Abstract

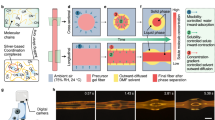

Early insights into the unique structure and properties of native silk suggested that β-sheet nanocrystallites in silk would degrade prior to melting when subjected to thermal processing. Since then, canonical approaches for fabricating silk-based materials typically involve solution-derived processing methods, which have inherent limitations with respect to silk protein solubility and stability in solution, and time and cost efficiency. Here we report a thermal processing method for the direct solid-state moulding of regenerated silk into bulk ‘parts’ or devices with tunable mechanical properties. At elevated temperature and pressure, regenerated amorphous silk nanomaterials with ultralow β-sheet content undergo thermal fusion via molecular rearrangement and self-assembly assisted by bound water to form a robust bulk material that retains biocompatibility, degradability and machinability. This technique reverses presumptions about the limitations of direct thermal processing of silk into a wide range of new material formats and composite materials with tailored properties and functionalities.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that all data supporting the findings of this study are available within the paper and its Supplementary Information files and from the corresponding author upon reasonable request.

References

Vepari, C. & Kaplan, D. L. Silk as a biomaterial. Prog. Polym. Sci. 32, 991–1007 (2007).

Vollrath, F. & Porter, D. Spider silk as archetypal protein elastomer. Soft Matter 2, 377–385 (2006).

Vollrath, F. & Knight, D. P. Liquid crystalline spinning of spider silk. Nature 410, 541–548 (2001).

Shao, Z. Z. & Vollrath, F. Materials: surprising strength of silkworm silk. Nature 418, 741 (2002).

Jin, H. J. & Kaplan, D. L. Mechanism of silk processing in insects and spiders. Nature 424, 1057–1061 (2003).

Askarieh, G. et al. Self-assembly of spider silk proteins is controlled by a pH-sensitive relay. Nature 465, 236–238 (2010).

Hagn, F. et al. A conserved spider silk domain acts as a molecular switch that controls fibre assembly. Nature 465, 239–242 (2010).

Andersson, M., Johansson, J. & Rising, A. Silk spinning in silkworms and spiders. Int. J. Mol. Sci. 17, 1290–1303 (2016).

Yarger, J. L., Cherry, B. R. & van der Vaart, A. Uncovering the structure-function relationship in spider silk. Nat. Rev. Mater. 3, 18008–18018 (2018).

Guo, C. et al. Structural comparison of various silkworm silks: an insight into the structure-property relationship. Biomacromolecules 19, 906–917 (2018).

Rockwood, D. N. et al. Materials fabrication from Bombyx mori silk fibroin. Nat. Protoc. 6, 1612–1631 (2011).

Teule, F. et al. A protocol for the production of recombinant spider silk-like proteins for artificial fiber spinning. Nat. Protoc. 4, 341–355 (2009).

Heim, M., Keerl, D. & Scheibel, T. Spider silk: from soluble protein to extraordinary fiber. Angew. Chem. Int. Edit. 48, 3584–3596 (2009).

Andersson, M. et al. Biomimetic spinning of artificial spider silk from a chimeric minispidroin. Nat. Chem. Biol. 13, 262–264 (2017).

Zhou, Z. et al. Engineering the future of silk materials through advanced manufacturing. Adv. Mater. 30, 1706983–1707008 (2018).

Kundu, B., Rajkhowa, R., Kundu, S. C. & Wang, X. Silk fibroin biomaterials for tissue regenerations. Adv. Drug Deliv. Rev. 65, 457–470 (2013).

Abbott, R. D., Kimmerling, E. P., Cairns, D. M. & Kaplan, D. L. Silk as a biomaterial to support long-term three-dimensional tissue cultures. ACS Appl. Mater. Interfaces 8, 21861–21868 (2016).

Bhattacharjee, P. et al. Silk scaffolds in bone tissue engineering: an overview. Acta Biomater. 63, 1–17 (2017).

Crivelli, B. et al. Silk nanoparticles: from inert supports to bioactive natural carriers for drug delivery. Soft Matter 14, 546–557 (2018).

Holland, C., Numata, K., Rnjak-Kovacina, J. & Seib, F. P. The biomedical use of silk: past, present, future. Adv. Healthc. Mater. 8, 1800465–1800490 (2019).

Koh, L.-D. et al. Structures, mechanical properties and applications of silk fibroin materials. Prog. Polym. Sci. 46, 86–110 (2015).

Pauling, L. & Corey, R. B. The pleated sheet, a new layer configuration of polypeptide chains. Proc. Natl Acad. Sci. USA 37, 251–256 (1951).

Marsh, R. E., Corey, R. B. & Pauling, L. An investigation of the structure of silk fibroin. Biochim. Biophys. Acta 16, 1–34 (1955).

Keten, S., Xu, Z., Ihle, B. & Buehler, M. J. Nanoconfinement controls stiffness, strength and mechanical toughness of beta-sheet crystals in silk. Nat. Mater. 9, 359–367 (2010).

Liang, C. X. & Hirabayashi, K. Influence of solvation temperature on the molecular-features and physical-properties of fibroin membrane. Polymer 33, 4388–4393 (1992).

Trabbic, K. A. & Yager, P. Comparative structural characterization of naturally- and synthetically-spun fibers of Bombyx mori fibroin. Macromolecules 31, 462–471 (1998).

Ha, S. W., Tonelli, A. E. & Hudson, S. M. Structural studies of Bombyx mori silk fibroin during regeneration from solutions and wet fiber spinning. Biomacromolecules 6, 1722–1731 (2005).

Cheng, G., Wang, X., Tao, S., Xia, J. & Xu, S. Differences in regenerated silk fibroin prepared with different solvent systems: from structures to conformational changes. J. Appl. Polym. Sci. 132, 41959–41966 (2015).

Marelli, B. et al. Programming function into mechanical forms by directed assembly of silk bulk materials. Proc. Natl Acad. Sci. USA 114, 451–456 (2017).

Yamaguchi, K. et al. Primary structure of the silk fibroin light chain determined by cDNA sequencing and peptide analysis. J. Mol. Biol. 210, 127–139 (1989).

Zhou, C. Z. et al. Silk fibroin: structural implications of a remarkable amino acid sequence. Proteins 44, 119–122 (2001).

Suzuki, Y., Yamazaki, T., Aoki, A., Shindo, H. & Asakura, T. NMR study of the structures of repeated sequences, GAGXGA (X = S, Y, V), in Bombyx mori liquid silk. Biomacromolecules 15, 104–112 (2014).

Hu, X., Kaplan, D. & Cebe, P. Effect of water on the thermal properties of silk fibroin. Thermochim. Acta 461, 137–144 (2007).

Agarwal, N., Hoagland, D. A. & Farris, R. J. Effect of moisture absorption on the thermal properties of Bombyx mori silk fibroin films. J. Appl. Polym. Sci. 63, 401–410 (1997).

Yazawa, K., Ishida, K., Masunaga, H., Hikima, T. & Numata, K. Influence of water content on the beta-sheet formation, thermal stability, water removal, and mechanical properties of silk materials. Biomacromolecules 17, 1057–1066 (2016).

Brenckle, M. A. et al. Protein-protein nanoimprinting of silk fibroin films. Adv. Mater. 25, 2409–2414 (2013).

Brenckle, M. A. et al. Methods and applications of multilayer silk fibroin laminates based on spatially controlled welding in protein films. Adv. Funct. Mater. 26, 44–50 (2016).

Cebe, P. et al. Beating the heat—fast scanning melts silk beta sheet crystals. Sci. Rep. 3, 1130–1136 (2013).

Lu, Q. et al. Silk self-assembly mechanisms and control from thermodynamics to kinetics. Biomacromolecules 13, 826–832 (2012).

Koebley, S. R. et al. Silk reconstitution disrupts fibroin self-assembly. Biomacromolecules 16, 2796–2804 (2015).

Perrone, G. S. et al. The use of silk-based devices for fracture fixation. Nat. Commun. 5, 3385–3393 (2014).

Li, C. et al. Regenerated silk materials for functionalized silk orthopedic devices by mimicking natural processing. Biomaterials 110, 24–33 (2016).

Liu, K. et al. A silk cranial fixation system for neurosurgery. Adv. Healthc. Mater. 7, 1701359–1701371 (2018).

Guziewicz, N. A., Massetti, A. J., Perez-Ramirez, B. J. & Kaplan, D. L. Mechanisms of monoclonal antibody stabilization and release from silk biomaterials. Biomaterials 34, 7766–7775 (2013).

Li, A. B., Kluge, J. A., Guziewicz, N. A., Omenetto, F. G. & Kaplan, D. L. Silk-based stabilization of biomacromolecules. J. Control. Release 219, 416–430 (2015).

Lee, J. H. et al. Preparation of new natural silk non-woven fabrics by using adhesion characteristics of sericin and their characterization. Int. J. Biol. Macromol. 106, 39–47 (2018).

Kluge, J. A., Kahn, B. T., Brown, J. E., Omenetto, F. G. & Kaplan, D. L. Optimizing molecular weight of lyophilized silk as a shelf-stable source material. ACS Biomater. Sci. Eng. 2, 595–605 (2016).

Wegst, U. G., Bai, H., Saiz, E., Tomsia, A. P. & Ritchie, R. O. Bioinspired structural materials. Nat. Mater. 14, 23–36 (2015).

Mao, L. B. et al. Synthetic nacre by predesigned matrix-directed mineralization. Science 354, 107–110 (2016).

Acknowledgements

This work was supported by grants from the National Institutes of Health (R01AR068048, R01DE016525), the Air Force Office of Scientific Research (FA9550-17-1-0333) and the Stepping Strong Foundation, Brigham and Women’s Hospital (A. Nazarian and G. Dyer). We thank J. Yarger, B. Cherry and N. Sisco at Arizona State University for help with NMR instrumentation and data collection. We thank G. Dyer for clinical relevance discussions. We also thank S. Maccorkle and D. Dupuis at the Tufts University Machine Shop for materials machining.

Author information

Authors and Affiliations

Contributions

C.G., C.L and D.L.K. conceived and designed the project and experiments; C.G., C.L., H.V.V. and Y.Q. performed the materials fabrication and characterizations; P.H., A.L. and A.N. performed animal studies; C.G., C.L., X.M., S.L. and S.J.L. performed the data analysis and results discussion; D.L.K. supervised the entire project; and C.G. and C.L. wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary information

Supplementary Figures 1–27, Tables 1–8, a note and refs. 1–7.

Rights and permissions

About this article

Cite this article

Guo, C., Li, C., Vu, H.V. et al. Thermoplastic moulding of regenerated silk. Nat. Mater. 19, 102–108 (2020). https://doi.org/10.1038/s41563-019-0560-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-019-0560-8

This article is cited by

-

The construction of elastin-like polypeptides and their applications in drug delivery system and tissue repair

Journal of Nanobiotechnology (2023)

-

Hierarchically structured bioinspired nanocomposites

Nature Materials (2023)

-

Volumetric additive manufacturing of pristine silk-based (bio)inks

Nature Communications (2023)

-

Biocompatible Scaffold Based on Silk Fibroin for Tissue Engineering Applications

Journal of The Institution of Engineers (India): Series C (2023)

-

Effect of coconut coir and regenerated silk microparticles as blends and natural binders for construction and demolition waste (CDW) wood on the mechanical, thermal, and structural properties of biomicrocomposites prepared by hot-pressing

Biomass Conversion and Biorefinery (2023)