Abstract

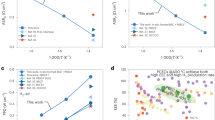

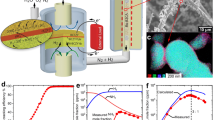

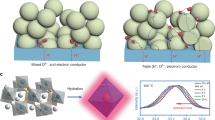

Reversible fuel cells based on both proton exchange membrane fuel cell and solid oxide fuel cell technologies have been proposed to address energy storage and conversion challenges and to provide versatile pathways for renewable fuels production. Both technologies suffer challenges associated with cost, durability, low round-trip efficiency and the need to separate H2O from the product fuel. Here, we present a reversible protonic ceramic electrochemical cell based on an yttrium and ytterbium co-doped barium cerate–zirconate electrolyte and a triple-conducting oxide air/steam (reversible) electrode that addresses many of these issues. Our reversible protonic ceramic electrochemical cell achieves a high Faradaic efficiency (90–98%) and can operate endothermically with a >97% overall electric-to-hydrogen energy conversion efficiency (based on the lower heating value of H2) at a current density of −1,000 mA cm−2. Even higher efficiencies are obtained for H2O electrolysis with co-fed CO2 to produce CO and CH4. We demonstrate a repeatable round-trip (electricity-to-hydrogen-to-electricity) efficiency of >75% and stable operation, with a degradation rate of <30 mV over 1,000 h.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors on reasonable request. See Author contributions for specific datasets.

Change history

22 July 2020

A Correction to this paper has been published: https://doi.org/10.1038/s41560-020-0669-7

References

Xu, L. et al. Plasma-engraved Co3O4 nanosheets with oxygen vacancies and high surface area for the oxygen evolution reaction. Angew. Chem. Int. Ed. 128, 5363–5367 (2016).

Dresp, S. et al. An efficient bifunctional two-component catalyst for oxygen reduction and oxygen evolution in reversible fuel cells, electrolyzers and rechargeable air electrodes. Energy Environ. Sci. 9, 2020–2024 (2016).

Park, S., Shao, Y., Liu, J. & Wang, Y. Oxygen electrocatalysts for water electrolyzers and reversible fuel cells: status and perspective. Energy Environ. Sci. 5, 9331 (2012).

Liu, M. et al. Enhanced sulfur and coking tolerance of a mixed ion conductor for SOFCs: BaZr0.1Ce0.7Y0.2-xYbxO3-δ. Science 326, 126–129 (2009).

Pellow, M. A., Emmott, C. J. M., Barnhart, C. J. & Benson, S. M. Hydrogen or batteries for grid storage? A net energy analysis. Energy Environ. Sci. 8, 1938–1952 (2015).

Einar Vøllestad, R. Strandbakke, Beeaff, D. & Norby, T. Tubular proton ceramic steam electrolysers. In ICE2017 Conf. (2017).

2017 Annual Merit Review and Peer Evaluation (DOE Hydrogen and Fuel Cells Program, 2018); https://www.hydrogen.energy.gov/annual_review.html

Chen, T. et al. High performance of intermediate temperature solid oxide electrolysis cells using Nd2NiO4+δ impregnated scandia stabilized zirconia oxygen electrode. J. Power Sources 276, 1–6 (2015).

Liu, T. et al. Steam electrolysis in a solid oxide electrolysis cell fabricated by the phase-inversion tape casting method. Electrochem. Commun. 61, 106–109 (2015).

Fang, Q., Blum, L. & Menzler, N. H. Performance and degradation of solid oxide electrolysis cells in stack. J. Electrochem. Soc. 162, F907–F912 (2015).

Laguna-Bercero, M. A., Campana, R., Larrea, A., Kilner, J. A. & Orera, V. M. Steam electrolysis using a microtubular solid oxide fuel cell. J. Electrochem. Soc. 157, B852 (2010).

Jensen, S. H., Larsen, P. H. & Mogensen, M. Hydrogen and synthetic fuel production from renewable energy sources. Int. J. Hydrogen Energy 32, 3253–3257 (2007).

Wendel, C. H., Gao, Z., Barnett, S. A. & Braun, R. J. Modeling and experimental performance of an intermediate temperature reversible solid oxide cell for high-efficiency, distributed-scale electrical energy storage. J. Power Sources 283, 329–342 (2015).

Jensen, S. H. et al. Large-scale electricity storage utilizing reversible solid oxide cells combined with underground storage of CO2 and CH4. Energy Environ. Sci. 8, 2471–2479 (2015).

Gao, Z. et al. Tape casting of high-performance low-temperature solid oxide cells with thin La0.8Sr0.2Ga0.8Mg0.2O3−δ electrolytes and impregnated nano anodes. ACS Appl. Mater. Interfaces 9, 7115–7124 (2017).

Zhang, S.-L. et al. Cobalt-substituted SrTi0.3Fe0.7O3−δ: a stable high-performance oxygen electrode material for intermediate-temperature solid oxide electrochemical cells. Energy Environ. Sci. 11, 1870–1879 (2018).

Ishihara, T., Jirathiwathanakul, N. & Zhong, H. Intermediate temperature solid oxide electrolysis cell using LaGaO3 based perovskite electrolyte. Energy Environ. Sci. 3, 665–672 (2010).

Morejudo, S. H. et al. Direct conversion of methane to aromatics in a catalytic co-ionic membrane reactor. Science 353, 563–566 (2016).

Malerød-Fjeld, H. et al. Thermo-electrochemical production of compressed hydrogen from methane with near-zero energy loss. Nat. Energy 2, 923–931 (2017).

Gan, Y. et al. Composite oxygen electrode based on LSCM for steam electrolysis in a proton conducting solid oxide electrolyzer. J. Electrochem. Soc. 159, F763–F767 (2012).

Li, S., Yan, R., Wu, G., Xie, K. & Cheng, J. Composite oxygen electrode LSM-BCZYZ impregnated with Co3O4 nanoparticles for steam electrolysis in a proton-conducting solid oxide electrolyzer. Int. J. Hydrogen Energy 38, 14943–14951 (2013).

Li, H., Chen, X., Chen, S., Wu, Y. & Xie, K. Composite manganate oxygen electrode enhanced with iron oxide nanocatalyst for high temperature steam electrolysis in a proton-conducting solid oxide electrolyzer. Int. J. Hydrogen Energy 40, 7920–7931 (2015).

Li, S. & Xie, K. Composite oxygen electrode based on LSCF and BSCF for steam electrolysis in a proton-conducting solid oxide electrolyzer. J. Electrochem. Soc. 160, F224–F233 (2013).

Gan, L. et al. A scandium-doped manganate anode for a proton-conducting solid oxide steam electrolyzer. RSC Adv. 6, 641–647 (2016).

Duan, C. et al. Readily processed protonic ceramic fuel cells with high performance at low temperatures. Science 349, 1321–1326 (2015).

Dippon, M., Babiniec, S. M., Ding, H., Ricote, S. & Sullivan, N. P. Exploring electronic conduction through BaCexZr0.9-xY0.1O3-d proton-conducting ceramics. Solid State Ion. 286, 117–121 (2016).

Babiniec, S. M., Ricote, S. & Sullivan, N. P. Characterization of ionic transport through BaCe0.2 Zr0.7Y0.1O3-δ membranes in galvanic and electrolytic operation. Int. J. Hydrogen Energy 40, 9278–9286 (2015).

Zhu, H. & Kee, R. J. Membrane polarization in mixed-conducting ceramic fuel cells and electrolyzers. Int. J. Hydrogen Energy 41, 2931–2943 (2016).

Ricote, S., Bonanos, N. & Caboche, G. Water vapour solubility and conductivity study of the proton conductor BaCe0.9-xZrxY0.1O13-δ. Solid State Ion. 180, 990–997 (2009).

Zhu, H. et al. Defect incorporation and transport within dense BaZr0.8Y0.2O3−δ (BZY20) proton-conducting membranes. J. Electrochem. Soc. 165, F581–F588 (2018).

Nomura, K. & Kageyama, H. Transport properties of Ba(Zr0.8Y0.2)O3-δ perovskite. Solid State Ion. 178, 661–665 (2007).

Sumikawa, T. et al. Physicochemical properties of proton-conductive BaZr0.1Ce0.7Y0.1Yb0.1O3−δ solid electrolyte in terms of electrochemical performance of solid oxide fuel cells. Int. J. Hydrogen Energy 41, 17539–17547 (2016).

Kattel, S., Liu, P. & Chen, J. G. Tuning selectivity of CO2 hydrogenation reactions at the metal/oxide interface. J. Am. Chem. Soc. 139, 9739–9754 (2017).

Kee, R. J. et al. Modeling the steady-state and transient response of polarized and non-polarized proton-conducting doped-perovskite membranes. J. Electrochem. Soc. 160, F290–F300 (2013).

Vøllestad, E., Zhu, H. & Kee, R. J. Interpretation of defect and gas-phase fluxes through mixed-conducting ceramics using Nernst–Planck–Poisson and integral formulations. J. Electrochem. Soc. 161, 114–124 (2014).

Zhu, H. & Kee, R. J. Modeling protonic-ceramic fuel cells with porous composite electrodes in a button-cell configuration. J. Electrochem. Soc. 164, F1400–F1411 (2017).

Zhu, H., Ricote, S., Coors, W. G. & Kee, R. J. Interpreting equilibrium-conductivity and conductivity-relaxation measurements to establish thermodynamic and transport properties for multiple charged defect conducting ceramics. Faraday Discuss. 182, 49–74 (2015).

O’Hayre, R., Cha, S. W., Prinz, F. B. & Colella, W. Fuel Cell Fundamentals (John Wiley & Sons, 2016).

Frade, J. R. Theoretical behaviour of concentration cells based on ABO3 perovskite materials with protonic and oxygen ion conduction. Solid State Ion. 78, 87–97 (1995).

Acknowledgements

This work was supported by the Advanced Research Projects Agency–Energy (ARPA-E) through the REFUEL (award DE-AR0000808) and REBELS programmes (award DE-AR0000493). Additional support was provided by the Army Research Office under grant number W911NF-17-1-0051, the Office of Naval Research via grant N00014-16-1-2780, the National Science Foundation via grant DMR156375, the Colorado School of Mines Foundation via the Angel Research Fund and the Colorado Office of Economic Development and International Trade (COEDIT) under their Advanced Industries Proof-of-Concept Grant programme. The views and conclusions contained in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of ARPA-E, the Department of Energy, the Army Research Office or the US Government.

Author information

Authors and Affiliations

Contributions

C.D. and R.O. developed the intellectual concept, designed the experiments, analysed the data and led the manuscript writing. H.Z. and R.K. developed the PCFC and PCEC model comparisons and contributed to the discussion and analysis. D.J. performed the transmission electron microscopy. N.S., L.Z. and L.B. provided suggestions on the experiments, data interpretation and manuscript refinement.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figures 1–16, Supplementary Note 1, Supplementary Tables 1–5, Supplementary references.

Rights and permissions

About this article

Cite this article

Duan, C., Kee, R., Zhu, H. et al. Highly efficient reversible protonic ceramic electrochemical cells for power generation and fuel production. Nat Energy 4, 230–240 (2019). https://doi.org/10.1038/s41560-019-0333-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-019-0333-2

This article is cited by

-

Synergistic dual-phase air electrode enables high and durable performance of reversible proton ceramic electrochemical cells

Nature Communications (2024)

-

Quantification of correlation between microstructure and mechanical properties of Ni–BaZrxCe0.8−xY0.1Yb0.1O3-δ (x = 0.1, 0.5) cermet anodes by image analysis

Journal of the Korean Ceramic Society (2024)

-

Robust tantalum tuned perovskite oxygen electrode for reversible protonic ceramic electrochemical cells

Rare Metals (2024)

-

Lowering the operating temperature of protonic ceramic electrochemical cells to <450 °C

Nature Energy (2023)

-

Enhancing the Faradaic efficiency of solid oxide electrolysis cells: progress and perspective

npj Computational Materials (2023)