Abstract

The energy-consuming and carbon-intensive wastewater treatment plants could become significant energy producers and recycled organic and metallic material generators, thereby contributing to broad sustainable development goals, the circular economy, and the water-energy-sanitation-food-carbon nexus. This review provides an overview of the waste(water)-based energy-extracting technologies, their engineering performance, techno-economic feasibility, and environmental benefits. Here, we propose four crucial strategies to achieve net-zero carbon along with energy sufficiency in the water sector, including (1) improvement in process energy efficiency; (2) maximizing on-site renewable capacities and biogas upgrading; (3) harvesting energy from treated effluent; (4) a new paradigm for decentralized water-energy supply units.

Similar content being viewed by others

Introduction

By 2030, 40% of the world’s population will experience water scarcity, creating stresses exacerbated by climate change1. The interrelationship between the water and energy sectors has been coined the “Water-Energy Nexus”. Energy use in the water sector largely depends on fossil sources, increasing carbon dioxide (CO2) emissions. Specifically, the water sector accounts for 4% of total energy consumption, with highly energy-dependent wastewater treatment plants (WWTPs) accounting for 25% of the total energy use2. Globally, almost 400 billion m3 of wastewater is produced annually, and it is expected to increase by 25 and 50% by 2030 and 2050, respectively. Due to finance and resource limitations, 80% of all wastewater is discharged untreated, creating a serious sanitation crisis for 4.5 billion people and impacting the environment and the biome3.

The “Water-Energy-Sanitation” crisis is evident considering ~800 million people live without clean water, 2.5 billion do not have adequate sanitation4, and 1.1 billion people have no access to electricity5. Energy, water, and sanitation are inextricably linked to agriculture, food security, health, gender, and education; thus, they are essential to achieving many sustainable development goals (SDGs) and environmental justice. Another concern is wastewater treatment processes that are carbon-intensive; for example, WWTPs in the USA generated 20 million metric tons (MMT) CO2-eq in 20176. The energy needed for a typical domestic WWTP employing aerobic activated sludge processes and anaerobic digestion (AD) is 0.6 kWh per m3 of wastewater treated, about half of which is used for providing electrical energy to sustain the aeration basins7. Biogas, a renewable methane source produced from AD, can be utilized for combined heat and power (CHP), decreasing energy consumption and CO2 emissions. The US Environmental Protection Agency (USEPA)8 noted that 25–50% of a WWTP’s energy needs could be met by biogas, even with conventional methods involving aerobic treatment.

In fact, wastewater contains approximately five times more embedded energy than is required for its treatment9. The American Biogas Council reports ~80% of the latent energy in wastewater is thermal, ~20% is chemical, and <1% of the potential exists in hydraulic generation9. While the thermal energy load is significant, it is low-grade heat and typically only useful for district heating. In terms of valuable resources, 16.6 MMT of nitrogen is embedded in wastewater produced worldwide annually, with 3 MMT of phosphorus and 6.3 MMT of potassium10. In the World Energy Outlook, the International Energy Agency states3, “If waste from all those who lack access to safely managed sanitation in rural areas today was captured and digested, the biogas potential could be roughly 20–50 billion m3; this could be enough energy to provide clean cooking fuel to 60–180 million households.” The statement demonstrates the integration of water, energy, sanitation, and carbon into a single thread. Climate change increases global water demand and access uncertainty while aggravating regional water security. Therefore, it is essential to consider wastewater (sewage) treatment, water reuse, and resource recovery in an integrated manner to maximize benefits in managing the water-energy nexus11 in sanitation. Broad areas to consider include “energy and water efficiency” as well as “energy and nutrient resource recovery”. To provide broad access to water, energy, and sanitation, system designs should consider the circular economy as the core backbone of the infrastructure.

Most developed nations have strict effluent discharge standards that regulate WWTPs. The regulatory approach focuses on minimizing the environment’s detrimental impact while decreasing the health risks associated with untreated wastewater. Less developed economies suffer from the costs of treating wastewater, resulting in the release of untreated wastewater. As the WWTPs evolve into water resource recovery facilities, the revenue from recovered energy, nutrients, materials, and even water could support the broader deployment of sanitation, decreasing the discharge of untreated effluent12,13. Ultimately, advanced water resource recovery facilities could decrease demand for freshwater, even if the reclaimed water is not used as a potable source.

Recently, solar energy has also gained attention for wastewater treatment. Usually, external energy is required to overcome the thermodynamical barriers to electromethanogenesis. However, solar light-driven electro-driving power could accelerate the conversion of waste organics to bioenergy. Wang et al.14 found that the natural intermittent solar-powered mode was more beneficial for microorganisms involved in electron transfer and energy recovery than the manual sharp on-off mode and thus could be a promising perspective of solar-power-driven microbial biotechnology to boost bioenergy recovery from wastewater. For solar thermal sterilization coupled with bubble technologies, for example, bubble nucleation and cavitation, the interfacial properties of bubbles could improve the efficiency of biological wastewater treatment while also inactivating pathogens and mitigating biofouling15,16. Moreover, interfacial solar vapor generation is considered an efficient, sustainable, and low-cost method for producing clean water from solar desalination and wastewater treatment17.

WWTPs could become net energy producers with advanced design and possibly considered carbon-negative facilities. Numerous R&D programs have been conducted to make energy-dependent wastewater treatment technologies into energy-efficient or energy positive. Sewage can be the heart of the water-energy-sanitation-food-carbon nexus in a circular economy. However, to the best of our knowledge, little-to-no research on a systematic overview of energy-extracting technologies deployed in WWTPs has been conducted to build a pathway towards a net-zero water(waste) sector. In this study, we first review technologies developed for recovering energy from wastewater, including anaerobic bioreactors, salinity gradient energy (SGE) recovery processes, and fuel cells. Then, we summarize advances in existing technologies to reduce their energy footprint. We also evaluate different energy-extracting technologies from the aspects of engineering, economics, and environmental performance. Last, we suggest strategies for the role that WWTPs could play in achieving associated SDGs and net-zero carbon schemes.

Energy-extracting wastewater technologies

Typical wastewater treatment processes include screening, grit removal, primary settling tank, aeration (or activated sludge), secondary settling tanks, filtration, disinfection, and sludge treatment. These unit processes are usually energy-dependent and carbon-intensive. Several energy-extracting technologies could be adapted to existing WWTPs, such as anaerobic digestors or membrane reactors, salinity gradient or osmotic energy recovery processes, as well as fuel cells to realize net-zero carbon. In this section, we review and discuss the available energy-extracting technologies.

Anaerobic bioreactors

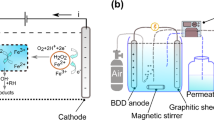

For decades, almost as an afterthought, AD has been used in WWTPs to stabilize sludge with biogas production (Fig. 1a). Table 1 compiles a sample of AD-based case studies of self-sufficient and energy-positive WWTPs. The net positive energy is often achieved by co-digesting sludge with high organic content substrates, including agricultural and food waste, fats, oil, and grease18. For example, the WWTP in Bern (Switzerland) uses co-digestion of sludge with green and food waste to produce twice as much energy as the facility consumes19. Hybrid or combined systems are also used to increase the efficiency of the AD process, such as integrating bipolar membrane electrodialysis to recover ions and solid oxide fuel cells to produce electricity, which has the potential to achieve 55% of the maximum net energy efficiency20. Also, the CHP systems with AD facilitate the onsite conversion of produced biogas into power, and thermal energy could support operations across the facility or provide power to the grid21.

a Anaerobic digestion and b Anaerobic membrane bioreactor. Credit: www.flaticon.com for the cliparts.

The anaerobic membrane bioreactor (AnMBR) is an anaerobic bioreactor coupled with a membrane unit (Fig. 1b), offering advantages such as improved effluent quality, low sludge production, compact size, and high biogas production (i.e., indirect energy generation). Anaerobic dynamic membrane bioreactors have proven to be an attractive option because they can be operated at an ambient temperature and can produce net energy of 0.05–0.06 kWh m−3 22. The operation of AnMBR in phases improves the biogas yield and is thus reliable for energy-neutral or positive treatment for low-strength wastewater. Kong et al.23 demonstrated a 5 m3 large-scale submerged AnMBR with a biogas yield of 0.09–0.10 L per liter of raw wastewater. Another demonstration study indicated a 20 L submerged AnMBR installed in Sen-En WWTP (Tagajo city, Japan) can generate net electrical energy of 1.82–2.27 kWh d−1 24.

In summary, anaerobic bioreactors have several inherent merits over other treatment processes, leading to their rapid universal adoption. AD-related processes employ a circular economy model by introducing wastewater into the supply chains, covering the energy demand of the wastewater utilities and communities, and promoting resource efficiency. It is a widely practiced technique that efficiently promotes renewable bioenergy and supports the bioeconomy. However, most of the current anaerobic bioreactors still need advancements in their designs and operating conditions to valorize the AD technological solutions.

Salinity gradient energy (SGE) recovery processes

SGE (so-called osmotic power, or blue energy) is the energy created from the difference in salt concentration between two fluids25. It is the thermodynamic reverse of using energy to desalinate saline water. Theoretically, around 2.24–2.25 MW of work26,27 could be extracted from per m3 of river water that flows into the ocean. Similarly, approximately 18 GW of salinity gradient power could be harvested while discarding treated wastewater into the oceans28. The chemical concentration gradient available in the aforementioned cases is a Gibbs-free energy that could be utilized for producing energy. This initiated series of attempts to develop technologies, such as pressure retarded osmosis (PRO), reverse electrodialysis (RED), and single-pore osmotic generators (OPGs). They are being explored as a renewable hybrid process for recovering energy from highly saline brine (e.g., effluent from desalination or salt mining) and treated wastewater effluents29. Table 2 summarizes several recent SGE studies that explored the power generation potential of wastewater or brine from desalination or salt mining29.

As shown in Fig. 2a, first conceived by Professor Sidney Loeb in 1974, PRO is a forward osmosis-based process utilizing Gibb’s free energy of mixing and is similar to hydropower technology30. The first standalone PRO-based energy power plant with a capacity of 10 kW was constructed by Statkraft in Oslo fjord, Tofte, Norway, in 2009; however, it was terminated in 2012 due to economic feasibility constraints31. After that, Toray industries developed the largest hybrid PRO powerplant with a capacity of 5 kW m−2 32. Kyowakiden Industry Corporation Limited and Statkraft lead the PRO system development in Japan and Norway, respectively. A demonstration (Fig. 2b) conducted by Kyowakiden Industry Corporation Limited used a mixed discharge system of treated sewage from Wajiro Wastewater Treatment Center and brine from Fukuoka Seawater Desalination Center Japan to feed into a hybrid PRO system and harvest 10 W m−2 of power. This demonstration showed decreased environmental stress, a gray water footprint, and an energy footprint later proved in the “Megaton Water System” national project organized by Toray Kurihara Fellow. Kyowakiden Industry Corporation Limited Japan has also registered a patent for this PRO system (PCT/JP2014/051873) in Israel, Saudi Arabia, Australia, the United States, and Japan33. Apart from these pilot or large-scale plants, lab-scale R&D advances PROs hybrids, or similar technologies continue to be developed. For example, Hon et al.34 and Jiao et al.35 introduced a novel hybrid forward osmosis-electrokinetic system similar to PRO (Fig. 2c). The FO submodule ensures continuous fluid transportation in the entire system, and the electrokinetic submodule is responsible for electricity generation35. The other PRO hybrid process includes investigations of SWRO-PRO36 (seawater reverse osmosis-pressure retarded osmosis), MD-PRO (Membrane distillation-pressure retarded osmosis)37, and a combined SWRO-MD-PRO36.

a Schematic diagram of a pressure retarded osmosis plant run on river water vs. seawater [adapted from ref. 28], b A demonstration conducted by Kyowakiden Industry Co., Ltd., used a mixed discharge system of treated sewage from Wajiro Wastewater Treatment Center and brine from Fukuoka Seawater Desalination Center, Japan, to feed into pressure retarded osmosis system and harvest power of 10 W m−2 [adapted from ref. 32], and c forward osmosis-pressure retarded osmosis hybrid system to mitigate membrane fouling for sustainable salinity gradient energy [adapted from ref. 167]. Credit: www.flaticon.com for the cliparts.

RED is an energy-free electrochemical technology or salt battery38 originating from the natural, spontaneous, and irreversible mixing of river/fresh water and ocean/saline water (refer to Fig. 3). In 2005, REDStack with a European Salt Company Frisia jointly started a RED pilot project of 5 kW capacity32. The European REApower project’s framework extended a RED experiment utilizing less saline wastewater to the pilot project39. Showcasing the scale-up RED units, Tedesco et al.40 installed three RED units with a total power capacity of 1 kW in Sicily, Italy; and on a laboratory scale, Nam et al.41 reported the largest RED unit with 1000 cell pairs and a power density of 0.76 W m−2. RED was extended under the European Seventh Framework Program to innovate membrane-free CapMix technology. The seawater and freshwater are alternately fed into a chamber comprising electrodes; that are charged when exposed to seawater and discharged when introduced to freshwater; this charging and discharging continues in cycles. Ongoing research aims to inherit the energy by mixing treated wastewater and brine from the desalination plant42.

a Vertical representation of a reverse electrodialysis mechanism [adapted from ref. 28] and b Horizontal representation of a reverse electrodialysis mechanism.

The ion-exchange membranes are the core of membrane-based energy-generation technologies; however, they have distinct physical limitations. Pore size is comparable to the ionic species’ size, and it is also thick (micro to millimeters), inhibiting mass transport and resulting in high membrane resistance, limiting power densities to <2.2 W m−2 43. Therefore, transmembrane ion transport encounters steric hindrance and high electrical resistance, leading to low throughput of ions. Nanofluidic OPGs are technological breakthroughs because they can overcome challenges with pore size on a nanometer scale. For instance, Gao et al.44 reported an ionic diode membrane-scale nanofluidic device comprising heterojunctions between cathode-microporous alumina and anode-mesoporous carbon for harvesting SGE up to a power density of 3.46 W m−2.

Similarly, Hwang et al.45 designed a mesoporous silica-based nanofluidic SGE harvesting system employing three monovalent electrolytes viz KCl, NaCl, and LiCl with power densities of 3.90, 2.39, and 1.29 W m−2, respectively. Ji et al.46 developed a 2D-material-based nanofluidic RED utilizing graphene oxide membrane pairs and ended up having 54% greater power density than commercial ion-exchange membranes. Several demerits of nanopores, such as electrical inhibition, high resistance, small switching currents leading to lower power generation, and weak signals causing difficulty in differentiating from background noise, made the researchers switch to the other emerging osmotic single-pore platforms. These brought the OPGs to an attractive high-power density of 26 pW (2.6 kW m−2 reported by Guo et al.47) and 225 pW (103 kW m−2 by Feng et al.48) under optimized conditions, compared to the conventional membrane-based energy harvesting processes.

Yeh et al.49 reported a power density of 5.85 kW m−2 using a single alumina nanopore at pH 3.5 under a 1000-fold concentration ratio. Single-pore platforms overcome the issue of low power density and constant entering resistance in nanofluidic OPGs. In the direction of power density, Gao et al.50 addressed the giant gap between the single-pore demonstration and the membrane-scale application originating from the different ion transport properties in a porous membrane, based on a reservoir-interface-nanopore resistance paradigm. Importantly the study highlighted by suppressing the reservoir and interfacial resistances, kW m–2 to MW m–2 power density could be achieved with multi-pore membranes, approaching the level of a single-pore system. Cao et al.51 also developed integrated nanofluidic REDs, showing a lower fluidic resistance and a higher ionic flux. Power levels of 45, 29, and 17 pW were generated with the cation-selective negatively charged nanopores for KCl, NaCl, and LiCl, respectively. While with the anion-selective positively charged nanopores, a power of 22, 14, and 6 pW was produced.

In summary, SGE is considered a breakthrough in renewable energy and has the potential to produce energy at a scale comparable to intermittent solar and wind energy. While the deployment of salinity gradients for energy recovery is nascent, potential sites for productive energy generation are broadly distributed, especially in highly-populated coastal regions. Single-pore OPGs have shown extremely high-power density. More power can be harnessed in the future with advancements in the existing semipermeable and ion-exchange membranes, significantly reducing the required capital investment and thus supporting their economic viability. In addition, the SGE techniques’ hybrid scheme can complement the desalination and local (waste)water management strategies in dry urban coastal areas.

Fuel cells

Fuel cells have gained popularity for generating electricity, hydrogen, and valuable chemicals. Fuel cells are functionally the reverse of an electrolysis cell. They are a device that can transform chemical energy into electrical energy. It normally consists of an anode and a cathode, which are connected through an external circuit and a chemical fuel. There is strong interest in hydrogen fuel cells for clean trucks52. The carbon content in wastewater is a viable feedstock for fuel cells. Figure 4 shows the typical diagrammatic representations of fuel cells, including microbial, enzymatic, and photocatalytic systems. Tables 3, 4 also compile some recent studies utilizing wastewater for bioenergy or biohydrogen generation using MFC and AnMBR, as well as MEC, respectively.

Microbial systems include microbial fuel cells (MFC, as shown in Fig. 4a), microbial desalination cells (MDCs, in Fig. 4b), and microbial electrolysis cells (MECs, in Fig. 4c). MFC, introduced in 1911 by Potter53, is a type of microbial system that obtains electrical energy from the chemical energy of organics by utilizing the exoelectrogenic bio-agents activities of bacteria (e.g., Clostridium cellulolyticum, G. sulfurreducens, Enterobacter cloacae, and Clostridium butyricum), as well as fungi (e.g., Aspergillus awamori and Phanerochaete chrysosporium)54. In fact, an individual MFC unit offers relatively low energy density. In practice, a few studies55,56 suggested the miniaturization in physical stacking and electrical connections of multiple MFCs to scale up the power output (see Table 3). A power density of ~0.15 W m−2 was achieved with swine wastewater57. Rabaey et al.58 reported 4.31 W m−2 power density using closely spaced graphite blocks with a large ion-exchange membrane surface and a ferricyanide catholyte. A parallel configuration of five MFC units with a tubular approach produced 175.7 W m−2 59.

As an estimate, ten times the current produced energy can be generated by converting a mere 1% solar energy60. Solar energy-based photosynthetic MFCs were first reported in 198061 and are gaining popularity. They consist of microbes with certain specialized light-harvesting complexes where photosystem I and photosystem II function as the photosynthetic units. Two kinds of photosynthetic MFC were reported, including sub-cellular photo MFCs utilizing anoxygenic photosynthetic entities attached to the electron acceptor and whole-cell photo MFCs using whole-cell autotrophic microbes. Moreover, biohydrogen can be further converted into bioelectricity to avoid any handling or recovery problems and can also be produced by photo MFCs. Pillot et al.62 and Rashid et al.63 highlighted a synergistic relationship and a better green electrical output on mixing photosynthetic autotrophic microbes with heterotrophic bacteria.

MDCs are a cheaper alternative that could support existing desalination technologies (reverse osmosis, electrodialysis, and capacitive deionization), which can desalinate and treat (waste)water, as well as generate electricity using bacteria (exoelectrogens). It has three chambers, i.e., anode, desalination, and cathode chambers, and is being practiced at a lab scale. For instance, a hydraulic-coupled MDC generated 0.86 W m−2 power density64; a recirculation MDC65 reported ~0.93 W m−2, and a novel two-chamber MDC66 produced 2.0 W m−2. Besides electricity generation, MDCs have more benefits to offer, namely, >90% nitrate removal, >80% heavy metal and calcium carbonate removal, and 80% ammonia removal, along with the production of H2, acid, and base chemicals65,67.

The MEC is capable of removing organics while simultaneously producing H2 (see Table 4). Microbes are utilized as biocatalysts to reduce the activation overpotential of a certain redox process, enhancing the voltage efficiency and production rate. According to Heidrich68, an onsite 0.12 m3 MEC created 0.015 m3-H2 m−3d−1 (a purity of 100 ± 6.4%) with a Coulombic efficiency of 55% and retrieved ~70% of the electric power input. MECs combining new technologies with traditional ones may be used to overcome the thermodynamic limits, as well as material prices, methanogens, substrate concentration, and other issues the MEC faces on its own. When the MEC is integrated with other fermentation systems, 96% of the H2 was recovered at a production rate of 2.11 m3 H2 m−3d−1, resulting in electrical energy productivity of 287%69,70. An integrated MEC-AD generated biogas of good quality, with CH4 content coming to 86 ± 6%. For metropolitan wastewater, the benchtop investigation produced standardized net energy of 25.96 kWh m−3d−1 71. The net energy of a 1000-L pilot-scale framework with a cathodic surface area of 18.1 m2 m−3 was determined to be 2.11 kWh m−3d−1 for vineyard wastewater72. The H2 produced by MECs is green hydrogen and the US Department of Energy’s Energy Earthshots Initiative are aiming to reduce the cost of clean (green) hydrogen by 80% to US$1 per 1 kg in 1 decade (“111”). As with salinity gradient technologies, microbial systems are nascent but have the potential for broad deployment. In addition, they provide additional benefits in (waste)water treatment.

An enzymatic fuel cell (EFC, as presented in Fig. 4e) is a renewable and environmentally friendly energy source, first demonstrated by Yahiro et al.73. It employs enzymes as a catalyst that transform the released chemical energy from the enzymatic oxidation of fuels such as hydrogen, alcohols, and sugars, with oxygen as an oxidant, to electrical energy by the movement of electrons released from the chemical reaction. The wastewater-powered EFCs utilizing the hydrogen recovered from MEC could reduce ~9.3 kg CO2-eq emissions per kg of H2 produced from the conventional steam methane reforming (SMR) technology to produce H274. A thermocatalytic method involving splitting methane from the rising natural gases and extracting viable H2 can act as a wastewater H2 feedstock74 for EFCs. The optimized EFC was tested in the municipal wastewater of Zonguldak city in Turkey, generating 4.6 mW m−2 75.

A photocatalytic fuel cell (PFC, a synergistic integration between photocatalysis and fuel cell, as presented in Fig. 4f) can degrade organic contaminants present in sewage and recover the chemical energy. The main components of a PFC include a light source, cathode, photoanode, and organic wastewater as the chemical fuel. Hybridization of PFCs with nanobubbles is one of the techniques that may promise a synergistic effect in treating various types of wastewater76. A burr-like Ag-TiO2 coated photoanode-based brewery effluent flow-PFC ran at 2.75 A m−2 over a 6-h period, generating a minimum voltage and power density of 0.65 V and 1.85 W m−2, respectively77. Xu et al.78 designed an integrated PFC-electro-Fenton process with WO3/W photoanode and Fe@Fe2O3/carbon felt cathode with maximum power output and current density of 3.4 W m−2 and 5.9 A m−2, respectively. Liao et al.79 reported a high-power density of 42.6 W m−2 and a current density of 112 A m−2 employing a visible-light responsive photoanode and air-breathing cathode.

The fuel cells function like batteries and offer several advantages over fossil fuel-based technologies. The microbial and enzymatic systems are bioelectrochemical-based solutions; therefore, the microbes and the enzymes play a vital role in the related treatments. The R&D goals to address the key challenges of fuel cells are (i) to minimize the cost, (ii) to increase the performance and durability, and (iii) to advance the designs of membranes and modules. Despite the challenges and shortcomings, it is well-known the energy systems discussed above play a vital role in the future energy mix and decarbonized energy systems, as they are sustainably sound in terms of energy conversion, production, storage, controlling pollution, and thus greenhouse gas emissions. To promote these wastewater-based renewable energy-generation technologies, several innovative ongoing projects to make WWTPs energy surplus are POWERSTEP80, Enerwater80, R3Water80, BioBZ81, DEMOSOFC82 (installation of three fuel cell modules for co-production of 175 kW electric power) and SMART-Plant80.

Technology evaluation

This section surveys the state of technology to evaluate the opportunities and gaps in developing and deploying systems while maximizing wastewater treatment benefits. We compare the engineering, economics, and environmental performance of the aforementioned technologies.

Engineering performance

Technology readiness level (TRL, on a scale from 1 to 9: 1 being the lowest and 9 being the highest) is an indicator of the maturity of a particular technology, reflecting the implementation of an actual system in an operational environment. For the anaerobic bioreactors, AD is considered the most mature and widely practiced technology with TRL 9. AD is deployed over a range of small, isolated facilities to the world’s largest WWTPs. The AnMBRs are still at TRL 4 and could rise to TRL 6 by 202783. For the SGE recovery technologies, PRO has reached TRL 7 because the power density of the PRO membrane is 6-fold higher than the commercial requirement of 5 W m−2 under lab conditions and twofold higher when tested with the waste streams84. The PRO membrane has demonstrated stable power generation under extensive pilot tests. RED has achieved TRL 7 because its prototype is fully demonstrated in an operational environment85. The MFCs and EFCs are at a general TRL of 3–4 because there is a need for increased electrical outputs by establishing pathways contributing to the transfer of extracellular electrons; cost-effective cathodes; feasibility establishment in real conditions; optimized designs for efficient performance; and extension to other complex substrates with specific bacteria for scale-up applications. However, it is expected to reach TRL 6 by 203586. The MECs and MDCs are at TRL 3. The current challenges include cheaper cathodes, platinum substitution; catalyst reduction; lack of comprehensive understanding of unique electron transfer mechanisms in the complex matrix of electrodes, bacterial cells, or other microbes; and insufficient long-term experiments in real conditions. Similar to MFCs, the TRL level of MECs and MDCs will increase to 4 by 2027 and reach 6 by 203587. The TRL of PFC varies as per its application: for water splitting and hydrogen production, the TRL is 2–3; for water treatment, the TRL is 3–4; however, it is a mature technology for air purification and self-cleaning88. The TRLs of standalone technologies are low; however, the integrated or hybrid technologies could have higher TRLs as they overcome the demerits and perform better with higher yields and efficiency. The technologies are marked on the TRL scale in Fig. 5.

Figure 5 compiles the power density and associated current density of energy-extracting wastewater technologies from the literature44,48,49,78,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107. The single-pore OPGs have secured the highest coordinates on the power and current densities, illustrating their abundant potential. The hybrid schemes have generated power and current with higher densities than their standalone prototypes78,89,107. The power density of PRO is much higher than the RED, as the PRO can take advantage of the increased salinity gradient due to its logarithmic dependence on the solution concentration, unlike RED108. Therefore, the membrane permeability–selectivity at a small efficiency cost can improve the power density of PRO. The power and current densities of fuel cells are very low when implemented on a large scale. Fuel cells require more research in the direction of harvesting greater power and current density. However, the combination and integration could boost the power density to a significant extent. The anaerobic digestors and AnMBRs are biogas producers and indirect sources of electricity. The electricity generation depends on the installed CHP units or other energy recovery techniques. This area needs the attention of researchers to improve the current, power, and energy densities of the energy-generating technologies for scale-up and deployment.

Techno-economic analysis (TEA)

Green technologies for WWTPs are analyzed by carbon neutrality, energy, and economic analysis. TEA is a method to analyze economic performance, and it is important to evaluate the sustainability-based potential for deployment. Apart from the efficiency and technical assessment, economic assessment is necessary to understand the potential for the technology to meet market demand. TEA combines process modeling and engineering design with economic evaluation and helps to assess the economic viability of the technology or system. It is important in identifying the future potential of energy-extracting technologies. For example, the TEA of a Kraft pulp mill using AD to produce renewable diesel revealed production costs (€0.47–0.82 per liter of diesel equivalent) similar to conventional diesel in Sweden (€0.68 per liter of diesel)109. Stoll et al.110 used TEA to compare different anodes (hard felt, carbon foam, and standard graphite brush) for a unit m3 pilot-scale MFC. The TEA of energy generated by RED is reported by Turek et al.111, which determined a high specific cost equal to US$ 6.79 per kWh against a total investment cost of US$ 100 m−2 for the installed membrane. For the TEA of PRO, Benjamin et al.112 used the Tampa Bay Seawater Desalination Plant as a case study and calculated a potential savings of 9% if PRO was installed. The electricity generation by OPG (US$ 0.04 kW h−1) is not competitive with the wholesale conventional US grid electricity reported in the TEA of OPG by Hickenbottom et al.113. For PRO to be commercially viable, the target power density is 5 W per m2 114. However, for techno-economic feasibility, Chung et al.115 developed a model to calculate the minimum required net power density to achieve the target levelized cost of electricity. The minimum required net power density for the PRO system in achieving a levelized cost of electricity of US$ 0.074 per kWh (the capacity-weighted average levelized cost of electricity of solar photovoltaic in the USA) was found to be 56.4 W per m2. Hybrid technologies could perform better in acquiring required power densities. Trapero et al.116 performed an economic assessment on three different scenarios, optimistic, pessimistic, and most likely scenarios, based on the maximum power density of a solo MFC implementation for wastewater treatment and compared with conventional activated sludge process; MFC was found to be a beneficial technology in all three scenarios.

Environmental benefits

Life-cycle assessment (LCA) methodology to evaluate the carbon emissions and environmental impacts of WWTP products’ and processes’ environmental aspects are described in ISO 14040:2006 standard. Rebello et al.117 proposed a guideline framework suitable for urban WWTPs based on a review of over 111 LCA studies of WWTPs. Mueller et al.118 compared RED to existing renewable energy technologies with a functional unit of 1 MWh of net electricity production, and under baseline assumptions, the impacts are an average of 50% higher for natural water compared to the concentrated brine. The study highlighted RED’s superior performance to other renewable energy technologies; however, several key environmental impacts were found in RED, including carcinogenic activity and eutrophication due to membranes. Foley et al.119 conducted an LCA to compare the environmental impact of energy-producing wastewater treatment processes such as AD, MFC, and MEC. The study found significant environmental benefits of MFC compared with AD and MEC. In an LCA of AnMBR, two process subcomponents, including sludge management as well as sulfide and phosphorus removal, were indicated as environmental hotspots affecting the environment and costs120. In an LCA of sewage sludge, Lanko et al.121 analyzed the Mesophilic, Thermophilic, and Temperature-Phased AD and reported the best performance of temperature-phased AD.

Table 5 presents the advantages, disadvantages, and future outlooks of the treatment techniques discussed in this article. To begin with, for the full-scale deployment of PRO, the effects of constant pressure operation, draw solution dilution, and feed solution concentration in membrane modules are crucial factors for overall performance122. The realistic membranes are neither perfectly selective nor achieve perfect hydrodynamics; and realistic modules also have limited area causing an incomplete mixing process. Therefore, more novel specific module designs, along with the hybrids such as FO-RO-PRO123 are required to target the water-energy sustainability. Similarly, in RED, the ion-exchange membrane, as well as the stack/module designs, are crucial for highly efficient large-scale treatment plants124. The SGE has reached advanced levels on lab-scale R&D; however, for large-scale deployment, the designs are yet to be optimized for desired water-energy solutions. Despite numerous benefits, the fuel cells such as MFC, EFC, Plant MFC, and PFC are struggling for commercialization because their architecture, cost, and durability are yet to be optimized125. Most energy-generation technologies are in their infancy and require more advancement to overcome their drawbacks or limitations and improve their TRLs. The less efficient and expensive semipermeable membranes, friction losses in plant streams, and low efficiency of rotating components in the case of PRO; the expensive catalysts in biofuel cells; expensive electrodes in RED; slow and intrinsic electron transfer in EFCs must be replaced prior to scaling up these technologies to a full-scale plant. The thinner the membranes, the higher the power density; atomically thin membranes have gained the limelight because they maintain their structural integrity while providing minimal resistance to the ions. Extensive usage of membranes in membrane-based energy-extracting technologies has been contributing to membranes’ evolution.

Strategies On transforming Wwtp to net-zero Co2

More countries are coming on board and joining the race towards net-zero. By 2021, Global Water Intelligence traced 65 water utilities and WWTPs with commitments toward the net-zero or climate neutrality targets; 26 utilities out of those have joined the United Nations Framework Convention on Climate Change’s Race To Zero global campaign to show their commitment and performance globally (Fig. 6)126. According to the USEPA, there are opportunities for energy efficiency, renewable energy, and water efficiency at each stage of the water use cycle127. The USEPA proposed a seven-step process in Ensuring a Sustainable Future: An Energy Management Guidebook for Water and Wastewater Utilities128 based on the circular evolving Plan-Do-Check-Act management systems approach described in ENERGY STAR® Guidelines for Energy Management129. To achieve net-zero carbon emissions by 2050, society needs a coordinated investment in research, sharing of best practices, and joint deployment. Net-zero water sectors can also contribute to several SDGs and life quality for all people.

a Summary of year-based commitments. b Net-zero carbon emission utilities, c Carbon-neutral utilities, and d Net-zero emission utilities [Adapted from ref. 168].

This section proposes four strategies based on the existing energy-positive WWTPs execution plans to become net energy producers and achieve a net-zero carbon emission sector, including (1) improvement in process energy efficiency, (2) maximization of on-site renewable capacities and biogas upgrading, (3) harvesting of energy from treated effluent, and (4) a new paradigm for decentralized water-energy supply facilities. These strategies aim to provide clean water to all of society while minimizing carbon emissions and environmental impacts, thereby effectively managing the implementation costs. These strategies could also serve as the basis for broader action plans for researchers, technology developers, service providers, operators, regulators, and municipalities.

Improvement in process energy efficiency

The most common energy-consuming processes at WWTPs are aeration systems and mechanical pumping. The first accounts for 45 to 75% of the WWTP’s energy expenditure, and the latter accounts for 18.9%130. The energy consumption of pumps can be improved by designing proper pumps in the right position. First, a broad investigation is required in the design stage to minimize the requirement to lift wastewater and consider the flooding flow mode131. Second, appropriate pumps considering the combination of sewage lifting amount and changing characteristics are needed to meet the high operating efficiency range and water level132. Panepinto et al.133 identified several opportunities for energy saving, such as ~25% energy saving by optimizing the primary settling efficiency with coagulants, 20–36% by aerating oxidation tanks equipped with automatized controlled dissolved oxygen and sludge retention time, and 64% by optimizing dissolved air flotation into solids thickening. A partial and intermittent operation of blowers instead of 24/7 operation would guarantee an unchanged effect with reduced energy consumption. Turning off mixers when aerators operate can save 90% of the energy130.

Following the USEPA’s plan128, several (waste)water utilities have reduced their energy consumption and CO2 emissions by improving their process energy efficiency. The Green Bay, Wisconsin Metropolitan Sewerage District serving 217,000 residents, saved 2,144,000 MWh yr−1 and 1480 metric tons of CO2-eq by installing new energy-efficient blowers. The East Bay Municipal Utility District uses the microturbine CHP units and water distribution via downhill pipes to consume 82% less energy than the California average in delivering each million gallons of drinking water. Millbrae, California, generating 1.7 million kWh yr−1 electricity, is 80% self-sufficient energy by utilizing inedible kitchen grease diverted from the city’s WWTP. Also, the sewage source heat pump can exchange heat between the sewage and the heat pump, and the internal heat pump is driven by electric power for heating or cooling purposes. Generally, the heating/cooling coefficient of the sewage source heat pump is 5.0–6.0134, which is much higher than the conventional air-source heat pumps. Also, it decreases the CO2 and SO2 emissions by 68%135 and 75%136, respectively. Kollman et al.137 reported a sewage source heat pump supplied by electricity from renewable resources only as the most sustainable option for producing the heat demand of 9057 MWhth yr−1 with an ecological footprint reduction of almost 99%. Awe et al.138 mentioned, “variable frequency drives (VFDs) can be used to vary the speed of the pump to match the flow conditions and affinity laws for centrifugal pumps suggest that even a small reduction in motor speed can reduce pump energy by as much as 50%.”

Moreover, smartness and intelligence innovations are essential in the path toward sustainable circularity in the water sector. Smart systems such as sensors, tailored treatment systems, adaptive outputs, industrial resilience, continuous process improvement and learning, and reimagining water resource recovery facilities can reduce energy consumption and water loss while improving process energy efficiency. This could be the most important management step towards circularity and sustainability. It is estimated the energy requirements of sewage pumping are 69 kWh per population equivalent139 per year, or exceeding double the average energy consumption for treating wastewater to a good quality140. Thus, intelligent wastewater pumping systems, real-time decision support systems, and adaptive mixers can cut 50% of the energy-related emissions; smart mixing and aeration systems can reduce the N2O emissions. Melbourne’s Main Outfall Sewer was recognized with a Gold Award for Sustainability in Design. Vacuum sewer systems are 24% cheaper141 and can lower the overall energy by 30–35% for their operation compared to the conventional gravity sewers140. In other words, smart and automated technological modifications/add-ons can improve the process energy efficiency and reduce the energy requirement of the WWTPs, contributing to their goal of self-sufficiency.

Maximizing on-site renewable capacities and biogas upgrading

The on-site integration of renewables such as solar or wind energy, AD equipped with CHP facilities, or installation of energy extracting technologies will contribute to the self-sufficiency of WWTPs. The on-site installation of standalone or hybrid renewable energy generators with energy storage could provide the decarbonized power source for wastewater treatment systems (e.g., distillation, photocatalytic oxidation, direct heat, desalination, and UV disinfection) as well as pumping. Solar energy can be applied in the WWTPs, including (1) the solar thermal to increase the reaction temperature and improve treatment efficiency, (2) the sludge can be dewatered utilizing the solar thermal energy, and (3) it can be employed for desalination (reverse osmosis or electrodialysis) or evaporation purposes. Geothermal or industrial waste heat could also be used as a thermal source. Photovoltaic power generation electrolysis could remove and recover pollutants from wastewater and provide electricity for other unit operations. Yiannopoulos et al.142 used anaerobic biofilter reactors to increase the sewage treatment temperature to 35 oC by solar heating. Ren et al.143 proposed several improvements to anaerobic biological treatment utilizing solar thermal systems. Similarly, wind or other clean-electricity generators could drive treatment systems, pumps, or disinfection systems. Wind turbines start pumping at speeds between 2.5 and 3.5 m s−1 and could provide mechanical energy at lower speeds than electrical wind turbines (minimum average speed of 5–6 m s−1). Emerging hybrid systems (photovoltaics, wind turbines, backup generator, and battery storage) are gaining popularity for remote or islanded applications.

In addition, biogas (e.g., from the AD of sludge) upgrading should be deployed in WWTPs to produce renewable natural gas to replace fossil fuel sources144,145. Natural gas has broad applications in society and mature infrastructure, and hydrogen infrastructure and utilization are less mature. Therefore, deploying renewable natural gas from biogas is easier than hydrogen. In 2017, Europe ranked first, having 17,783 installed biogas-based power generation facilities with 18.4 billion Nm3; and 340 biomethane plants out of 540 were fed into the grid146,147. Biogas can be upgraded to a sustainable fuel (i.e., biomethane) by the mature technologies of chemical or water scrubbing and pressure swing adsorption (market share of 25, 34, and 20% in Europe)80; later, it can be fed into gas grids, CHPs, and vehicles.

Moreover, upgrading biogas to biomethane increases the calorific value facilitating utilization pathways, such as domestic stoves, boilers, internal combustion engines, Stirling engines, gas turbines/microturbines, and natural gas grid injections, vehicles’ fuel, and fuel cells. However, upgrade challenges include avoiding methane release, minimizing water leakage from the water scrubber, high energy/chemical usage, and operating cost, leaving the research scope for cost-effective and chemical-saving microbial/electrochemical or biological methods. Some new upgrading techniques reported recently are ecological lung, in-situ methane enrichment in AD, and cryogenic upgrading148. Besides methane, biogas comprises 25–50 vol% of CO2 produced by the AD process, and it is estimated that ~32.2 Gt of CO2 is emitted annually by AD around the world. The bioenergy-derived CO2 can be further collected and utilized to realize a negative carbon scheme149. For instance, numerous approaches limit atmospheric release by injection for enhanced oil recovery or production of suits of chemicals such as Fischer-Tropsch liquids, polymers, alcohols, polyols, succinic acid, and syngas/hydrogen80. The WWTPs require innovative and integrated resource- and energy-efficient treatment technologies and enhanced carbon capture from a circular economy perspective.

Harvesting energy from treated effluent for coastal nations

Most coastal nations rely on desalination to meet some of their water demands, and desalination plants are intensive energy users, the production of which typically requires burning fossil fuels in large power plants. Heihsel et al.150 developed a tailor-made multi-regional input-output model to examine the greenhouse gases for 2005–2015 from seawater desalination in Australia, using conventional energies. The electricity component contributed 69% during the zenith of the construction phase and 96% during the operating phase to the entire emissions of 1193 kt CO2-eq. Liu et al.151 calculated the carbon emissions for three desalination plants used in the United Arab Emirates to produce one m3 of clean water from seawater: ~13.7 t-CO2 d−1 for multi-stage flash, ~0.72 t-CO2 d−1 for multiple effect distillation, and ~1.46 t-CO2 d−1 for reverse osmosis. Thus, the energy-efficient or energy-plus carbon-free SGE techniques can be integrated or hybridized for an effective energy-generating advanced treatment for brine effluent and treated wastewater effluent in the coastal nations152,153,154. PROs, REDs, and OPGs utilize the WWTPs’ treated effluent with freshwater/seawater, creating convenient conditions for blue energy production; some of the exemplary studies are listed in Table 2. Ye et al.155 proposed an electrochemistry-based charge-free mixing entropy battery (no membranes) which maintained 97% efficiency in capturing SGE for over 180 cycles. Fotiadou and Papagiannopoulos-Miaoulis156 identified how blue energy introduction could function as a driving force for the Mediterranean Sea’s conceptualization as ‘marine space,’ acknowledged in the preamble of Directive 2014/89/EU of the European Parliament and the Council in 2014 for establishing a framework of Maritime Spatial Planning. The European Union launched the COASTENERGY project (2019–2021)157 to adopt a participatory approach for gathering and involving Quadruple Helix actors in a multi-level network to develop a common roadmap and deploy coastal blue energy systems in pilot areas. Single-pore osmotic platforms, nanofluidic OPGs integrated with RED or PRO, can be the solutions for the urban water-energy nexus. As shown in Fig. 5, the highest current and voltage density can be achieved by single-pore OPGs platforms. Blue energy can also restore unique marine ecological systems in coastal nations because it utilizes the highly concentrated brine from desalination plants (for example, creating a fish migration stream from salt to fresh water and vice-versa; SDG 6.6)158.

New paradigm for decentralized water-energy supply units

Decentralized water-energy supply facilities are standalone/hybridized facilities or can be integrated with centralized WWTPs, installed at/near the source of wastewater generation, and designed based on site-specific conditions. These decentralized WWTPs are smart and cost-effective alternatives because they can avoid large initial investments, operation, and maintenance costs, increase the potential for wastewater reuse, create jobs, promote business, use land and energy wisely, put less pressure on the natural water budget, consume less fertilizer, recover more nutrients and energy, and preserve green space. In fact, water providers and consumers play a vital role in achieving net-zero emissions in the water sector. For example, consumers in the United Kingdom’s housing sector saved 1.33 Mt CO2-eq yr−1 by reducing water consumption by 5–6% from 2017 to 2019159.

The energy and capital invested in sewage collection and transportation can be significantly decreased in decentralized systems. Applying natural treatment technologies increases up to 33% in decentralized facilities, implying simple operations with lower costs160 can be implemented in the middle- and lower-income countries. The DEWATS initiative161 aims for decentralized treatment and sanitation in developing countries, usually without technical energy inputs, thus providing more reliable operation and fewer effluent quality fluctuations. Tervahauta et al.141 compared the decentralized and standardized collection systems and found the highest energy consumption of 914 MJ per capita per year within a centralized system; source separation into the urine, black- and gray water decreased the overall energy consumption to 208 MJ per capita per year for gravity-based systems and 190 MJ per capita per year for vacuum-based systems. Decentralization with a proper source separation stage is a long-term winning strategy for improving the energy efficiency of the urban water cycle; it offers closed loops of resource uses, which is in line with the circular economy principles. Kalehbasti et al.162 tested a novel method to design and optimize the hourly demand and supply of integrated energy and water system in an urban district for environmental and economic sustainability. The model is tested on a sample neighborhood from San Francisco in California, with 21 building prototypes, 32 CHP engines, 16 chillers, and 3 wastewater treatment systems (one centralized and two decentralized membrane-based systems). The results indicated the normalized life-cycle cost, social cost of carbon, annual energy demand, and annual wastewater production of the integrated designs of the decentralized water-energy systems were 20, 75, 8, and 20%, respectively, lower than those of the centralized WWTPs.

Developed countries with high carbon footprints have already started progressing towards a low-carbon economy. For example, >50% of new capacity added to the grid in the US is carbon-free and is expected to shift to 90% carbon-free energy by 2035163,164. However, switching to a completely decarbonized energy system is still a big challenge for developing countries (economies in transition, least developed countries, and highly indebted poor countries), where water reuse is generally practiced out of necessity to avoid the carbon-intensive pathways while growing their economies, providing access to energy, and much more. This is strongly supported by a hypothesis of an inverted U-shaped relationship between economic output per capita and some measures of environmental quality known as the Environmental Kuznets Curve, “As GDP per capita rises, so does environmental degradation. However, beyond a certain point, increases in GDP per capita lead to reductions in environmental damage”165.

Decentralization can be one of the cost-effective solutions toward the net-zero goal and is also recommended for water reuse and improved energy efficiency by the USEPA166. There is a need to recognize the benefits of water reuse along with its safety; it can be accomplished by better regulation and the provision of incentives. Therefore, it is clear that with enough political will and the creation of adequate incentives for businesses and policymakers alike, sustainable and productive sanitation can be a major contributing factor to the achievement of greener economies, fostering job creation and poverty reduction along with the entire sanitation wastewater treatment and reuse chain. The link between water and city planning is clearly a major issue for the entire world, including the developing nations growing at an unprecedented rate and older or lower growth nation-states. Water cannot be the sole driver in urban planning, but it needs to be a large part of the equation to create sustainable cities. Often innovation takes place without the other two supporting legs, i.e., the need or future requirement that it might meet, and the capital - both human (knowledge and expertise) and financial. There is a mounting consensus that we should not be looking backward for solutions but be more innovative in delivering the outcomes required from our water-energy systems. Last, collaboration, coordination, and investment should be placed to develop and deploy an integrated suite of wastewater technologies to secure a water future for broad segments of society.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

United Nations Environment Programme (UNEP). Half the world to face severe water stress by 2030 unless water use is “decoupled” from economic growth, says International Resource Panel. Press Release (21 March 2016).

International Energy Agency. Water energy nexus (Excerpt from the World Energy Outlook). https://www.iea.org/reports/water-energy-nexus (2016).

International Energy Agency. World energy outlook. https://www.iea.org/reports/world-energy-outlook-2018 (2018).

Dickin, S., Bayoumi, M., Giné, R., Andersson, K. & Jiménez, A. Sustainable sanitation and gaps in global climate policy and financing. npj Clean. Water 3, 1–7 (2020).

International Energy Agency. Energy access outlook 2017 from poverty to prosperity. https://www.oecd.org/publications/energy-access-outlook-2017-9789264285569-en.htm (2017).

Environmental Protection Agency. Inventory of US greenhouse gas emissions and sinks: 1990-2017-waste. https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks-1990-2017 (2017).

Curtis, T. P. in Environmental Microbiology (eds Mitchell, R. & Gu, J. -D.) Ch. 13 (Wiley, 2010).

Environmental Protection Agency. Energy efficiency for water utilities https://www.epa.gov/sustainable-water-infrastructure/energy-efficiency-water-utilities (2021).

Fluence News Team. How much energy exists in wastewater? https://www.fluencecorp.com/how-much-energy-exists-in-wastewater/ (2020).

Qadir, M. et al. Global and regional potential of wastewater as a water, nutrient and energy source. Nat. Resour. Forum 44, 40–51 (2020).

Simon, A. J. & Snyder, S. W. in Pathways to Water Sector Decarbonization, Carbon Capture and Utilization (ed Ren, Z. J. & Pagilla, K.) Ch. 2 (IWA Publishing, 2022).

Mihelcic, J. R. et al. Accelerating innovation that enhances resource recovery in the wastewater sector: advancing a national testbed network. Environ. Sci. Technol. 51, 14, 7749–7758 (2017).

Simon, A. J. & Snyder, S. W. Concept of Operations: National Technology Test Bed Network for Water Resource Recovery. Report No. INL-EXT-18-50231-Rev000 (Idaho National Lab, Idaho Falls & United States Department of Energy: Office of Scientific and Technical Information https://doi.org/10.2172/1435801, 2018).

Wang, B., Liu, W., Zhang, Y. & Wang, A. Bioenergy recovery from wastewater accelerated by solar power: intermittent electro-driving regulation and capacitive storage in biomass. Water Res 175, 115696 (2020).

Wang, L., Feng, Y., Wang, K. & Liu, G. Solar water sterilization enabled by photothermal nanomaterials. Nano Energy 87, 106158 (2021).

Liu, G. et al. Salt-rejecting solar interfacial evaporation. Cell Rep. 2, 100310 (2021).

Zang, L. et al. Interfacial solar vapor generation for desalination and brine treatment: evaluating current strategies of solving scaling. Water Res. 198, 117135 (2021).

Ghimire, U., Sarpong, G. & Gude, V. G. Transitioning wastewater treatment plants toward circular economy and energy sustainability. ACS Omega 6, 11794–11803 (2021).

Holliger, C., Fruteau de Laclos, H. & Hack, G. Methane production of full-scale anaerobic digestion plants calculated from substrate’s biomethane potentials compares well with the one measured on-site. Front. Energy Res. 5, 12 (2017).

Xu, L. et al. Electricity generation and acid and alkaline recovery from pickled waters/wastewaters through anaerobic digestion, bipolar membrane electrodialysis and solid oxide fuel cell hybrid system. Energy Convers. Manag. 251, 114973 (2022).

Nowak, O., Enderle, P. & Varbanov, P. Ways to optimize the energy balance of municipal wastewater systems: lessons learned from Austrian applications. J. Clean. Prod. 88, 125–131 (2015).

Aslam, M., McCarty, P. L., Shin, C., Bae, J. & Kim, J. Low energy single-staged anaerobic fluidized bed ceramic membrane bioreactor (AFCMBR) for wastewater treatment. Bioresour. Technol. 240, 33–41 (2017).

Kong, Z. et al. Large pilot-scale submerged anaerobic membrane bioreactor for the treatment of municipal wastewater and biogas production at 25 °C. Bioresour. Technol. 319, 124123 (2021).

Ji, J. et al. Important effects of temperature on treating real municipal wastewater by a submerged anaerobic membrane bioreactor: Removal efficiency, biogas, and microbial community. Bioresour. Technol. 336, 125306 (2021).

Pattle, R. Production of electric power by mixing fresh and salt water in the hydroelectric pile. Nature 174, 660–660 (1954).

Norman, R. S. Water salination: a source of energy. Science 186, 350–352 (1974).

Weinstein, J. N. & Leitz, F. B. Electric power from differences in salinity: the dialytic battery. Science 191, 557–559 (1976).

Logan, B. E. & Elimelech, M. Membrane-based processes for sustainable power generation using water. Nature 488, 313–319 (2012).

Jiao, Y. et al. Membrane-based indirect power generation technologies for harvesting salinity gradient energy-A review. Desalination 525, 115485 (2022).

Loeb, S. & Norman, R. S. Osmotic power plants. Science 189, 654–655 (1975).

Kempener, R. & Neumann, F. Wave Energy Technology Brief (International Renewable Energy Agency, 2014).

Kempener, R. & Neumann, F. Salinity Gradient Energy: Technology Brief (International Renewable Energy Agency, 2014).

Makabe, R., Ueyama, T., Sakai, H. & Tanioka, A. Commercial pressure retarded osmosis systems for seawater desalination plants. Membranes 11, 69 (2021).

Cherng Hon, K., Zhao, C., Yang, C. & Chay Low, S. A method of producing electrokinetic power through forward osmosis. Appl. Phys. Lett. 101, 143902 (2012).

Jiao, Y., Yang, C. & Kang, Y. Energy conversion from salinity gradients by forward osmosis–electrokinetics. J. Phys. Chem. C. 118, 10574–10583 (2014).

Chae, S. H. et al. Modeling and simulation studies analyzing the pressure-retarded osmosis (PRO) and PRO-hybridized processes. Energies 12, 243 (2019).

Lin, S., Yip, N. Y., Cath, T. Y., Osuji, C. O. & Elimelech, M. Hybrid pressure retarded osmosis–membrane distillation system for power generation from low-grade heat: thermodynamic analysis and energy efficiency. Environ. Sci. Technol. 48, 5306–5313 (2014).

Newell, A., Nuttall, P. & Holland, E. A. United nations global sustainable development report 2015. https://sustainabledevelopment.un.org/content/documents/1758GSDR%202015%20Advance%20Unedited%20Version.pdf (2015).

Genné, I. & Brauns, E. Reverse electrodialysis alternative power. Energy generation and desalination: the REAPOWER project. https://www.researchgate.net/publication/317232967_REAPower_Reverse_Electrodialysis_Alternative_Power (2011).

Tedesco, M., Cipollina, A., Tamburini, A. & Micale, G. Towards 1 kW power production in a reverse electrodialysis pilot plant with saline waters and concentrated brines. J. Membr. Sci. 522, 226–236 (2017).

Nam, J.-Y. et al. Assessing the behavior of the feed-water constituents of a pilot-scale 1000-cell-pair reverse electrodialysis with seawater and municipal wastewater effluent. Water Res. 148, 261–271 (2019).

Lempriere, M. Decarbonisation, decentralisation and digitalisation: the big drivers at PowerGen 2017. Power Technology (28 June 2017).

Zhang, Z., Wen, L. & Jiang, L. Nanofluidics for osmotic energy conversion. Nat. Rev. Mater. 6, 622–639 (2021).

Gao, J. et al. High-performance ionic diode membrane for salinity gradient power generation. J. Am. Chem. Soc. 136, 12265–12272 (2014).

Hwang, J., Kataoka, S., Endo, A. & Daiguji, H. Enhanced energy harvesting by concentration gradient-driven ion transport in SBA-15 mesoporous silica thin films. Lab a Chip 16, 3824–3832 (2016).

Ji, J. et al. Osmotic power generation with positively and negatively charged 2D nanofluidic membrane pairs. Adv. Funct. Mater. 27, 1603623 (2017).

Guo, W. et al. Energy harvesting with single‐ion‐selective nanopores: a concentration‐gradient‐driven nanofluidic power source. Adv. Funct. Mater. 20, 1339–1344 (2010).

Feng, J. et al. Single-layer MoS2 nanopores as nanopower generators. Nature 536, 197–200 (2016).

Yeh, L. H., Chen, F., Chiou, Y. T. & Su, Y. S. Anomalous pH‐dependent nanofluidic salinity gradient power. Small 13, 1702691 (2017).

Gao, J. et al. Understanding the giant gap between single‐pore‐and membrane‐based nanofluidic osmotic power generators. Small 15, 1804279 (2019).

Cao, L. et al. Towards understanding the nanofluidic reverse electrodialysis system: well matched charge selectivity and ionic composition. Energy Environ. Sci. 4, 2259–2266 (2011).

United States Department of Energy: Office of Energy Efficiency & Renewable Energy. 21st century truck partnership. https://www.energy.gov/eere/vehicles/21st-century-truck-partnership (2019).

Potter, M. C. Electrical effects accompanying the decomposition of organic compounds. Proc. R. Soc. Lond. Ser. B 84, 571, 260–276 (1911).

Gul, M. M. & Ahmad, K. S. Bioelectrochemical systems: sustainable bio-energy powerhouses. Biosens. Bioelectron. 142, 111576 (2019).

Ieropoulos, I., Greenman, J. & Melhuish, C. Urine utilisation by microbial fuel cells; energy fuel for the future. Phys. Chem. Chem. Phys. 14, 94–98 (2012).

Asensio, Y. et al. Towards the scale-up of bioelectrogenic technology: stacking microbial fuel cells to produce larger amounts of electricity. J. Appl. Electrochem. 47, 1115–1125 (2017).

Liu, H. & Logan, B. E. Electricity generation using an air-cathode single chamber microbial fuel cell in the presence and absence of a proton exchange membrane. Environ. Sci. Technol. 38, 4040–4046 (2004).

Rabaey, K., Lissens, G., Siciliano, S. D. & Verstraete, W. A microbial fuel cell capable of converting glucose to electricity at high rate and efficiency. Biotechnol. Lett. 25, 1531–1535 (2003).

Zhuang, L. et al. Scalable microbial fuel cell (MFC) stack for continuous real wastewater treatment. Bioresour. Technol. 106, 82–88 (2012).

Service, R. F. Is it time to shoot for the sun? Science 309, 548–551 (2005).

Janzen, A. F. & Seibert, M. Photoelectrochemical conversion using reaction-centre electrodes. Nature 286, 584–585 (1980).

Pillot, G. et al. Production of current by syntrophy between exoelectrogenic and fermentative hyperthermophilic microorganisms in heterotrophic biofilm from a deep-sea hydrothermal chimney. Microb. Ecol. 79, 38–49 (2020).

Rashid, N., Lee, B. & Chang, Y.-K. in Microalgae Biotechnology for Development of Biofuel and Wastewater Treatment (eds Alam, M. A. & Zhongming, W.) Ch. 1 (Springer, 2019).

Qu, Y. et al. Salt removal using multiple microbial desalination cells under continuous flow conditions. Desalination 317, 17–22 (2013).

Qu, Y. et al. Simultaneous water desalination and electricity generation in a microbial desalination cell with electrolyte recirculation for pH control. Bioresour. Technol. 106, 89–94 (2012).

Cao, X. et al. A new method for water desalination using microbial desalination cells. Environ. Sci. Technol. 43, 7148–7152 (2009).

Al-Mamun, A., Ahmad, W., Baawain, M. S., Khadem, M. & Dhar, B. R. A review of microbial desalination cell technology: configurations, optimization and applications. J. Clean. Prod. 183, 458–480 (2018).

Heidrich, E. S., Edwards, S. R., Dolfing, J., Cotterill, S. E. & Curtis, T. P. Performance of a pilot scale microbial electrolysis cell fed on domestic wastewater at ambient temperatures for a 12 month period. Bioresour. Technol. 173, 87–95 (2014).

Dange, P. et al. Recent developments in microbial electrolysis cell-based biohydrogen production utilizing wastewater as a feedstock. Sustainability 13, 8796 (2021).

Sankir, M. & Sankir N. D. Hydrogen Production Technologies (Wiley-Scrivener, 2017).

Aiken, D. C., Curtis, T. P. & Heidrich, E. S. Avenues to the financial viability of microbial electrolysis cells [MEC] for domestic wastewater treatment and hydrogen production. Int. J. Hydrog. Energy 44, 2426–2434 (2019).

Cusick, R. D. et al. Performance of a pilot-scale continuous flow microbial electrolysis cell fed winery wastewater. Appl. Microbiol. Biotechnol. 89, 2053–2063 (2011).

Yahiro, A., Lee, S. & Kimble, D. Bioelectrochemistry: I. Enzyme utilizing bio-fuel cell studies. Biochim. Biophys. Acta. 88, 375–383 (1964).

Marsh, J. Can wastewater be used to power fuel cells? Fuel Cells Works (31 May 2021).

Kilic, M. S., Korkut, S. & Hazer, B. A novel poly (propylene-co-imidazole) based biofuel cell: system optimization and operation for energy generation. Mater. Sci. Eng. C. 47, 165–171 (2015).

Selihin, N. M. & Tay, M. G. A review on future wastewater treatment technologies: micro-nanobubbles, hybrid electro-Fenton processes, photocatalytic fuel cells, and microbial fuel cells. Water Sci. Technol. 85, 319–341 (2022).

Lui, G., Jiang, G., Fowler, M., Yu, A. & Chen, Z. A high performance wastewater-fed flow-photocatalytic fuel cell. J. Power Sources 425, 69–75 (2019).

Xu, P., Xu, H. & Zheng, D. Simultaneous electricity generation and wastewater treatment in a photocatalytic fuel cell integrating electro-Fenton process. J. Power Sources 421, 156–161 (2019).

Liao, Q. et al. Respective electrode potential characteristics of photocatalytic fuel cell with visible-light responsive photoanode and air-breathing cathode. Int. J. Hydrog. Energy 40, 16547–16555 (2015).

Maktabifard, M., Zaborowska, E. & Makinia, J. Achieving energy neutrality in wastewater treatment plants through energy savings and enhancing renewable energy production. Rev. Environ. Sci. Biotechnol. 17, 655–689 (2018).

Federal Ministry for Economic Affair and Climate Action. Energy from Sewage (German Energy Solutions Initiative, 2020).

Schröer, H. Wastewater energy project begins. Horizon 2020 Projects https://horizon2020projects.com/sc-energy/wastewater-energy-project-begins/ (5 October 2015).

Urgun-Demirtas, M. Production of methane from organic waste streams with novel biofilm enhanced anaerobic membrane bioreactors. Argonne National Laboratory https://www.energy.gov/sites/default/files/2021-04/beto-10-peer-review-2021-organic-urgun-demirtas.pdf (2019).

Vietnam Investment and Technology Exchange (VINTEX). Membrane development for osmotic power generation. https://sangiaodichcongnghe.vn/Membrane-Development-for-Osmotic-Power-Generation.html (2019).

Tech Detectors. Reverse electrodialysis (RED). https://techdetector.de/applications/reverse-electrodialysis-red (2021).

Mukherjee, A., Patel, V., Shah, M. T. & Munshi, N. S. in Handbook of Biofuels. (ed Sahay, S.) Ch. 29 (Elsevier, 2022).

Wang, J., Wang, H. & Fan, Y. Techno-economic challenges of fuel cell commercialization. Engineering 4, 352–360 (2018).

Spasiano, D., Marotta, R., Malato, S., Fernandez-Ibanez, P. & Di Somma, I. Solar photocatalysis: materials, reactors, some commercial, and pre-industrialized applications. A comprehensive approach. Appl. Catal. B 170, 90–123 (2015).

Zhu, X., Kim, T., Rahimi, M., Gorski, C. A. & Logan, B. E. Integrating reverse‐electrodialysis stacks with flow batteries for improved energy recovery from salinity gradients and energy storage. ChemSusChem 10, 797–803 (2017).

D’Angelo, A. et al. Reverse electrodialysis performed at pilot plant scale: evaluation of redox processes and simultaneous generation of electric energy and treatment of wastewater. Water Res. 125, 123–131 (2017).

Kim, H.-K. et al. High power density of reverse electrodialysis with pore-filling ion exchange membranes and a high-open-area spacer. J. Mater. Chem. A 3, 16302–16306 (2015).

Zaffora, A. et al. Energy harvesting by waste acid/base neutralization via bipolar membrane reverse electrodialysis. Energies 13, 5510 (2020).

Yan, H. et al. Bipolar membrane-assisted reverse electrodialysis for high power density energy conversion via acid-base neutralization. J. Membr. Sci. 647, 120288 (2022).

Liu, Y.-C., Yeh, L.-H., Zheng, M.-J. & Wu, K. C.-W. Highly selective and high-performance osmotic power generators in subnanochannel membranes enabled by metal-organic frameworks. Sci. Adv. 7, eabe9924 (2021).

Zhang, Z. et al. Improved osmotic energy conversion in heterogeneous membrane boosted by three-dimensional hydrogel interface. Nat. Commun. 11, 1–8 (2020).

Wang, R. et al. FeS2 nanoparticles decorated graphene as microbial‐fuel‐cell anode achieving high power density. Adv. Mater. 30, 1800618 (2018).

Gadkari, S., Fontmorin, J.-M., Yu, E. & Sadhukhan, J. Influence of temperature and other system parameters on microbial fuel cell performance: numerical and experimental investigation. Chem. Eng. J. 388, 124176 (2020).

Liang, B., Li, K., Liu, Y. & Kang, X. Nitrogen and phosphorus dual-doped carbon derived from chitosan: an excellent cathode catalyst in microbial fuel cell. Chem. Eng. J. 358, 1002–1011 (2019).

Helder, M. et al. Concurrent bio-electricity and biomass production in three plant-microbial fuel cells using Spartina anglica, Arundinella anomala and Arundo donax. Bioresour. Technol. 101, 3541–3547 (2010).

Rahman, S., Al-Mamun, A., Jafary, T., Alhimali, H. & Baawain, M. S. Effect of internal and external resistances on desalination in microbial desalination cell. Water Sci. Technol. 83, 2389–2403 (2021).

Colmati, F., Yoshioka, S. A., Silva, V., Varela, H. & Gonzalez, E. R. Enzymatic based biocathode in a polymer electrolyte membrane fuel cell. Int. J. Electrochem. Sci. 2, 195–202 (2007).

Rasmussen, M., Abdellaoui, S. & Minteer, S. D. Enzymatic biofuel cells: 30 years of critical advancements. Biosens. Bioelectron. 76, 91–102 (2016).

Sakai, H. et al. A high-power glucose/oxygen biofuel cell operating under quiescent conditions. Energy Environ. Sci. 2, 133–138 (2009).

Qiu, M., Sun, P., Cui, G., Tong, Y. & Mai, W. A flexible microsupercapacitor with integral photocatalytic fuel cell for self-charging. ACS Nano 13, 8246–8255 (2019).

Ouyang, K., Xie, S., Wang, P., Zhu, J. & Zhan, P. A novel visible-light responsive photocatalytic fuel cell with a highly efficient BiVO4/WO3 inverse opal photoanode and a MnO2/graphene oxide nanocomposite modified cathode. Int. J. Hydrog. Energy 44, 7288–7299 (2019).

Kee, M.-W., Lam, S.-M., Sin, J.-C., Zeng, H. & Mohamed, A. R. Explicating charge transfer dynamics in anodic TiO2/ZnO/Zn photocatalytic fuel cell for ameliorated palm oil mill effluent treatment and synchronized energy generation. J. Photochem. Photobiol. A Chem. 391, 112353 (2020).

Bhat, Z. M. et al. An electrochemical neutralization cell for spontaneous water desalination. Joule 4, 1730–1742 (2020).

Yip, N. Y. & Elimelech, M. Comparison of energy efficiency and power density in pressure retarded osmosis and reverse electrodialysis. Environ. Sci. Technol. 48, 11002–11012 (2014).

Larsson, M., Jansson, M., Grönkvist, S. & Alvfors, P. Techno-economic assessment of anaerobic digestion in a typical Kraft pulp mill to produce biomethane for the road transport sector. J. Clean. Prod. 104, 460–467 (2015).

Stoll, Z. A., Ma, Z., Trivedi, C. B., Spear, J. R. & Xu, P. Sacrificing power for more cost-effective treatment: A techno-economic approach for engineering microbial fuel cells. Chemosphere 161, 10–18 (2016).

Turek, M. & Bandura, B. Renewable energy by reverse electrodialysis. Desalination 205, 67–74 (2007).

Benjamin, J., Arias, M. E. & Zhang, Q. A techno-economic process model for pressure retarded osmosis based energy recovery in desalination plants. Desalination 476, 114218 (2020).

Hickenbottom, K. L. et al. Techno-economic assessment of a closed-loop osmotic heat engine. J. Membr. Sci. 535, 178–187 (2017).

Touati, K. & Tadeo, F. Green energy generation by pressure retarded osmosis: State of the art and technical advancement. Int. J. Green. Energy 14, 337–360 (2017).

Chung, H. W., Swaminathan, J., Banchik, L. D. & Lienhard, J. H. Economic framework for net power density and levelized cost of electricity in pressure-retarded osmosis. Desalination 448, 13–20 (2018).

Trapero, J. R., Horcajada, L., Linares, J. J. & Lobato, J. Is microbial fuel cell technology ready? An economic answer towards industrial commercialization. Appl. Energy 185, 698–707 (2017).

Rebello, T. A., Roque, R. P., Gonçalves, R. F., Calmon, J. L. & Queiroz, L. M. Life cycle assessment of urban wastewater treatment plants: a critical analysis and guideline proposal. Water Sci. Technol. 83, 501–514 (2021).

Mueller, K. E., Thomas, J. T., Johnson, J. X., DeCarolis, J. F. & Call, D. F. Life cycle assessment of salinity gradient energy recovery using reverse electrodialysis. J. Ind. Ecol. 25, 1194–1206 (2021).

Foley, J. M., Rozendal, R. A., Hertle, C. K., Lant, P. A. & Rabaey, K. Life cycle assessment of high-rate anaerobic treatment, microbial fuel cells, and microbial electrolysis cells. Environ. Sci. Technol. 44, 3629–3637 (2010).

Harclerode, M. et al. Life cycle assessment and economic analysis of anaerobic membrane bioreactor whole-plant configurations for resource recovery from domestic wastewater. J. Environ. Manag. 269, 110720 (2020).

Lanko, I. et al. Life cycle assessment of the mesophilic, thermophilic, and temperature-phased anaerobic digestion of sewage sludge. Water 12, 3140 (2020).

Straub, A. P., Lin, S. & Elimelech, M. Module-scale analysis of pressure retarded osmosis: performance limitations and implications for full-scale operation. Environ. Sci. Technol. 48, 12435–12444 (2014).

Lugito, G., Ariono, D., Putra, M. R. T. & Zafra, Z. N. Progress, challenges, and prospects of forward osmosis (FO) and pressure retarded osmosis (PRO) as an alternative solution for water and energy crisis. IOP Conf. Ser. Mater. Sci. Eng. 1143, 012060 (2021).

Moreno, J., Grasman, S., Van Engelen, R. & Nijmeijer, K. Upscaling reverse electrodialysis. Environ. Sci. Technol. 52, 10856–10863 (2018).

Ezziat, L., Elabed, A., Ibnsouda, S. & El Abed, S. Challenges of microbial fuel cell architecture on heavy metal recovery and removal from wastewater. Front. Energy Res. 7, 1 (2019).

Global Water Intelligence. Water without carbon: the net zero utilities observatory. https://www.globalwaterintel.com/water-without-carbon (2021).

United States Environmental Protection Agency. Energy efficiency in water and wastewater facilities: a guide to developing and implementing greenhouse gas reduction programs. https://www.epa.gov/sites/default/files/2015-08/documents/wastewater-guide.pdf (2013).

United States Environmental Protection Agency. Ensuring a Sustainable Future: An Energy Management Guidebook for Water and Wastewater Utilities (National Service Center for Environmental Publications, 2008).

United States Environmental Protection Agency. ENERGY STAR guidelines for energy management. https://www.energystar.gov/ (2011).

Daw, J., Hallett, K., DeWolfe, J. & Venner, I. Energy Efficiency Strategies for Municipal Wastewater Treatment Facilities. Report No. NREL/TP-7A30-53341 (National Renewable Energy Lab, 2012).

Guven, H. et al. Effect of hydraulic retention time on the performance of high-rate activated sludge system: a pilot-scale study. Wat. Air Soil Poll. 228, 1–10 (2017).