Abstract

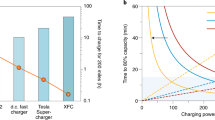

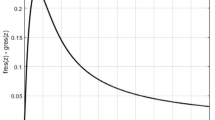

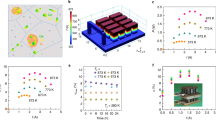

Phase change materials can improve the efficiency of energy systems by time shifting or reducing peak thermal loads. The value of a phase change material is defined by its energy and power density—the total available storage capacity and the speed at which it can be accessed. These are influenced by material properties but cannot be defined with these properties alone. Here we show the close link between energy and power density by developing thermal rate capability and Ragone plots, a framework widely used to describe the trade-off between energy and power in electrochemical storage systems (that is, batteries). Our results elucidate how material properties, geometry and operating conditions influence the performance of phase change thermal storage. This research sets a clear framework for comparing thermal storage materials and devices and can be used by researchers and designers to increase clean energy use with storage.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in the published article, its Supplementary Information and Source Data files

Code availability

The numerical model developed for this work was generated in MATLAB R2019b. Unrestricted access to the source code is available at https://github.com/NREL/ThermalRagone.

References

Cabeza, L. F., Castell, A., Barreneche, C., de Gracia, A. & Fernández, A. I. Materials used as PCM in thermal energy storage in buildings: a review. Renew. Sustain. Energy Rev. 15, 1675–1695 (2011).

Kalnæs, S. E. & Jelle, B. P. Phase change materials and products for building applications: a state-of-the-art review and future research opportunities. Energy Build. 94, 150–176 (2015).

Mavrigiannaki, A. & Ampatzi, E. Latent heat storage in building elements: a systematic review on properties and contextual performance factors. Renew. Sustain. Energy Rev. 60, 852–866 (2016).

Souayfane, F., Fardoun, F. & Biwole, P.-H. Phase change materials (PCM) for cooling applications in buildings: a review. Energy Build. 129, 396–431 (2016).

Xiao, Q., Fan, J., Li, L., Xu, T. & Yuan, W. Solar thermal energy storage based on sodium acetate trihydrate phase change hydrogels with excellent light-to-thermal conversion performance. Energy 165, 1240–1247 (2018).

Sharan, P., Turchi, C. & Kurup, P. Optimal design of phase change material storage for steam production using annual simulation. Sol. Energy 185, 494–507 (2019).

Laughlin, R. B. Pumped thermal grid storage with heat exchange. J. Renew. Sustain. Energy 9, 044103 (2017).

Amy, C., Seyf, H. R., Steiner, M. A., Friedman, D. J. & Henry, A. Thermal energy grid storage using multi-junction photovoltaics. Energy Environ. Sci. 12, 334–343 (2019).

Datas, A., Ramos, A., Martí, A., del Cañizo, C. & Luque, A. Ultra high temperature latent heat energy storage and thermophotovoltaic energy conversion. Energy 107, 542–549 (2016).

Albertus, P., Manser, J. S. & Litzelman, S. Long-duration electricity storage applications, economics, and technologies. Joule 4, 21–32 (2020).

Ling, Z. et al. Review on thermal management systems using phase change materials for electronic components, Li-ion batteries and photovoltaic modules. Renew. Sustain. Energy Rev. 31, 427–438 (2014).

Barako, M. T. et al. Optimizing the design of composite phase change materials for high thermal power density. J. Appl. Phys. 124, 145103 (2018).

Yang, T. et al. A composite phase change material thermal buffer based on porous metal foam and low-melting-temperature metal alloy. Appl. Phys. Lett. 116, 071901 (2020).

Zhou, D., Zhao, C. Y. & Tian, Y. Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl. Energy 92, 593–605 (2012).

Mohamed, S. A. et al. A review on current status and challenges of inorganic phase change materials for thermal energy storage systems. Renew. Sustain. Energy Rev. 70, 1072–1089 (2017).

Sharma, A., Tyagi, V. V., Chen, C. R. & Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 13, 318–345 (2009).

Kenisarin, M. M. High-temperature phase change materials for thermal energy storage. Renew. Sustain. Energy Rev. 14, 955–970 (2010).

Pielichowska, K. & Pielichowski, K. Phase change materials for thermal energy storage. Prog. Mater. Sci. 65, 67–123 (2014).

Gur, I., Sawyer, K. & Prasher, R. Searching for a better thermal battery. Science 335, 1454 (2012).

Ragone, D. V. Review of battery systems for electrically powered vehicles. SAE Tech. Pap. Ser. https://doi.org/10.4271/680453 (1968).

Li, Y., Tan, B. & Wu, Y. Mesoporous Co3O4 nanowire arrays for lithium ion batteries with high capacity and rate capability. Nano Lett. 8, 265–270 (2008).

Qie, L. et al. Nitrogen-doped porous carbon nanofiber webs as anodes for lithium ion batteries with a superhigh capacity and rate capability. Adv. Mater. 24, 2047–2050 (2012).

Colclasure, A. M. et al. Electrode scale and electrolyte transport effects on extreme fast charging of lithium-ion cells. Electrochim. Acta 337, 135854 (2020).

Ji, H. et al. Ultrahigh power and energy density in partially ordered lithium-ion cathode materials. Nat. Energy 5, 213–221 (2020).

Shamberger, P. J. Cooling capacity figure of merit for phase change materials. J. Heat Trans. 138, https://doi.org/10.1115/1.4031252 (2015).

Shao, L. et al. Figure-of-merit for phase-change materials used in thermal management. Int. J. Heat. Mass Transf. 101, 764–771 (2016).

Yazawa, K., Shamberger, P. J. & Fisher, T. S. Ragone relations for thermal energy storage technologies. Front. Mech. Eng. 5, https://doi.org/10.3389/fmech.2019.00029 (2019).

Christen, T. Ragone plots and discharge efficiency-power relations of electric and thermal energy storage devices. J. Energy Storage 27, 101084 (2020).

Ji, H. et al. Enhanced thermal conductivity of phase change materials with ultrathin-graphite foams for thermal energy storage. Energy Environ. Sci. 7, 1185–1192 (2014).

Liu, L., Su, D., Tang, Y. & Fang, G. Thermal conductivity enhancement of phase change materials for thermal energy storage: a review. Renew. Sustain. Energy Rev. 62, 305–317 (2016).

Kumar, N., Hirschey, J., LaClair, T. J., Gluesenkamp, K. R. & Graham, S. Review of stability and thermal conductivity enhancements for salt hydrates. J. Energy Storage 24, 100794 (2019).

Kholmanov, I., Kim, J., Ou, E., Ruoff, R. S. & Shi, L. Continuous carbon nanotube–ultrathin graphite hybrid foams for increased thermal conductivity and suppressed subcooling in composite phase change materials. ACS Nano 9, 11699–11707 (2015).

Liu, M., Ma, Y., Wu, H. & Wang, R. Y. Metal matrix–metal nanoparticle composites with tunable melting temperature and high thermal conductivity for phase-change thermal storage. ACS Nano 9, 1341–1351 (2015).

Wu, S. et al. High-performance thermally conductive phase change composites by large-size oriented graphite sheets for scalable thermal energy harvesting. Adv. Mater. 31, 1905099 (2019).

Sekulic, D. P., Sciubba, E. & Moran, M. J. Entransy: a misleading concept for the analysis and optimization of thermal systems. Energy 80, 251–253 (2015).

Py, X., Olives, R. & Mauran, S. Paraffin/porous-graphite-matrix composite as a high and constant power thermal storage material. Int. J. Heat. Mass Transf. 44, 2727–2737 (2001).

Thomas, B. R. & Linden, D. in Linden’s Handbook of Batteries 4th edn, 3.1–3.22 (McGraw-Hill Education, 2011).

Zimny-Schmitt, D. Utility Rate Database (US Department of Energy’s Energy Information Administration, 2020); https://openei.org/wiki/Utility_Rate_Database

Nellis, G. & Klein, S. Heat Transfer (Cambridge Univ. Press, 2009).

Minkowycz, W. J., Sparrow, E. M. & Murthy, J. Y. Handbook of Numerical Heat Transfer 2nd edn (John Wiley & Sons, 2006).

Patankar, S. V. Numerical Heat Transfer and Fluid Flow (Hemisphere Publishing Corporation, 1980).

Bell, I. H., Wronski, J., Quoilin, S. & Lemort, V. Pure and pseudo-pure fluid thermophysical property evaluation and the open-source thermophysical property library coolProp. Ind. Eng. Chem. Res. 53, 2498–2508 (2014).

Hahn, D. W. & Özisik, M. N. in Heat Conduction 3rd edn, 467–470 (John Wiley & Sons, 2012).

Buildings Energy Efficiency Frontiers and Innovation Technologies (BENEFIT) DE-FOA-0002090 (US Department of Energy, Office of Energy Efficiency and Renewable Energy, 2019).

Acknowledgements

This work was authored by the National Renewable Energy Laboratory (NREL), operated by Alliance for Sustainable Energy, LLC, for the US DOE under contract no. DE-AC36-08GO28308. Funding provided by US DOE Building Technologies Office. The views expressed in the article do not necessarily represent the views of the DOE or the US Government. We thank S. Mumme from the DOE Building Technologies Office for his support and insight on this paper. We also thank J. Vidal and M. Bianchi from NREL for their feedback on our work.

Author information

Authors and Affiliations

Contributions

J.W. developed the concept of thermal rate capability and Ragone plots and oversaw the project, A.M. developed the numerical model, performed experiments on the thermal storage device, analysed the data and created the figures, A.G. and E.K. helped design the thermal storage device experiments and contributed to developing the concept, A.O. measured material properties and contributed to developing the concept, R.J. helped develop the idea and provided guidance during the project. J.W. and A.M. wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Energy thanks Patrick Shamberger and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–8, Notes 1–6, Tables 1 and 2 and references.

Supplementary Video 1

The PCM phase and the PCM and fluid temperatures when the baseline device is discharged at 1 C.

Supplementary Video 2

The PCM phase and the surface heat flux at y = 0 when the baseline device is discharged at 1 C.

Supplementary Table 1

The raw experimental data used to generate Supplementary Figs. 3 and 4.

Rights and permissions

About this article

Cite this article

Woods, J., Mahvi, A., Goyal, A. et al. Rate capability and Ragone plots for phase change thermal energy storage. Nat Energy 6, 295–302 (2021). https://doi.org/10.1038/s41560-021-00778-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-021-00778-w

This article is cited by

-

Superior Latent Heat Eutectic Salt Na2CO3-Li2CO3-LiF for Thermal Energy Storage: Preparation and Performance Investigation

Journal of Thermal Science (2024)

-

Self-Assembly of Binderless MXene Aerogel for Multiple-Scenario and Responsive Phase Change Composites with Ultrahigh Thermal Energy Storage Density and Exceptional Electromagnetic Interference Shielding

Nano-Micro Letters (2024)

-

Adaptive multi-temperature control for transport and storage containers enabled by phase-change materials

Nature Communications (2023)

-

Accelerating the solar-thermal energy storage via inner-light supplying with optical waveguide

Nature Communications (2023)

-

Processing Compressed Expanded Natural Graphite for Phase Change Material Composites

Journal of Thermal Science (2023)