Abstract

A growing emphasis on water recycling resulted in intense research activity, aiming to develop and validate reliable and high-quality water treatment processes at lowest cost. In parallel, significant advances in the field of osmotically driven processes have been obtained in the past decade. While the combination of membrane bioreactor (MBR) and reverse osmosis (RO) has become the preferred choice for water reuse, the osmotic membrane bioreactor (OMBR) has begun to be considered as a promising alternative. Based on the current state of knowledge, this paper critically asses the potential for OMBR to be implemented for water reuse application and highlights challenges to reach full scale operation. The initial vision of an energy-free osmotic gradient process is not realistic and its low fouling behaviour is still to be properly assessed. However, OMBR demonstrated unique features such as high rejection of contaminants and an absence of RO brine stream that can support its implementation, especially in the context of high end (potable, industrial) water reuse. However, to become a viable and effective technology for water reuse, significant research and development is still required. Tackling the salinity build-up, developing membranes and modules adapted to OMBR, evaluating long term performance and economics, validating removal of contaminants and developing design, maintenance and automatic control systems constitute critical topics to be considered in future research.

Similar content being viewed by others

Introduction: Water reuse context

The World Health Organisation and the United Nations have identified wastewater reuse as a key solution to the problem of water scarcity and associated food-related issues and to improper wastewater disposal.1,2 The global water reuse market is booming (+22% annual growth forecasted for 2014–2019)3 pushed by the implementation of both non-potable and potable water reuse schemes.4 Water reuse requires the development and validation of water treatment schemes that can assure safe, high and reliable water quality at competitive costs.5 Thanks to the early experience gained during the development of water reuse schemes and by transposition from desalination plant technologies, typical potable water reuse trains already emerged. Such schemes generally consist in pursuing wastewater treatment with successive membrane treatment steps (i.e. multi-barrier approach), typically a combination of ultrafiltration (UF) or membrane bioreactor (MBR) and reverse osmosis (RO) followed by a disinfection step.6 Despite the practical implementation of such schemes, however, a number of challenges remain or are emerging, such as the validation of pathogen removal of the treatment train (log removal credits), the rejection of trace organic contaminants (TrOCs), the monitoring of membrane integrity and the costs of RO brine disposal that require further research and the development of innovative technologies.6 This paper aims at critically discussing the opportunity for the osmotic MBR (OMBR) to become a future technology for water reuse. Key aspects such as (1) OMBR implementation in water reuse treatment schemes, (2) the potential and need for improved water quality using OMBR-RO, (3) its technical–economical comparison with MBR-RO and (4) the required technical OMBR improvement for full scale operation are discussed in the following sections.

Where can osmotic membrane bioreactor be implemented in water reuse trains?

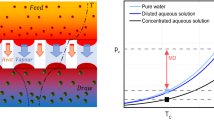

OMBR has been developed by analogy with MBR technology.7 However, instead of using a porous UF or microfiltration (MF) membrane as in MBR systems, a dense forward osmosis (FO) membrane is used and a (draw) solute concentration gradient (also called osmotic pressure differential) acts as the driving force. As a result, permeation of water occurs through the membrane from the lowest (activated sludge suspension) to the highest solute concentration solution (draw solution).7,8

In a stand-alone water-recycling train, a reconcentration step (typically RO) is required to extract the purified water and reconcentrate the draw solution that is operated in closed loop. Thus, OMBR can be considered, within a hybrid OMBR-RO system, as an alternative to the more conventional MBR-RO option (Fig. 1). The first studies on OMBR-RO demonstrated interesting properties of the hybrid system:8,9 (1) two successive dense membrane barriers for reliable production of high quality water, (2) low fouling propensity of OMBR, (3) low fouling in the RO step since the draw solution that must be concentrated is a clean stream (OMBR effluent), (4) no brine production (Fig. 1b).

Another possible configuration is to combine seawater desalination and water reuse (ref. 10 and Fig. 1c) to take advantage of using seawater as draw solution. In this configuration, diluted seawater requires less energy for the RO step and wastewater pollutants cannot accumulate in the draw loop; however, RO brine is produced and this configuration is limited by the required co-location of the two streams.

Can OMBR-RO improve water quality and safety?

Despite exhibiting a double dense barrier membrane system, the critical advantage of OMBR-RO compared to MBR-RO still needs to be demonstrated in terms of improved water quality and process resilience. This will strongly impact the process acceptance by key stakeholders since only significant technological advantages will support its implementation when compared with MBR-RO.

Pathogens removal /system robustness and log removal values

Pathogen removal is a key parameter in water reuse considerations, with several guidelines and frameworks already in place to limit health risks. For example in California, the required overall treatment process log removal values (LRV) for viruses, Giardia and Cryptosporidium are respectively 12, 10 and 10 for potable water reuse.11 Such high level of removal is difficult to demonstrate with MBR and RO due to the lack of sensitivity of existing on-site process monitoring.12 Thus, the current limited LRV credit allocated to MF/UF removal of viruses (0) and RO (2)11 results in the need for intense advanced oxidation processes (AOP) and/or disinfection processes to increase the low LRV affecting costs and producing harmful disinfection by-products.

It could be envisioned that with OMBR-RO and the double dense barrier concept high rejection of pathogens can be obtained13 but membrane robustness in operation and adapted online monitoring integrity tests still have to be validated to obtain additional LRV credits. The presence of a highly saline (and clean) solution in the draw side facilitates several process monitoring approaches regarding the loss of membrane integrity or selectivity. Monitoring the increase of turbidity in the draw solution or the increase of salinity in the mixed liquor can be envisioned; the addition of a tracer in the draw solution as the dprShield with breach-activated barrier proposed by Porifera is also an option to monitor any defect in the process.14

TrOCs removal

Due to the porous nature of MF/UF membranes used in MBR, TrOCs (i.e. small organic compounds such as pesticides, pharmaceuticals, endocrine-disrupting chemicals and/or disinfection by-products) are expected to permeate through the membrane.15 RO allows for a high rejection of most of these compounds but some of the small pollutants are not well rejected. Due to the high retention time of activated sludge in OMBR that allows for enhanced biodegradation16,17 and its double dense membrane process, OMBR-RO has demonstrated to be very efficient in the removal of most TrOCs.18 The accumulation of TrOCs in the draw solution loop (and release through RO) observed in FO–RO19 can be a major limitation for OMBR-RO and should be evaluated and monitored; recalcitrant TrOCs can also accumulate in the mixed liquor. However, the combination of novel generation thin film composite (TFC) membranes with improved TrOCs rejection,20 the biological degradation occurring in the OMBR (potentially enhanced by enzymatic degradation21) and the periodical draw solution replacement can limit TrOCs accumulation in the draw solution. Other configurations such as combined OMBR/MBR (Tackling the salinity build-up section) or water reuse combined with seawater desalination (Fig. 1c) can be also considered to prevent TrOCs accumulation.

What are the necessary OMBR improvements for implementation?

Developing OMBR modules

Many types of OMBR designs can be envisioned in term of (1) membrane types (hollow fibre (HF), flat-sheet, tubular), (2) arrangement in modules and (3) process configurations (submerged or side stream). So far, spiral wound and plate and frame (pressurised) modules using flat sheet membranes10 and (pressurised) HF FO modules are commercially available but are not recommended in such sidestream operation due to membrane clogging;22 tubular FO membranes, usually preferred in these types of applications, are not commercially available yet.23 Also, those FO modules are not suitable for submerged operation (as preferred in MBR design for urban wastewater treatment), and specific modules dedicated to OMBR need to be developed. HF modules are of great interest but HF membranes with an outer selective layer to prevent permanent fouling need first to be developed.

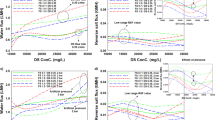

So far, most OMBR studies have been conducted using cellulose triacetate (CTA) flat sheet FO membrane from HTI company, arranged in home-made setups (either submerged or side stream) leading to permeation flux below 10 L m−2 h−1, despite using at least 0.5 M NaCl draw solution concentration.9 Significant improvement of osmotic pressure efficiency is required for OMBR to become competitive, i.e. by reaching similar operating flux as for MBR (at least 10 L m−2 h−1) while reducing significantly the osmotic pressure of the draw solutions (below 10 bar for stand-alone OMBR-RO) in order to limit energy costs for RO draw recovery. The use of novel TFC FO membranes already demonstrated significant flux improvement.24,25 However, the substantial drop in performance observed when scaling up from cross flow cell to plate and frame submerged module emphasises the crucial importance of module design (hydrodynamics).26 Submerged OMBR modules have to feature distinct parameters from existing submerged MBR or cross flow modules, especially regarding draw channel design, so as to provide optimised mass transfer as well as membrane support.

Tackling the salinity build-up

Salt accumulation in the OMBR tank, resulting from both the high rejection of dissolved solids (from the wastewater) by the membrane and the reverse salt diffusion (RSD) occurring in the FO process remains a main challenge for OMBR.27 Salt accumulation can affect the physical and biological properties of the mixed liquor and ultimately the removal efficiency of the process.16 Typically, non-halophilic organisms usually found in activated sludge processes and MBR, can tolerate salinities up to 10 g L−1.17 Salinity in the mixed liquor is dependent on the influent salinity, hydraulic and solid retention times (HRT, SRT), forward salt diffusion and RSD. RSD can be mitigated by using novel TFC membranes with improved selectivity or using larger / biodegradable draw solutes; however, the problematics due to the high rejection of salts by OMBR will remain.28 For typical wastewater salinities of 0.5 g L−1 and even in the case of no RSD, the concentration factor SRT/HRT has to be limited below 20 in order to operate with non-halophilic bacteria17 and possibly down to 10 when accounting for RSD effect in OMBR. These concentration factors, well below the typical range of MBR operation (SRT/HRT above 30), constitute an important limitation of OMBR compared to MBR which can be highly detrimental to OMBR economics, affecting sludge disposal costs and requiring larger OMBR tanks. One alternative is to operate at higher mixed liquor salinity by inoculating halophilic microorganisms. Even if this is a feasible strategy, such system requires even higher draw solution osmotic pressure to allow for sufficient driving force especially considering enhanced external concentration polarisation.

Another proposed solution is to create salt bleeding via the addition of a UF/MF system in parallel to OMBR.29,30 This process is more complex to operate since two sets of well-balanced membrane systems are required but also offers the advantage of extracting concentrated pollutants or resources which facilitates their further recovery. Among the configurations tested, the (partial) retrofitting of MBR into OMBR can limit investment costs and water production can be adapted to seasonal water needs and to the end user.31 In combined MBR/OMBR system, the ratio of water produced in both streams, which is crucial in term of water management, will depend on local water needs and flexibility on salinity control.

Developing fouling control and cleaning strategies

Fouling occurrence and control

Low fouling rates observed in early FO/OMBR studies8,32,33 were (one of) the main motivation(s) for OMBR development. Membrane orientation with active layer facing feed is the most appropriate for severe fouling conditions and is preferred in OMBR.33 Interestingly, most OMBR studies were conducted using HTI CTA membranes with low permeation fluxes34 while our recent work demonstrated that with operation at higher flux (above 10 L m−2 h−1) a higher fouling rate can be expected.35 This confirms the presence of a 'critical flux' in FO and the need to study this parameter in OMBR, as it might be as important in optimised MBR operation.36,37 The development of a dedicated methodology and the comparison of critical flux values of OMBR and MBR and their associated fouling propensities is thus required. Also, since transmembrane pressure (TMP) is not the driving force in OMBR, it is no longer, a relevant indicator to evaluate fouling rate and the need for cleaning in those systems. Most likely OMBR will be operated at constant draw solution concentration; permeation flux will decrease with fouling load. Therefore permeation flux is a relevant indicator for process monitoring and, in a near future, as an automatic closed-loop control parameter, which has proved to be essential in MBR to reduce operational costs.

Fouling mitigation and cleaning

Creating turbulence at the membrane surface either through aeration (air scouring) for submerged systems or through higher cross flow velocities for side stream modules has proven to be efficient for fouling mitigation in FO and MBR systems.9,33 Backwashing may be of interest for HF or side stream configurations. Relaxation is not adapted to OMBR: stopping the draw pump does not immediately release the osmotic gradient. Osmotic backwashing, which relies on reversing the osmotic gradient so to reverse the flux and detach foulants from the membrane surface, is a fouling mitigation well-adapted to FO.33 Replacing the draw solution by water or low strength NaOH and HCl solutions assures ‘’cleaning in place” (chemically enhanced) osmotic backwash.9 Innovative strategies could be envisioned to allow for automatic osmotic backwashing. More evidence is required to determine long term efficiency and feasibility, frequency of cycles and impact on membrane ageing.

As for MBR, a membrane cleaning strategy outside the OMBR tank may be required for submerged modules. Common MBR chemical cleaning agents (acidic, alkaline, chlorine based) cannot be used due to the low tolerance to extreme pH and chlorine of TFC FO membranes. Again, osmotic backwashing can be a more suitable strategy. In this case, water is circulated in the draw channel and the membrane module/skid is submerged in a higher salinity solution. Osmotic backwashing is followed by simply rinsing the membrane with water so as to remove the foulant cake and the salts still present on the membrane surface.9,38

Evaluating membrane resistance and management of unexpected breakage

FO membranes are not only thinner than MF/UF membranes but also their separation properties rely entirely on their thin active layer facing the challenging activated sludge. A few studies already demonstrated that membrane degradation occurs during long term OMBR operation, leading to a loss of selectivity for both CTA and TFC membranes.24,39 Biodegradation, physical defects and chemical modifications were hypothesised as potential causes but more studies are required to determine the causes and identify also the potential impact of mechanical constraints, chemical attack and abrasion. This is a key question as it may impact process stability and membrane replacement rate and point out the required development of tailor-made membranes for OMBR.

Another potential unexpected event is the loss of membrane integrity or material failure, leading to a salt leakage from the draw solution into the mixed liquor and/or pollution of the draw solution. A salinity shock is to be avoided to protect the biological system from irreversible damage; early detection of leaks would be crucial for process validation in potable reuse. As it has happened in MBR operation, new developments on automation and automatic control are expected to reduce costs while increasing robustness for OMBR operation.40

Can OMBR-RO be financially competitive?

Carrying out a thorough technical economic evaluation of OMBR-RO is critical to estimate if OMBR-RO can be competitive and in which contexts. At this stage of OMBR development, only initial assumptions can be made and specific focus points to be optimised and assessed are summarised in Table 1.

Table 1 observations also apply to OMBR-RO combined with desalination for all aspects regarding the OMBR operation. However, since seawater is used as draw solution, there are no costs of draw replenishment (#5 in Table 1) and obtaining a competitive flux is less challenging (9). Thanks to the lower salinity of the seawater entering the RO, lower operating pressure and/or higher recovery can be obtained depending on the envisioned water scenario.41 Brine management costs (#6 and 10 in Table 1) apply but are largely mitigated thanks to the joint disposal with usual RO brine. In combined OMBR/MBR operation, additional investment/operational costs due the operation of two systems are expected but can be balanced by avoided sludge management costs (#14), flexibility in water management and MBR retrofitting.

Outlook: challenges and perspectives

Recent literature shows that the initial FO/OMBR technical and economic potential (i.e., free osmotic gradient energy process with low fouling behaviour) may be limited. However, generated evidence that OMBR has high rejection of contaminants and limited brine production can warrant OMBR-RO implementation, especially in the context of high end (potable, industrial…) water reuse. Apart from the technical challenge of salinity build-up, developing membranes and modules adapted to OMBR, full scale validation of OMBR-RO schemes and setting up maintenance and control tools are important issues to be considered in future research, as they can largely impact OMBR economics (Fig. 2).

References

World Health Organization. Guidelines for the Safe use of Wastewater, Excreta and Greywater: wastewater use in Agriculture. Vol. 2 (World Health Organization, Geneva, 2006).

United Nations. Sustainable development goals: Goal 6: Ensure access to water and sanitation for all, http://www.un.org/sustainabledevelopment/water-and-sanitation/.

Technavio. Global Water Recycle and Reuse Market 2015-2019, http://www.reportsnreports.com/reports/407795-global-water-recycle-and-reuse-market-2015-2019.html (2015).

US Wastewater Market To Total US$11.0B Through 2025, https://www.wateronline.com/doc/us-wastewater-market-to-total-us-b-through-0001 (2015).

Wade Miller, G. Integrated concepts in water reuse: managing global water needs. Desalination 187, 65–75 (2006).

The Long Read: Do we have the technology for potable water reuse?, https://www.desalination.biz/news/3/The-Long-Read-Do-we-have-the-technology-for-potable-water-reuse/8660/ (2017).

Cornelissen, E. R. et al. The innovative osmotic membrane bioreactor (OMBR) for reuse of wastewater. Water Sci. Technol. 63, 1557–1565 (2011).

Achilli, A., Cath, T. Y., Marchand, E. A. & Childress, A. E. The forward osmosis membrane bioreactor: a low fouling alternative to MBR processes. Desalination 239, 10–21 (2009).

Holloway, R. W., Achilli, A. & Cath, T. Y. The osmotic membrane bioreactor: a critical review. Environ. Sci. Water Res. Technol. 1, 581–605 (2015).

Blandin, G., Verliefde, A.R., Comas, J., Rodriguez-Roda, I. & Le-Clech, P. Efficiently combining water reuse and desalination through forward osmosis—reverse osmosis (FO-RO) hybrids: a critical review. Membranes 6, E37 (2016).

Raucher, R. S. & Tchobanoglous, G. The opportunities and economics of direct potable reuse. (WateReuse Research Foundation, Alexandria VA, 2014).

Antony, A., Blackbeard, J. & Leslie, G. Removal efficiency and integrity monitoring techniques for virus removal by membrane processes. Crit. Rev. Environ. Sci. Technol. 42, 891–933 (2012).

Wettereau, G. Permitting for direct potable reuse and the role of FO. In IFOA World Summit (Vancouver, Canada, 2015).

Desormeaux, E. Porifera: creating a world with less waste, water reuse instead of discarded, concentrated products, erik-desormeaux.squarespace.com/s/Porifera-Technology-Overview-March2017.pdf (2017).

Siegrist, H. & Joss, A. Review on the fate of organic micropollutants in wastewater treatment and water reuse with membranes. Water Sci. Technol. 66, 1369–1376 (2012).

Luo, W. et al. High retention membrane bioreactors: challenges and opportunities. Bioresour. Technol. 167, 539–546 (2014).

Lay, W. C. L., Liu, Y. & Fane, A. G. Impacts of salinity on the performance of high retention membrane bioreactors for water reclamation: a review. Water Res. 44, 21–40 (2010).

Luo, W. et al. Osmotic versus conventional membrane bioreactors integrated with reverse osmosis for water reuse: biological stability, membrane fouling, and contaminant removal. Water Res. 109, 122–134 (2017).

D’Haese, A. et al. Trace organic solutes in closed-loop forward osmosis applications: influence of membrane fouling and modeling of solute build-up. Water Res. 47, 5232–5244 (2013).

Blandin, G. et al. Impact of hydraulic pressure on membrane deformation and trace organic contaminants rejection in pressure assisted osmosis (PAO). Process Saf. Environ. Prot. 102, 316–327 (2016).

Asif, M. B., Nguyen, L. N., Hai, F. I., Price, W. E. & Nghiem, L. D. Integration of an enzymatic bioreactor with membrane distillation for enhanced biodegradation of trace organic contaminants. Int. Biodeterior. Biodegrad. 124, 73–81 (2017).

Aquaporin. Aquaporin Inside™ Forward Osmosis membrane products, http://aquaporin.dk/products/fo/ (2016).

Judd, S. The MBR book: principles and applications of membrane bioreactors for water and wastewater treatment. (Elsevier, Amsterdam, The Netherlands, 2010).

Bell, E. A., Holloway, R. W. & Cath, T. Y. Evaluation of forward osmosis membrane performance and fouling during long-term osmotic membrane bioreactor study. J. Memb. Sci. 517, 1–13 (2016).

Qiu, G., Zhang, S., Srinivasa Raghavan, D. S., Das, S. & Ting, Y. P. Towards high through-put biological treatment of municipal wastewater and enhanced phosphorus recovery using a hybrid microfiltration-forward osmosis membrane bioreactor with hydraulic retention time in sub-hour level. Bioresour. Technol. 219, 298–310 (2016).

Blandin, G., Comas, J. & Rodriguez-Roda, I. in Frontiers International Conference on Wastewater Treatment and Modelling 188–192 (Springer, New York, 2017).

Boo, C., Lee, S., Elimelech, M., Meng, Z. & Hong, S. Colloidal fouling in forward osmosis: role of reverse salt diffusion. J. Memb. Sci. 390–391, 277–284 (2012).

Bowden, K. S., Achilli, A. & Childress, A. E. Organic ionic salt draw solutions for osmotic membrane bioreactors. Bioresour. Technol. 122, 207–216 (2012).

Luo, W. et al. The role of forward osmosis and microfiltration in an integrated osmotic-microfiltration membrane bioreactor system. Chemosphere 136, 125–132 (2015).

Holloway, R. W. et al. Long-term pilot scale investigation of novel hybrid ultrafiltration-osmotic membrane bioreactors. Desalination 363, 64–74 (2015).

Blandin, G., Gautier, Sauchelli Toran, M., Monclús, H.,C., Rodriguez-Roda, I., & Comas, J. Retrofitting membrane bioreactor (MBR) into osmotic membrane bioreactor (OMBR): a pilot scale study. Chemical engineering journal (2018).

Cornelissen, E. R. et al. Membrane fouling and process performance of forward osmosis membranes on activated sludge. J. Memb. Sci. 319, 158–168 (2008).

She, Q., Wang, R., Fane, A. G. & Tang, C. Y. Membrane fouling in osmotically driven membrane processes: a review. J. Memb. Sci. 499, 201–233 (2016).

Wang, X., Chang, V. W. C. & Tang, C. Y. Osmotic membrane bioreactor (OMBR) technology for wastewater treatment and reclamation: advances, challenges, and prospects for the future. J. Memb. Sci. 504, 113–132 (2016).

Blandin, G., Vervoort, H., Le-Clech, P. & Verliefde, A. R. D. Fouling and cleaning of high permeability forward osmosis membranes. J. Water Process Eng. 9, 161–169 (2016).

Le Clech, P., Jefferson, B., Chang, I. S. & Judd, S. J. Critical flux determination by the flux-step method in a submerged membrane bioreactor. J. Memb. Sci. 227, 81–93 (2003).

Field, R. W., Wu, D., Howell, J. A. & Gupta, B. B. Critical flux concept for microfiltration fouling. J. Memb. Sci. 100, 259–272 (1995).

Blandin, G., Verliefde, A. R. D. & Le-Clech, P. Pressure enhanced fouling and adapted anti-fouling strategy in pressure assisted osmosis (PAO). J. Memb. Sci. 493, 557–567 (2015).

Luo, W., Xie, M., Hai, F. I., Price, W. E. & Nghiem, L. D. Biodegradation of cellulose triacetate and polyamide forward osmosis membranes in an activated sludge bioreactor: observations and implications. J. Memb. Sci. 510, 284–292 (2016).

Ferrero, G., Rodríguez-Roda, I. & Comas, J. Automatic control systems for submerged membrane bioreactors: a state-of-the-art review. Water Res. 46, 3421–3433 (2012).

Teusner, A, Blandin, G & Le-Clech, P. Augmenting water supply by combined desalination/water recycling methods: an economic assessment. Environ. Technol. 38, 257–265 (2016).

Desormeaux, E. Porifera Commercialization Landscapre for Foward Osmosis www.desaltech2015. com/assets/presenters/Desormeaux_Erik.pdf (2015).

Qin, J. J., Lay, W. C. L. & Kekre, K. A. Recent developments and future challenges of forward osmosis for desalination: A review. Desalin. Water Treat. 39, 123–136 (2012).

De la torre, T. et al. in International Forward Osmosis Association Summit (Lisbon, 2014).

Acknowledgements

The research leading to these results has received funding from the People Programme (Marie Curie Actions) of the Seventh Framework Programme of the European Union (FP7/2007-2013) under REA grant agreement n° 600388 (TECNIOspring programme), and from the Agency for Business Competitiveness of the Government of Catalonia, ACCIO. LEQUIA and ICRA were recognised as consolidated research groups by the Catalan Government with codes 2014-SGR-1168 and 2014-SGR-291, respectively.

Author information

Authors and Affiliations

Contributions

The writing of this manuscript was led by G.B. All co-authors have made substantial contributions in the design, writing and successive revisions of the manuscript.

Corresponding author

Ethics declarations

Competing interests

P.L.-C. and A.R.D.V. certify that they have NO potential conflict of interest that they should disclose. G.B., J.C. and I.R.-R. disclose that they are listed as inventor of the patent application PCT/EP2017/064605 related to the retrofitting of MBR in OMBR. E.C. discloses that he is listed as inventor of the Dutch Patent NL1028484, Priority date 8-3-2005 related to the operation and design of the OMBR.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Blandin, G., Le-Clech, P., Cornelissen, E. et al. Can osmotic membrane bioreactor be a realistic solution for water reuse?. npj Clean Water 1, 7 (2018). https://doi.org/10.1038/s41545-018-0006-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41545-018-0006-x

This article is cited by

-

Understanding the mechanisms of trace organic contaminant removal by high retention membrane bioreactors: a critical review

Environmental Science and Pollution Research (2019)