Abstract

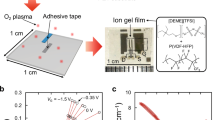

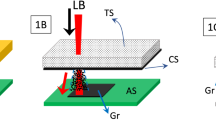

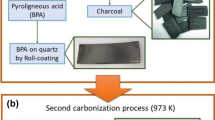

The development of ultrahigh-temperature thermoelectric materials could enable thermoelectric topping of combustion power cycles as well as extending the range of direct thermoelectric power generation in concentrated solar power. However, thermoelectric operation temperatures have been restricted to under 1,500 K due to the lack of suitable materials. Here, we demonstrate a thermoelectric conversion material based on high-temperature reduced graphene oxide nanosheets that can perform reliably up to 3,000 K. After a reduction treatment at 3,300 K, the nanosheet film exhibits an increased conductivity to ~4,000 S cm−1 at 3,000 K and a high power factor S2σ = 54.5 µW cm−1 K−2. We report measurements characterizing the film’s thermoelectric properties up to 3,000 K. The reduced graphene oxide film also exhibits a high broadband radiation absorbance and can act as both a radiative receiver and a thermoelectric generator. The printable, lightweight and flexible film is attractive for system integration and scalable manufacturing.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Heremans, J. P., Dresselhaus, M. S., Bell, L. E. & Morelli, D. T. When thermoelectrics reached the nanoscale. Nat. Nanotechnol. 8, 471–473 (2013).

Snyder, G. J. & Toberer, E. S. Complex thermoelectric materials. Nat. Mater. 7, 105–114 (2008).

Zhao, L.-D., Dravid, V. P. & Kanatzidis, M. G. The panoscopic approach to high performance thermoelectrics. Energy Env. Sci. 7, 251–268 (2014).

Chung, D.-Y. et al. CsBi4Te6: A high-performance thermoelectric material for low-temperature applications. Science 287, 1024–1027 (2000).

Poudel, B. et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 320, 634–638 (2008).

Hsu, K. F. et al. Cubic AgPbmSbTe2+m: bulk thermoelectric materials with high figure of merit. Science 303, 818–821 (2004).

Harman, T. C., Taylor, P. J., Walsh, M. P. & LaForge, B. E. Quantum dot superlattice thermoelectric materials and devices. Science 297, 2229–2232 (2002).

Heremans, J. P. et al. Enhancement of thermoelectric efficiency in PbTe by distortion of the electronic density of states. Science 321, 554–557 (2008).

Kauzlarich, S. M., Brown, S. R. & Snyder, G. J. Zintl phases for thermoelectric devices. Dalton Trans. 21, 2099–2107 (2007).

Rowe, D. Thermoelectric waste heat recovery as a renewable energy source. Int. J. Innov. Energy Syst. Power 1, 13–23 (2006).

Bux, S. K. et al. Nanostructured bulk silicon as an effective thermoelectric material. Adv. Funct. Mater. 19, 2445–2452 (2009).

Zhu, G. H. et al. Increased phonon scattering by nanograins and point defects in nanostructured silicon with a low concentration of germanium. Phys. Rev. Lett. 102, 196803 (2009).

Joshi, G. et al. Enhanced thermoelectric figure-of-merit in nanostructured p-type silicon germanium bulk alloys. Nano Lett. 8, 4670–4674 (2008).

Hochbaum, A. I. et al. Enhanced thermoelectric performance of rough silicon nanowires. Nature 451, 163–167 (2008).

Minnich, A. J., Dresselhaus, M. S., Ren, Z. F. & Chen, G. Bulk nanostructured thermoelectric materials: current research and future prospects. Energy Environ. Sci. 2, 466–479 (2009).

Hicks, L. D. & Dresselhaus, M. S. Thermoelectric figure of merit of a one-dimensional conductor. Phys. Rev. B 47, 16631–16634 (1993).

Kim, J. Y. & Grossman, J. C. High-efficiency thermoelectrics with functionalized graphene. Nano Lett. 15, 2830–2835 (2015).

Xiao, N. et al. Enhanced thermopower of graphene films with oxygen plasma treatment. ACS Nano 5, 2749–2755 (2011).

Gao, J. et al. Enhanced power factor in flexible reduced graphene oxide/nanowires hybrid films for thermoelectrics. RSC Adv. 6, 31580–31587 (2016).

Choi, J. et al. Controlled oxidation level of reduced graphene oxides and its effect on thermoelectric properties. Macromol. Res. 22, 1104–1108 (2014).

Wang, W. et al. An efficient thermoelectric material: preparation of reduced graphene oxide/polyaniline hybrid composites by cryogenic grinding. RSC Adv. 5, 8988–8995 (2015).

Beekman, M., Morelli, D. T. & Nolas, G. S. Better thermoelectrics through glass-like crystals. Nat. Mater. 14, 1182–1185 (2015).

Yazawa, K. et al. Thermoelectric topping cycles for power plants to eliminate cooling water consumption. Energy Convers. Manag. 84, 244–252 (2014).

Adiabatic Flame Temperatures (The Engineering ToolBox, accessed 4 July 2017); http://www.engineeringtoolbox.com/adiabatic-flame-temperature-d_996.html

Marcano, D. C. et al. Improved synthesis of graphene oxide. ACS Nano 4, 4806–4814 (2010).

Bao, W. et al. Flexible, high temperature, planar lighting with large scale printable nanocarbon paper. Adv. Mater. 28, 4684–4691 (2016).

Eda, G., Fanchini, G. & Chhowalla, M. Large-area ultrathin films of reduced graphene oxide as a transparent and flexible electronic material. Nat. Nanotechnol. 3, 270–274 (2008).

Kobayashi, T., Kimura, N., Chi, J., Hirata, S. & Hobara, D. Channel-length-dependent field-effect mobility and carrier concentration of reduced graphene oxide thin-film transistors. Small 6, 1210–1215 (2010).

Negishi, R. et al. Synthesis of very narrow multilayer graphene nanoribbon with turbostratic stacking. Appl. Phys. Lett. 110, 201901 (2017).

Nair, R. R. et al. Fine structure constant defines visual transparency of graphene. Science 320, 1308–1308 (2008).

Cusack, N. & Kendall, P. The absolute scale of thermoelectric power at high temperature. Proc. Phys. Soc. 72, 898–907 (1958).

Bahk, J.-H., Bian, Z. & Shakouri, A. Electron energy filtering by a nonplanar potential to enhance the thermoelectric power factor in bulk materials. Phys. Rev. B 87, 75204 (2013).

Zhang, Y. et al. Hot carrier filtering in solution processed heterostructures: a paradigm for improving thermoelectric efficiency. Adv. Mater. 26, 2755–2761 (2014).

Neophytou, N. & Kosina, H. Optimizing thermoelectric power factor by means of a potential barrier. J. Appl. Phys. 114, 44315 (2013).

Nonoguchi, Y. et al. Systematic conversion of single walled carbon nanotubes into n-type thermoelectric materials by molecular dopants. Sci. Rep. 3, 3344 (2013).

Fukumaru, T., Fujigaya, T. & Nakashima, N. Development of n-type cobaltocene-encapsulated carbon nanotubes with remarkable thermoelectric property. Sci. Rep. 5, 7951 (2015).

Ramirez, C., Leborán, V., Rivadulla, F., Miranzo, P. & Osendi, M. I. Thermopower and Hall effect in silicon nitride composites containing thermally reduced graphene and pure graphene nanosheets. Ceram. Int. 42, 11341–11347 (2016).

Avery, A. D. et al. Tailored semiconducting carbon nanotube networks with enhanced thermoelectric properties. Nat. Energy 1, 16033 (2016).

Crispin, X. Thermoelectrics: Carbon nanotubes get high. Nat. Energy 1, 16037 (2016).

Zuev, Y. M., Chang, W. & Kim, P. Thermoelectric and magnetothermoelectric transport measurements of graphene. Phys. Rev. Lett. 102, 096807 (2009).

Wei, P., Bao, W., Pu, Y., Lau, C. N. & Shi, J. Anomalous thermoelectric transport of Dirac particles in graphene. Phys. Rev. Lett. 102, 166808 (2009).

Ashcroft, N. W. & Mermin, N. D. Solid State Physics (Harcourt College Publisher, San Diego, 1976).

Ghahari, F. et al. Enhanced thermoelectric power in graphene: violation of the Mott relation by inelastic scattering. Phys. Rev. Lett. 116, 136802 (2016).

Chen, J.-H. et al. Charged-impurity scattering in graphene. Nat. Phys. 4, 377–381 (2008).

Chen, J.-H., Cullen, W. G., Jang, C., Fuhrer, M. S. & Williams, E. D. Defect scattering in graphene. Phys. Rev. Lett. 102, 236805 (2009).

Li, F., Cai, K., Shen, S. & Chen, S. Preparation and thermoelectric properties of reduced graphene oxide/PEDOT:PSS composite films. Synth. Met. 197, 58–61 (2014).

Acknowledgements

We acknowledge the Dean’s support from the University of Maryland, which was used to set up our experimental equipment. The constructive discussions with J. P. Heremans as well as use of the probe station in A. Shakouri’s laboratory to measure room-temperature thermal conductivity were greatly appreciated. A.D.P. acknowledges the support provided by the National Science Foundation Graduate Research Fellowship. S.D.L. acknowledges the support by the Department of Defense (DoD) through the National Defense Science and Engineering Graduate (NDSEG) Fellowship Program. M.S.F. is supported by an Australian Research Council Laureate Fellowship.

Authors contributions

T.L., D.H.D. and L.H. conceived the idea. T.L., Y.Y., Y.C., S.D.L., Y.L., J.D. and Y.W. contributed to material preparation and characterization. A.D.P., Y.Z., C.D., A.M., T.L. and B.Y. contributed to the characterization and analysis of thermal properties. T.L., Y.W., M.S.F. and D.H.D. contributed to the characterization and analysis of electrical properties. All authors contributed to writing.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Discussion 1–6 and Supplementary Figure 1–13

Rights and permissions

About this article

Cite this article

Li, T., Pickel, A.D., Yao, Y. et al. Thermoelectric properties and performance of flexible reduced graphene oxide films up to 3,000 K. Nat Energy 3, 148–156 (2018). https://doi.org/10.1038/s41560-018-0086-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-018-0086-3

This article is cited by

-

Nature-inspired interfacial engineering for energy harvesting

Nature Reviews Electrical Engineering (2024)

-

Continuous and low-carbon production of biomass flash graphene

Nature Communications (2024)

-

Intelligent Recognition Using Ultralight Multifunctional Nano-Layered Carbon Aerogel Sensors with Human-Like Tactile Perception

Nano-Micro Letters (2024)

-

Staggered circular nanoporous graphene converts electromagnetic waves into electricity

Nature Communications (2023)

-

Thermal and light-induced electrical properties in nanocomposites of reduced graphene oxide and silver nanoparticles

Journal of Materials Science: Materials in Electronics (2023)