Abstract

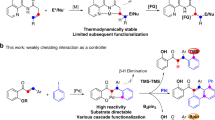

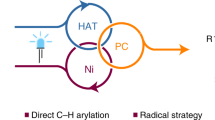

Transition metal catalysis has emerged as an important means for C–C activation that allows mild and selective transformations. However, the current scope of C–C bonds that can be activated is primarily restricted to either highly strained systems or more polarized C–C bonds. In contrast, the catalytic activation of non-polar and unstrained C–C moieties remains an unmet challenge. Here we report a general approach for the catalytic activation of the unstrained C(aryl)–C(aryl) bonds in 2,2′-biphenols. The key is to utilize the phenol moiety as a handle to install phosphinites as a recyclable directing group. Using hydrogen gas as the reductant, monophenols are obtained with a low catalyst loading and high functional group tolerance. This approach is also applied to the synthesis of 2,3,4-trisubstituted phenols. A further mechanistic study suggests that the C–C activation step is mediated by a rhodium(i) monohydride species. Finally, a preliminary study on breaking the inert biphenolic moieties in lignin models is illustrated.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Crystallographic data for the structures reported in this article have been deposited at the Cambridge Crystallographic Data Centre, under deposition nos CCDC 1848268 (2z), 1848266 ([Rh(2al)Cl)]2) and 1848267 (8g). Copies of the data can be obtained free of charge from www.ccdc.cam.ac.uk/structures/. All other data that supporting the findings of this study are available within the article and its Supplementary Information, or from the corresponding author upon reasonable request.

References

Drahl, M. A., Manpadi, M. & Williams, L. J. C−C fragmentation: origins and recent applications. Angew. Chem. Int. Ed. 52, 11222–11251 (2013).

Fahim, M. A., Alsahhaf, T. A. & Elkilani, A. Fundamentals of Petroleum Refining 199–235 (Elsevier, Oxford, 2010).

Murakami, M. & Ito, Y. Cleavage of carbon−carbon single bonds by transition metals. Top. Organomet. Chem. 3, 97–129 (1999).

Rybtchinski, B. & Milstein, D. Metal insertion into C−C bonds in solution. Angew. Chem. Int. Ed. 38, 870–883 (1999).

Chen, F., Wang, T. & Jiao, N. Recent advances in transition-metal-catalyzed functionalization of unstrained carbon–carbon bonds. Chem. Rev. 114, 8613–8661 (2014).

Dong, G. C–C Bond Activation (Topics in Current Chemistry 346, Springer, Berlin, 2014).

Souillart, L. & Cramer, N. Catalytic C–C bond activations via oxidative addition to transition metals. Chem. Rev. 115, 9410–9464 (2015).

Murakami, M. Cleavage of Carbon–Carbon Single Bonds by Transition Metals (Wiley-VCH, Weinheim, 2015)

Kim, D.-S., Park, W.-J. & Jun, C.-H. Metal–organic cooperative catalysis in C–H and C–C bond activation. Chem. Rev. 117, 8977–9015 (2017).

Fumagalli, G., Stanton, S. & Bower, J. F. Recent methodologies that exploit C–C single-bond cleavage of strained ring systems by transition metal complexes. Chem. Rev. 117, 9404–9432 (2017).

Gozin, M., Weisman, A., Ben-David, Y. & Milstein, D. Activation of a carbon–carbon bond in solution by transition-metal insertion. Nature 364, 699–701 (1993).

Gozin, M. et al. Transfer of methylene groups promoted by metal complexation. Nature 370, 42–44 (1994).

Ruhland, K., Obenhuber, A. & Hoffmann, S. D. Cleavage of unstrained C(sp 2)–C(sp 2) single bonds with Ni0 complexes using chelating assistance. Organometallics 27, 3482–3495 (2008).

Grein, F. Twist angles and rotational energy barriers of biphenyl and substituted biphenyls. J. Phys. Chem. A 106, 3823–3827 (2002).

Rousseau, G. & Breit, B. Removable directing groups in organic synthesis and catalysis. Angew. Chem. Int. Ed. 50, 2450–2494 (2011).

Lewis, L. N. & Smith, J. F. Catalytic carbon–carbon bond formation via ortho-metalated complexes. J. Am. Chem. Soc. 108, 2728–2735 (1986).

Bedford, R. B., Coles, S. J., Hursthouse, M. B. & Limmert, M. E. The catalytic intermolecular orthoarylation of phenols. Angew. Chem. Int. Ed. 42, 112–114 (2003).

Liou, S.-Y., Gozin, M. & Milstein, D. Directly observed oxidative addition of a strong carbon–carbon bond to a soluble metal complex. J. Am. Chem. Soc. 117, 9774–9775 (1995).

Liou, S.-Y., van der Boom, M. E. & Milstein, D. Catalytic selective cleavage of a strong C–C single bond by rhodium in solution. Chem. Commun. 687–688 (1998).

Evans, D., Osborn, J. A. & Wilkinson, G. Hydroformylation of alkenes by use of rhodium complex catalysts. J. Chem. Soc. A 3133–3142 (1968).

Dai, H.-X., Li, G., Zhang, X.-G., Stepan, A. F. & Yu, J.-Q. Pd(ii)-catalyzed ortho- or meta-C–H olefination of phenol derivatives. J. Am. Chem. Soc. 135, 7567–7571 (2013).

Luo, J., Preciado, S. & Larrosa, I. Overriding ortho–para selectivity via a traceless directing group relay strategy: the meta-selective arylation of phenols. J. Am. Chem. Soc. 136, 4109–4112 (2014).

Schröder, N., Wencel-Delord, J. & Glorius, F. High-yielding, versatile, and practical [Rh(iii)Cp*] catalyzed ortho bromination and iodination of arenes. J. Am. Chem. Soc. 134, 8298–8301 (2012).

Kar, A., Mangu, N., Kaiser, H. M., Beller, M. & Tse, M. A general gold-catalyzed direct oxidative coupling of non-activated arenes. Chem. Commun. 386–388 (2008).

Zakzeski, J., Bruijnincx, P. C. A., Jongerius, A. L. & Weckhuysen, B. M. The catalytic valorization of lignin for the production of renewable chemicals. Chem. Rev. 110, 3552–3599 (2010).

Sergeev, A. G. & Hartwig, J. F. Selective, nickel-catalyzed hydrogenolysis of aryl ethers. Science 332, 439–443 (2011).

Rahimi, A., Azarpira, A., Kim, H., Ralph, J. & Stahl, S. S. Chemoselective metal-free aerobic alcohol oxidation in lignin. J. Am. Chem. Soc. 135, 6415–6418 (2013).

Rahimi, A., Ulbrich, A., Coon, J. J. & Stahl, S. S. Formic-acid-induced depolymerization of oxidized lignin to aromatics. Nature 515, 249–252 (2014).

Van den Bosch, S. et al. Reductive lignocellulose fractionation into soluble lignin-derived phenolic monomers and dimers and processable carbohydrate pulps. Energy Environ. Sci. 8, 1748–1763 (2015).

Gao, F., Webb, J. D., Sorek, H., Wemmer, D. E. & Hartwig, J. F. Fragmentation of lignin samples with commercial Pd/C under ambient pressure of hydrogen. ACS Catal. 6, 7385–7392 (2016).

Shuai, L. et al. Formaldehyde stabilization facilitates lignin monomer production during biomass depolymerization. Science 354, 329–333 (2016).

Karkas, M. D., Matsuura, B. S., Monos, T. M., Magallanes, G. & Stephenson, C. R. J. Transition-metal catalyzed valorization of lignin: the key to a sustainable carbon-neutral future. Org. Biomol. Chem. 14, 1853–1914 (2016).

Zakzeski, J. & Weckhuysen, B. M. Lignin solubilization and aqueous phase reforming for the production of aromatic chemicals and hydrogen. ChemSusChem 4, 369–378 (2011).

Dimmel, D. & Gellerstedt, G. in Lignin and Lignans: Advances in Chemistry (eds Heitner C., Dimmel D. & Schmidt J.) 349–391 (CRC Press, Boca Raton, 2010).

Rinaldi, R. et al. Paving the way for lignin valorisation: recent advances in bioengineering, biorefining and catalysis. Angew. Chem. Int. Ed. 55, 8164–8215 (2016).

Argyropoulos, D. S. et al. Abundance and reactivity of dibenzodioxocins in softwood lignin. J. Agric. Food. Chem. 50, 658–666 (2002).

Acknowledgements

We thank the University of Chicago, NIGMS (R01GM109054) and the Sloan Foundation for research support. We acknowledge G. Lu and P. Liu (University of Pittsburgh) for helpful discussion on the computational study. Calculations were performed at the Extreme Science and Engineering Discovery Environment (XSEDE) supported by the NSF. J.Z. acknowledges the financial support from Shanghai Institute of Organic Chemistry (SIOC), Pharmaron and Zhejiang Medicine for a joint postdoctoral fellowship. We are grateful to H. N. Lim for providing some rhodium catalysts and K.-Y. Yoon for X-ray analysis. V. Rawal, Z. Dong and J. Xie are thanked for helpful suggestions. We thank Z. Rong for assistance with using the autoclave and Y. Xu for checking the experimental procedures.

Author information

Authors and Affiliations

Contributions

J.Z. and G.D. conceived and designed the experiments. J.Z. performed the experiments. J.W. performed the DFT calculation. J.Z., J.W. and G.D. co-wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary information

Characterization data, supplementary experimental data, synthetic procedures and supplementary figures

Crystallographic data

CIF for compound 2z; CCDC reference: 1848268

Crystallographic data

CIF for compound [Rh(2al)Cl]2; CCDC reference: 1848266

Crystallographic data

CIF for compound 8g; CCDC reference: 1848267

Rights and permissions

About this article

Cite this article

Zhu, J., Wang, J. & Dong, G. Catalytic activation of unstrained C(aryl)–C(aryl) bonds in 2,2′-biphenols. Nature Chem 11, 45–51 (2019). https://doi.org/10.1038/s41557-018-0157-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41557-018-0157-x