Abstract

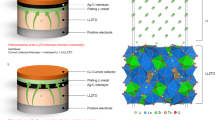

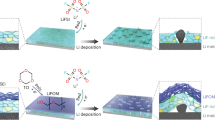

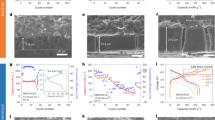

Lithium batteries with Si, Al or Bi microsized (>10 µm) particle anodes promise a high capacity, ease of production, low cost and low environmental impact, yet they suffer from fast degradation and a low Coulombic efficiency. Here we demonstrate that a rationally designed electrolyte (2.0 M LiPF6 in 1:1 v/v mixture of tetrahydrofuran and 2-methyltetrahydrofuran) enables 100 cycles of full cells that contain microsized Si, Al and Bi anodes with commercial LiFePO4 and LiNi0.8Co0.15Al0.05O2 cathodes. Alloy anodes with areal capacities of more than 2.5 mAh cm−2 achieved >300 cycles with a high initial Coulombic efficiency of >90% and average Coulombic efficiency of >99.9%. These improvements are facilitated by the formation of a high-modulus LiF–organic bilayer interphase, in which LiF possesses a high interfacial energy with the alloy anode to accommodate plastic deformation of the lithiated alloy during cycling. This work provides a simple yet practical solution to current battery technology without any binder modification or special fabrication methods.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are available within the article and its Supplementary Information files.

References

Li, J. & Dahn, J. An in situ X-ray diffraction study of the reaction of Li with crystalline Si. J. Electrochem. Soc. 154, A156–A161 (2007).

Kasavajjula, U., Wang, C. & Appleby, A. J. Nano-and bulk-silicon-based insertion anodes for lithium-ion secondary cells. J. Power Sources 163, 1003–1039 (2007).

Chen, Z., Chevrier, V., Christensen, L. & Dahn, J. Design of amorphous alloy electrodes for Li-ion batteries a big challenge. Electrochem. Solid State Lett. 7, A310–A314 (2004).

Liu, W.-R. et al. Effect of electrode structure on performance of Si anode in Li-ion batteries: Si particle size and conductive additive. J. Power Sources 140, 139–144 (2005).

Obrovac, M. & Krause, L. Reversible cycling of crystalline silicon powder. J. Electrochem. Soc. 154, A103–A108 (2007).

Kim, H., Seo, M., Park, M. H. & Cho, J. A critical size of silicon nano‐anodes for lithium rechargeable batteries. Angew. Chem. Int. Ed. 49, 2146–2149 (2010).

Liu, X. H. et al. Anisotropic swelling and fracture of silicon nanowires during lithiation. Nano Lett. 11, 3312–3318 (2011).

Chan, C. K. et al. in Materials for Sustainable Energy: A Collection of Peer-Reviewed Research and Review Articles from Nature Publishing Group (ed. Dusastre, V.) 187-191 (World Scientific, 2011).

Cui, L.-F., Ruffo, R., Chan, C. K., Peng, H. & Cui, Y. Crystalline-amorphous core−shell silicon nanowires for high capacity and high current battery electrodes. Nano Lett. 9, 491–495 (2008).

Li, S. et al. High-rate aluminium yolk–shell nanoparticle anode for Li-ion battery with long cycle life and ultrahigh capacity. Nat. Commun. 6, 7872 (2015).

Yao, Y. et al. Interconnected silicon hollow nanospheres for lithium-ion battery anodes with long cycle life. Nano Lett. 11, 2949–2954 (2011).

Park, M.-H. et al. Silicon nanotube battery anodes. Nano Lett. 9, 3844–3847 (2009).

Lu, Z. et al. Nonfilling carbon coating of porous silicon micrometer-sized particles for high-performance lithium battery anodes. ACS Nano 9, 2540–2547 (2015).

Magasinski, A. et al. High-performance lithium-ion anodes using a hierarchical bottom-up approach. Nat. Mater. 9, 353–358 (2010).

Son, I. H. et al. Silicon carbide-free graphene growth on silicon for lithium-ion battery with high volumetric energy density. Nat. Commun. 6, 8393 (2015).

Zhang, C. J. et al. High capacity silicon anodes enabled by MXene viscous aqueous ink. Nat. Commun. 10, 849 (2019).

Wang, C. et al. Self-healing chemistry enables the stable operation of silicon microparticle anodes for high-energy lithium-ion batteries. Nat. Chem. 5, 1042–1048 (2013).

Choi, S., Kwon, T.-w, Coskun, A. & Choi, J. W. Highly elastic binders integrating polyrotaxanes for silicon microparticle anodes in lithium ion batteries. Science 357, 279–283 (2017).

Xu, Z. et al. Silicon microparticle anodes with self-healing multiple network binder. Joule 2, 950–961 (2018).

Kovalenko, I. et al. A major constituent of brown algae for use in high-capacity Li-ion batteries. Science 334, 75–79 (2011).

Li, Y. et al. Growth of conformal graphene cages on micrometre-sized silicon particles as stable battery anodes. Nat. Energy 1, 15029 (2016).

Peled, E. & Menkin, S. SEI: past, present and future. J. Electrochem. Soc. 164, A1703–A1719 (2017).

Sina, M. et al. Direct visualization of the solid electrolyte interphase and its effects on silicon electrochemical performance. Adv. Mater. Interfaces 3, 1600438 (2016).

Michan, A. L. et al. Solid electrolyte interphase growth and capacity loss in silicon electrodes. J. Am. Chem. Soc. 138, 7918–7931 (2016).

Jin, Y. et al. Understanding fluoroethylene carbonate and vinylene carbonate based electrolytes for Si anodes in lithium ion batteries with NMR spectroscopy. J. Am. Chem. Soc. 140, 9854–9867 (2018).

Vogl, U. S. et al. The mechanism of SEI formation on a single crystal Si(100) electrode. J. Electrochem. Soc. 162, A603–A607 (2015).

Suo, L. et al. ‘Water-in-salt’ electrolyte enables high-voltage aqueous lithium-ion chemistries. Science 350, 938–943 (2015).

Borodin, O. Challenges with prediction of battery electrolyte electrochemical stability window and guiding the electrode–electrolyte stabilization. Curr. Opin. Electrochem. 13, 86–93 (2019).

Suo, L. et al. Advanced high‐voltage aqueous lithium‐ion battery enabled by ‘water‐in‐bisalt’ electrolyte. Angew. Chem. Int. Ed. 55, 7136–7141 (2016).

Zheng, J. et al. 3D visualization of inhomogeneous multi-layered structure and Young’s modulus of the solid electrolyte interphase (SEI) on silicon anodes for lithium ion batteries. Phys. Chem. Chem. Phys. 16, 13229–13238 (2014).

Hall, D. S., Self, J. & Dahn, J. R. Dielectric constants for quantum chemistry and Li-ion batteries: solvent blends of ethylene carbonate and ethyl methyl carbonate. J. Phys. Chem. C 119, 22322–22330 (2015).

Jiao, S. et al. Stable cycling of high-voltage lithium metal batteries in ether electrolytes. Nat. Energy 3, 739–746 (2018).

Ren, X. et al. High-concentration ether electrolytes for stable high-voltage lithium metal batteries. ACS Energy Lett. 4, 896–902 (2019).

Chan, C. K., Ruffo, R., Hong, S. S. & Cui, Y. Surface chemistry and morphology of the solid electrolyte interphase on silicon nanowire lithium-ion battery anodes. J. Power Sources 189, 1132–1140 (2009).

Yoon, T., Chapman, N., Seo, D. M. & Lucht, B. L. Lithium salt effects on silicon electrode performance and solid electrolyte interphase (SEI) structure, role of solution structure on SEI formation. J. Electrochem. Soc. 164, A2082–A2088 (2017).

Chang, X. et al. Enabling high performance lithium storage in aluminum: the double edged surface oxide. Nano Energy 41, 731–737 (2017).

Ridgway, P. et al. Comparison of cycling performance of lithium ion cell anode graphites. J. Electrochem. Soc. 159, A520–A524 (2012).

Wang, X. et al. High damage tolerance of electrochemically lithiated silicon. Nat. Commun. 6, 8417 (2015).

Park, M. S. et al. A highly reversible lithium metal anode. Sci. Rep. 4, 3815 (2014).

Boniface, M. et al. Nanoscale chemical evolution of silicon negative electrodes characterized by low-loss STEM-EELS. Nano Lett. 16, 7381–7388 (2016).

Danet, J., Brousse, T., Rasim, K., Guyomard, D. & Moreau, P. Valence electron energy-loss spectroscopy of silicon negative electrodes for lithium batteries. Phys. Chem. Chem. Phys. 12, 220–226 (2010).

Zhang, Q. et al. Synergetic effects of inorganic components in solid electrolyte interphase on high cycle efficiency of lithium ion batteries. Nano Lett. 16, 2011–2016 (2016).

Bedrov, D., Borodin, O. & Hooper, J. B. Li+ transport and mechanical properties of model solid electrolyte interphases (SEI): insight from atomistic molecular dynamics simulations. J. Phys. Chem. C 121, 16098–16109 (2017).

Wang, X., Li, Y. & Meng, Y. S. Cryogenic electron microscopy for characterizing and diagnosing batteries. Joule 2, 2225–2234 (2018).

Hohenberg, P. & Kohn, W. Inhomogeneous electron gas. Phys. Rev. 136, B864 (1964).

Kohn, W. & Sham, L. J. Self-consistent equations including exchange and correlation effects. Phys. Rev. 140, A1133 (1965).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558 (1993).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Stournara, M. E. et al. Li segregation induces structure and strength changes at the amorphous Si/Cu interface. Nano Lett. 13, 4759–4768 (2013).

Borodin, O. Polarizable force field development and molecular dynamics simulations of ionic liquids. J. Phys. Chem. B 113, 11463–11478 (2009).

Alvarado, J. et al. Bisalt ether electrolytes: a pathway towards lithium metal batteries with Ni-rich cathodes. Ener. Env. Sci. 12, 780–794 (2019).

Yang, Y. et al. High-efficiency lithium-metal anode enabled by liquefied gas electrolytes. Joule 3, 1986–2000 (2019).

Borodin, O. et al. Insights into the structure and transport of the lithium, sodium, magnesium, and zinc bis(trifluoromethansulfonyl) imide salts in ionic liquids. J. Phys. Chem. C. 122, 20108–20121 (2018).

Borodin, O. & Smith, G. D. Quantum chemistry and molecular dynamics simulation study of dimethyl carbonate: ethylene carbonate electrolytes doped with LiPF6. J. Phys. Chem. B 113, 1763–1776 (2009).

Neumann, M. & Steinhauser, O. Computer simulation and the dielectric constant of polarizable polar systems. Chem. Phys. Lett. 106, 563–569 (1984).

Giner, B., Gascón, I., Villares, A., Cea, P. & Lafuente, C. Densities and viscosities of the binary mixtures of tetrahydrofuran with isomeric chlorobutanes at 298.15 K and 313.15 K. J. Chem. Eng. Data 51, 1321–1325 (2006).

Vallés, C., Pérez, E., Mainar, A. M., Santafé, J. & Domínguez, M. Excess enthalpy, density, speed of sound, and viscosity for 2-methyltetrahydrofuran + 1-butanol at (283.15, 298.15, and 313.15) K. J. Chem. Eng. Data 51, 1105–1109 (2006).

Hayamizu, K., Aihara, Y., Arai, S. & Martinez, C. G. Pulse-gradient spin-echo H-1, Li-7, and F-19 NMR diffusion and ionic conductivity measurements of 14 organic electrolytes containing LiN(SO2CF3)2. J. Phys. Chem. B. 103, 519–524 (1999).

Hatnes, W. M. & Lide, D. R. CRC Handbook of Chemistry and Physics 2012–2013 93rd edn (CRC, 2012).

Delsignore, M., Maaser, H. E. & Petrucci, S. Molecular relaxation of lithium salts in 2-methyltetrahydrofuran at 25° C. J. Phys. Chem. 88, 2405–2411 (1984).

Borodin, O., Behl, W. & Jow, T. R. Oxidative stability and initial decomposition reactions of carbonate, sulfone, and alkyl phosphate-based electrolytes. J. Phys. Chem. C 117, 8661–8682 (2013).

Fry, A. J. Computational applications in organic electrochemistry. Curr. Opin. Electrochem. 2, 67–75 (2017).

Jow, T. R., Xu, K., Borodin, O. & Ue, M. Electrolytes for Lithium and Lithium-Ion Batteries Vol. 58 (Springer, 2014).

Frisch, M. J. T. et al. Gaussain 09 (Gaussian Inc., 2016).

Acknowledgements

This project was supported by the Department of Energy (DOE) Office of Energy Efficiency and Renewable Energy (EERE) through Battery500 Consortium under contract no. DE-EE0008202. Cryo-EM work was performed at the Center for Functional Nanomaterials, which is a US DOE Office of Science User Facility at Brookhaven National Laboratory, under Contract no. DE-SC0012704. Modelling work at the Army Research Laboratory (ARL) by O.B. was supported by ARL Enterprise for Multiscale Modeling. The authors acknowledge helpful discussions with M. Schroeder (ARL) and T. Pollard (ARL).

Author information

Authors and Affiliations

Contributions

J.C., X.F. and Q.L. contributed equally to this work. J.C., X.F. and C.W. conceived the idea for the project. J.C., X.F. and Q.L. prepared the materials and performed the electrochemical experiments. O.B. and X.J. conducted the QC calculations and MD simulations. M.R.K. and H.H. conducted the electrochemical AFM measurements. S.H., D.S., Y.X. and C.W. performed the cryo-TEM measurements. H.Y. and E.G. obtained the LiF spatial distribution and EELS spectra. L.C. and C.Y. coated the electrodes. All the authors discussed the results, analysed the data and drafted the manuscript.

Corresponding authors

Ethics declarations

Competing interests

A US patent with the provisional application number 62/978637 has been filed.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–12, Figs. 1–41 and refs. 1–11.

Rights and permissions

About this article

Cite this article

Chen, J., Fan, X., Li, Q. et al. Electrolyte design for LiF-rich solid–electrolyte interfaces to enable high-performance microsized alloy anodes for batteries. Nat Energy 5, 386–397 (2020). https://doi.org/10.1038/s41560-020-0601-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-020-0601-1

This article is cited by

-

High voltage electrolytes for lithium-ion batteries with micro-sized silicon anodes

Nature Communications (2024)

-

Catalytic role of in-situ formed C-N species for enhanced Li2CO3 decomposition

Nature Communications (2024)

-

Methylation enables high-voltage ether electrolytes for lithium metal batteries

Nature Chemistry (2024)

-

Single-phase local-high-concentration solid polymer electrolytes for lithium-metal batteries

Nature Energy (2024)

-

Study on modification of different amino silanes modified polyacrylic acid for ball milling silicon anode of lithium-ion batteries

Ionics (2024)