Abstract

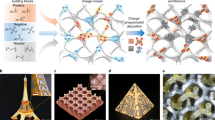

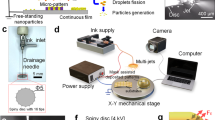

Piezoelectric coefficients are constrained by the intrinsic crystal structure of the constituent material. Here we describe design and manufacturing routes to previously inaccessible classes of piezoelectric materials that have arbitrary piezoelectric coefficient tensors. Our scheme is based on the manipulation of electric displacement maps from families of structural cell patterns. We implement our designs by additively manufacturing free-form, perovskite-based piezoelectric nanocomposites with complex three-dimensional architectures. The resulting voltage response of the activated piezoelectric metamaterials at a given mode can be selectively suppressed, reversed or enhanced with applied stress. Additionally, these electromechanical metamaterials achieve high specific piezoelectric constants and tailorable flexibility using only a fraction of their parent materials. This strategy may be applied to create the next generation of intelligent infrastructure, able to perform a variety of structural and functional tasks, including simultaneous impact absorption and monitoring, three-dimensional pressure mapping and directionality detection.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated during this study are included within the paper and its Supplementary Information files and/or are available from the corresponding author upon request.

References

Ferren, R. A. Advances in polymeric piezoelectric transducers. Nature 350, 26–27 (1991).

Anderson, J. C. & Eriksson, C. Piezoelectric properties of dry and wet bone. Nature 227, 491–492 (1970).

Priya, S. & Nahm, S. Lead-free Piezoelectrics (Springer, New York, 2011).

Li, F. et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 17, 349–354 (2018).

Guerin, S. et al. Control of piezoelectricity in amino acids by supramolecular packing. Nat. Mater. 17, 180–186 (2018).

Egusa, S. et al. Multimaterial piezoelectric fibres. Nat. Mater. 9, 643–648 (2010).

Lu, X., Qu, H. & Skorobogatiy, M. Piezoelectric micro- and nanostructured fibers fabricated from thermoplastic nanocomposites using a fiber drawing technique: comparative study and potential applications. ACS Nano 11, 2103–2114 (2017).

Masmanidis, S. C. et al. Multifunctional nanomechanical systems via tunably coupled piezoelectric actuation. Science 317, 780–783 (2007).

Wang, X. et al. Subatomic deformation driven by vertical piezoelectricity from CdS ultrathin films. Sci. Adv. 2, e1600209 (2016).

Ganeshkumar, R., Cheah, C. W., Xu, R., Kim, S.-G. & Zhao, R. A high output voltage flexible piezoelectric nanogenerator using porous lead-free KNbO3 nanofibers. Appl. Phys. Lett. 111, 013905 (2017).

Gafforelli, G., Corigliano, A., Xu, R. & Kim, S.-G. Experimental verification of a bridge-shaped, nonlinear vibration energy harvester. Appl. Phys. Lett. 105, 203901 (2014).

Dagdeviren, C. et al. Conformal piezoelectric systems for clinical and experimental characterization of soft tissue biomechanics. Nat. Mater. 14, 728–736 (2015).

Grupp, D. E. & Goldman, A. M. Giant piezoelectric effect in strontium titanate at cryogenic temperatures. Science 276, 392–394 (1997).

Espinosa, H. D., Bernal, R. A. & Minary-Jolandan, M. A review of mechanical and electromechanical properties of piezoelectric nanowires. Adv. Mater. 24, 4656–4675 (2012).

Laurenti, M. et al. Nanobranched ZnO Structure: p-Type doping induces piezoelectric voltage generation and ferroelectric-photovoltaic effect. Adv Mater 27, 4218–4223 (2015).

Shin, S. H. et al. Lithium-doped zinc oxide nanowires-polymer composite for high performance flexible piezoelectric nanogenerator. ACS Nano 8, 10844–10850 (2014).

Harris, D. T., Burch, M. J., Mily, E. J., Dickey, E. C. & Maria, J. P. Microstructure and dielectric properties with CuO additions to liquid phase sintered BaTiO3 thin films. J. Mater. Res. 31, 1018–1026 (2016).

Nag, S. K. & Agrawal, D. C. Piezoelectric and mechanical-properties of ceria-doped lead zirconate titanate ceramics. J. Mater. Sci. 27, 4125–4130 (1992).

Manna, S., Brennecka, G. L., Stevanović, V. & Ciobanu, C. V. Tuning the piezoelectric and mechanical properties of the AlN system via alloying with YN and BN. J. Appl. Phys. 122, 105101 (2017).

McCall, W. R., Kim, K., Heath, C., La Pierre, G. & Sirbuly, D. J. Piezoelectric nanoparticle-polymer composite foams. ACS Appl. Mater. Inter. 6, 19504–19509 (2014).

Smay, J. E., Tuttle, B. & III, J. C. Piezoelectric and Acoustic Materials for Transducer Applications 305–318 (Springer, Boston, 2008).

Challagulla, K. S. & Venkatesh, T. A. Electromechanical response of piezoelectric foams. Acta Mater. 60, 2111–2127 (2012).

Zheng, X. et al. Ultralight, ultrastiff mechanical metamaterials. Science 344, 1373–1377 (2014).

Bauer, J. et al. Nanolattices: An emerging class of mechanical metamaterials. Adv. Mater. 29, 1701850 (2017).

Hashimoto, K. Y. & Yamaguchi, M. Elastic, piezoelectric and dielectric properties of composite materials. IEEE 1986 Ultras. Symp. 2, 697–702 (1986).

Glushanin, S., Topolov, V. Y. & Krivoruchko, A. V. Features of piezoelectric properties of 0–3 PbTiO3-type ceramic/polymer composites. Mater. Chem. Phys. 97, 357–364 (2006).

Huang, J. H. & Kuo, W. S. Micromechanics determination of the effective properties of piezoelectric composites containing spatially oriented short fibers. Acta Mater. 44, 4889–4898 (1996).

Bowen, C. R. & Topolov, V. Y. Electromechanical Properties In Composites Based On Ferroelectrics 1–202 (Springer, London, 2009).

Nix, E. L. & Ward, I. M. The measurement of the shear piezoelectric coefficients of polyvinylidene fluoride. Ferroelectrics 67, 137–141 (1986).

Wang, H., Zhang, Q. M., Cross, L. E. & Sykes, A. O. Piezoelectric, dielectric, and elastic properties of poly(vinylidene fluoride/trifluoroethylene). J. Appl. Phys. 74, 3394–3398 (1993).

Deshpande, V. S., Ashby, M. F. & Fleck, N. A. Foam topology bending versus stretching dominated architectures. Acta Mater. 49, 1035–1040 (2001).

Cui, H. C., Hensleigh, R., Chen, H. S. & Zheng, X. Y. Additive manufacturing and size-dependent mechanical properties of three-dimensional microarchitected, high-temperature ceramic metamaterials. J. Mater. Res. 33, 360–371 (2018).

Kim, K. et al. 3D optical printing of piezoelectric nanoparticle–polymer composite materials. ACS Nano 8, 9799–9806 (2014).

Singhal, N., Sharma, M. & Mangal, S. K. Optimal placement of piezoelectric patches over a smart structure. Integrated Ferroelectrics 183, 60–90 (2017).

Annamdas, V. G. M. & Soh, C. K. Influence of loading on the near field based passive metamaterial in structural health monitoring. Strut. Health Monit. 1, 633–640 (2015).

He, X. M. et al. Synthetic homeostatic materials with chemo-mechano-chemical self-regulation. Nature 487, 214–218 (2012).

Eliades, S. J. & Wang, X. Q. Neural substrates of vocalization feedback monitoring in primate auditory cortex. Nature 453, 1102–1106 (2008).

Wu, W. Z., Wen, X. N. & Wang, Z. L. Taxel-addressable matrix of vertical-nanowire piezotronic transistors for active and adaptive tactile imaging. Science 340, 952–957 (2013).

Liu, W. et al. Piezoelectric and mechanical properties of CaO reinforced porous PZT ceramics with one-dimensional pore channels. Ceramics Int. 43, 2063–2068 (2017).

Bowen, C. R., Perry, A., Lewis, A. C. F. & Kara, H. Processing and properties of porous piezoelectric materials with high hydrostatic figures of merit. J. Eur. Ceram. Soc. 24, 541–545 (2004).

Wang, J. X. et al. Microstructure, electrical and mechanical properties of MgO nanoparticles—reinforced porous PZT 95/5 ferroelectric ceramics. Ceramics Int. 39, 3915–3919 (2013).

Pu, J. A., Yan, X. J., Jiang, Y. D., Chang, C. E. & Lin, L. W. Piezoelectric actuation of direct-write electrospun fibers. Sensors Actuators A 164, 131–136 (2010).

He, X. J. & Yao, K. Crystallization mechanism and piezoelectric properties of solution-derived ferroelectric poly(vinylidene fluoride) thin films. Appl. Phys. Lett. 89, 112909 (2006).

Babu, I. & de With, G. Highly flexible piezoelectric 0–3 PZT-PDMS composites with high filler content. Composites Sci. Technol. 91, 91–97 (2014).

Fang, L. C., Li, J., Zhu, Z. Y., Orrego, S. & Kang, S. H. Piezoelectric polymer thin films with architected cuts. J. Mater. Res. 33, 330–342 (2018).

Wan, Hu,J. & Park, T. Continuum models for the plastic deformation of octet-truss lattice materials under multiaxial loading. J. Eng. Mater. Technol. 135, 021004 (2013).

Zheng, X. et al. Multiscale metallic metamaterials. Nat. Mater. 15, 1100–1106 (2016).

Netfabb, Netfabb Ultimate 2019 (Autodesk, 2019).

Liu, L., Kamm, P., Garcia-Moreno, F., Banhart, J. & Pasini, D. Elastic and failure response of imperfect three-dimensional metallic lattices: the role of geometric defects induced by Selective Laser Melting. J. Mech. Phys. Solids. 107, 160–184 (2017).

Abaqus, Abaqus 6.14 Documentation (Dassault Systèmes, 2014).

Kar-Gupta, R. & Venkatesh, T. A. Electromechanical response of piezoelectric composites: effects of geometric connectivity and grain size. Acta Mater. 56, 3810–3823 (2008).

Acknowledgements

We acknowledge funding from the ICTAS Junior Faculty Award, NSF CMMI 1727492, the Air Force Office of Scientific Research (FA9550-18-1-0299) and the Office of Naval Research (N00014-18-1-2553) for supporting this work. D.M. and S.P. acknowledge the financial support from NSF through award IIP-1832179. P.M. and M.G.K. are thankful for the support from Air Force Office of Scientific Research through grant FA9550-18-1-0233. We thank E. Ventrella, R. Mondschein and Dr. T. Long for help with collecting PZT particle diameter data, A. Wei, K. Jung, H. Chen, and Z. Xu for assitance with analysis and fabrication.

Author information

Authors and Affiliations

Contributions

X.Z. conceived and designed the research. R.H. synthesized the functionalized piezoelectric materials and functionalization measurement. H.C. fabricated samples, performed testing and data analysis. D.Y. and H.C. designed the models and performed the analytical and numerical calculations. H.C., R.H. and X.Z. developed the materials and fabrication methods. D.Y., H.C. and X.Z. developed the method for manipulating anisotropy. D.M., P.K., M.G.K. and S.P. developed the poling method and contributed to the testing of the piezoelectric properties of the 3D metamaterials. H.C., R.H., D.Y. and X.Z. wrote the manuscript with input from all authors. All authors participated in drafting the manuscript, discussion and interpretation of the data.

Corresponding author

Ethics declarations

Competing interests

The design and material fabrication methods have been submitted for pending US patents.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Sections 1–14, Supplementary Video Captions 1–5, Supplementary References 1–37, Supplementary Figures 1–24, Supplementary Tables 1–5.

Supplementary Video 1

Flexible metamaterial for energy conversion: hand tapping induced voltage response of the N = 12 flexible piezoelectric metamaterial conformally attached onto a curved surface.

Supplementary Video 2

Flexible 3D ring-like piezo-sensor: a ring-like sensor was prepared and tested to show the signal generated during the folding and unfolding process of human figures.

Supplementary Video 3

Directional voltage response: real-time voltage outputs of piezoelectric metamaterials comprising N = 5 node unit with θθ = 75°, 90° and 120° under impact coming from 1, 2 and 3 directions.

Supplementary Video 4

Drop-weight impact absorption and self-sensing: drop-weight impact test on the piezoelectric metamaterial comprised of N = 12 node units.

Supplementary Video 5

Directionality sensing: real-time voltage output of the piezoelectric infrastructure comprised of stacked architecture under impact coming from 1, 2 and 3 directions.

Rights and permissions

About this article

Cite this article

Cui, H., Hensleigh, R., Yao, D. et al. Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nature Mater 18, 234–241 (2019). https://doi.org/10.1038/s41563-018-0268-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-018-0268-1

This article is cited by

-

Injectable ultrasound-powered bone-adhesive nanocomposite hydrogel for electrically accelerated irregular bone defect healing

Journal of Nanobiotechnology (2024)

-

Designing transparent piezoelectric metasurfaces for adaptive optics

Nature Communications (2024)

-

Fast and versatile electrostatic disc microprinting for piezoelectric elements

Nature Communications (2023)

-

Engineering zero modes in transformable mechanical metamaterials

Nature Communications (2023)

-

Mechanical metamaterials and beyond

Nature Communications (2023)