Abstract

Changing market demand and increasing environmental regulations challenge the refining industry to shift crude slates and reconfigure production processes while reducing emissions. Yet sellers and buyers remain unaware of the carbon footprint of individual marketable networks, and each crude oil has different specifications and is processed in different destination markets. Here we show the global refining carbon intensity at country level and crude level are 13.9–62.1 kg of CO2-equivalent (CO2e) per barrel and 10.1–72.1 kgCO2e per barrel, respectively, with a volume-weighted average of 40.7 kgCO2e per barrel (equivalent to 7.3 gCO2e MJ−1) and energy use of 606 MJ per barrel. We used bottom-up engineering-based refinery modelling on crude oils representing 93% of 2015 global refining throughput. On the basis of projected oil consumption under 2 °C scenarios, the industry could save 56–79 GtCO2e to 2100 by targeting primary emission sources. These results provide guidance on climate-sensitive refining choices and future investment in emissions mitigation technologies.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from Wood Mackenzie, but restrictions apply to the availability of these data, which were used under license for the current study and so are not publicly available. Data are however available from the corresponding author upon reasonable request and with permission of Wood Mackenzie.

Code availability

We use PRELIM v1.2.1 for this study. PRELIM v1.2.1 is publicly available from https://www.ucalgary.ca/lcaost/files/lcaost/prelim-v1.2_1.xlsm. The Matlab codes for aggregating and processing PRELIM output are available from the corresponding author upon reasonable request.

References

World Energy Outlook 2018 (IEA, 2018).

Tollefson, J. Global industrial carbon emissions to reach all-time high in 2018. Nature https://doi.org/10.1038/d41586-018-07666-6 (2018).

Andress, D., Dean Nguyen, T. & Das, S. Low-carbon fuel standard—status and analytic issues. Energy Policy 38, 580–591 (2010).

Christensen, A. & Hobbs, B. A model of state and federal biofuel policy: feasibility assessment of the California low carbon fuel standard. Appl. Energy 169, 799–812 (2016).

Masnadi, M. S. et al. Well-to-refinery emissions and net-energy analysis of China’s crude-oil supply. Nat. Energy 3, 220–226 (2018).

Oil 2018 (IEA, 2018).

OGCI at Work: Commited to Climate Change (OGCI, 2018).

Moretti, C., Moro, A., Edwards, R., Rocco, M. V. & Colombo, E. Analysis of standard and innovative methods for allocating upstream and refinery GHG emissions to oil products. Appl. Energy 206, 372–381 (2017).

Elgowainy, A. et al. Energy efficiency and greenhouse gas emission intensity of petroleum products at US refineries. Environ. Sci. Technol. 48, 7612–7624 (2014).

Szklo, A. & Schaeffer, R. Fuel specification, energy consumption and CO2 emission in oil refineries. Energy 32, 1075–1092 (2007).

Bredeson, L., Quiceno-Gonzalez, R., Riera-Palou, X. & Harrison, A. Factors driving refinery CO2 intensity, with allocation into products. Int. J. Life Cycle Assess. 15, 817–826 (2010).

Cai, H. et al. Well-to-wheels greenhouse gas emissions of Canadian oil sands products: implications for U.S. petroleum fuels. Environ. Sci. Technol. 49, 8219–8227 (2015).

Cooney, G. et al. Updating the US life cycle GHG petroleum baseline to 2014 with projections to 2040 using open-source engineering-based models. Environ. Sci. Technol. 51, 977–987 (2017).

Nimana, B., Canter, C. & Kumar, A. Energy consumption and greenhouse gas emissions in upgrading and refining of Canada’s oil sands products. Energy 83, 65–79 (2015).

Forman, G. S. et al. US refinery efficiency: impacts analysis and implications for fuel carbon policy implementation. Environ. Sci. Technol. 48, 7625–7633 (2014).

Obnamia, J. A., Dias, G. M., MacLean, H. L. & Saville, B. A. Comparison of US Midwest corn stover ethanol greenhouse gas emissions from GREET and GHGenius. Appl. Energy 235, 591–601 (2019).

Brandt, A. R., Masnadi, M. S., Englander, J. G., Koomey, J. & Gordon, D. Climate-wise choices in a world of oil abundance. Environ. Res. Lett. 13, 044027 (2018).

Di Lullo, G., Zhang, H. & Kumar, A. Evaluation of uncertainty in the well-to-tank and combustion greenhouse gas emissions of various transportation fuels. Appl. Energy 184, 413–426 (2016).

Abella, J. P. & Bergerson, J. A. Model to investigate energy and greenhouse gas emissions implications of refining petroleum: impacts of crude quality and refinery configuration. Environ. Sci. Technol. 46, 13037–13047 (2012).

Motazedi, K., Abella, J. P. & Bergerson, J. A. Techno-economic evaluation of technologies to mitigate greenhouse gas emissions at North American refineries. Environ. Sci. Technol. 51, 1918–1928 (2017).

Motazedi, K., Posen, I. D. & Bergerson, J. A. GHG emissions impact of shifts in the ratio of gasoline to diesel production at US refineries: a PADD level analysis. Environ. Sci. Technol. 52, 13609–13618 (2018).

Oil Refining & Marketing Analysis (Wood Mackenzie, 2015).

Refinery Benchmarking Tool (Wood Mackenzie, 2019).

World Energy Outlook 2016 (IEA, 2016).

DataBank: World Development Indicators (World Bank, 2015); https://data.worldbank.org/indicator/NY.GDP.MKTP.CD?end=2015

International Energy Outlook 2016 (EIA, 2016).

The Future of Petrochemicals (IEA, 2018).

Masnadi, M. S. et al. Global carbon intensity of crude oil production. Science 361, 851–853 (2018).

Petroleum & Other Liquids (EIA, 2019); https://www.eia.gov/petroleum/data.php#summary

Crude Oil Facts (Natural Resources Canada, 2019); https://www.nrcan.gc.ca/science-data/data-analysis/energy-data-analysis/energy-facts/crude-oil-facts/20064

IPCC Climate Change 2014: Synthesis Report (eds Core Writing Team, Pachauri, R. K. & Meyer, L. A.) (IPCC, 2014).

Energy Technology Perspectives 2014 (IEA, 2014).

Krabbe, O. et al. Aligning corporate greenhouse-gas emissions targets with climate goals. Nat. Clim. Change 5, 1057–1060 (2015).

IPCC Special Report on Global Warming of 1.5 °C (eds Masson-Delmotte, V. et al.) (WMO, 2018).

Muradov, N. Low to near-zero CO2 production of hydrogen from fossil fuels: status and perspectives. Int. J. Hydrogen Energy 42, 14058–14088 (2017).

World Oil Outlook 2040 (OPEC, 2017).

Lipman, T. An Overview of Hydrogen Production and Storage Systems with Renewable Hydrogen Case Studies (Clean Energy States Alliance, 2011).

Morrow, W. R., Marano, J., Hasanbeigi, A., Masanet, E. & Sathaye, J. Efficiency improvement and CO2 emission reduction potentials in the United States petroleum refining industry. Energy 93, 95–105 (2015).

Supekar, S. D. & Skerlos, S. J. Analysis of costs and time frame for reducing CO2 emissions by 70% in the US auto and energy sectors by 2050. Environ. Sci. Technol. 51, 10932–10942 (2017).

Emissions Factors (IEA, 2019).

Young, B. et al. Expansion of the petroleum refinery life cycle inventory model to support characterization of a full suite of commonly tracked impact potentials. Environ. Sci. Technol. 53, 2238–2248 (2019).

Shakerian, F., Kim, K. H., Szulejko, J. E. & Park, J. W. A comparative review between amines and ammonia as sorptive media for post-combustion CO2 capture. Appl. Energy 148, 10–22 (2015).

Stec, M. et al. Pilot plant results for advanced CO2 capture process using amine scrubbing at the Jaworzno II power plant in Poland. Fuel 151, 50–56 (2015).

de Mello, L. F. et al. A technical and economical evaluation of CO2 capture from FCC units. Energy Procedia 1, 117–124 (2009).

GREET: The Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation Model (Argonne National Laboratory, 2017).

Wang, Z., Fan, W. & Zhang, G. Comparison of the exergy efficiency of four power generation systems from methane using fuel cells. RSC Adv. 7, 39391–39402 (2017).

Louwen, A., Van Sark, W. G. J. H. M., Faaij, A. P. C. & Schropp, R. E. I. Re-assessment of net energy production and greenhouse gas emissions avoidance after 40 years of photovoltaics development. Nat. Commun. 7, 13728 (2016).

Pehl, M. et al. Understanding future emissions from low-carbon power systems by integration of life-cycle assessment and integrated energy modelling. Nat. Energy 2, 939–945 (2017).

Acknowledgements

Aramco Services Company (MI, USA) provided financial support to L.J. Special thanks go to Natural Sciences and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Contributions

L.J., H.M.E.-H., J-C.M. and J.A.B. were involved in data gathering, data processing and modelling framework design. The final modelling results were integrated by L.J. L.J. wrote the manuscript, and all authors contributed to revising the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Daily volume of crude oil refined by country in 2015.

Numbers below country names represent the numbers of refineries with reported data. For clarity, only countries with ≥0.2% of global oil refining share are mapped (see Supplementary Table 3 for all countries).

Extended Data Fig. 2 Source country volume-weighted average crude oil refining CI in 2015.

Numbers below country names represent the percentage of crude oil refined domestically. Source country refining CI is the emissions intensity associated with refining all crudes produced in that country including any refining of these crudes that occurs in other countries. The global volume-weighted average refining CI is 40.7 kg CO2eq bbl−1. For clarity, only countries with ≥0.2% of global oil refining and production share are mapped (see Supplementary Table 2 for details). Countries with white colored background means either not included in this study or refining volume is < 0.2% cut-off threshold.

Extended Data Fig. 3 Destination country-level volume-weighted-average estimate of crude oil refining CI in 2015.

Numbers below country names represent the numbers of refineries with reported data. Destination country CI is the estimated emissions intensity associated with all crude refined in that country, including domestically produced and imported crude. The global volume-weighted-average CI estimate is 40.7 kg CO2eq bbl−1. For clarity, only countries with ≥0.2% of global oil refining and production share are mapped (see Supplementary Table 3 for full details). Countries with white color means either not included in this study or its refining volume is less than the 0.2% cut-off threshold. It is worth noting that destination refining CI and annual absolute refining emissions do not coincide in many cases. When the ranking of highest CI destination countries is compared with that of the rank of countries with the highest total annual emissions, only China and India are in the top 10 in both lists. Some countries (for example, Chile and Slovakia) have high refining CI but low total emissions, while others (for example, Japan and Russia) differ. Interestingly, the US is ranked 12th in terms of destination CI (44.4 kg CO2eq bbl−1) but is ranked 1st in terms of total annual emissions (251.4 Mt CO2eq) in 2015.

Extended Data Fig. 4 Destination, source country-level, and CO2-CH4-N2O breakdown of volume-weighted-average crude oil refining CI.

Plots show a, Destination, b, source country-level, and c, CO2-CH4-N2O breakdown of volume-weighted-average crude oil refining CI curve (kg CO2eq bbl−1) in 2015. See definitions of destination and source country CI in Methods. Curves are sorted by increasing CI value. Colour scheme reflects continental grouping. For destination countries, 76% of them have a country-level refining CI that is lower than the global average. For source countries, this percentage drops to 59%. In fact, the top 10 refining countries consume 65% of global crude oil production and emit 69% of global refining emissions, while the top 10 oil production countries supply 69% of global crude oil production and are responsible for 70% of global refining emissions. Again, this skewness is due in part to one third of global crude oil production being refined in China and the US where most of their refineries are deep conversion. Also see Supplementary Table 3 for refining CI based on 20-year GWP settings.

Extended Data Fig. 5 Correlation matrix plot for destination country-level refining CI, quality of crude refined, and volume shares of different types of refinery.

All values are volume-weighted-average of each destination country. Numbers in top left of each subplot are Pearson correlation coefficients. A negative correlation (R = −0.2) exists between refining CI and the volume-weighted-average crude API gravity of each destination country. This implies that countries that refine crudes with higher API gravity would generally result in lower emissions. Destination refining CI is negatively correlated with the volume share of hydroskimming (R = −0.71), and moderately positively correlated with the volume shares of deep conversion coking (R = 0.33) and hydrocracking (R = 0.44). One could derive a first approximation of a country’s refining CI solely based on its refining capacity of hydroskimming, even though hydroskimming only has a 7% global volume share. As counterintuitive as this might seem, hydroskimming refineries generally have, if volume-weighted-average values are taken, lighter crude inputs and thus significantly lower refining CI (17.3 kg CO2eq bbl−1) as compared to the global average (CI = 40.7 kg CO2eq bbl−1) as well as other refinery types (Supplementary Table 6). Therefore, countries that solely rely on hydroskimming tend to have refining emissions that are significantly lower than others.

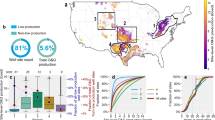

Extended Data Fig. 6 Boxplot showing variations of crude-level volume-weighted-average refining CI in destination countries.

Each bar represents the variation of a crude’s refining CI (kg CO2eq bbl−1) in different countries. Bars are sorted by increasing median refining CI as shown by black dotted line. Colour scheme reflects crude quality grouping.

Extended Data Fig. 7 Crude-level volume-weighted-average refining CI curve in 2015 (by refinery configuration).

Each vertical bar in the upper portion of this plot represents volume-weighted-average refining CI (kg CO2eq bbl−1) of a crude (sorted by increasing value, comprised of contributions from four refinery types). Each vertical bar in the lower portion of this plot reflects refining emissions reductions from the corresponding crude in two scenarios. Emissions reduction scenarios are the same as shown in Fig. 5.

Extended Data Fig. 8 Crude-level volume-weighted-average refining CI curve in 2015 (by continent).

Curve is sorted by increasing CI (kg CO2eq bbl−1). Colour scheme reflects continental grouping. Organization of the Petroleum Exporting Countries (OPEC) produces 40% of global crude oil, and refining crudes originating from OPEC regions generates 40% of worldwide refining emissions.

Extended Data Fig. 9 Crude-level volume-weighted-average refining CI curve in 2015 (by crude quality).

Curve is sorted by increasing CI (kg CO2eq bbl−1). Colour scheme reflects crude quality grouping. Crude oils are classified into light (API gravity > 32°), medium (22° < API gravity ≤ 32°), and heavy (API gravity ≤ 22°) based on API gravity, and sour (sulfur wt% > 0.5) and sweet (sulfur wt% ≤ 0.5) based on sulfur content (See Supplementary Table 4 for more details on crude oil quality classification).

Extended Data Fig. 10 Flowchart showing the calculation steps for refining CI at crude-, refinery-, and country-level.

Refinery-level refining CI (kg CO2eq bbl−1) is calculated by running each crude assay separately via PRELIM and take the volume-weighted-average. Note for destination country refining CI, n is the number of crudes refined at a refinery; m is the number of refineries located in a destination country; for source country refining CI, j is the number of refineries that process a crude, and k is the number of crudes produced from a source country.

Supplementary information

Supplementary Information

Supplementary Tables 1–11, Figs. 1–16 and Notes 1–4.

Rights and permissions

About this article

Cite this article

Jing, L., El-Houjeiri, H.M., Monfort, JC. et al. Carbon intensity of global crude oil refining and mitigation potential. Nat. Clim. Chang. 10, 526–532 (2020). https://doi.org/10.1038/s41558-020-0775-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41558-020-0775-3

This article is cited by

-

Reducing uncertainties in greenhouse gas emissions from chemical production

Nature Chemical Engineering (2024)

-

Emission pathways and mitigation options for achieving consumption-based climate targets in Sweden

Communications Earth & Environment (2023)

-

Greenhouse gas emissions from U.S. crude oil pipeline accidents: 1968 to 2020

Scientific Data (2023)

-

Floating Treatment Wetlands (FTWs) is an Innovative Approach for the Remediation of Petroleum Hydrocarbons-Contaminated Water

Journal of Plant Growth Regulation (2023)

-

Greenhouse Gas Emission Reduction Potential of European Union’s Circularity Related Targets for Plastics

Circular Economy and Sustainability (2023)