Abstract

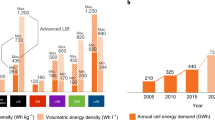

Anode-free lithium metal cells store 60% more energy per volume than conventional lithium-ion cells. Such high energy density can increase the range of electric vehicles by approximately 280 km or even enable electrified urban aviation. However, these cells tend to experience rapid capacity loss and short cycle life. Furthermore, safety issues concerning metallic lithium often remain unaddressed in the literature. Recently, we demonstrated long-lifetime anode-free cells using a dual-salt carbonate electrolyte. Here we characterize the degradation of anode-free cells with this lean (2.6 g Ah−1) liquid electrolyte. We observe deterioration of the pristine lithium morphology using scanning electron microscopy and X-ray tomography, and diagnose the cause as electrolyte degradation and depletion using nuclear magnetic resonance spectroscopy and ultrasonic transmission mapping. For the safety characterization tests, we measure the cell temperature during nail penetration. Finally, we use the insights gained in this work to develop an optimized electrolyte, extending the lifetime of anode-free cells to 200 cycles.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All relevant data are included in the paper and its Supplementary Information. Source data are provided with this paper.

References

Kasliwal, A. et al. Role of flying cars in sustainable mobility. Nat. Commun. 10, 1555 (2019).

Holden, J. & Goel, N. Fast-forwarding to a Future of On-demand Urban Air Transportation (Uber Elevate, 2016); https://www.uber.com/elevate.pdf

Blomgren, G. E. The development and future of lithium ion batteries. J. Electrochem. Soc. 164, A5019–A5025 (2017).

Neudecker, B. J., Dudney, N. J. & Bates, J. B. ‘Lithium-free’ thin-film battery with in situ plated Li anode. J. Electrochem. Soc. 147, 517 (2000).

Qian, J. et al. Anode-free rechargeable lithium metal batteries. Adv. Funct. Mater. 26, 7094–7102 (2016).

Albertus, P., Babinec, S., Litzelman, S. & Newman, A. Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries. Nat. Energy 3, 16–21 (2018).

Liu, J. et al. Pathways for practical high-energy long-cycling lithium metal batteries. Nat. Energy 4, 180–186 (2019).

Schmuch, R., Wagner, R., Hörpel, G., Placke, T. & Winter, M. Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat. Energy 3, 267–278 (2018).

Betz, J. et al. Theoretical versus practical energy: a plea for more transparency in the energy calculation of different rechargeable battery systems. Adv. Energy Mater. 9, 1803170 (2018).

Abrha, L. H. et al. Li7La2.75Ca0.25Zr1.75Nb0.25O12@LiClO4 composite film derived solid electrolyte interphase for anode-free lithium metal battery. Electrochim. Acta 325, 134825 (2019).

Aurbach, D., Zinigrad, E., Cohen, Y. & Teller, H. A short review of failure mechanisms of lithium metal and lithiaded graphite anodes in liquid electrolyte solutions. Solid State Ion. 148, 405–416 (2002).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 12, 194–206 (2017).

Fang, C. et al. Quantifying inactive lithium in lithium metal batteries. Nature 572, 511–515 (2019).

Ding, F. et al. Effects of carbonate solvents and lithium salts on morphology and Coulombic efficiency of lithium electrode. J. Electrochem. Soc. 160, A1894–A1901 (2013).

Wood, K. N. et al. Dendrites and pits: untangling the complex behavior of lithium metal anodes through operando video microscopy. ACS Cent. Sci. 2, 790–801 (2016).

López, C. M., Vaughey, J. T. & Dees, D. W. Morphological transitions on lithium metal anodes. J. Electrochem. Soc. 156, A726 (2009).

Rodriguez, R. et al. Separator-free and concentrated LiNO3 electrolyte cells enable uniform lithium electrodeposition. J. Mater. Chem. A https://doi.org/10.1039/c9ta10929c (2020).

Ren, X. et al. Enabling high-voltage lithium-metal batteries under practical conditions. Joule 3, 1662–1676 (2019).

Chen, S. et al. High-voltage lithium-metal batteries enabled by localized high-concentration electrolytes. Adv. Mater. 30, 1–7 (2018).

Wilkinson, D. P., Blom, H., Brandt, K. & Wainwright, D. Effects of physical constraints on Li cyclability. J. Power Sources 36, 517–527 (1991).

Louli, A. J. et al. Exploring the impact of mechanical pressure on the performance of anode-free lithium metal cells. J. Electrochem. Soc. 166, A1291–A1299 (2019).

Yin, X. et al. Insights into morphological evolution and cycling behaviour of lithium metal anode under mechanical pressure. Nano Energy 50, 659–664 (2018).

Niu, C. et al. High-energy lithium metal pouch cells with limited anode swelling and long stable cycles. Nat. Energy 4, 551–559 (2019).

Brandt, K. Historical development of secondary lithium batteries. Solid State Ion. 69, 173–183 (1994).

Zhang, H. et al. Ionic liquid electrolyte with highly concentrated LiTFSI for lithium metal batteries. Electrochim. Acta 285, 78–85 (2018).

Guo, Q. et al. Flame retardant and stable Li1.5Al0.5Ge1.5(PO4)3-supported ionic liquid gel polymer electrolytes for high safety rechargeable solid-state lithium metal batteries. J. Phys. Chem. C 122, 10334–10342 (2018).

von Saken, U., Nodwell, E., Sundher, A. & Dahn, J. R. Comparative thermal stability of carbon intercalation anodes and lithium metal anodes for rechargeable lithium batteries. J. Power Sources 54, 240–245 (1995).

Zhou, Q. et al. A temperature-responsive electrolyte endowing superior safety characteristic of lithium metal batteries. Adv. Energy Mater. 10, 1–8 (2020).

Weber, R. et al. Long cycle life and dendrite-free lithium morphology in anode-free lithium pouch cells enabled by a dual-salt liquid electrolyte. Nat. Energy 4, 683–689 (2019).

Smith, A. J., Burns, J. C., Xiong, D. & Dahn, J. R. Interpreting high precision coulometry results on Li-ion cells. J. Electrochem. Soc. 158, A1136–A1142 (2011).

Nelson, K. J. et al. Studies of the effect of high voltage on the impedance and cycling performance of Li[Ni0.4Mn0.4Co0.2]O2/graphite lithium-ion pouch cells. J. Electrochem. Soc. 162, A1046–A1054 (2015).

Nelson, K. Studies of the Effects of High Voltage on the Performance and Impedance of Lithium-ion Batteries. PhD thesis, Dalhousie Univ. (2017).

Zhu, Y., Li, Y., Bettge, M. & Abraham, D. P. Positive electrode passivation by LiDFOB electrolyte additive in high-capacity lithium-ion cells. J. Electrochem. Soc. 159, A2109–A2117 (2012).

Cha, J., Han, J. G., Hwang, J., Cho, J. & Choi, N. S. Mechanisms for electrochemical performance enhancement by the salt-type electrolyte additive, lithium difluoro(oxalato)borate, in high-voltage lithium-ion batteries. J. Power Sources 357, 97–106 (2017).

Chen, X. et al. Reduction mechanism of fluoroethylene carbonate for stable solid-electrolyte interphase film on silicon anode. ChemSusChem 7, 549–554 (2014).

Streich, D. et al. Online electrochemical mass spectrometry of high energy lithium nickel cobalt manganese oxide/graphite half- and full-cells with ethylene carbonate and fluoroethylene carbonate based electrolytes. J. Electrochem. Soc. 163, A964–A970 (2016).

Nakai, H., Kubota, T., Kita, A. & Kawashima, A. Investigation of the solid electrolyte interphase formed by fluoroethylene carbonate on Si electrodes. J. Electrochem. Soc. 158, A798 (2011).

Schroder, K. et al. The effect of fluoroethylene carbonate as an additive on the solid electrolyte interphase on silicon lithium-ion electrodes. Chem. Mater. 27, 5531–5542 (2015).

Jung, R. et al. Consumption of fluoroethylene carbonate (FEC) on Si-C composite electrodes for Li-ion batteries. J. Electrochem. Soc. 163, A1705–A1716 (2016).

Petibon, R. et al. Studies of the capacity fade mechanisms of LiCoO2/Si-alloy:graphite cells. J. Electrochem. Soc. 163, A1146–A1156 (2016).

Xu, C. et al. Improved performance of the silicon anode for Li-ion batteries: understanding the surface modification mechanism of fluoroethylene carbonate as an effective electrolyte additive. Chem. Mater. 27, 2591–2599 (2015).

Parimalam, B. S. & Lucht, B. L. Reduction reactions of electrolyte salts for lithium ion batteries: LiPF6, LiBF4, LiDFOB, LiBOB, and LiTFSI. J. Electrochem. Soc. 165, A251–A255 (2018).

Allen, J. L., Han, S. D., Boyle, P. D. & Henderson, W. A. Crystal structure and physical properties of lithium difluoro(oxalato) borate (LiDFOB or LiBF2Ox). J. Power Sources 196, 9737–9742 (2011).

Jurng, S., Brown, Z. L., Kim, J. & Lucht, B. L. Effect of electrolyte on the nanostructure of the solid electrolyte interphase (SEI) and performance of lithium metal anodes. Energy Environ. Sci. https://doi.org/10.1039/C8EE00364E (2018).

Bommier, C. et al. In operando acoustic detection of lithium metal plating in commercial LiCoO2/Graphite pouch cells. Cell Rep. Phys. Sci. https://doi.org/10.1016/j.xcrp.2020.100035 (2020).

Deng, Z. et al. Observation of the electrolyte wetting and ‘unwetting’ in Li-ion pouch cells via ultrasonic scanning technology. Joule https://doi.org/10.1016/j.joule.2020.07.014 (2020).

Hatchard, T. D., Trussler, S. & Dahn, J. R. Building a ‘smart nail’ for penetration tests on Li-ion cells. J. Power Sources 247, 821–823 (2014).

Genovese, M. et al. Hot formation for improved low temperature cycling of anode-free lithium metal batteries. J. Electrochem. Soc. 166, A3342–A3347 (2019).

Li, J. et al. Comparison of single crystal and polycrystalline LiNi0.5Mn0.3Co0.2O2 positive electrode materials for high voltage Li-ion cells. J. Electrochem. Soc. 164, A1534–A1544 (2017).

Acknowledgements

This research was financially supported by Tesla Canada and NSERC under the Industrial Research Chairs Program. A.J.L. and A.E. thank NSERC, the Killam Foundation and the Nova Scotia Graduate Scholarship programmes for financial support. M.G. thanks the NSERC PDF Program. We acknowledge J. Li (formerly of BASF) and D. J. Xiong (formerly of Capchem) for providing the chemicals used in the electrolytes. We also acknowledge P. Scallion for SEM support, as well as S. Trussler for expert fabrication of the parts used in this work.

Author information

Authors and Affiliations

Contributions

A.J.L., M.G., R.W. and J.R.D. conceived the idea. A.J.L. performed the electrochemical measurements and the SEM analysis with the assistance of M.C. and J.d.G. A.E. and R.W. performed and analysed the NMR experiments with the assistance of M.C. and J.d.G. X-ray tomography was performed by R.T.W., J.L. and T.R. A.J.L. performed the safety characterization with the assistance of J.d.G. Z.D. performed the ultrasonic transmission mapping measurements. R.P., S.J.H.C. and S.H. contributed to useful discussions. A.J.L., A.E. and J.R.D. prepared the manuscript with input from all other co-authors.

Corresponding author

Ethics declarations

Competing interests

R.W., R.P., S.H. and S.J.H.C. are employed by Tesla Canada R&D. R.T.W., J.L. and T.R. are employed by Carl Zeiss Microscopy.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Table 1, Figs. 1–16 and discussion.

Supplementary Video 1

Submerge and observe qualitative reactivity test pictured in Fig. 6. Charged negative electrode (graphite and plated lithium) samples retrieved from cycled pouch cells at the top of charge are submerged into water to observe their reactivity. The electrolyte chemistries used in the pouch cells from which these samples were retrieved are indicated in the video titles before each submersion.

Supplementary Video 2

Nail test videos pictured in Fig. 6. Anode-free pouch cells at the top of charge after being cycled 50 times were penetrated with nail. The electrolyte chemistries used in each pouch cell nailed are indicated in the video titles before each experiment.

Supplementary Data

Source data for Supplementary Figs. 1 and 2.

Source data

Source Data Fig. 2

Source data Fig. 2.

Source Data Fig. 3

Source data Fig. 3.

Source Data Fig. 6

Source data Fig. 6.

Source Data Fig. 7

Source data Fig. 7.

Rights and permissions

About this article

Cite this article

Louli, A.J., Eldesoky, A., Weber, R. et al. Diagnosing and correcting anode-free cell failure via electrolyte and morphological analysis. Nat Energy 5, 693–702 (2020). https://doi.org/10.1038/s41560-020-0668-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-020-0668-8

This article is cited by

-

Uncovering the impact of pressure on lithium-metal pouch cells with liquid electrolytes

Nature Energy (2024)

-

Recovery of isolated lithium through discharged state calendar ageing

Nature (2024)

-

Controlled large-area lithium deposition to reduce swelling of high-energy lithium metal pouch cells in liquid electrolytes

Nature Energy (2024)

-

Dynamically lithium-compensated polymer artificial SEI to assist highly stable lithium-rich manganese-based anode-free lithium metal batteries

Rare Metals (2024)

-

Design Strategies for Aqueous Zinc Metal Batteries with High Zinc Utilization: From Metal Anodes to Anode-Free Structures

Nano-Micro Letters (2024)