Abstract

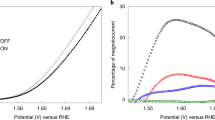

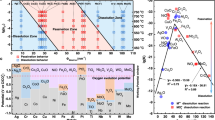

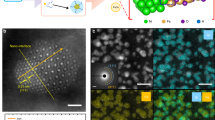

Water electrolysis enables the storage of renewable electricity via the chemical bonds of hydrogen. However, proton-exchange-membrane electrolysers are impeded by the high cost and low availability of their noble-metal electrocatalysts, whereas alkaline electrolysers operate at a low power density. Here, we demonstrate that electrocatalytic reactions relevant for water splitting can be improved by employing magnetic heating of noble-metal-free catalysts. Using nickel-coated iron carbide nanoparticles, which are prone to magnetic heating under high-frequency alternating magnetic fields, the overpotential (at 20 mA cm−2) required for oxygen evolution in an alkaline water-electrolysis flow-cell was decreased by 200 mV and that for hydrogen evolution was decreased by 100 mV. This enhancement of oxygen-evolution kinetics is equivalent to a rise of the cell temperature to ~200 °C, but in practice it increased by 5 °C only. This work suggests that, in the future, water splitting near the equilibrium voltage could be possible at room temperature, which is currently beyond reach in the classic approach to water electrolysis.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Ghoniem, A. F. Needs, resources and climate change: clean and efficient conversion technologies. Prog. Energ. Comb. Sci. 37, 15–51 (2011).

Schultz, M. G., Diehl, T., Brasseur, G. P. & Zittel, W. Air pollution and climate-forcing, impacts of a global, hydrogen economy. Science 302, 624–627 (2003).

Jacobson, M. Z., Colella, W. G. & Golden, D. M. Atmospheric science: cleaning the air and improving health with hydrogen fuel-cell vehicles. Science 308, 1901–1905 (2005).

Coughlin, R. W. & Farooque, M. Hydrogen production from coal, water and electrons. Nature 279, 301–303 (1979).

Karlsson, T. Hydrogen and Fuel Cells: A Clean, Real, and Global Opportunity (IPHE, 2016).

Götz, M. et al. Renewable power-to-gas: a technological and economic review. Renew. Energy 85, 1371–1390 (2016).

Dunn, B., Kamath, H. & Tarascon, J. M. Electrical energy storage for the grid: a battery of choices. Science 334, 928–935 (2011).

Nakato, Y., Takamori, N. & Tsubomura, H. A composite semiconductor photoanode for water electrolysis. Nature 295, 312–313 (1982).

Khaselev, O. & Turner, J. A. A monolithic photovoltaic–photoelectrochemical device for hydrogen production via water splitting. Science 280, 425–427 (1998).

Katz, J. E., Gingrich, T. R., Santori, E. A. & Lewis, N. S. Combinatorial synthesis and high-throughput photopotential and photocurrent screening of mixed-metal oxides for photoelectrochemical water splitting. Energy Environ. Sci. 2, 103–112 (2009).

Tran, P. D., Artero, V. & Fontecave, M. Water electrolysis and photoelectrolysis on electrodes engineered using biological and bio-inspired molecular systems. Energy Environ. Sci. 3, 727–747 (2010).

McCormick, A. J. et al. Hydrogen production through oxygenic photosynthesis using the cyanobacterium Synechocystis sp. PCC 6803 in a bio-photoelectrolysis cell (BPE) system. Energy Environ. Sci. 6, 2682–2690 (2013).

Berger, A., Segalman, R. A. & Newman, J. Material requirements for membrane separators in a water-splitting photoelectrochemical cell. Energy Environ. Sci. 7, 1468–1476 (2014).

Mergel, J., Maier, W. & Stolten, D. in 20th World Hydrogen Energy Conference (WHEC 2014) 1165–1169 (Curran Associates, New York, 2015).

Holladay, J. D., Hu, J., King, D. L. & Wang, Y. An overview of hydrogen production technologies. Catal. Today 139, 244–260 (2009).

Marini, S. et al. Advanced alkaline water electrolysis. Electrochim. Acta 82, 384–391 (2012).

Carmo, M., Fritz, D. L., Mergel, J. & Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrog. Energy 38, 4901–4934 (2013).

Xu, J. et al. Oxygen evolution catalysts on supports with a 3-D ordered array structure and intrinsic proton conductivity for proton exchange membrane steam electrolysis. Energy Environ. Sci. 7, 820–830 (2014).

Hall, D. E. Alkaline water electrolysis anode materials. J. Electrochem. Soc. 132, 41C–48C (1985).

Wendt, H. & Imarisio, G. Nine years of research and development on advanced water electrolysis. A review of the research programme of the Commission of the European Communities. J. Appl. Electrochem. 18, 1–14 (1988).

Singh, R. N., Mishra, D., Anindita, S., Sinha, A. S. K. & Singh, A. Novel electrocatalysts for generating oxygen from alkaline water electrolysis. Electrochem. Commun. 9, 1369–1373 (2007).

Bates, M. K., Jia, Q., Doan, H., Liang, W. & Mukerjee, S. Charge-transfer effects in Ni–Fe and Ni–Fe–Co mixed-metal oxides for the alkaline oxygen evolution reaction. ACS Catal. 6, 155–161 (2016).

Detsi, E. et al. Mesoporous Ni60Fe30Mn10-alloy based metal/metal oxide composite thick films as highly active and robust oxygen evolution catalysts. Energy Environ. Sci. 9, 540–549 (2016).

Li, J. et al. Highly efficient and robust nickel phosphides as bifunctional electrocatalysts for overall water-splitting. ACS Appl. Mater. Interfaces 8, 10826–10834 (2016).

Wang, T., Wang, X., Liu, Y., Zheng, J. & Li, X. A highly efficient and stable biphasic nanocrystalline Ni–Mo–N catalyst for hydrogen evolution in both acidic and alkaline electrolytes. Nano Energy 22, 111–119 (2016).

Cui, X., Ren, P., Deng, D., Deng, J. & Bao, X. Single layer graphene encapsulating non-precious metals as high-performance electrocatalysts for water oxidation. Energy Environ. Sci. 9, 123–129 (2016).

Divisek, J., Mergel, J. & Schmitz, H. Improvement of water electrolysis in alkaline media at intermediate temperatures. Int. J. Hydrog. Energy 7, 695–701 (1982).

Meffre, A. et al. A simple chemical route toward monodisperse iron carbide nanoparticles displaying tunable magnetic and unprecedented hyperthermia properties. Nano Lett. 12, 4722–4728 (2012).

Goya, G. F., Asín, L. & Ibarra, M. R. Cell death induced by AC magnetic fields and magnetic nanoparticles: current state and perspectives. Int. J. Hyperth. 29, 810–818 (2013).

Huang, H., Delikanli, S., Zeng, H., Ferkey, D. M. & Pralle, A. Remote control of ion channels and neurons through magnetic-field heating of nanoparticles. Nat. Nano 5, 602–606 (2010).

Périgo, E. A. et al. Fundamentals and advances in magnetic hyperthermia. Appl. Phys. Rev. 2, 041302 (2015).

Piñol, R. et al. Joining time-resolved thermometry and magnetic-induced heating in a single nanoparticle unveils intriguing thermal properties. ACS Nano 9, 3134–3142 (2015).

Riedinger, A. et al. Subnanometer local temperature probing and remotely controlled drug release based on azo-functionalized iron oxide nanoparticles. Nano Lett. 13, 2399–2406 (2013).

Meffre, A. et al. Complex nano-objects displaying both magnetic and catalytic properties: a proof of concept for magnetically induced heterogeneous catalysis. Nano Lett. 15, 3241–3248 (2015).

Bordet, A. et al. Magnetically induced continuous CO2 hydrogenation using composite iron carbide nanoparticles of exceptionally high heating power. Angew. Chem. Int. Ed. 55, 15894–15898 (2016).

Bordet, A., Lacroix, L. M., Soulantica, K. & Chaudret, B. A new approach to the mechanism of Fischer–Tropsch syntheses arising from gas phase NMR and mass spectrometry. ChemCatChem 8, 1727–1731 (2016).

Arteaga-Cardona, F. et al. Improving the magnetic heating by disaggregating nanoparticles. J. Alloy. Compd 663, 636–644 (2016).

Park, S., Shao, Y., Liu, J. & Wang, Y. Oxygen electrocatalysts for water electrolyzers and reversible fuel cells: status and perspective. Energy Environ. Sci. 5, 9331–9344 (2012).

Ross, P. N. & Sokol, H. The corrosion of carbon-black anodes in alkaline electrolyte. 1. Acetylene black and the effect of cobalt catalyzation. J. Electrochem. Soc. 131, 1742–1750 (1984).

Sattler, M. L. & Ross, P. N. The surface structure of Pt crystallites supported on carbon black. Ultramicroscopy 20, 21–28 (1986).

Staud, N. & Ross, P. N. The corrosion of carbon-black anodes in alkaline electrolyte. 2. Acetylene black and the effect of oxygen evolution catalysts on corrosion. J. Electrochem. Soc. 133, 1079–1084 (1986).

Ross, P. N. & Sattler, M. The corrosion of carbon-black anodes in alkaline electrolyte. 3. The effect of graphitization on the corrosion-resistance of furnace blacks. J. Electrochem. Soc. 135, 1464–1470 (1988).

Staud, N., Sokol, H. & Ross, P. N. The corrosion of carbon-black anodes in alkaline electrolyte. 4. Current efficiencies for oxygen evolution from metal oxide-impregnated graphitized furnace blacks. J. Electrochem. Soc. 136, 3570–3576 (1989).

Miles, M. H., Kissel, G., Lu, P. W. T. & Srinivasan, S. Effect of temperature on electrode kinetic parameters for hydrogen and oxygen evolution reactions on nickel electrodes in alkaline solutions. J. Electrochem. Soc. 123, 332–336 (1976).

Akamoto, H. The C–Fe (carbon-iron) system. J. Phase Equilibria 13, 543–565 (1992).

Acknowledgements

The authors thank Engie and its scientific director J.-P. Reich for its willingness to explore breakthrough technologies and funding the present feasibility study in 2016, in which we explored magnetic heating-improved alkaline water electrolysis. The electrochemical characterizations were performed at LEPMI, within the framework of the Centre of Excellence of Multifunctional Architectured Materials (CEMAM no. AN-10-LABX-44-01). M.C. also thanks the IUF for funding.

Author information

Authors and Affiliations

Contributions

C.N. contributed to the experimental work, data analysis and writing of the manuscript. S.F. contributed to the experimental work and review of the manuscript. A.B. contributed to the experimental work. J.D. contributed to the project planning, experimental work, data analysis and writing of the manuscript. M.C. contributed to the project planning, experimental work, data analysis and writing of the manuscript. J.C. contributed to the data analysis and writing of the manuscript. B.C. contributed to the project planning, data analysis and writing of the manuscript. A.R. had the original idea of the study, and contributed to the project planning and review of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figures 1–13, Supplementary Tables 1–4 and Supplementary References

Rights and permissions

About this article

Cite this article

Niether, C., Faure, S., Bordet, A. et al. Improved water electrolysis using magnetic heating of FeC–Ni core–shell nanoparticles. Nat Energy 3, 476–483 (2018). https://doi.org/10.1038/s41560-018-0132-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-018-0132-1

This article is cited by

-

Single-atom platinum with asymmetric coordination environment on fully conjugated covalent organic framework for efficient electrocatalysis

Nature Communications (2024)

-

Optimizing spin arrangement by permeability modulation of high-entropy alloys to promote O-O formation for efficient water oxidation

Science China Materials (2024)

-

Bimetallic 3D hollow-nanoshell FeCo-oxynitride/N and S co-doped carbon nanotubes as a robust bifunctional oxygen electrocatalyst for rechargeable Zn-air batteries

Journal of Materials Science (2023)

-

Advances in magnetic field-assisted ECM—from magnetoelectric effects to technology applications

The International Journal of Advanced Manufacturing Technology (2023)

-

Elucidating the electronic metal-support interaction enhanced hydrogen evolution activity on Ti3C2Tx MXene basal plane by scanning electrochemical microscopy

Nano Research (2023)