Abstract

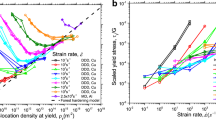

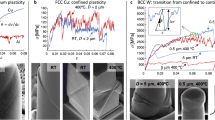

For millennia, humans have exploited the natural property of metals to get stronger or harden when mechanically deformed. Ultimately rooted in the motion of dislocations, mechanisms of metal hardening have remained in the cross-hairs of physical metallurgists for over a century. Here, we performed atomistic simulations at the limits of supercomputing that are sufficiently large to be statistically representative of macroscopic crystal plasticity yet fully resolved to examine the origins of metal hardening at its most fundamental level of atomic motion. We demonstrate that the notorious staged (inflection) hardening of metals is a direct consequence of crystal rotation under uniaxial straining. At odds with widely divergent and contradictory views in the literature, we observe that basic mechanisms of dislocation behaviour are the same across all stages of metal hardening.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All figures in the main text and Supplementary Information, as well as the data used to produce the figures, are available at https://figshare.com/projects/Data_from_figures_in_Atomistic_insights_into_metal_hardening_/89417. In addition, large arrays of data (around 400 GB in total) used for producing plots and Supplementary Videos 1–5 have been retained and are available from the corresponding author on reasonable request.

Code availability

The open-source computer code LAMMPS used in this study is developed and maintained at the Sandia National Laboratories. LAMMPS is available at https://lammps.sandia.gov.

References

Kocks, U. F. & Mecking, H. Physics and phenomenology of strain hardening: the FCC case. Prog. Mater. Sci. 48, 171–273 (2003).

Cottrell, A. H. Commentary. A brief view on work hardening. Dislocations Solids 11, vii–xvii (2002).

Takeuchi, T. Work hardening of copper single crystals with multiple glide orientations. Trans. JIM 16, 629–640 (1975).

Lücke, K. & Lange, H. Uber die form der verfestgungskurve von reinstaluminiumkristallen un die bildung von deformationsbandern. Z. Metallk. 43, 55–66 (1952).

Staubwasser, W. Uber die verfestigung von aluminium einkristallen (99.99% Al) und ihre deutung. Acta Metall. 7, 43–50 (1969).

Clarebrough, L. M. & Hargreaves, M. E. The orientation dependence of work-hardening in crystals of face-centered cubic metals. Aust. J. Phys. 13, 316–325 (1960).

Nabarro, F. R. N., Basinski, Z. S. & Holt, D. B. The plasticity of pure single crystals. Adv. Phys. 13, 193–323 (1964).

Noggle, T. S. & Koehler, J. S. Electron microscopy of aluminum crystals deformed at various temperatures. J. Appl. Phys. 28, 53–62 (1957).

Garstone, J., Honeycombe, R. W. K. & Greetham, G. Easy glide of cubic metal crystals. Acta Metall. 4, 485–494 (1956).

Hosford, W. F., Fleischer, R. L. & Backofen, W. A. Tensile deformation of aluminum single crystals at low temperatures. Acta Metall. 8, 187–199 (1960).

Orowan, E. Zur kristallplastizitat. Z. Phys. 89, 605–659 (1934).

Taylor, G. The mechanism of plastic deformation in crystal. Part I: theoretical. Proc. R. Soc. A 145, 363–404 (1934).

Polanyi, M. Über eine art gitterstörung, die einen kristall plastisch machen könnt. Z. Phys. 89, 660–664 (1934).

Hirsch, P. B., Horne, R. W. & Whelan, M. J. Direct observations of the arrangement and motion of dislocations in aluminium. Phil. Mag. 86, 677–684 (1956).

Rosenhain, W. Further observations on slip-bands in metallic fractures: preliminary note. Proc. R. Soc. Lond. 74, 557–562 (1905).

Frenkel, J. Zur theorie der elastizitätsgrenze und der festigkeit kristallinischer körper. Z. Phys. 37, 572–609 (1926).

Schmid, E., Boas, W. Kristallplastizität (Struktur und Eigenschaften der Materie Vol. 17, Julius Springer, 1935).

Schmid, E. Beiträge zur physik und metallographie des magnesiums. Z. Elektrochem. Angew. P. 37, 447–459 (1931).

Mark, H., Polanyi, M. & Schmid, E. Vorgänge bei der dehnung von zinkkristallen. Z. Phys. 12, 78–110 (1923).

Hosford, W. F. Mechanical Behavior of Materials 2nd edn 129–131 (Cambridge Univ. Press, 2009).

Kubin, L. P. & Canova, G. The modeling of dislocation patterns. Scripta Metall. Mater. 27, 957–962 (1991).

Bulatov, V. V. & Cai, W. Computer Simulations of Dislocations 196–240 (Oxford Univ. Press, 2006).

Liu, X.-Y., Ercolessi, F. & Adams, J. B. Aluminium interatomic potential from density functional theory calculations with improved stacking fault energy. Model. Simul. Mater. Sci. Eng. 12, 665–670 (2004).

Zepeda-Ruiz, L. A., Stukowski, A., Oppelstrup, T. & Bulatov, V. V. Probing the limits of metal plasticity with molecular dynamics simulations. Nature 550, 492–495 (2017).

Aubry, S., Rhee, M., Hommes, G., Bulatov, V. V. & Arsenlis, A. Dislocation dynamics in hexagonal close-packed crystals. J. Mech. Phys. Solids 94, 105–126 (2016).

Stricker, M. & Weygand, D. Dislocation multiplication mechanisms—Glissile junctions and their role on the plastic deformation at the microscale. Acta Mater. 99, 130–139 (2015).

Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2010).

Stukowski, A. & Albe, K. Extracting dislocations and non-dislocation crystal defects from atomistic simulation data. Model. Simul. Mater. Sci. Eng. 18, 085001 (2010).

Miller, W. H. A Treatise on Crystallography (J. & J. J. Deighton, 1839).

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 117, 1–19 (1995).

Parrinello, M. & Rahman, A. Polymorphic transitions in single crystals: a new molecular dynamics method. J. Appl. Phys. 52, 7182–7190 (1981).

Acknowledgements

We acknowledge discussions with W. Cai, E. Tadmor and D. Karls and editorial suggestions from D. Bulatova. This work was funded by the NNSA ASC Program and Technische Universität Darmstadt and was performed under the auspices of the US Department of Energy by Lawrence Livermore National Laboratory under contract number W-7405-Eng-48. Computing support came from the DOE INCITE programme and LLNL Computing Grand Challenge programme. The simulations were performed on Mira and Vulcan supercomputers at the Argonne Laboratory Computational Facility and Livermore Computing Facility, respectively. We dedicate this paper to the memory of A. Argon.

Author information

Authors and Affiliations

Contributions

L.A.Z.-R. and R.F. ran atomistic simulations. L.A.Z.-R. produced three atomistic videos. A.S. developed methods for in silico computational microscopy and visualization. T.O. optimized run-time efficiency and data management of ultra-large-scale simulations. N.B. developed algorithms for initialization of the atomistic simulations. N.R.B. performed finite-element simulations and produced the dog bone video. V.V.B. developed the concept, planned the research and generated starting configurations for the MD simulations. All authors analysed the simulation results and wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Discussion 1–5, Figs. 1–4 and Tables 1 and 2.

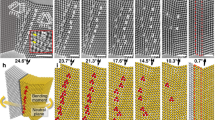

Supplementary Video 1

Simulated response of single-crystal aluminium to tensile straining along the x axis initially oriented along the [001] direction of the cubic lattice. Two animated sequences at the top depict continuous elongation of the simulated crystal along the x axis and simultaneous reduction of its lateral dimensions due to the Poisson effect. The sequence at the top left shows emergence and coarsening of slip traces on fictitious surfaces of the simulated crystal. The sequence at the top right shows dislocation motion and multiplication resulting in the development of a dense dislocation network. Shown at the bottom left is the stress–strain response of this crystal under tensile straining, which is distinctly parabolic (no inflection). At the bottom right is the orientation trajectory of the tensile axis expressed in a frame tied to the cubic lattice of the strained crystal. The axis remains within 2 angular degrees from its initial [001] orientation during straining. All four animated sequences are synchronized. Axis orientations of the Laboratory (specimen) frame are shown at the far left.

Supplementary Video 2

Simulated response of single-crystal aluminium to tensile straining along the x axis initially oriented along the [101] direction of the cubic lattice. The meaning of the four synchronized sequences is as explained in the caption to Supplementary Video 1. In this case an initially orthorhombic crystal not only elongates along its straining axis x, but also changes its shape and becomes distinctly triclinic. Although not immediately obvious from the changing orientations of the slip traces in the upper left sequence, axis rotation from its initial [101] orientation at the corner of the standard triangle towards [112] as well as axis overshoot, are both clearly shown at the bottom right. The stress–strain response shown at the bottom left is a typical staged (inflection) hardening.

Supplementary Video 3

Simulated response of single-crystal aluminium to tensile straining along the x axis initially oriented along the [213] direction of the cubic lattice. The meaning of the four synchronized sequences is as explained in the caption to Supplementary Video 1. As shown at the bottom right, the axis rotates along the triangle edge towards the [112] orientation. The stress–strain response shown at the bottom left shows a distinct inflection.

Supplementary Video 4

Deformation of a dog bone specimen subjected to uniaxial straining in tension. Left, evolution of the stress tensor in the dog bone under tensile straining. Colours other than white indicate a misalignment between the first principal axis of the stress tensor (corresponding to its maximum eigenvalue) and the tensile axis. Right, six components of the stress tensor averaged over the middle portion of the specimen. The position of the vertical bar along the strain axis is synchronized with specimen deformation shown on left. All stress components but σxx remain close to zero along the entire straining path.

Rights and permissions

About this article

Cite this article

Zepeda-Ruiz, L.A., Stukowski, A., Oppelstrup, T. et al. Atomistic insights into metal hardening. Nat. Mater. 20, 315–320 (2021). https://doi.org/10.1038/s41563-020-00815-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-020-00815-1

This article is cited by

-

Nonequilibrium statistical thermodynamics of thermally activated dislocation ensembles: part 3—Taylor–Quinney coefficient, size effects and generalized normality

Journal of Materials Science (2024)

-

Atomistic modeling of idealized equal channel angular pressing process

Journal of Materials Science (2024)

-

Dislocation interactions during plastic relaxation of epitaxial colloidal crystals

Nature Communications (2023)

-

Regulation on Annealing Multiscale Laminar Structure and Mechanical Characteristics of Plain Medium Carbon Steel by Warm Pre-deformation Extent

Metallurgical and Materials Transactions A (2023)

-

Sweep-tracing algorithm: in silico slip crystallography and tension-compression asymmetry in BCC metals

Materials Theory (2022)