Abstract

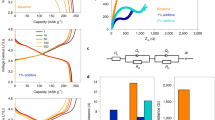

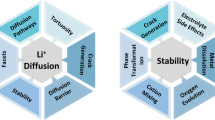

The demand for energy sources with high energy densities continues to push the limits of Ni-rich layered oxides, which are currently the most promising cathode materials in automobile batteries. Although most current research is focused on extending battery life using Ni-rich layered cathodes, long-term cycling stability using a full cell is yet to be demonstrated. Here, we introduce Li[Ni0.90Co0.09Ta0.01]O2, which exhibits 90% capacity retention after 2,000 cycles at full depth of discharge (DOD) and a cathode energy density >850 Wh kg−1. In contrast, the currently most sought-after Li[Ni0.90Co0.09Al0.01]O2 cathode loses ~40% of its initial capacity within 500 cycles at full DOD. Cycling stability is achieved by radially aligned primary particles with [003] crystallographic texture that effectively dissipate the internal strain occurring in the deeply charged state, while the substitution of Ni3+ with higher valence ions induces ordered occupation of Ni ions in the Li slab and stabilizes the delithiated structure.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All the data generated or analysed during this study are included in this published article and its Supplementary Information files. The data that support the plots within this paper and other findings of this study are available from the corresponding author upon reasonable request.

Change history

09 December 2020

An amendment to this paper has been published and can be accessed via a link at the top of the paper.

References

Naceur, K. B Tracking Clean Energy Progress (International Energy Agency, 2016).

2017 Annual Merit Review, Vehicle Technologies Office (US Department of Energy, 2017); http://go.nature.com/2EFTGeh.

Schmuch, R., Wagner, R., Hörpel, G., Placke, T. & Winter, M. Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat. Energy 3, 267–278 (2018).

Andre, D. et al. Future generations of cathode materials: an automotive industry perspective. J. Mater. Chem. A 3, 6709–6732 (2015).

Liu, Z., Yu, A. & Lee, J. Y. Synthesis and characterization of LiNi1−x−yCoxMnyO2 as the cathode materials of secondary lithium batteries. J. Power Sources 81–82, 416–419 (1999).

Noh, H.-J., Youn, S., Yoon, C. S. & Sun, Y.-K. Comparison of the structural and electrochemical properties of layered Li[NixCoyMnz]O2 (x = 1/3, 0.5, 0.6, 0.7, 0.8, and 0.85) cathode material for lithium-ion batteries. J. Power Sources 233, 121–130 (2013).

Zhou, P. et al. Stable layered Ni-rich LiNi0.9Co0.07Al0.03O2 microspheres assembled with nanoparticles as high-performance cathode materials for lithium-ion batteries. J. Mater. Chem. A 5, 2724–2731 (2017).

Nam, G. W. et al. Capacity fading of Ni-rich NCA cathodes: effect of microcracking extent. ACS Energy Lett. 4, 2995–3001 (2019).

Wang, X., Ding, Y.-L., Deng, Y.-P. & Chen, Z. Ni-rich/Co-poor layered cathode for automotive Li-ion batteries: promises and challenges. Adv. Energy Mater. 10, 1903864 (2020).

Liu, D. et al. Revealing the effect of Ti doping on significantly enhancing cyclic performance at a high cutoff voltage for Ni-rich LiNi0.8Co0.15Al0.05O2 cathode. ACS Sustain. Chem. Eng. 7, 10661–10669 (2019).

Kim, U.-H., Kuo, L.-Y., Kaghazchi, P., Yoon, C. S. & Sun, Y.-K. Quaternary layered Ni-rich NCMA cathode for lithium-ion batteries. ACS Energy Lett. 4, 576–582 (2019).

Han, S.-H. et al. Improvement of structural stability during high-voltage cycling in high-nickel cathode materials with B2O3 addition. J. Electrochem. Soc. 163, A748–A750 (2016).

Xin, F. et al. Li-Nb-O coating/substitution enhances the electrochemical performance of the LiNi0.8Mn0.1Co0.1O2 (NMC 811) cathode. ACS Appl. Mater. Interfaces 11, 34889–34894 (2019).

Schipper, F. et al. From surface ZrO2 coating to bulk Zr doping by high temperature annealing of nickel-rich lithiated oxides and their enhanced electrochemical performance in lithium ion batteries. Adv. Energy Mater. 8, 1701682 (2018).

Weigel, T. et al. Structural and electrochemical aspects of LiNi0.8Co0.1Mn0.1O2 cathode materials doped by various cations. ACS Energy Lett. 4, 508–516 (2019).

Kim, U.-H. et al. Pushing the limit of layered transition metal oxide cathodes for high-energy density rechargeable Li ion batteries. Energy Environ. Sci. 11, 1271–1279 (2018).

Cho, J., Kim, Y. J. & Park, B. Novel LiCoO2 cathode materials with Al2O3 coating for a Li ion cell. Chem. Mater. 12, 3788–3791 (2000).

Woo, S.-U., Yoon, C. S., Amine, K., Belharouak, I. & Sun, Y.-K. Significant improvement of electrochemical performance of AlF3-coated Li[Ni0.8Co0.1Mn0.1]O2 cathode materials. J. Electrochem. Soc. 154, A1005–A1009 (2007).

Yan, P. et al. Tailoring grain boundary structures and chemistry of Ni-rich layered cathodes for enhanced cycle stability of lithium-ion batteries. Nat. Energy 3, 600–605 (2018).

Watanabe, S., Kinoshita, M., Hosokawa, T., Morigaki, K. & Nakura, K. Capacity fading of LiAlyNi1−x−yCoxO2 cathode for lithium-ion batteries during accelerated calendar and cycle life tests (effect of depth of discharge in charge–discharge cycling on the suppression of the micro-crack generation of LiAlyNi1−x−yCoxO2 particle). J. Power Sources 260, 50–56 (2014).

Ryu, H.-H., Park, K.-J., Yoon, C. S. & Sun, Y.-K. Capacity fading of Ni-rich Li[NixCoyMn1−x−y]O2 (0.6 ≤ x ≤ 0.95) cathodes for high-energy-density lithium-ion batteries: bulk or surface degradation? Chem. Mater. 30, 1155–1163 (2018).

Yang, P. et al. Intragranular cracking as a critical barrier for high-voltage usage of layer-structured cathode for lithium-ion batteries. Nat. Commun. 8, 14101 (2017).

Park, K.-J. et al. Degradation mechanism of Ni-enriched NCA cathode for lithium batteries: are microcracks really critical? ACS Energy Lett. 4, 1394–1400 (2019).

Sun, Y.-K. et al. Nanostructured high-energy cathode materials for advanced lithium batteries. Nat. Mater. 11, 942–947 (2012).

Kim, U.-H. et al. Microstructure‐controlled Ni‐rich cathode material by microscale compositional partition for next‐generation electric vehicles. Adv. Energy Mater. 9, 1803902 (2019).

Park, K.-J. et al. Improved cycling stability of Li[Ni0.90Co0.05Mn0.05]O2 through microstructure modification by boron doping for Li-ion batteries. Adv. Energy Mater. 8, 1801202 (2018).

Ryu, H.-H. et al. Li[Ni0.9Co0.09W0.01]O2: a new type of layered oxide cathode with high cycling stability. Adv. Energy Mater. 9, 1902698 (2019).

Ryu, H.-H. et al. A highly stabilized Ni-rich NCA cathode for high-energy lithium-ion batteries. Mater. Today 36, 73–82 (2020).

Yoon, C. S. et al. Cation ordering of Zr-doped LiNiO2 cathode for lithium-ion batteries. Chem. Mater. 30, 1808–1814 (2018).

Kim, U.-H. et al. Compositionally and structurally redesigned high-energy Ni-rich layered cathode for next-generation lithium batteries. Mater. Today 23, 26–36 (2019).

Meng, Y. S. et al. Cationordering in layered O3 Li[NixLi1/3−2x/3Mn2/3−x/3]O2(0≤ x ≤1/2) compounds. Chem. Mater. 17, 2386–2394 (2005).

Acknowledgements

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korea government Ministry of Education and Science Technology (MEST) (no. NRF-2018R1A2B3008794). Additionally, this work was also supported by the Human Resources Development program (no. 20184010201720) of the Korea Institute of Energy Technology Evaluation and Planning funded by the Ministry of Trade, Industry and Energy of the Korean government. J.L. thanks the University of Washington for supporting his effort on this manuscript.

Author information

Authors and Affiliations

Contributions

U.-H.K. and Y.-K.S. conceived and designed the research. U.-H.K., G.-T.P., B.-K.S. and G.W.N. performed the experiments and characterization of materials. U.-H.K., C.S.Y. and Y.-K.S. analysed the data. L.-Y.K. and P.K. performed the theoretical calculations. U.-H.K., C.S.Y., J.L. and Y.-K.S. contributed to the discussion of the results. C.S.Y. and Y.-K.S. wrote the manuscript. All the authors commented on and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Note 1, refs. 1–4, Figs. 1–14 and Tables 1–3.

Rights and permissions

About this article

Cite this article

Kim, UH., Park, GT., Son, BK. et al. Heuristic solution for achieving long-term cycle stability for Ni-rich layered cathodes at full depth of discharge. Nat Energy 5, 860–869 (2020). https://doi.org/10.1038/s41560-020-00693-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-020-00693-6

This article is cited by

-

Cobalt-free composite-structured cathodes with lithium-stoichiometry control for sustainable lithium-ion batteries

Nature Communications (2024)

-

Enhanced cycling stability and rate performance of Co-doped and La2O3-coated LiNi0.9Mn0.1O2 toward power battery

Rare Metals (2024)

-

LiNbO3 coating on Mg-doped NCM-622 cathode—a dual modification to enhance the electrochemical performance at higher voltage for lithium-ion batteries

Journal of Solid State Electrochemistry (2024)

-

A surface-modification strategy for high-energy-density and durable nickel-rich layered cathodes

Nature Energy (2023)

-

Morphology controlled performance of ternary layered oxide cathodes

Communications Materials (2023)