Abstract

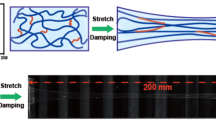

In nature, bone adapts to mechanical forces it experiences, strengthening itself to match the conditions placed upon it. Here we report a composite material that adapts to the mechanical environment it experiences—varying its modulus as a function of force, time and the frequency of mechanical agitation. Adaptation in the material is managed by mechanically responsive ZnO, which controls a crosslinking reaction between a thiol and an alkene within a polymer composite gel, resulting in a mechanically driven ×66 increase in modulus. As the amount of chemical energy is a function of the mechanical energy input, the material senses and adapts its modulus along the distribution of stress, resembling the bone remodelling behaviour that materials can adapt accordingly to the loading location. Such material design might find use in a wide range of applications, from adhesives to materials that interface with biological systems.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. The other data that support the findings of this study are available within the paper and its Supplementary Information files and available from the corresponding author upon reasonable request.

References

Gin, S., Dillmann, P. & Birbilis, N. Material degradation foreseen in the very long term: the case of glasses and ferrous metals. NPJ Mater. Degrad. 1, 10 (2017).

Patrick, J. F., Robb, M. J., Sottos, N. R., Moore, J. S. & White, S. R. Polymers with autonomous life-cycle control. Nature 540, 363–370 (2016).

White, S. R. et al. Autonomic healing of polymer composites. Nature 409, 794–797 (2001).

Diesendruck, C. E., Sottos, N. R., Moore, J. S. & White, S. R. Biomimetic self-healing. Angew. Chem. Int. Ed. 54, 10428–10447 (2015).

Shchukin, D. & Möhwald, H. A coat of many functions. Science 341, 1458–1459 (2013).

Chen, J.-H., Liu, C., You, L. & Simmons, C. A. Boning up on Wolff’s law: mechanical regulation of the cells that make and maintain bone. J. Biomech. 43, 108–118 (2010).

Christen, P. et al. Bone remodelling in humans is load-driven but not lazy. Nat. Commun. 5, 4855 (2014).

Lin, S. et al. Anti-fatigue-fracture hydrogels. Sci. Adv. 5, eaau8528 (2019).

Chen, Y., Kushner, A. M., Williams, G. A. & Guan, Z. Multiphase design of autonomic self-healing thermoplastic elastomers. Nat. Chem. 4, 467–472 (2012).

Orrego, S. et al. Bioinspired materials with self-adaptable mechanical properties. Adv. Mater. https://doi.org/10.1002/adma.201906970 (2020).

Brown, E. et al. Generality of shear thickening in dense suspensions. Nat. Mater. 9, 220–224 (2010).

Xu, D., Hawk, J. L., Loveless, D. M., Jeon, S. L. & Craig, S. L. Mechanism of shear thickening in reversibly cross-linked supramolecular polymer networks. Macromolecules 43, 3556–3565 (2010).

Ramirez, A. L. B. et al. Mechanochemical strengthening of a synthetic polymer in response to typically destructive shear forces. Nat. Chem. https://doi.org/10.1038/nchem.1720 (2013).

Li, J., Nagamani, C. & Moore, J. S. Polymer mechanochemistry: from destructive to productive. Acc. Chem. Res. 48, 2181–2190 (2015).

Chen, Z. et al. Mechanochemical unzipping of insulating polyladderene to semiconducting polyacetylene. Science 357, 475–479 (2017).

Baytekin, H. T., Baytekin, B. & Grzybowski, B. A. Mechanoradicals created in “polymeric sponges” drive reactions in aqueous media. Angew. Chem. Int. Ed. 51, 3596–3600 (2012).

Matsuda, T., Kawakami, R., Namba, R., Nakajima, T. & Gong, J. P. Mechanoresponsive self-growing hydrogels inspired by muscle training. Science 363, 504–508 (2019).

Wang, Z. et al. Ultrasonication-induced aqueous atom transfer radical polymerization. ACS Macro Lett. 7, 275–280 (2018).

Collins, J. et al. Sonochemically initiated RAFT polymerization in organic solvents. Macromolecules 52, 185–195 (2019).

Mohapatra, H. et al. Ultrasound promoted step-growth polymerization and polymer crosslinking via copper catalyzed azide–alkyne “click” reaction. Angew. Chem. Int. Ed. 57, 11208–11212 (2018).

Ren, W., Peng, B., Shen, J., Li, Y. & Yu, Y. Study on vibration characteristics and human riding comfort of a special equipment cab. J. Sens. 2018, 7140610 (2018).

Yu, Y., Naganathan, N. G. & Dukkipati, R. V. A literature review of automotive vehicle engine mounting systems. Mech. Mach. Theory 36, 123–142 (2001).

Xu, H., Yuan, S. & Zong, L. Analysis of the time-frequency characteristics of internal combustion engine vibration signal based on Hilbert-Huang transform. In 2010 3rd International Congress on Image and Signal Processing 3400–3404 (IEEE, 2010).

Le, M. Q. et al. Review on energy harvesting for structural health monitoring in aeronautical applications. Prog. Aerosp. Sci. 79, 147–157 (2015).

Kubota, K., Pang, Y., Miura, A. & Ito, H. Redox reactions of small organic molecules using ball milling and piezoelectric materials. Science 366, 1500–1504 (2019).

Lalanne, C. Mechanical Vibration and Shock Analysis, Fatigue Damage (John Wiley & Sons, 2010).

Wang, Z., Ayarza, J. & Esser-Kahn, A. P. Mechanically initiated bulk-scale free-radical polymerization. Angew. Chem. Int. Ed. 58, 12023–12026 (2019).

Wang, Z. et al. Enhancing mechanically induced ATRP by promoting interfacial electron transfer from piezoelectric nanoparticles to Cu catalysts. Macromolecules 50, 7940–7948 (2017).

Skinner, E. K., Whiffin, F. M. & Price, G. J. Room temperature sonochemical initiation of thiol-ene reactions. Chem. Commun. 48, 6800–6802 (2012).

Lowe, A. B. Thiol–ene “click” reactions and recent applications in polymer and materials synthesis: a first update. Polym. Chem. 5, 4820–4870 (2014).

Xu, J. & Boyer, C. Visible light photocatalytic thiol–ene reaction: an elegant approach for fast polymer postfunctionalization and step-growth polymerization. Macromolecules 48, 520–529 (2015).

Mohapatra, H., Kleiman, M. & Esser-Kahn, A. P. Mechanically controlled radical polymerization initiated by ultrasound. Nat. Chem. 9, 135–139 (2017).

Hoyle, C. E., Lee, T. Y. & Roper, T. Thiol–enes: chemistry of the past with promise for the future. J. Polym. Sci. A Polym. Chem. 42, 5301–5338 (2004).

Cole, M. A., Jankousky, K. C. & Bowman, C. N. Redox initiation of bulk thiol–ene polymerizations. Polym. Chem. 4, 1167–1175 (2013).

Mohinuddin, P. M. K. & Gangi Reddy, N. C. Zinc oxide catalyzed solvent-free mechanochemical route for C–S bond construction: a sustainable process. Eur. J. Org. Chem. 2017, 1207–1214 (2017).

Kim, S. M., Kim, H., Nam, Y. & Kim, S. Effects of external surface charges on the enhanced piezoelectric potential of ZnO and AlN nanowires and nanotubes. AIP Adv. 2, 042174 (2012).

Weston, J. S., Harwell, J. H. & Grady, B. P. Rheological characterization of yield stress gels formed via electrostatic heteroaggregation of metal oxide nanoparticles. Soft Matter 13, 6743–6755 (2017).

Lang, G. F. & Snyder, D. Understanding the physics of electrodynamic shaker performance. Sound Vib. 35, 24–33 (2001).

Wu, J. et al. Insights into the role of ferroelectric polarization in piezocatalysis of nanocrystalline BaTiO3. ACS Appl. Mater. Interfaces 10, 17842–17849 (2018).

Singh, R. P. & Kundu, P. P. Thermogelation of methylcellulose from solution in N,N-dimethylformamide and characterization of the transparent gels. J. Appl. Polym. Sci. 110, 3031–3037 (2008).

Acknowledgements

We thank M. Garg for performing the μCT imaging and S. C. W. Huang for the helpful discussion. Parts of this work were carried out at the Soft Matter Characterization Facility, the FIB-SEM facility of the University of Chicago and the SPID facility of Northwestern University’s NUANCE Center. The work was supported by AFOSR COE 5‐29168, NSF CHE‐1710116 and ARO W911NF‐17‐1‐0598 (71524‐CH). We dedicate this paper to Prof. Scott White who served as both an inspiration for this work and a personal inspiration for the authors.

Author information

Authors and Affiliations

Contributions

Z.W., J.W., J.A. and A.P.E.-K. conceived the concept. Z.W., J.W. and A.P.E.-K. designed the experiments. Z.W., J.W., J.A., Z.H. and S.M. performed the experiments and analysed the data. T.S. conducted the finite element simulation. All authors participated in writing the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Materials thanks Stephen Craig and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–14 and Tables 1–5.

Supplementary Video 1

Compression test of the control sample without mechanical activation.

Supplementary Video 2

Compression test of the organo-gel via mechano-chemical crosslinking.

Source data

Source Data Fig. 1

Molecular weight versus monomer conversion and GPC traces at different times.

Source Data Fig. 2

Stress–strain curves of the gel.

Source Data Fig. 3

Storage modulus change as a function of force, frequency and time.

Rights and permissions

About this article

Cite this article

Wang, Z., Wang, J., Ayarza, J. et al. Bio-inspired mechanically adaptive materials through vibration-induced crosslinking. Nat. Mater. 20, 869–874 (2021). https://doi.org/10.1038/s41563-021-00932-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-021-00932-5

This article is cited by

-

Bioinspired nanocomposites with self-adaptive mechanical properties

Nano Research (2024)

-

Thermally trainable dual network hydrogels

Nature Communications (2023)

-

Bioinspired mechanical mineralization of organogels

Nature Communications (2023)

-

Temperature-dependent rheological behaviour of methylcellulose nanocomposite organogels

Macromolecular Research (2023)

-

Modulus adaptive lubricating prototype inspired by instant muscle hardening mechanism of catfish skin

Nature Communications (2022)