Abstract

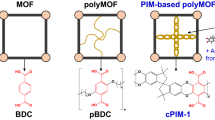

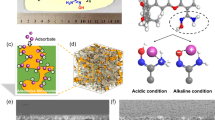

Metal-induced ordered microporous polymers (MMPs), a class of porous polymer, are synthesized from amine-bearing polymers, small organic linkers and divalent metal ions using a polymer-directed chemical synthesis process. Specifically, small organic linkers first coordinate to metal ions, with the resulting unit cells then self-assembling along the extension of polymer chains to construct three-dimensional frameworks. The MMPs demonstrate good controllability of crystal and framework size, as well as hydrolytic stability. MMP dispersions were coated on a modified polysulfone substrate to fabricate MMP/mPSf membranes with an ultrathin selective layer (below 50 nm) and surface areas of >100 cm2. The MMPs are readily fabricated into defect-free thin selective-layered membranes with high CO2 permeance (3,000 GPU) and stable CO2/N2 selectivity (78) under both humid and dry gas feed conditions, demonstrating promising CO2 membrane separation performance. This synthetic methodology could be extended to other polymers, potentially enabling facile synthesis of membrane materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All the data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Baker, R. & Low, B. T. Gas separation membrane materials: a perspective. Macromolecules 47, 6999–7013 (2014).

Bernardo, P., Drioli, E. & Golemme, G. Membrane gas separation: a review/state of the art. Ind. Eng. Chem. Res. 48, 4638–4663 (2009).

Eddaoudi, M. et al. Systematic design of pore size and functionality in isoreticular MOFs and their application in methane storage. Science 295, 469–472 (2002).

Rosi, N. L. et al. Hydrogen storage in microporous metal organic frameworks. Science 300, 1127–1129 (2003).

Furukawa, H. et al. Ultra high porosity in metal–organic frameworks. Science 329, 424–428 (2010).

Hayashi, H., Côté, A. P., Furukawa, H., O’Keeffe, M. & Yaghi, O. M. Zeolite aimidazolate frameworks. Nat. Mater. 6, 501–506 (2007).

Côté, A. P. et al. Porous, crystalline, covalent organic frameworks. Science 310, 1166–1170 (2005).

Kuhn, P., Antonietti, M. & Thomas, A. Porous, covalent triazine-based frameworks prepared by ionothermal synthesis. Angew. Chem. Int. Ed. 47, 3450–3453 (2008).

Choi, M. et al. Amphiphilic organo silane-directed synthesis of crystalline zeolite with tunable mesoporosity. Nat. Mater. 5, 718–723 (2006).

Hsueh, H. Y., Yao, C. T. & Ho, R. M. Well-ordered nanohybrids and nanoporous materials from gyroid block copolymer templates. Chem. Soc. Rev. 44, 1974–2018 (2015).

Du, N. et al. Polymer nanosieve membranes for CO2-capture applications. Nat. Mater. 10, 372–375 (2011).

Guiver, M. D. & Lee, Y. M. Polymer rigidity improves microporous membranes. Science 339, 284–285 (2013).

Peng, Y. et al. Metal–organic framework nanosheets as building blocks for molecular sieving membranes. Science 346, 1356–1359 (2014).

Li, P. et al. Recent developments in membranes for efficient hydrogen purification. J. Membr. Sci. 495, 130–168 (2015).

Jeon, M. Y. et al. Ultra-selective high-flux membranes from directly synthesized zeolite nanosheets. Nature 543, 690–694 (2017).

Yin, Y. & Guiver, M. D. Microporous polymers: ultrapermeable membranes. Nat. Mater. 16, 880–881 (2017).

Park, H. B., Kamcev, J., Robeson, L. M., Elimelech, M. & Freeman, B. D. Maximizing the right stuff: the trade-off between membrane permeability and selectivity. Science 356, 1137–1147 (2017).

Livingston, A. & Baker, R. Membranes from academia to industry. Nat. Mater. 16, 280–282 (2017).

Kitao, T., Zhang, Y., Kitagawa, S., Wang, B. & Uemura, T. Hybridization of MOFs and polymers. Chem. Soc. Rev. 46, 3108–3133 (2017).

Dechnik, J., Gascon, J., Doonan, C. J., Janiak, C. & Sumby, C. J. Mixed-matrix membranes. Angew. Chem. Int. Ed. 56, 9292–9310 (2017).

Zhang, Z., Nguyen, H. T. H., Miller, S. A. & Cohen, S. M. PolyMOFs: a class of interconvertible polymer–metal–organic-framework hybrid materials. Angew. Chem. Int. Ed. 54, 6152–6157 (2015).

Zhang, Z. et al. Polymer–metal–organic-framework (polyMOFs) as water tolerant materials for selective carbon dioxide separations. J. Am. Chem. Soc. 138, 920–925 (2016).

Yuan, S. et al. Improvement of CO2/N2 separation characteristics of polyvinylamine by modifying with ethylenediamine. J. Membr. Sci. 378, 425–437 (2011).

Robeson, L. M. The upper bound revisited. J. Membr. Sci. 320, 390–400 (2008).

Merkel, T. C., Lin, H., Wei, X. & Baker, R. Power plant post-combustion carbon dioxide capture: an opportunity for membranes. J. Membr. Sci. 359, 126–139 (2010).

Acknowledgements

This research is supported by the National Key R&D Program of China (no. 2017YFB0603400) and the Natural Science Foundation of China (no. 21436009).

Author information

Authors and Affiliations

Contributions

Z.Q., S.Z. and M.S. fabricated the materials and conducted the characterization. Z.W., C.Z. and M.D.G. carried out experimental design. J.W. and S.W. performed data analysis. Z.Q., S.Z., Z.W., C.Z. and M.D.G. wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Supplementary Information

Supplementary Sections 1–8, Supplementary Figures 1–19, Supplementary Tables 1–2, Supplementary References 1–13

Rights and permissions

About this article

Cite this article

Qiao, Z., Zhao, S., Sheng, M. et al. Metal-induced ordered microporous polymers for fabricating large-area gas separation membranes. Nature Mater 18, 163–168 (2019). https://doi.org/10.1038/s41563-018-0221-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-018-0221-3

This article is cited by

-

Roll-to-roll fabrication of large-area metal–organic framework-based membranes for high-performance aqueous separations

Nature Water (2024)

-

Hydrogel particles for CO2 capture

Polymer Journal (2024)

-

ZIF-62 glass foam self-supported membranes to address CH4/N2 separations

Nature Materials (2023)

-

Porous organic polymers: a progress report in China

Science China Chemistry (2023)

-

MOF-in-COF molecular sieving membrane for selective hydrogen separation

Nature Communications (2021)