, and their applications. Int. J. Adv. Manuf. Technol. 95, 2641–2659 (2018).

Bauer, J. et al. Nanolattices: an emerging class of mechanical metamaterials. Adv. Mater. 29, 1701850 (2017).

Zhang, X., Wang, Y., Ding, B. & Li, X. Design, fabrication, and mechanics of 3D micro-/nanolattices. Small 16, e1902842 (2020).

Zheng, X. et al. Multiscale metallic metamaterials. Nat. Mater. 15, 1100–1106 (2016).

Vyatskikh, A. et al. Additive manufacturing of 3D nano-architected metals. Nat. Commun. 9, 593 (2018).

Geng, Q., Wang, D., Chen, P. & Chen, S.-C. Ultrafast multi-focus 3-D nano-fabrication based on two-photon polymerization. Nat. Commun. 10, 2179 (2019).

Hsueh, H.-Y. et al. Nanoporous gyroid nickel from block copolymer templates via electroless plating. Adv. Mater. 23, 3041–3046 (2011).

Bagal, A. et al. Large-area nanolattice film with enhanced modulus, hardness, and energy dissipation. Sci. Rep. 7, 9145 (2017).

Jiang, Z., Hsain, Z. & Pikul, J. H. Thick free-standing metallic inverse opals enabled by new insights into the fracture of drying particle films. Langmuir 36, 7315–7324 (2020).

Pikul, J. H. et al. High strength metallic wood from nanostructured nickel inverse opal materials. Sci. Rep. 9, 719 (2019).

Zhang, C. et al. Enhanced capillary-fed boiling in copper inverse opals via template sintering. Adv. Funct. Mater. 28, 1803689 (2018).

Zhang, R., Cohen, J., Fan, S. & Braun, P. V. Electrodeposited high strength, thermally stable spectrally selective rhenium nickel inverse opals. Nanoscale 9, 11187–11194 (2017).

Pikul, J. H., Zhang, H. G., Cho, J., Braun, P. V. & King, W. P. High-power lithium ion microbatteries from interdigitated three-dimensional bicontinuous nanoporous electrodes. Nat. Commun. 4, 1732 (2013).

Kränzlin, N. & Niederberger, M. Controlled fabrication of porous metals from the nanometer to the macroscopic scale. Mater. Horiz. 2, 359–377 (2015).

Pham, Q. N., Barako, M. T., Tice, J. & Won, Y. Microscale liquid transport in polycrystalline inverse opals across grain boundaries. Sci. Rep. 7, 10465 (2017).

Phillips, K. R. et al. Nanocrystalline precursors for the co-assembly of crack-free metal oxide inverse opals. Adv. Mater. 30, e1706329 (2018).

Vogel, N., Retsch, M., Fustin, C.-A., del Campo, A. & Jonas, U. Advances in colloidal assembly: the design of structure and hierarchy in two and three dimensions. Chem. Rev. 115, 6265–6311 (2015).

Hatton, B., Mishchenko, L., Davis, S., Sandhage, K. H. & Aizenberg, J. Assembly of large-area, highly ordered, crack-free inverse opal films. Proc. Natl Acad. Sci. USA 107, 10354–10359 (2010).

Montemayor, L. C., Wong, W. H., Zhang, Y. W. & Greer, J. R. Insensitivity to flaws leads to damage tolerance in brittle architected meta-materials. Sci. Rep. 6, 20570 (2016).

do Rosário, J. J., Berger, J. B., Lilleodden, E. T., McMeeking, R. M. & Schneider, G. A. The stiffness and strength of metamaterials based on the inverse opal architecture. Extrem. Mech. Lett. 12, 86–96 (2017).

Schmalbach, K. M. et al. Temperature-dependent mechanical behavior of three-dimensionally ordered macroporous tungsten. J. Mater. Res. 35, 2556–2566 (2020).

Ramachandramoorthy, R. et al. Dual-templated electrodeposition and characterization of regular metallic foam based microarchitectures. Appl. Mater. Today 20, 100667 (2020).

do Rosário, J. J., Häntsch, Y., Schneider, G. A. & Lilleodden, E. T. A combined compression and indentation study of mechanical metamaterials based on inverse opal coatings. Acta Mater. 195, 98–108 (2020).

do Rosário, J. J. et al. Self-assembled ultra high strength, ultra stiff mechanical metamaterials based on inverse opals. Adv. Eng. Mater. 17, 1420–1424 (2015).

Meza, L. R., Das, S. & Greer, J. R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 345, 1322–1326 (2014).

Jang, D., Meza, L. R., Greer, F. & Greer, J. R. Fabrication and deformation of three-dimensional hollow ceramic nanostructures. Nat. Mater. 12, 893–898 (2013).

Bauer, J., Schroer, A., Schwaiger, R. & Kraft, O. The impact of size and loading direction on the strength of architected lattice materials. Adv. Eng. Mater. 18, 1537–1543 (2016).

Mateos, A. J., Huang, W., Zhang, Y.-W. & Greer, J. R. Discrete-continuum duality of architected materials: failure, flaws, and fracture. Adv. Funct. Mater. 29, 1806772 (2019).

Manoharan, V. N. Colloidal matter: packing, geometry, and entropy. Science 349, 1253751 (2015).

Li, Q., Jonas, U., Zhao, X. & Kappl, M. The forces at work in colloidal self-assembly: a review on fundamental interactions between colloidal particles. Asia Pac. J. Chem. Eng. 3, 255–268 (2008).

Goehring, L., Clegg, W. J. & Routh, A. F. Solidification and ordering during directional drying of a colloidal dispersion. Langmuir 26, 9269–9275 (2010).

Guglielmi, N. Kinetics of the deposition of inert particles from electrolytic baths. J. Electrochem. Soc. 119, 1009–1012 (1972).

Gibson, L. J. & Ashby, M. F. Cellular Solids: Structure and Properties (Cambridge Univ. Press, 1999).

Aly, M. S. Tensile properties of open-cell nickel foams. Mater. Des. 31, 2237–2240 (2010).

Lee, K. & Lewandowski, J. J. Effects of microstructural characteristics on mechanical properties of open-cell nickel foams. Mater. Sci. Technol. 21, 1355–1358 (2005).

Kashani, H. & Chen, M. W. Flaw-free nanoporous Ni for tensile properties. Acta Mater. 166, 402–412 (2019).

Furumoto, T. et al. Permeability and strength of a porous metal structure fabricated by additive manufacturing. J. Mater. Process. Tech. 219, 10–16 (2015).

Kashihara, M. et al. Fabrication of lotus-type porous carbon steel via continuous zone melting and its mechanical properties. Mater. Sci. Eng. A 524, 112–118 (2009).

Kato, K. et al. Cytocompatibility and mechanical properties of novel porous 316 L stainless steel. Mater. Sci. Eng. C 33, 2736–2743 (2013).

Falkowska, A., Seweryn, A. & Szusta, J. Predicting the fatigue strength and life of 316L steel sinters of varying porosity for implants in a uniaxial loading state. Eng. Fract. Mech. 200, 146–165 (2018).

Kelly, C. N. et al. Fatigue behavior of as-built selective laser melted titanium scaffolds with sheet-based gyroid microarchitecture for bone tissue engineering. Acta Biomater. 94, 610–626 (2019).

Tao, X. F. & Zhao, Y. Y. Compressive failure of Al alloy matrix syntactic foams manufactured by melt infiltration. Mater. Sci. Eng. A 549, 228–232 (2012).

Nakajima, H. Fabrication, properties and application of porous metals with directional pores. Prog. Mater. Sci. 52, 1091–1173 (2007).

Simone, A. E. & Gibson, L. J. The tensile strength of porous copper made by the GASAR process. Acta Mater. 44, 1437–1447 (1996).

Gwak, E. J., Jeon, H., Song, E. J., Kang, N. R. & Kim, J. Y. Twinned nanoporous gold with enhanced tensile strength. Acta Mater. 155, 253–261 (2018).

Xia, R. et al. Microtensile tests of mechanical properties of nanoporous Au thin films. J. Mater. Sci. 44, 4728–4733 (2009).

Badwe, N., Chen, X. Y. & Sieradzki, K. Mechanical properties of nanoporous gold in tension. Acta Mater. 129, 251–258 (2017).

Ahmed, H. S. T. & Jankowski, A. F. Stiffening of sub-micro-porous silver membranes under tensile deformation. Mater. Sci. Eng. B 177, 43–47 (2012).

Gadaud, P., Caccuri, V., Bertheau, D., Carr, J. & Milhet, X. Ageing sintered silver: relationship between tensile behavior, mechanical properties and the nanoporous structure evolution. Mater. Sci. Eng. A 669, 379–386 (2016).

Budrovic, Z., Swygenhoven, H. V., Derlet, P. M., Petegem, S. V. & Schmitt, B. Plastic deformation with reversible peak broadening in nanocrystalline nickel. Science 304, 273–276 (2004).

Sun, H., Xu, Z. & Gao, C. Multifunctional, ultra-flyweight, synergistically assembled carbon aerogels. Adv. Mater. 25, 2554–2560 (2013).

Kashani, H., Ito, Y., Han, J., Liu, P. & Chen, M. Extraordinary tensile strength and ductility of scalable nanoporous graphene. Sci. Adv. 5, eaat6951 (2019).

Xu, Z., Zhang, Y., Li, P. & Gao, C. Strong, conductive, lightweight, neat graphene aerogel fibers with aligned pores. ACS Nano 6, 7103–7113 (2012).

Parmenter, K. E. & Milstein, F. Mechanical properties of silica aerogels. J. Non Cryst. Solids 223, 179–189 (1998).

Betts, C. Benefits of metal foams and developments in modelling techniques to assess their materials behaviour: a review. Mater. Sci. Technol. 28, 129–143 (2012).

Acknowledgements

We thank J. L. Bassani for insightful discussions on mechanics, D. Lee and J. Rosenfeld for helpful discussions on zeta potential characterization and L. Yang for discussions on particle synthesis. This work was partially funded by the pilot grant programme from the Center for Innovation and Precision Dentistry at the University of Pennsylvania, by the National Science Foundation under CAREER Grant no. 1943243 and by the American Society of Mechanical Engineers (ASME) Applied Mechanics Division Haythornthwaite Foundation Research Initiation Grant (J.H.P. and Z.J.). This work was carried out in part at the Singh Center for Nanotechnology, which is supported by the National Science Foundation National Nanotechnology Coordinated Infrastructure Program under grant NNCI-1542153.

Author information

Authors and Affiliations

Contributions

Z.J. and J.H.P conceived the idea. Z.J. designed and performed the experiments, and J.H.P directed the project. All authors analysed the data and wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Materials thanks the anonymous reviewers for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–34, Sections 1–28 and Tables 1–8.

Rights and permissions

About this article

Cite this article

Jiang, Z., Pikul, J.H. Centimetre-scale crack-free self-assembly for ultra-high tensile strength metallic nanolattices. Nat. Mater. 20, 1512–1518 (2021). https://doi.org/10.1038/s41563-021-01039-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-021-01039-7

This article is cited by

-

Macroscopic photonic single crystals via seeded growth of DNA-coated colloids

Nature Communications (2023)

-

Dislocation-strained MoS2 nanosheets for high-efficiency hydrogen evolution reaction

Nano Research (2022)

-

Nano goes the distance

Nature Materials (2021)