Abstract

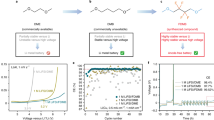

Lithium metal batteries hold promise for pushing cell-level energy densities beyond 300 Wh kg−1 while operating at ultra-low temperatures (below −30 °C). Batteries capable of both charging and discharging at these temperature extremes are highly desirable due to their inherent reduction in the need for external warming. Here we demonstrate that the local solvation structure of the electrolyte defines the charge-transfer behaviour at ultra-low temperature, which is crucial for achieving high Li metal Coulombic efficiency and avoiding dendritic growth. These insights were applied to Li metal full-cells, where a high-loading 3.5 mAh cm−2 sulfurized polyacrylonitrile (SPAN) cathode was paired with a onefold excess Li metal anode. The cell retained 84% and 76% of its room temperature capacity when cycled at −40 and −60 °C, respectively, which presented stable performance over 50 cycles. This work provides design criteria for ultra-low-temperature lithium metal battery electrolytes, and represents a defining step for the performance of low-temperature batteries.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All relevant data are included in the paper and its Supplementary Information.

References

Zhang, S. S., Xu, K. & Jow, T. R. The low temperature performance of Li-ion batteries. J. Power Sources 115, 137–140 (2003).

Smart, M. C. et al. The use of lithium-ion batteries for JPL’s Mars missions. Electrochim. Acta 268, 27–40 (2018).

Gupta, A. & Manthiram, A. Designing advanced lithium-based batteries for low-temperature conditions. Adv. Energy Mater. 10, 2001972 (2020).

Huang, C.-K., Sakamoto, J. S., Wolfenstine, J. & Surampudi, S. The limits of low‐temperature performance of Li‐ion cells. J. Electrochem. Soc. 147, 2893–2896 (2000).

Plichta, E. J. et al. Development of low temperature Li-ion electrolytes for NASA and DoD applications. J. Power Sources 94, 160–162 (2001).

Li, Q. et al. Wide-temperature electrolytes for lithium-ion batteries. ACS Appl. Mater. Interfaces 9, 18826–18835 (2017).

Liu, J. et al. Pathways for practical high-energy long-cycling lithium metal batteries. Nat. Energy 4, 180–186 (2019).

Xu, W. et al. Lithium metal anodes for rechargeable batteries. Energy Environ. Sci. 7, 513–537 (2014).

Li, S. et al. Developing high-performance lithium metal anode in liquid electrolytes: challenges and progress. Adv. Mater. 30, 1706375 (2018).

Zhou, H., Yu, S., Liu, H. & Liu, P. Protective coatings for lithium metal anodes: recent progress and future perspectives. J. Power Sources 450, 227632 (2020).

Xu, K., von Cresce, A. & Lee, U. Differentiating contributions to “ion transfer” barrier from interphasial resistance and Li+ desolvation at electrolyte/graphite interface. Langmuir 26, 11538–11543 (2010).

Li, Q. et al. Li+-desolvation dictating lithium-ion battery’s low-temperature performances. ACS Appl. Mater. Interfaces 9, 42761–42768 (2017).

Holoubek, J. et al. Exploiting mechanistic solvation kinetics for dual-graphite batteries with high power output at extremely low temperature. Angew. Chem. Int. Ed. 58, 18892–18897 (2019).

Rustomji, C. S. et al. Liquefied gas electrolytes for electrochemical energy storage devices. Science 356, eaal4263 (2017).

Dong, X. et al. High-energy rechargeable metallic lithium battery at −70 °C enabled by a cosolvent electrolyte. Angew. Chem. Int. Ed. 58, 5623–5627 (2019).

Fan, X. et al. All-temperature batteries enabled by fluorinated electrolytes with non-polar solvents. Nat. Energy 4, 882–890 (2019).

Dong, X., Guo, Z., Guo, Z., Wang, Y. & Xia, Y. Organic batteries operated at −70 °C. Joule 2, 902–913 (2018).

Smart, M. C., Ratnakumar, B. V., Chin, K. B. & Whitcanack, L. D. Lithium-ion electrolytes containing ester cosolvents for improved low temperature performance. J. Electrochem. Soc. 157, A1361–A1374 (2010).

Smart, M. C. et al. Gel polymer electrolyte lithium-ion cells with improved low temperature performance. J. Power Sources 165, 535–543 (2007).

Plichta, E. J. & Behl, W. K. A low-temperature electrolyte for lithium and lithium-ion batteries. J. Power Sources 88, 192–196 (2000).

Smart, M. C., Lucht, B. L., Dalavi, S., Krause, F. C. & Ratnakumar, B. V. The effect of additives upon the performance of MCMB/LiNixCo1−xO2 Li-ion cells containing methyl butyrate-based wide operating temperature range electrolytes. J. Electrochem. Soc. 159, A739–A751 (2012).

Zhang, S. S., Xu, K. & Jow, T. R. A new approach toward improved low temperature performance of Li-ion battery. Electrochem. Commun. 4, 928–932 (2002).

Liao, B. et al. Designing low impedance interface films simultaneously on anode and cathode for high energy batteries. Adv. Energy Mater. 8, 1800802 (2018).

Gao, Y. et al. Low-temperature and high-rate-charging lithium metal batteries enabled by an electrochemically active monolayer-regulated interface. Nat. Energy 5, 534–542 (2020).

Wang, C.-Y. et al. Lithium-ion battery structure that self-heats at low temperatures. Nature 529, 515–518 (2016).

Ji, Y. & Wang, C. Y. Heating strategies for Li-ion batteries operated from subzero temperatures. Electrochim. Acta 107, 664–674 (2013).

Chen, S. et al. High-voltage lithium-metal batteries enabled by localized high-concentration electrolytes. Adv. Mater. 30, 1706102 (2018).

Qian, J. et al. High rate and stable cycling of lithium metal anode. Nat. Commun. 6, 6362 (2015).

Niu, C. et al. High-energy lithium metal pouch cells with limited anode swelling and long stable cycles. Nat. Energy 4, 551–559 (2019).

Ren, X. et al. Enabling high-voltage lithium-metal batteries under practical conditions. Joule 3, 1662–1676 (2019).

Zhang, X.-Q. et al. Regulating anions in the solvation sheath of lithium ions for stable lithium metal batteries. ACS Energy Lett. 4, 411–416 (2019).

Thenuwara, A. C., Shetty, P. P. & McDowell, M. T. Distinct nanoscale interphases and morphology of lithium metal electrodes operating at low temperatures. Nano Lett. 19, 8664–8672 (2019).

Wang, J. et al. Improving cyclability of Li metal batteries at elevated temperatures and its origin revealed by cryo-electron microscopy. Nat. Energy 4, 664–670 (2019).

Adams, B. D., Zheng, J., Ren, X., Xu, W. & Zhang, J.-G. Accurate determination of Coulombic efficiency for lithium metal anodes and lithium metal batteries. Adv. Energy Mater. 8, 1702097 (2018).

Bai, P., Li, J., R. Brushett, F. & Bazant, Z. M. Transition of lithium growth mechanisms in liquid electrolytes. Energy Environ. Sci. 9, 3221–3229 (2016).

Park, C. et al. Molecular simulations of electrolyte structure and dynamics in lithium–sulfur battery solvents. J. Power Sources 373, 70–78 (2018).

Callsen, M., Sodeyama, K., Futera, Z., Tateyama, Y. & Hamada, I. The solvation structure of lithium ions in an ether based electrolyte solution from first-principles molecular dynamics. J. Phys. Chem. B 121, 180–188 (2017).

Chaban, V. Solvation of lithium ion in dimethoxyethane and propylene carbonate. Chem. Phys. Lett. 631–632, 1–5 (2015).

Ueno, K. et al. Glyme–lithium salt equimolar molten mixtures: concentrated solutions or solvate ionic liquids? J. Phys. Chem. B 116, 11323–11331 (2012).

Suo, L., Zheng, F., Hu, Y.-S. & Chen, L. FT-Raman spectroscopy study of solvent-in-salt electrolytes. Chin. Phys. B 25, 016101 (2016).

Sand, H. J. S. III On the concentration at the electrodes in a solution, with special reference to the liberation of hydrogen by electrolysis of a mixture of copper sulphate and sulphuric acid. Philos. Mag. 1, 45–79 (1901).

Borodin, O. et al. Competitive lithium solvation of linear and cyclic carbonates from quantum chemistry. Phys. Chem. Chem. Phys. 18, 164–175 (2016).

Wei, S., Ma, L., Hendrickson, K. E., Tu, Z. & Archer, L. A. Metal–sulfur battery cathodes based on PAN–sulfur composites. J. Am. Chem. Soc. 137, 12143–12152 (2015).

Yang, H., Chen, J., Yang, J. & Wang, J. Prospect of sulfurized pyrolyzed poly(acrylonitrile) (S@pPAN) cathode materials for rechargeable lithium batteries. Angew. Chem. Int. Ed. 59, 7306–7318 (2019).

Xing, X. et al. Cathode electrolyte interface enabling stable Li–S batteries. Energy Storage Mater. 21, 474–480 (2019).

Chen, X. et al. Ether-compatible sulfurized polyacrylonitrile cathode with excellent performance enabled by fast kinetics via selenium doping. Nat. Commun. 10, 1021 (2019).

Zhou, J. et al. A new ether-based electrolyte for lithium sulfur batteries using a S@pPAN cathode. Chem. Commun. 54, 5478–5481 (2018).

Betz, J. et al. Theoretical versus practical energy: a plea for more transparency in the energy calculation of different rechargeable battery systems. Adv. Energy Mater. 9, 1803170 (2019).

Cho, Y.-G., Kim, Y.-S., Sung, D.-G., Seo, M.-S. & Song, H.-K. Nitrile-assistant eutectic electrolytes for cryogenic operation of lithium ion batteries at fast charges and discharges. Energy Environ. Sci. 7, 1737–1743 (2014).

Holoubek, J. et al. An all-fluorinated ester electrolyte for stable high-voltage Li metal batteries capable of ultra-low-temperature operation. ACS Energy Lett. 5, 1438–1447 (2020).

Kaminski, G. A., Friesner, R. A., Tirado-Rives, J. & Jorgensen, W. L. Evaluation and reparametrization of the OPLS-AA force field for proteins via comparison with accurate quantum chemical calculations on peptides. J. Phys. Chem. B 105, 6474–6487 (2001).

Gouveia, A. S. L. et al. Ionic liquids with anions based on fluorosulfonyl derivatives: from asymmetrical substitutions to a consistent force field model. Phys. Chem. Chem. Phys. 19, 29617–29624 (2017).

Towns, J. et al. XSEDE: accelerating scientific discovery. Comput. Sci. Eng. 16, 62–74 (2014).

Acknowledgements

This work was supported by a NASA Space Technology Graduate Research Opportunity. This work was also partially supported by the Office of Vehicle Technologies of the US Department of Energy through the Advanced Battery Materials Research (BMR) Program (Battery500 Consortium) under contract no. DE-EE0007764 to P.L. This work was also partially supported by an Early Career Faculty grant from NASA’s Space Technology Research Grants Program (ECF 80NSSC18K1512) to Z.C. Part of the work used the UCSD-MTI Battery Fabrication Facility and the UCSD-Arbin Battery Testing Facility. Electron microscopic characterization was performed at the San Diego Nanotechnology Infrastructure (SDNI) of UCSD, a member of the National Nanotechnology Coordinated Infrastructure, which is supported by the National Science Foundation (grant ECCS-1542148). Computational support for this work was provided by the National Energy Research Scientific Computing Center (NERSC), a US Department of Energy Office of Science User Facility operated under contract no. DE-AC02-05CH11231. This work also used the Extreme Science and Engineering Discovery Environment (XSEDE)53 on the Comet supercomputer at the San Diego Supercomputing Center, which is supported by National Science Foundation grant no. ACI-1548562.

Author information

Authors and Affiliations

Contributions

J.H. conceived the original idea. P.L. and Z.C. directed the project. J.H., H.L. and Z.W. carried out the experiments. Z.W., X.X., S.Y., G.C. and Y.Y. assisted with characterization. T.A.P. directed the computational experiments. J.H., H.L., Z.C. and P.L. wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Energy thanks Kevin Leung and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–23, Discussion 1–5, Tables 1–3 and references.

Rights and permissions

About this article

Cite this article

Holoubek, J., Liu, H., Wu, Z. et al. Tailoring electrolyte solvation for Li metal batteries cycled at ultra-low temperature. Nat Energy 6, 303–313 (2021). https://doi.org/10.1038/s41560-021-00783-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-021-00783-z

This article is cited by

-

Single-phase local-high-concentration solid polymer electrolytes for lithium-metal batteries

Nature Energy (2024)

-

Tiny sheaths of solvent boost battery performance

Nature (2024)

-

Molecular anchoring of free solvents for high-voltage and high-safety lithium metal batteries

Nature Communications (2024)

-

A dicarbonate solvent electrolyte for high performance 5 V-Class Lithium-based batteries

Nature Communications (2024)

-

Electrolyte Design for Low-Temperature Li-Metal Batteries: Challenges and Prospects

Nano-Micro Letters (2024)