Abstract

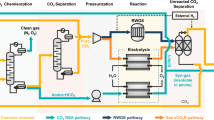

The renewable electricity-driven electroreduction of carbon dioxide (CO2) offers an alternative pathway to producing carbon chemicals that are traditionally manufactured using fossil fuels. Typical CO2 electroreduction approaches couple cathodic CO2 reduction with the anodic oxygen evolution reaction (OER), resulting in approximately 90% of the electricity input being consumed by the OER. Here, we explore alternatives to the OER and show that the anodic electro-oxidation of glycerol (a byproduct of industrial biodiesel and soap production) can lower electricity consumption by up to 53%. This reduces the process’s operating costs and carbon footprint, thus opening avenues for a carbon-neutral cradle-to-gate process even when driven by grid electricity (~13% renewables today), as well as economical production of the 12-electron products ethylene and ethanol. This study may thus serve as a framework for the design of CO2 electroreduction processes with low electricity requirements, enhancing their CO2 utilization potential and economic viability.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The electrochemical data that support the plots, as well other findings of this study, are available in the Supplementary Information.

References

IPCC Climate Change 2013: The Physical Science Basis (eds Stocker, T. F. et al.) (Cambridge Univ. Press, 2013).

Adoption of the Paris Agreement FCCC/CP/2015/L.9/Rev.1 (UNFCCC, 2015).

Pacala, S. & Socolow, R. Stabilization wedges: solving the climate problem for the next 50 years with current technologies. Science 305, 968–972 (2004).

Chu, S. & Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 488, 294–303 (2012).

Leung, D. Y. C., Caramanna, G. & Maroto-Valer, M. M. An overview of current status of carbon dioxide capture and storage technologies. Renew. Sustain. Energy Rev. 39, 426–443 (2014).

Herron, J. A., Kim, J., Upadhye, A. A., Huber, G. W. & Maravelias, C. T. A general framework for the assessment of solar fuel technologies. Energy Environ. Sci. 8, 126–157 (2015).

Jhong, H. R. M., Ma, S. & Kenis, P. J. A. Electrochemical conversion of CO2 to useful chemicals: current status, remaining challenges, and future opportunities. Curr. Opin. Chem. Eng. 2, 191–199 (2013).

Hietala, J. et al. in Ullmann’s Encyclopedia of Industrial Chemistry 1–22 (Wiley-VCH, 2016).

Bierhals, J. in Ullmann’s Encyclopedia of Industrial Chemistry 679–693 (Wiley-VCH, 2001).

Hammer, G. et al. in Ullmann’s Encyclopedia of Industrial Chemistry 739–792 (Wiley-VCH, 2006).

Ott, J. et al. in Ullmann’s Encyclopedia of Industrial Chemistry 1–27 (Wiley–VCH, 2012).

Zimmermann, H. & Walzl, R. in Ullmann’s Encyclopedia of Industrial Chemistry 465–529 (Wiley-VCH, 2009).

Kosaric, N. et al. in Ullmann’s Encyclopedia of Industrial Chemistry 333–403 (Wiley-VCH, 2011).

Hori, Y., Wakebe, H., Tsukamoto, T. & Koga, O. Electrocatalytic process of CO selectivity in electrochemical reduction of CO2 at metal electrodes in aqueous media. Electrochim. Acta 39, 1833–1839 (1994).

Hori, Y. in Modern Aspects of Electrochemistry 89–189 (Springer, 2008).

Qiao, J. L., Liu, Y. Y., Hong, F. & Zhang, J. J. A review of catalysts for the electroreduction of carbon dioxide to produce low-carbon fuels. Chem. Soc. Rev. 43, 631–675 (2014).

Kumar, B. et al. New trends in the development of heterogeneous catalysts for electrochemical CO2 reduction. Catal. Today 270, 19–30 (2016).

Lu, Q. & Jiao, F. Electrochemical CO2 reduction: electrocatalyst, reaction mechanism, and process engineering. Nano Energy 29, 439–456 (2016).

Khezri, B., Fisher, A. C. & Pumera, M. CO2 reduction: the quest for electrocatalytic materials. J. Mater. Chem. A 5, 8230–8246 (2017).

Sharma, P. P. & Zhou, X. D. Electrocatalytic conversion of carbon dioxide to fuels: a review on the interaction between CO2 and the liquid electrolyte. WIREs Energy Environ. 6, e239 (2017).

Endrődi, B. et al. Continuous-flow electroreduction of carbon dioxide. Prog. Energy Combust. Sci. 62, 133–154 (2017).

Verma, S., Kim, B., Jhong, H. R. M., Ma, S. & Kenis, P. J. A. A gross-margin model for defining technoeconomic benchmarks in the electroreduction of CO2. ChemSusChem 9, 1972–1979 (2016).

Li, X. P. et al. Greenhouse gas emissions, energy efficiency, and cost of synthetic fuel production using electrochemical CO2 conversion and the Fischer–Tropsch process. Energy Fuels 30, 5980–5989 (2016).

eGRID2014 v2 (US Environmental Protection Agency, 2017).

Annual Energy Outlook (US Energy Information Administration, 2017).

Yazdani, S. S. & Gonzalez, R. Anaerobic fermentation of glycerol: a path to economic viability for the biofuels industry. Curr. Opin. Biotechnol. 18, 213–219 (2007).

Simoes, M., Baranton, S. & Coutanceau, C. Electrochemical valorisation of glycerol. ChemSusChem 5, 2106–2124 (2012).

David, J. & Herzog, H. The cost of carbon capture. In 5th International Conference on Greenhouse Gas Control Technologies (GHGT-5) 985–990 (CSIRO, 2001).

Bains, P., Psarras, P. & Wilcox, J. CO2 capture from the industry sector. Prog. Energy Combust. Sci. 63, 146–172 (2017).

Inventory of U.S. Greenhous Gas Emissions and Sinks (1990–2015) (US Environmental Protection Agency, 2017).

Kuramochi, T., Ramírez, A., Turkenburg, W. & Faaij, A. Comparative assessment of CO2 capture technologies for carbon-intensive industrial processes. Prog. Energy Combust. Sci. 38, 87–112 (2012).

Kim, B., Ma, S., Jhong, H. R. M. & Kenis, P. J. A. Influence of dilute feed and pH on electrochemical reduction of CO2 to CO on Ag in a continuous flow electrolyzer. Electrochim. Acta 166, 271–276 (2015).

House, K. Z. et al. Economic and energetic analysis of capturing CO2 from ambient air. Proc. Natl Acad. Sci. USA 108, 20428–20433 (2011).

Sherman, S. R. et al. Compilation and correlation of limiting activity coefficients of nonelectrolytes in water. Ind. Eng. Chem. Res. 35, 1044–1058 (1996).

Robinson, R. A. & Stokes, R. H. Tables of osmotic and activity coefficients of electrolytes in aqueous solution at 25 °C. Trans. Faraday Soc. 45, 612–624 (1949).

Cussler, E. L. & Dutta, B. K. On separation efficiency. AIChE J. 58, 3825–3831 (2012).

Kiss, A. A., Landaeta, S. J. F. & Ferreira, C. A. I. Towards energy efficient distillation technologies—making the right choice. Energy 47, 531–542 (2012).

Mudd, G. M. Sustainability reporting and the platinum group metals: a global mining industry leader? Platin. Met. Rev. 56, 2–19 (2012).

Bard, A. J., Parsons, R. & Jordan, J. Standard Potentials in Aqueous Solutions (CRC Press, 1985).

Bevilacqua, M. et al. Energy savings in the conversion of CO2 to fuels using an electrolytic device. Energy Technol. 2, 522–525 (2014).

Li, T. F., Cao, Y., He, J. F. & Berlinguette, C. P. Electrolytic CO2 reduction in tandem with oxidative organic chemistry. ACS Cent. Sci. 3, 778–783 (2017).

Ciriminna, R., Della Pina, C., Rossi, M. & Pagliaro, M. Understanding the glycerol market. Eur. J. Lipid Sci. Technol. 116, 1432–1439 (2014).

Malakoff, D. The gas surge. Science 344, 1464–1467 (2014).

Von der Assen, N., Jung, J. & Bardow, A. Life-cycle assessment of carbon dioxide capture and utilization: avoiding the pitfalls. Energy Environ. Sci. 6, 2721–2734 (2013).

Whipple, D. T., Finke, E. C. & Kenis, P. J. A. Microfluidic reactor for the electrochemical reduction of carbon dioxide: the effect of pH. Electrochem. Solid State Lett. 13, D109–D111 (2010).

Ma, S. et al. One-step electrosynthesis of ethylene and ethanol from CO2 in an alkaline electrolyzer. J. Power Sources 301, 219–228 (2016).

Verma, S., Lu, X., Ma, S., Masel, R. I. & Kenis, P. J. A. The effect of electrolyte composition on the electroreduction of CO2 to CO on Ag based gas diffusion electrodes. Phys. Chem. Chem. Phys. 18, 7075–7084 (2016).

Verma, S. et al. Insights into the low overpotential electroreduction of CO2 to CO on a supported gold catalyst in an alkaline flow electrolyzer. ACS Energy Lett. 3, 193–198 (2018).

Kwon, Y., Lai, S. C. S., Rodriguez, P. & Koper, M. T. M. Electrocatalytic oxidation of alcohols on gold in alkaline media: base or gold catalysis? J. Am. Chem. Soc. 133, 6914–6917 (2011).

Narsimhan, K., Iyoki, K., Dinh, K. & Roman-Leshkov, Y. Catalytic oxidation of methane into methanol over copper-exchanged zeolites with oxygen at low temperature. ACS Cent. Sci. 2, 424–429 (2016).

Jhong, H. R., Brushett, F. R. & Kenis, P. J. A. The effects of catalyst layer deposition methodology on electrode performance. Adv. Energy Mater. 3, 589–599 (2013).

Acknowledgements

The authors acknowledge financial support from the International Institute for Carbon Neutral Energy Research (WPI-I2CNER), sponsored by the Japanese Ministry of Education, Culture, Sports, Science and Technology, as well as the Dow Chemical Company, and Glenn E. and Barbara R. Ullyot for graduate fellowships to S.V. The 1H NMR experiments were performed in the School of Chemical Sciences NMR Laboratory at the University of Illinois.

Author information

Authors and Affiliations

Contributions

S.V. conceived the project, performed the cradle-to-gate CO2 analysis, designed and conducted the electrochemical experiments, analysed the data and wrote the manuscript. S.L. prepared the electrodes, contributed to the electrochemical experiments and commented on the manuscript. P.J.A.K. conceived the project, directed the research and wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have filed a patent application (US patent application number 15/971,223) on technology related to the processes described in this article.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–3, Supplementary Tables 1–11, Supplementary references

Rights and permissions

About this article

Cite this article

Verma, S., Lu, S. & Kenis, P.J.A. Co-electrolysis of CO2 and glycerol as a pathway to carbon chemicals with improved technoeconomics due to low electricity consumption. Nat Energy 4, 466–474 (2019). https://doi.org/10.1038/s41560-019-0374-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-019-0374-6

This article is cited by

-

Selective and energy-efficient electrosynthesis of ethylene from CO2 by tuning the valence of Cu catalysts through aryl diazonium functionalization

Nature Energy (2024)

-

Solar reforming as an emerging technology for circular chemical industries

Nature Reviews Chemistry (2024)

-

Integrating hydrogen utilization in CO2 electrolysis with reduced energy loss

Nature Communications (2024)

-

Influence of electric double layer rigidity on CO adsorption and electroreduction rate

Nature Communications (2024)

-

Paired photoelectrochemical conversion of CO2/H2O and glycerol at high rate

Nature Catalysis (2024)