Abstract

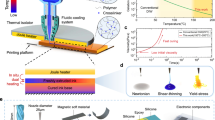

Thermoelectric energy conversion offers a unique solution for generating electricity from waste heat. However, despite recent improvements in the efficiency of thermoelectric materials, the widespread application of thermoelectric generators has been hampered by challenges in fabricating thermoelectric materials with appropriate dimensions to perfectly fit heat sources. Herein, we report an extrusion-based three-dimensional printing method to produce thermoelectric materials with geometries suitable for heat sources. All-inorganic viscoelastic inks were synthesized using Sb2Te3 chalcogenidometallate ions as inorganic binders for Bi2Te3-based particles. Three-dimensional printed materials with various geometries showed homogenous thermoelectric properties, and their dimensionless figure-of-merit values of 0.9 (p-type) and 0.6 (n-type) were comparable to the bulk values. Conformal cylindrical thermoelectric generators made of 3D-printed half rings mounted on an alumina pipe were studied both experimentally and computationally. Simulations show that the power output of the conformal, shape-optimized generator is higher than that of conventional planar generators.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Bell, L. E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 321, 1457–1461 (2008).

DiSalvo, F. J. Thermoelectric cooling and power generation. Science 285, 703–706 (1999).

Snyder, G. J. & Toberer, E. S. Complex thermoelectric materials. Nat. Mater. 7, 105–114 (2008).

LeBlanc, S. Thermoelectric generators: linking material properties and systems engineering for waste heat recovery applications. Sustain. Mater. Technol 1–2, 26–35 (2014).

Bahk, J.-H., Fang, H., Yazawa, K. & Shakouri, A. Flexible thermoelectric materials and device optimization for wearable energy harvesting. J. Mater. Chem. C 3, 10362–10374 (2015).

Rowe, D. M. & Min, G. Design theory of thermoelectric modules for electrical power generation. IEE Proc. Sci. Meas. Technol. 143, 351–356 (1996).

Kraemer, D. et al. Concentrating solar thermoelectric generators with a peak efficiency of 7.4%. Nat. Energy 1, 16153 (2016).

Deng, Y. D., Liu, X., Chen, S. & Tong, N. Q. Thermal optimization of the heat exchanger in an automotive exhaust-based thermoelectric generator. J. Electron. Mater. 42, 1634–1640 (2012).

Jiang, J., Chen, L., Bai, S., Yao, Q. & Wang, Q. Thermoelectric properties of p-type (Bi2Te3)x(Sb2Te3)1−x crystals prepared via zone melting. J. Cryst. Growth 277, 258–263 (2005).

Poudel, B. et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 320, 634–638 (2008).

Jo, S. et al. Simultaneous improvement in electrical and thermal properties of interface-engineered BiSbTe nanostructured thermoelectric materials. J. Alloys Compd. 689, 899–907 (2016).

Kim, S. I. et al. Thermoelectrics. Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 348, 109–114 (2015).

Ma, Y. et al. Enhanced thermoelectric figure-of-merit in p-type nanostructured bismuth antimony tellurium alloys made from elemental chunks. Nano Lett. 8, 2580–2584 (2008).

Son, J. S. et al. n-Type nanostructured thermoelectric materials prepared from chemically synthesized ultrathin Bi2Te3 nanoplates. Nano Lett. 12, 640–647 (2012).

Li, J. et al. BiSbTe-based nanocomposites with high ZT: the effect of SiC nanodispersion on thermoelectric properties. Adv. Funct. Mater. 23, 4317–4323 (2013).

Kim, S. J., We, J. H. & Cho, B. J. A wearable thermoelectric generator fabricated on a glass fabric. Energy Environ. Sci. 7, 1959–1965 (2014).

Kim, S. J. et al. Post ionized defect engineering of screen-printed Bi2Te2.7Se0.3 thick film for high performance flexible thermoelectric generator. Nano Energy 31, 258–263 (2017).

We, J. H., Kim, S. J. & Cho, B. J. Hybrid composite of screen printed inorganic thermoelectric film and organic conducting polymer for flexible thermoelectric power generator. Energy 73, 506–512 (2014).

Varghese, T. et al. High-performance and flexible thermoelectric films by screen printing solution-processed nanoplate crystals. Sci. Rep. 6, 33135 (2016).

Navone, C., Soulier, M., Plissonnier, M. & Seiler, A. L. Development of (Bi,Sb)2(Te,Se)3-based thermoelectric modules by a screen-printing process. J. Electron. Mater. 39, 1755–1759 (2010).

Lewis, J. A. & Ahn, B. Y. Device fabrication: three-dimensional printed electronics. Nature 518, 42–43 (2015).

Sun, K. et al. 3D printing of interdigitated Li-ion microbattery architectures. Adv. Mater. 25, 4539–4543 (2013).

Faes, M., Valkenaers, H., Vogeler, F., Vleugels, J. & Ferraris, E. Extrusion-based 3D printing of ceramic components. Procedia CIRP 28, 76–81 (2015).

Zhu, C. et al. Highly compressible 3D periodic graphene aerogel microlattices. Nat. Commun. 6, 6962 (2015).

Du, Y., Shen, S. Z., Cai, K. & Casey, P. S. Research progress on polymer–inorganic thermoelectric nanocomposite materials. Prog. Polym. Sci. 37, 820–841 (2012).

Zhang, B., Sun, J., Katz, H. E., Fang, F. & Opila, R. L. Promising thermoelectric properties of commercial PEDOT:PSS materials and their Bi2Te3 powder composites. ACS Appl. Mater. Interfaces 2, 3170–3178 (2010).

Bae, E. J., Kang, Y. H., Jang, K. S. & Cho, S. Y. Enhancement of thermoelectric properties of PEDOT:PSS and tellurium-PEDOT:PSS hybrid composites by simple chemical treatment. Sci. Rep 6, 18805 (2016).

Bae, E. J., Kang, Y. H., Jang, K. S., Lee, C. & Cho, S. Y. Solution synthesis of telluride-based nano-barbell structures coated with PEDOT:PSS for spray-printed thermoelectric generators. Nanoscale 8, 10885–10890 (2016).

Mun, H., Choi, S. M., Lee, K. H. & Kim, S. W. Boundary engineering for the thermoelectric performance of bulk alloys based on bismuth telluride. ChemSusChem 8, 2312–2326 (2015).

Hyun, D.-B., Hwang, J.-S., Shim, J.-D. & Oh, T. S. Thermoelectric properties of (Bi0.25Sb0.75)2Te3 alloys fabricated by hot-pressing method. J. Mater. Sci. 36, 1285–1291 (2001).

Yan, X. et al. Experimental studies on anisotropic thermoelectric properties and structures of n-type Bi2Te2.7Se0.3. Nano Lett. 10, 3373–3378 (2010).

Kovalenko, M. V. et al. Semiconductor nanocrystals functionalized with antimony telluride zintl ions for nanostructured thermoelectrics. J. Am. Chem. Soc. 132, 6686–6695 (2010).

Dolzhnikov, D. S. et al. Composition-matched molecular “solders” for semiconductors. Science 347, 425–428 (2015).

Son, J. S. et al. All-inorganic nanocrystals as a glue for BiSbTe grains: design of interfaces in mesostructured thermoelectric materials. Angew. Chem. Int. Ed. 53, 7466–7470 (2014).

Nag, A. et al. Effect of metal ions on photoluminescence, charge transport, magnetic and catalytic properties of all-inorganic colloidal nanocrystals and nanocrystal solids. J. Am. Chem. Soc. 134, 13604–13615 (2012).

Liu, W., Lee, J. S. & Talapin, D. V. III–V nanocrystals capped with molecular metal chalcogenide ligands: high electron mobility and ambipolar photoresponse. J. Am. Chem. Soc 135, 1349–1357 (2013).

Park, S. H. et al. High-performance shape-engineerable thermoelectric painting. Nat. Commun. 7, 13403 (2016).

Tsng, W. J. & Wu, C. H. Sedimentation, rheology and particle-packing structure of aqueous Al2O3 suspensions. Ceram. Int. 29, 821–828 (2003).

Mewis, J. & Wagner, N. J. Colloidal Suspension Rheology (Cambridge Univ. Press, New York, 2012).

Eom, Y., Jung, D. E., Hwang, S. S. & Kim, B. C. Characteristic dynamic rheological responses of nematic poly(p-phenylene terephthalamide) and cholesteric hydroxypropyl cellulose phases. Polym. J. 48, 869–874 (2016).

Kim, B.-J. et al. Preparation of carbon fibers with excellent mechanical properties from isotropic pitches. Carbon 77, 747–755 (2014).

Seitz, H., Rieder, W., Irsen, S., Leukers, B. & Tille, C. Three-dimensional printing of porous ceramic scaffolds for bone tissue engineering. J. Biomed. Mater. Res. Part B Appl. Biomater. 74, 782–788 (2005).

Seitz, H., Deisinger, U., Leukers, B., Detsch, R. & Ziegler, G. Different calcium phosphate granules for 3-D printing of bone tissue engineering scaffolds. Adv. Eng. Mater. 11, B41–B46 (2009).

Schmitz, A., Stiewe, C. & Müller, E. Preparation of ring-shaped thermoelectric legs from PbTe powders for tubular thermoelectric modules. J. Electron. Mater. 42, 1702–1706 (2013).

Hori, Y. & Kusano, D. Effects of PbTe doping on the thermoelectric properties of (Bi2Te3)0.2(Sb2Te3)0.8. In Twenty-first International Conference on Thermoelectrics, 2002. Proceedings ICT '02 13–16 (IEEE, 2002).

He, M. et al. 3D printing fabrication of amorphous thermoelectric materials with ultralow thermal conductivity. Small 11, 5889–5894 (2015).

Kim, S. J. et al. High-performance flexible thermoelectric power generator using laser multiscanning lift-off process. ACS Nano 10, 10851–10857 (2016).

Suganuma, K. & Jiu, J. Advanced Bonding Technology Based on Nano- and Micro-metal Pastes in Materials for Advanced Packaging, 2nd edn (eds Lu, D. & Wong, C. P.) 589–626 (Springer, Cham, 2017).

Xue-Dong, L. & Park, Y.-H. Structure and transport properties of (Bi1−xSbx)2Te3 thermoelectric materials prepared by mechanical alloying and pulse discharge sintering. Mater. Trans. 43, 681–687 (2002).

Liu, W. et al. Studies on the Bi2Te3–Bi2Se3–Bi2S3 system for mid-temperature thermoelectric energy conversion. Energy Environ. Sci. 6, 552–560 (2013).

Gorbachuk, N. P., Bolgar, A. S., Sidorko, V. R. & Goncharuk, L. V. Heat capacity and enthalpy of Bi2Si3 and Bi2Te3 in the temperature range 58–1012 K. Powder Metall. Metal. Ceram. 43, 284–290 (2004).

Acknowledgements

We acknowledge the financial support from the R&D Convergence Program of National Research Council of Science and Technology (NST) of Republic of Korea, and the Center for Advanced Meta-Materials (CAMM) as a Global Frontier Project (NRF-2016M3A6B3936652), Leading Foreign Research Institute Recruitment Program (No. 2017K1A4A3015437), the Nano Material Technology Development Program (No. 2016M3A7B4900044), and individual research program (NRF-2016R1A2B4007452) through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (MSIT) of Republic of Korea.

Author information

Authors and Affiliations

Contributions

F.K., B.K. and J.S.S. designed the experiments, analysed the data and wrote the paper. F.K., S.P., S.J., T.S.M., K.T.K. and S.H.P. carried out the synthesis and basic characterization of the materials. Y. E. and H.G.C. performed the characterization of the rheological properties. F.K., J.E.L., B.-S.K., H.J.I., M.H.L. and J.S.S. carried out the fabrication and measurement of the TEGs. B.K. and W.P.K. performed the simulation studies of the TEGs. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figures 1–12, Supplementary Tables 1–2, Supplementary Discussion and Supplementary References

Videos

Supplementary Video 1

Extrusion-based 3D printing of a thermoelectric cuboid

Rights and permissions

About this article

Cite this article

Kim, F., Kwon, B., Eom, Y. et al. 3D printing of shape-conformable thermoelectric materials using all-inorganic Bi2Te3-based inks. Nat Energy 3, 301–309 (2018). https://doi.org/10.1038/s41560-017-0071-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-017-0071-2

This article is cited by

-

Hydraulic-driven adaptable morphing active-cooling elastomer with bioinspired bicontinuous phases

Nature Communications (2024)

-

Additive manufacturing of thermoelectric materials: materials, synthesis and manufacturing: a review

Journal of Materials Science (2024)

-

High-throughput printing of combinatorial materials from aerosols

Nature (2023)

-

Three dimensional architected thermoelectric devices with high toughness and power conversion efficiency

Nature Communications (2023)

-

Evoking natural thermal perceptions using a thin-film thermoelectric device with high cooling power density and speed

Nature Biomedical Engineering (2023)