Abstract

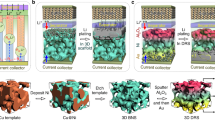

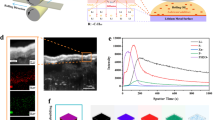

Problems related to dendrite growth on lithium-metal anodes such as capacity loss and short circuit present major barriers to next-generation high-energy-density batteries. The development of successful lithium dendrite mitigation strategies is impeded by an incomplete understanding of the Li dendrite growth mechanisms, and in particular, Li-plating-induced internal stress in Li metal and its effect on Li growth morphology are not well addressed. Here, we reveal the enabling role of plating residual stress in dendrite formation through depositing Li on soft substrates and a stress-driven dendrite growth model. We show that dendrite growth is mitigated on such soft substrates through surface-wrinkling-induced stress relaxation in the deposited Li film. We demonstrate that this dendrite mitigation mechanism can be utilized synergistically with other existing approaches in the form of three-dimensional soft scaffolds for Li plating, which achieves higher coulombic efficiency and better capacity retention than that for conventional copper substrates.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Zhamu, A. et al. Reviving rechargeable lithium metal batteries: enabling next-generation high-energy and high-power cells. Energy Environ. Sci. 5, 5701–5707 (2012).

Safari, M., Adams, B. & Nazar, L. Kinetics of oxygen reduction in aprotic Li–O2 cells: a model-based study. J. Phys. Chem. Lett. 5, 3486–3491 (2014).

Kim, S. et al. All-water-based electron-beam lithography using silk as a resist. Nat. Nanotech. 9, 306–310 (2014).

Dong, S. et al. Insight into enhanced cycling performance of Li-O2 batteries based on binary CoSe2/CoO nanocomposite electrodes. J. Phys. Chem. Lett. 5, 615–621 (2014).

Albertus, P., Babinec, S., Litzelman, S. & Newman, A. Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries. Nat. Energy 3, 16–21 (2018).

Hirai, T., Yoshimatsu, I. & Yamaki, J. i. Effect of additives on lithium cycling efficiency. J. Electrochem. Soc. 141, 2300–2305 (1994).

Aurbach, D., Markovsky, B., Shechter, A., Ein-Eli, Y. & Cohen, H. A comparative study of synthetic graphite and Li electrodes in electrolyte solutions based on ethylene carbonate-dimethyl carbonate mixtures. J. Electrochem. Soc. 143, 3809–3820 (1996).

Aurbach, D. et al. Recent studies of the lithium-liquid electrolyte interface. Electrochemical, morphological and spectral studies of a few important systems. J. Power Sources 54, 76–84 (1995).

Schechter, A., Aurbach, D. & Cohen, H. X-ray photoelectron spectroscopy study of surface films formed on Li electrodes freshly prepared in alkyl carbonate solutions. Langmuir 15, 3334–3342 (1999).

Xu, W. et al. Lithium metal anodes for rechargeable batteries. Energy Environ. Sci. 7, 513–537 (2014).

Murugan, R., Thangadurai, V. & Weppner, W. Fast lithium ion conduction in garnet-type Li7La3Zr2O12. Angew. Chem. Int. Ed. 46, 7778–7781 (2007).

Kim, K. H. et al. Characterization of the interface between LiCoO2 and Li7 La3Zr2O12 in an all-solid-state rechargeable lithium battery. J. Power Sources 196, 764–767 (2011).

Gireaud, L., Grugeon, S., Laruelle, S., Yrieix, B. & Tarascon, J.-M. Lithium metal stripping/plating mechanisms studies: A metallurgical approach. Electrochem. Commun. 8, 1639–1649 (2006).

Mayers, M. Z., Kaminski, J. W. & Miller, T. F.III. Suppression of dendrite formation via pulse charging in rechargeable lithium metal batteries. J. Phys. Chem. C 116, 26214–26221 (2012).

Yan, K. et al. Ultrathin two-dimensional atomic crystals as stable interfacial layer for improvement of lithium metal anode. Nano Lett. 14, 6016–6022 (2014).

Zheng, G. et al. Interconnected hollow carbon nanospheres for stable lithium metal anodes. Nat. Nanotech. 9, 618–623 (2014).

Lee, H., Lee, D. J., Kim, Y.-J., Park, J.-K. & Kim, H.-T. A simple composite protective layer coating that enhances the cycling stability of lithium metal batteries. J. Power Sources 284, 103–108 (2015).

Tikekar, M. D., Choudhury, S., Tu, Z. & Archer, L. A. Design principles for electrolytes and interfaces for stable lithium-metal batteries. Nat. Energy 1, 16114 (2016).

Choudhury, S. et al. Electroless formation of hybrid lithium anodes for fast interfacial ion transport. Angew. Chem. Int. Ed. 56, 13070–13077 (2017).

Yan, K. et al. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat. Energy 1, 16010 (2016).

Liu, Y. et al. Lithium-coated polymeric matrix as a minimum volume-change and dendrite-free lithium metal anode. Nat. Commun. 7, 10992 (2016).

Lin, D. et al. Layered reduced graphene oxide with nanoscale interlayer gaps as a stable host for lithium metal anodes. Nat. Nanotech. 11, 626–632 2016).

Lu, L.-L. et al. Free-standing copper nanowire network current collector for improving lithium anode performance. Nano Lett. 16, 4431–4437 (2016).

Yang, C.-P., Yin, Y.-X., Zhang, S.-F., Li, N.-W. & Guo, Y.-G. Accommodating lithium into 3D current collectors with a submicron skeleton towards long-life lithium metal anodes. Nat. Commun. 6, 8058 (2015).

Yun, Q. et al. Chemical dealloying derived 3D porous current collector for Li metal anodes. Adv. Mater. 28, 6932–6939 (2016).

Guo, Y., Li, H. & Zhai, T. Reviving lithium-metal anodes for next-generation high-energy batteries. Adv. Mater. 29, 1700007 (2017).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotech. 12, 194–206 (2017).

Monroe, C. & Newman, J. The impact of elastic deformation on deposition kinetics at lithium/polymer interfaces. J. Electrochem. Soc. 152, A396–A404 (2005).

Ahmad, Z. & Viswanathan, V. Stability of electrodeposition at solid-solid interfaces and implications for metal anodes. Phys. Rev. Lett. 119, 056003 (2017).

Chason, E., Jadhav, N., Pei, F., Buchovecky, E. & Bower, A. Growth of whiskers from Sn surfaces: driving forces and growth mechanisms. Prog. Surf. Sci. 88, 103–131 (2013).

Chason, E. et al. Understanding residual stress in electrodeposited Cu thin films. J. Electrochem. Soc. 160, D3285–D3289 (2013).

Shin, J. W. & Chason, E. Compressive stress generation in Sn thin films and the role of grain boundary diffusion. Phys. Rev. Lett. 103, 056102 (2009).

Li, W. Y. et al. The synergetic effect of lithium polysulfide and lithium nitrate to prevent lithium dendrite growth. Nat. Commun. 6, 7436 (2015).

Qian, J. F. et al. High rate and stable cycling of lithium metal anode. Nat. Commun. 6, 6362 (2015).

Wang, Z., Volinsky, A. A. & Gallant, N. D. Crosslinking effect on polydimethylsiloxane elastic modulus measured by custom-built compression instrument. J. Appl. Polym. Sci. 131, 41050 (2014).

James, A. M. & Lord, M. P. Macmillan’s Chemical and Physical Data (Macmillan, London, 1992).

Xu, C., Ahmad, Z., Aryanfar, A., Viswanathan, V. & Greer, J. R. Enhanced strength and temperature dependence of mechanical properties of Li at small scales and its implications for Li metal anodes. Proc. Natl Acad. Sci. USA 114, 57–61 (2017).

Yamaki, J. et al. A consideration of the morphology of electrochemically deposited lithium in an organic electrolyte. J. Power Sources 74, 219–227 (1998).

Bai, P., Li, J., Brushett, F. R. & Bazant, M. Z. Transition of lithium growth mechanisms in liquid electrolytes. Energy Environ. Sci. 9, 3221–3229 (2016).

Steiger, J., Kramer, D. & Monig, R. Mechanisms of dendritic growth investigated by in situ light microscopy during electrodeposition and dissolution of lithium. J. Power Sources 261, 112–119 (2014).

Sand, H. J. S. On the concentration at the electrodes in a solution, with special reference to the liberation of hydrogen by electrolysis of a mixture of copper sulphate and sulphuric acid. Philos. Mag. 1, 45–79 (1901).

Kato, T., Handwerker, C. A. & Bath, J. Mitigating Tin Whisker Risks: Theory and Practice (John Wiley & Sons, Hoboken, NJ, 2016).

Sarobol, P., Blendell, J. E. & Handwerker, C. A. Whisker and hillock growth via coupled localized Coble creep, grain boundary sliding, and shear induced grain boundary migration. Acta Mater. 61, 1991–2003 (2013).

Abermann, R. & Koch, R. The internal-stress in thin silver, copper and gold-films. Thin Solid Films 129, 71–78 (1985).

Spaepen, F. Interfaces and stresses in thin films. Acta Mater. 48, 31–42 (2000).

Chason, E., Sheldon, B. W., Freund, L. B., Floro, J. A. & Hearne, S. J. Origin of compressive residual stress in polycrystalline thin films. Phys. Rev. Lett. 88, 156103 (2002).

Li, Y. et al. Atomic structure of sensitive battery materials and interfaces revealed by cryo–electron microscopy. Science 358, 506–510 (2017).

Harry, K. J., Hallinan, D. T., Parkinson, D. Y., MacDowell, A. A. & Balsara, N. P. Detection of subsurface structures underneath dendrites formed on cycled lithium metal electrodes. Nat. Mater. 13, 69–73 (2014).

Wieland, O. & Carstanjen, H. D. Measurement of the low-temperature self-diffusivity of lithium by elastic recoil detection analysis. Def. Diff. Forum 194–199, 35–41 (2001).

Khang, D. Y., Jiang, H. Q., Huang, Y. & Rogers, J. A. A stretchable form of single-crystal silicon for high-performance electronics on rubber substrates. Science 311, 208–212 (2006).

Huang, Z. Y., Hong, W. & Suo, Z. Nonlinear analyses of wrinkles in a film bonded to a compliant substrate. J. Mech. Phys. Solids 53, 2101–2118 (2005).

Song, J. et al. An analytical study of two-dimensional buckling of thin films on compliant substrates. J. Appl. Phys. 103, 014303 (2008).

Yu, C. et al. Silicon thin films as anodes for high-performance lithium-ion batteries with effective stress relaxation. Adv. Energy Mater. 2, 68–73 (2012).

Jiang, H. et al. Finite deformation mechanics in buckled thin films on compliant supports. Proc. Natl Acad. Sci. USA 104, 15607–15612 (2007).

Acknowledgements

We gratefully acknowledge the use of facilities within the LeRoy Eyring Center for Solid State Science at Arizona State University. L.H. F.W. and M.T. acknowledge support from the DOE BES Physical Behaviour of Materials Program under grant no. DE-SC0014435. The research also uses HPC resources supported in part by the Big-Data Private-Cloud Research Cyberinfrastructure MRI-award funded by the NSF under grant CNS-1338099 by Rice University. We appreciate the discussion with C. Chan at Arizona State University on the full-cell characterization.

Author information

Authors and Affiliations

Contributions

X.W., W.Z. and H.J. designed the experiments. X.W., W.Z., W.X., H.Y., F.W., H.D. and H.J. carried out experiments and analysis. L.H. and M.T. developed the theory. X.W., M.T. and H.J. wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figures 1–16, Supplementary Discussion, Supplementary References.

Videos

Supplementary Video 1

Optical observation of 200 nm-thick Cu/PDMS soft substrate during Li plating

Supplementary Video 2

Optical observation of 400 nm-thick Cu/PDMS soft substrate during Li plating

Supplementary Video 3

Optical observation of 800 nm-thick Cu/PDMS soft substrate during Li plating

Rights and permissions

About this article

Cite this article

Wang, X., Zeng, W., Hong, L. et al. Stress-driven lithium dendrite growth mechanism and dendrite mitigation by electroplating on soft substrates. Nat Energy 3, 227–235 (2018). https://doi.org/10.1038/s41560-018-0104-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-018-0104-5

This article is cited by

-

Transition metals for stabilizing lithium metal anode: advances and perspectives

Tungsten (2024)

-

Tracking lithiation with transmission electron microscopy

Science China Chemistry (2024)

-

From Liquid to Solid-State Lithium Metal Batteries: Fundamental Issues and Recent Developments

Nano-Micro Letters (2024)

-

Insights into Nano- and Micro-Structured Scaffolds for Advanced Electrochemical Energy Storage

Nano-Micro Letters (2024)

-

Investigation of non-uniform oxidation based on a mechanochemical phase field model with nonlinear reaction kinetics and large inelastic deformation

npj Materials Degradation (2023)