Abstract

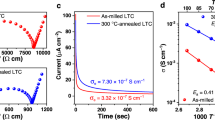

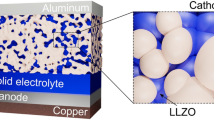

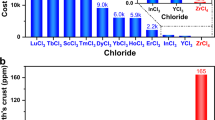

All-solid-state Li batteries (ASSBs) employing inorganic solid electrolytes offer improved safety and are exciting candidates for next-generation energy storage. Herein, we report a family of lithium mixed-metal chlorospinels, Li2InxSc0.666−xCl4 (0 ≤ x ≤ 0.666), with high ionic conductivity (up to 2.0 mS cm−1) owing to a highly disordered Li-ion distribution, and low electronic conductivity (4.7 × 10−10 S cm−1), which are implemented for high-performance ASSBs. Owing to the excellent interfacial stability of the SE against uncoated high-voltage cathode materials, ASSBs utilizing LiCoO2 or LiNi0.85Co0.1Mn0.05O2 exhibit superior rate capability and long-term cycling (up to 4.8 V versus Li+/Li) compared to state-of-the-art ASSBs. In particular, the ASSB with LiNi0.85Co0.1Mn0.05O2 exhibits a long life of >3,000 cycles with 80% capacity retention at room temperature. High cathode loadings are also demonstrated in ASSBs with stable capacity retention of >4 mAh cm−2 (~190 mAh g−1).

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Data generated and analysed in this study are included in the paper and Supplementary Information. The single-crystal X-ray crystallographic data for the structure reported in this study has been deposited at the Cambridge Crystallographic Data Centre under deposition number 2115525. These data can be obtained free of charge from the Cambridge Crystallographic Data Centre via www.ccdc.cam.ac.uk.

References

Trahey, L. et al. Energy storage emerging: a perspective from the Joint Center for Energy Storage Research. Proc. Natl Acad. Sci. USA 1, 12550–12557 (2020).

Lee, Y. G. et al. High-energy long-cycling all-solid-state lithium metal batteries enabled by silver-carbon composite anodes. Nat. Energy 5, 299–308 (2020).

Randau, S. et al. Benchmarking the performance of all-solid-state lithium batteries. Nat. Energy 5, 259–270 (2020).

Chen, R., Li, Q., Yu, X., Chen, L. & Li, H. Approaching practically accessible solid-state batteries: stability issues related to solid electrolytes and interfaces. Chem. Rev. 120, 6820–6877 (2020).

Zhang, Z. et al. New horizon for inorganic solid state ion conductors. Energy Environ. Sci. 11, 1945–1976 (2018).

Bachman, J. C. et al. Inorganic solid-state electrolytes for lithium batteries: mechanisms and properties governing ion conduction. Chem. Rev. 116, 140–162 (2016).

Park, K. H. et al. Design strategies, practical considerations, and new solution processes of sulfide solid electrolytes for all-solid-state batteries. Adv. Energy Mater. 8, 1800035 (2018).

Balaish, M. et al. Processing thin but robust electrolytes for solid-state batteries. Nat. Energy 6, 227–239 (2021).

Kamaya, N. et al. A lithium superionic conductor. Nat. Mater. 10, 682–686 (2011).

Kato, T. et al. High-power all-solid-state batteries using sulfide superionic conductors. Nat. Energy 1, 16030 (2016).

Zhu, Y., He, X. & Mo, Y. Origin of outstanding stability in the lithium solid electrolyte materials: insights from thermodynamic analyses based on first-principles calculations. ACS Appl. Mater. Interfaces 7, 23685–23693 (2015).

Dewald, G. F. et al. Experimental assessment of the practical oxidative stability of lithium thiophosphate solid electrolytes. Chem. Mater. 31, 8328–8337 (2019).

Schwietert, T. K. et al. Clarifying the relationship between redox activity and electrochemical stability in solid electrolytes. Nat. Mater. 19, 428–435 (2020).

Walther, F. et al. Visualization of the interfacial decomposition of composite cathodes in argyrodite-based all-solid-state batteries using time-of-flight secondary-ion mass spectrometry. Chem. Mater. 31, 3745–3755 (2019).

Banerjee, A., Wang, X., Fang, C., Wu, E. A. & Meng, Y. S. Interfaces and interphases in all-solid-state batteries with inorganic solid electrolytes. Chem. Rev. 120, 6878–6933 (2020).

Xiao, Y., Miara, L. J., Wang, Y. & Ceder, G. Computational screening of cathode coatings for solid-state batteries. Joule 3, 1252–1275 (2019).

Nolan, A. M., Liu, Y. & Mo, Y. Solid-state chemistries stable with high-energy cathodes for lithium-ion batteries. ACS Energy Lett. 4, 2444–2451 (2019).

Jung, S. H. et al. Li3BO3-Li2CO3: rationally designed buffering phase for sulfide all-solid-state Li-ion batteries. Chem. Mater. 30, 8190–8200 (2018).

Asano, T. et al. Solid halide electrolytes with high lithium-ion conductivity for application in 4 V class bulk-type all-solid-state batteries. Adv. Mater. 30, 1803075 (2018).

Wang, S. et al. Lithium chlorides and bromides as promising solid-state chemistries for fast ion conductors with good electrochemical stability. Angew. Chem. Int. Ed. Engl. 58, 8039–8043 (2019).

Muy, S. et al. High-throughput screening of solid-state Li-ion conductors using lattice-dynamics descriptors. iScience 16, 270–282 (2019).

Li, X. et al. Air-stable Li3InCl6 electrolyte with high voltage compatibility for all-solid-state batteries. Energy Environ. Sci. 12, 2665–2671 (2019).

Park, K. H. et al. High-voltage superionic halide solid electrolytes for all-solid-state Li-ion batteries. ACS Energy Lett. 5, 533–539 (2020).

Kim, S. Y. et al. Lithium ytterbium based halide solid electrolytes for high voltage all-solid-state batteries. ACS Mater. Lett. 3, 930–938 (2021).

Liang, J. et al. Site-occupation-tuned superionic LixScCl3+x halide solid electrolytes for all-solid-state batteries. J. Am. Chem. Soc. 142, 7012–7022 (2020).

Zhou, L. et al. A new halospinel superionic conductor for high-voltage all solid state lithium batteries. Energy Environ. Sci. 13, 2056–2063 (2020).

Kwak, H. et al. New cost-effective halide solid electrolytes for all-solid-state batteries: mechanochemically prepared Fe3+-substituted Li2ZrCl6. Adv. Energy Mater. 11, 2003190 (2021).

Park, J. et al. Heat treatment protocol for modulating ionic conductivity via structural evolution of Li3−xYb1−xMxCl6 (M = Hf4+, Zr4+) new halide superionic conductors for all-solid-state batteries. Chem. Eng. J. 425, 130630 (2021).

Kato, Y. et al. All-solid-state batteries with thick electrode configurations. J. Phys. Chem. Lett. 9, 607–613 (2018).

Minnmann, P., Quillmann, L., Burkhardt, S., Richter, F. H. & Janek, J. Quantifying the impact of charge transport bottlenecks in composite cathodes of all-solid-state batteries. J. Electrochem. Soc. 168, 040357 (2021).

Liu, H. et al. Elucidating the limit of Li insertion into the spinel Li4Ti5O12. ACS Mater. Lett. 1, 96–102 (2019).

Zhang, W. et al. Kinetic pathways of ionic transport in fast-charging lithium titanate. Science 367, 1030–1034 (2020).

Bohnsack, A. et al. Ternary halides of the A3MX6 type. Part VI. Ternary chlorides of the rare-earth elements with lithium, Li3MCl6 (M = Tb-Lu, Y, Sc): synthesis, crystal structures, and ionic motion. Z. Anorg. Allg. Chem. 623, 1067–1073 (1997).

Zhou, L. et al. New family of argyrodite thioantimonate lithium superionic conductors. J. Am. Chem. Soc. 141, 19002–19013 (2019).

Xue, W. et al. Ultra-high-voltage Ni-rich layered cathodes in practical Li metal batteries enabled by a sulfonamide-based electrolyte. Nat. Energy 6, 495–505 (2021).

Shi, T. et al. High active material loading in all-solid-state battery electrode via particle size optimization. Adv. Energy Mater. 10, 1902881 (2019).

Strauss, F. et al. Impact of cathode material particle size on the capacity of bulk-type all-solid-state batteries. ACS Energy Lett. 3, 992–996 (2018).

Han, F. et al. Interphase engineering enabled all-ceramic lithium battery. Joule 2, 497–508 (2018).

Kubanska, A., Castro, L., Tortet, L., Dollé, M. & Bouchet, R. Effect of composite electrode thickness on the electrochemical performance of all-solid-state Li-ion batteries. J. Electroceram. 38, 189–196 (2017).

Amin, R. & Chiang, Y. M. Characterization of electronic and ionic transport in in Li1−xNi0.33Mn0.33Co0.33O2 (NMC333) and Li1−xNi0.50Mn0.20Co0.30O2 (NMC523) as a function of Li content. J. Electrochem. Soc. 163, A1512 (2016).

Märker, K. et al. Evolution of structure and lithium dynamics in LiNi0.8Mn0.1Co0.1O2 (NMC811) cathodes during electrochemical cycling. Chem. Mater. 31, 2545–2554 (2019).

Han, Y. et al. Single- or poly-crystalline Ni-rich layered cathode, sulfide or halide solid electrolyte: which will be the winner for all-solid-state batteries? Adv. Energy Mater. 11, 2100126 (2021).

Walther, F. et al. The working principle of a Li2CO3/LiNbO3 coating on NCM for thiophosphate-based all-solid-state batteries. Chem. Mater. 33, 2110–2125 (2021).

Ohta, N. et al. LiNbO3-coated LiCoO2 as cathode material for all solid-state lithium secondary batteries. Electrochem. Commun. 9, 1486–1490 (2007).

Glass, A. M., Nassau, K. & Negran, T. J. Ionic conductivity of quenched alkali niobate and tantalate glasses. J. Appl. Phys. 49, 4808 (1978).

Strauss, F. et al. Li2ZrO3-coated NMC622 for application in inorganic solid-state batteries: role of surface carbonates in the cycling performance. ACS Appl. Mater. Interfaces 12, 557146–557154 (2020).

Banerjee, A. et al. Revealing nanoscale solid–solid interfacial phenomena for long-life and high-energy all-solid-state batteries. ACS Appl. Mater. Interfaces 11, 443138–43135 (2019).

Zhang, Y. Q. et al. Direct visualization of the interfacial degradation of cathode coating in solid state batteries: a combined experimental and computational study. Adv. Energy Mater. 10, 1903778 (2020).

Nakamura, T. et al. Guidelines for all-solid-state battery design and electrode buffer layers based on chemical potential profile calculation. ACS Appl. Mater. Interfaces 11, 19968–19976 (2019).

Koerver, R. et al. Chemo-mechanical expansion of lithium electrode materials—on the route to mechanically optimized all-solid-state batteries. Energy Environ. Sci. 11, 2142–2158 (2018).

Acknowledgements

This work was supported by the Joint Center for Energy Storage Research, an Energy Innovation Hub funded by the US Department of Energy, Office of Science, Basic Energy Sciences and NSERC via their Canada Research Chair and Discovery Grant programmes. The neutron diffraction measurement at the POWGEN instrument at Oak Ridge National Laboratory, Spallation Neutron Source, was sponsored by the Scientific User Facilities Division, Office of Basic Energy Sciences, US Department of Energy. TOF-SIMS measurements were performed at the Justus Liebig University Giessen (funding through Bundesministerium für Bildung und Forschung projects 03XP0177D/03XP0228C). We thank BASF SE for providing NCM622 and NCM85 cathode active materials.

Author information

Authors and Affiliations

Contributions

L.Z. and L.F.N. conceived and designed the experimental work. L.Z. performed the synthesis of the solid electrolytes, powder X-ray diffraction measurements, structural resolution of powder neutron diffraction and the electrochemistry of all-solid-state batteries. T.-T.Z. performed the TOF-SIMS measurements, and data analysis was performed by T.T.Z. and J.J. C.Y.K. performed the SEM measurements. S.Y.K. performed the electrochemistry of liquid NCM cells. A.A. performed single-crystal diffraction and structure resolution. Q.Z. performed the powder neutron diffraction measurements. L.Z. and L.F.N. wrote the manuscript with input from all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Energy thanks Yoon Seok Jung and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–28, Notes 1–6 and Tables 1–8.

Rights and permissions

About this article

Cite this article

Zhou, L., Zuo, TT., Kwok, C.Y. et al. High areal capacity, long cycle life 4 V ceramic all-solid-state Li-ion batteries enabled by chloride solid electrolytes. Nat Energy 7, 83–93 (2022). https://doi.org/10.1038/s41560-021-00952-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-021-00952-0

This article is cited by

-

Structural regulation of halide superionic conductors for all-solid-state lithium batteries

Nature Communications (2024)

-

Promoting high-voltage stability through local lattice distortion of halide solid electrolytes

Nature Communications (2024)

-

Metal electrodes for next-generation rechargeable batteries

Nature Reviews Electrical Engineering (2024)

-

Designing lithium halide solid electrolytes

Nature Communications (2024)

-

From Liquid to Solid-State Lithium Metal Batteries: Fundamental Issues and Recent Developments

Nano-Micro Letters (2024)