Abstract

Smart packaging materials enable active control of parameters that potentially influence the quality of a packaged food product. One type of these that have attracted extensive interest is self-healable films and coatings, which show the elegant, autonomous crack repairing ability upon the presence of appropriate stimuli. They exhibit increased durability and effectively lengthen the usage lifespan of the package. Over the years, extensive efforts have been paid to the design and development of polymeric materials that show self-healing properties; however, till now most of the discussions focus on the design of self-healable hydrogels. Efforts devoted to delineating related advances in the context of polymeric films and coatings are scant, not to mention works reviewing the use of self-healable polymeric materials for smart food packaging. This article fills this gap by offering a review of not only the major strategies for fabrication of self-healable polymeric films and coatings but also the mechanisms of the self-healing process. It is hoped that this article cannot only provide a snapshot of the recent development of self-healable food packaging materials, but insights into the optimization and design of new polymeric films and coatings with self-healing properties can also be gained for future research.

Similar content being viewed by others

Introduction

Packaging films and coatings can be used to protect a food product from the harsh environment, and to provide ingredient and nutritional information about the food1,2. Till now different types of materials have been adopted for food packaging applications. Examples of these include metals (e.g., aluminium foil and tinplate), glass and polymers3,4,5,6,7,8. Among them, polymers are the most extensively studied group partly because of their high structural flexibility and property tunability9,10,11,12. For example, starch films have been reported as edible clusteroluminogenic films to package frozen foods13. Food-grade polyelectrolyte complex films generated via electrostatic interactions between hypromellose-graft-chitosan and carboxymethylcellulose sodium (CMC) have also been designed for food packaging applications14. The films exhibit good barrier properties and high transparency. Owing to the antibacterial properties of the chitosan (CS) moiety, the films can inhibit the growth of both Gram-negative and Gram-positive bacteria14. Importantly, the physical properties (including the mechanical strength and water vapour permeability) of the films can be tuned easily by manipulating the film constituents14. Such high tunability in the properties of a polymeric film has also been observed in a film generated from a cellulose derivative15. The UV-shielding capacity and wettability of the film can be altered simply by changing the molecular weight of the derivative or the concentration of the film-forming solution15. This enables the properties of the film to be tuned to meet different needs of the food product to be packaged.

Despite the advances in the development of packaging materials and in optimization of material properties as mentioned above, proper functioning of the packaging materials is secured only when those materials remain intact. The food package may, however, be damaged during storage and transportation, leading to an irreversible decline in the ability of the package to protect the food from outside influences16,17,18,19. To address this problem, one strategy is to render the film and coating self-healable. Over the years, extensive efforts have been devoted to the development of self-healable polymeric materials; however, most of the discussions made in the literature are confined to self-healable hydrogels20,21,22,23,24. Efforts devoted to examining related advances in the context of polymeric food packaging films and coatings are scant. In order to fill this gap, the objectives of this article are to review existing strategies for fabrication of self-healable polymeric packaging films and coatings, and to revisit major mechanisms of the self-healing process. It is hoped that by reviewing the recent development of self-healable food packaging materials, insights into the optimization and design of smart packaging materials with self-healing properties can be attained for future research.

Mechanisms of the self-healing process exhibited by smart packaging materials

As far as self-healing of films and coatings is concerned, it can be extrinsic or intrinsic. Extrinsic self-healing is achieved mainly by adding a healing agent, which is embedded in capsules or vascular networks, into the polymer matrix during the film-forming process25. Inclusion of capsules or vascular networks, however, may reduce the mechanical strength of the generated film and coating. Along with the instability of the healing agent, applications of extrinsic self-healing are limited. An alternative to extrinsic self-healing is the intrinsic one, which relies on reversible interactions within the polymer matrix to achieve the self-healing process upon the presence of an external stimulus. It is mediated mainly by chain movement and recombination26, without being needed to be driven by any external healing agent prefilled in capsules or vascular networks. The possible integration of intrinsic self-healing into the design of a packaging material is partially demonstrated by the case of hydrophobic films generated from cellulose and natural wax27. The films can be obtained by first dispersing natural wax emulsion latex in an iced alkali/urea aqueous system, in which cotton linter pulp is also dissolved, to generate a cellulose/natural wax suspension27. Upon the process of solution casting and annealing treatment, the suspension is converted into films showing high tensile strength, good hydrophobicity, and good biodegradability27. After annealing treatment at elevated temperature to stimulate the release of wax from the inside to the surface of the cellulose matrix, damage in the films can be healed27. In addition, upon treatment with humidity, poly(vinyl alcohol) (PVA)-based packaging films containing layered double hydroxide (LDH) nanoplatelets and poly(sodium styrene-4-sulfonate) (PSS) can undergo self-healing upon damage28.

Intrinsic self-healing can be made possible by incorporating dynamic molecular interactions into the matrix of the packaging material (Table 1)29,30,31,32,33,34,35,36,37. One type of these interactions is Schiff base formation, which has been reported to be achieved when CS interacts with dialdehyde-modified cellulose nanocrystals (CNCs)38, zinc phthalocyanine tetra-aldehyde39, vanillin40 and dialdehyde starch41. Other examples of reversible interactions include hydrogen bonding interactions and electrostatic interactions. They can be obtained when CS interacts with poly(acryloyl-phenylalanine)42, CMC43, sodium alginate (SA)44, and poly(acrylic acid)45. So far electrostatic interactions are the most extensively adopted interactions exploited for the design of self-healable food packaging films. To achieve such interactions, a polycation and a polyanion are often involved during film fabrication. One good example is the polyelectrolyte multilayered edible film generated from negatively charged CMC and positively charged CS via layer-by-layer (LbL) electrostatic deposition43. Due to the antibacterial properties of CS, the film can inhibit the growth of Gram-negative bacteria43. The scratched film can undergo self-repair upon the addition of water to the damaged region43. By using freshly-cut apples as a model, the film has demonstrated good capacity in inhibiting the enzymatic browning process and the weight loss of the apples43. All these reveal the application potential of the film in fruit preservation.

Another type of interactions used in intrinsic self-healing is hydrogen bonding. The possible use of this in the design of self-healable packaging materials has been shown by the case of a zwitterionic anti-fogging coating generated from (methacryloyloxy)ethyldimethyl-(3-sulfopropyl), which is copolymerized by itaconic acid via the process of radical polymerization46. Because of the presence of hydrophilic groups in (methacryloyloxy)ethyldimethyl-(3-sulfopropyl), the coating shows anti-fogging capacity46. In addition, itaconic acid plays a role in mediating formation of reversible non-covalent hydrogen bonding interactions in the coating, rendering the coating self-healable46. Importantly, the (methacryloyloxy)ethyldimethyl-(3-sulfopropyl) moiety can adsorb water molecules, producing a protective layer on the coating surface to prevent adsorption of hydrophobic contaminants46. This allows the coating to show good self-cleaning properties. Besides Schiff base formation and hydrogen bonding interactions, host-guest interactions have been exploited during the design of self-healable food packaging materials. This is demonstrated by the case of the coating generated from SA and l-menthol-β-cyclodextrin-graft-CS47. During coating fabrication, β-cyclodextrin (β-CD) is first diluted in dimethyl sulfoxide and isobutyl alcohol, followed by the addition of sodium hydroxide and epichlorohydrin. Upon the addition of CS, β-CD-grafted CS is formed. It is then dissolved in water, and mixed with an alcoholic solution of l-menthol to form a complex solution. The solution is spin-coated on a glass substrate pre-coated with an aqueous solution of SA. The multi-layered coating is formed after multiple cycles of deposition. Incorporation of l-menthol has been found to increase intermolecular interactions among molecules inside the coating, leading to formation of a denser coating structure and hence an increase in the water vapour barrier capacity47. In addition, the incorporation of l-methanol makes the coating more hydrophobic and transparent47. The self-healing efficiency of the coating has been found to increase from 52.56% to 59.49% after the addition of l-menthol47. This is largely because the presence of l-methanol enables the damaged coating to undergo not only electrostatic interactions between polymer chains but also host-guest interactions between β-CD and l-menthol. This enhances the self-healing capacity of the coating.

Strategies for fabrication of self-healable food packaging materials

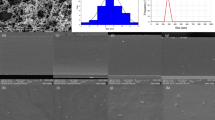

Over the years, different strategies (ranging from solvent casting and extrusion to dipping and panning) have been reported for generation of polymeric films and coatings (Table 2)32,48,49,50,51,52,53. As far as self-healable films and coatings are concerned, the LbL assembly approach is, however, the most commonly adopted one. This may be partially because the LbL assembly procedure is easy to be performed and allows the properties (e.g., the thickness of the film and the composition of each layer) to be precisely controlled, thereby enabling the performance of the self-healable film and coating to be better fine-tuned. By using this method, transparent films have previously been generated from acrylamide-modified CS (AMC) (having a degree of substitution of 0.54) and alginate aldehyde (ADA) (having an oxidation degree of 50%) via formation of the Schiff base linkage54. During film fabrication, polyethylenimine (PEI) is first pre-deposited on a glass slide (Fig. 1), which is pre-treated with a Piranha solution to endow it with negative surface charge. This process can facilitate the subsequent LbL assembly procedure54. The slide pre-deposited with PEI is immersed in an aqueous solution of ADA, followed by being rinsed in phosphate-buffered saline (PBS)54. An aqueous solution of AMC is coated on the slide via the process of spin-coating54. After the removal of unadsorbed AMC molecules, the first deposition cycle of the film is complete54. Characterization by ultraviolet-visible spectroscopy and field emission scanning electron microscopy reveals that the film undergoes linear growth during the LbL process54. The thickness of the film is in the range of 0.6 ± 0.10 μm (3 bilayers) to 2.7 ± 0.05 μm (15 bilayers)54. Once the film is damaged by using a razor blade and drops of water are added to the damaged zone, the crack fades upon 1 min and disappears after 2 min. This self-healing process is hypothesized to be caused by water-induced swelling of the film and the high mobility of the polymer network54. Both of these factors are expected to play a role in facilitating the reconstruction of the Schiff base linkage to heal the damaged film.

a A schematic diagram illustrating the process of ADA/AMC film preparation; b Mechanism of formation of the Schiff base linkage; c (i–iii) Microscopic and (iv–vi) SEM images of the ADA/AMC film exhibiting self-healing: (i, iv) fresh cut, (ii, v) self-healing for 1 min, and (iii, vi) self-healing for 2 min. The film has undergone six cycles of deposition. The scale bar in (i), (ii) and (iii) represents 100 µm. The scale bar in (iv), (v) and (vi) represents 5 µm. Reproduced from 48 with permission from American Chemical Society.

Since the turn of the last century, deep eutectic solvents have been employed for fabrication of self-healable films. These solvents were first reported in early 2000’s when a mixture of urea and choline chloride was found to be in the liquid state at ambient conditions55. Owing to charge delocalization caused by hydrogen bonding interactions between urea molecules and chloride ions, the mixture melts at a temperature lower than the melting point of each of the constituents55. Deep eutectic solvents show various favourable properties such as high chemical stability, non-flammability, high thermal stability and low volatility55. In addition, by modulating the molar ratio of different constituents, the properties of the deep eutectic solvent can be tuned55. Over the years, deep eutectic solvents have been used as modifiers of diverse polysaccharides (ranging from starch56 to guar gum57) owing to their capacity of forming a network of hydrogen bonds. Recently, a deep eutectic solvent, which consists of citric acid and choline chloride, has been used to combine with CS to generate a self-healable film58. Owing to the dynamic network of hydrogen bonds between CS and the components of the deep eutectic solvent, the mechanical strength of the generated film can be recovered after damage58. This demonstrates the possible role played by deep eutectic solvents in the design of self-healable films and coatings for food packaging.

Optimization and engineering of self-healable food packaging materials

In order to achieve the optimal performance of a self-healable film and coating, proper consideration of multiple factors is required (Fig. 2). One factor to be considered during the design of self-healable food packaging materials is the thickness of the film and coating. It may affect the number of times the damaged packaging material can be self-healed. This is demonstrated by the case of AMC/ADA films54. While films with different thickness show no significance difference in their healing time, the number of healing cycles increases as the thickness of the films increases54. This is due to the fact that a thicker film contains more free amino groups and aldehyde groups for reconstruction of the Schiff base linkage to heal the damaged area54. Another important factor to be considered is the chemical nature of the film constituent. Compared with coatings generated from proteins and lipids, those generated from polysaccharides are comparatively stable in performance and can be produced in a lower cost due to the natural abundance of polysaccharides59. In addition, incorporation of a nanobrick wall structure, in which layered materials and polymers are stacked with nanoplatelets, into a film or coating has been shown to enhance the performance of the generated product60. Common examples of nanoplatelets used for this purpose include graphene, LDH, and montmorillonite (MMT)60. Among them, MMT has attracted great interest because of its low cost and its high dispersibility in polymer solutions. Recently, Manabe and co-workers have developed a cephalopods-inspired self-healable nanoclay composite coating for food packaging applications60. The coating is an MMT-containing ion-doped multilayer membrane composed of branched PEI (bPEI) and poly(acrylic acid) (PAA). Not only can the presence of the counterions reduce the charge density of the polymer but it can also convert the conformation of the polymer from a loop structure to a train structure60. This helps improve the capacity of the coating in water absorption and retention60. In addition, the LbL approach allows the thickness of the coating to be finely tuned60. The process of self-healing is initiated upon the immersion of the coating into water60. Compared with the conventional non-ion-doped polymer multilayer in which the carboxyl groups of PAA dissociate completely and form bonds with PEI, the MMT-containing ion-doped counterpart enables repair of damage to be completed within a much shorter timeframe60. This is attributed to the fact that the addition of counterions and MMT inhibits formation of bonding interactions among polymer chains in the multilayer, thereby enhancing the mobility of the polymer chains during the self-healing process.

When a food packaging film is designed, bonding interactions involved in film formation and repair play a principal role in determining the ultimate properties of the film generated. In general, non-covalent interactions are weaker than covalent bonds61,62. Using different dynamic non-covalent bonding interactions to replace the conventional covalent ones in film design may result in a decline in the mechanical strength of the generated film. The trade-off between the self-healing capability and the mechanical strength, therefore, has to be considered. Among diverse film properties, the barrier properties, particularly gas permeability, are crucial to be taken into account during film design. In fact, oxidation in food products is one of the biggest problems to be addressed during food preservation63,64,65,66,67,68. This problem is particularly serious in food products (such as fish oils, nuts, and fishery products) rich in fats69. Lipid oxidation is one of the major processes leading to deterioration of the sensory attributes of a food product70,71. It leads to formation of toxic aldehydes, and causes a loss of nutritional values72. This problem is particularly severe in food products that possess a high content of polyunsaturated fatty acids (PUFAs)1, which are susceptible to oxidation reactions that can be initiated once a hydrogen atom is abstracted from an unsaturated fatty acid to produce an alkyl radical73. Because the initiation reaction is not thermodynamically favourable, an alkyl radical is generated mainly in the presence of pigments (which serve as photoensitizers) or singlet state oxygen74. The latter is produced when a food product is exposed to UV light or temperature change74. In addition, the generated alkyl radical can react with O2 to produce a peroxyl radical, which can abstract a hydrogen atom from an unsaturated fatty acid to generate a new alkyl radical and a lipid hydroperoxide75. The lipid hydroperoxide is tasteless and odourless; however, in the presence of light and heat, it can decompose to compounds that produce off-flavours. A large variety of volatile compounds (including alkenes, alkanes, aldehydes, and alkanals) are also generated during the process of lipid peroxidation. Some of these compounds (such as dimethyl disulphide, pentanal, hexanal, 3-hydroxy-2-butanone, 2-hexenal, butanoic acid, methanethiol, nonenone, 2-nonenal, and dimethyl trisulfide) can give off-odours73,74. To retard oxidative deterioration of a food product, one strategy is to lower the localized concentration of oxygen in a food package. Over the years, a variety of packaging materials showing low oxygen permeability have been designed76,77,78. Despite this, long-term durability is a problem that has yet to be fully solved. Influx of oxygen will occur when the films and coatings are flexed or when a crack is formed. This reduces the shelf life of the food product.

The possibility of manipulating the barrier properties of a self-healable food packaging material has been revealed by a recent study, in which humidity-triggered self-healable films with excellent oxygen barrier performance have been developed using the LbL self-assembly technique (Fig. 3)28. During film fabrication, a substrate is first dipped into a colloidal suspension of LDH nanoplatelets, followed by a washing step before the substrate is further immersed in an aqueous solution of PSS. After alternate deposition of LDH nanoplatelets and PSS for a number of cycles, the LbL films are produced. The films are then immersed in a PVA solution to enable PVA molecules to permeate into the films. Proper optimization of the process of PVA permeation is vital to enable the generated films to show high self-healing capacity28. While the self-healing performance will be poor if the PVA coating is too thin, the healing time needed by the films will be very long if the coating is too thick28. In addition, PVA permeation causes the films to have a more compact structure, leading to a decrease in the oxygen transmission rate (OTR)28. Upon flexing, the OTR of the films increases. Yet, the oxygen diffusion resistance of the films can be recovered after being put in an environment with the humidity of around 85%28. This demonstrates the humidity-triggered self-healing capability of the films.

Applications of self-healable polymeric materials in smart food packaging

Films and coatings can be applied to package different food types, ranging from seafood to fruits and vegetables. For example, the self-healable polyurethane films, in which diacetyl oxime and coumarin diol serve as the reactive filler, have been applied to package shrimps, with their fluorescence intensity and colour being able to function as a sensor for real-time and visual monitoring of the freshness of seafood (Fig. 4)79. Edible self-healable coatings generated from SA and l- menthol-β-cyclodextrin-graft-CS have also been used to improve the post-harvest quality and to prolong the shelf life of fruits and vegetables47. During fruit preservation, the fruit is first immersed in a hypochlorite solution for 30 s before being flushed with distilled water. It is then immersed in a SA solution for 6 min, followed by immersion in a clathrate complex solution for 6 min. After the coating is air-dried at ambient conditions, another cycle of the coating process is conducted. In total 10 deposition cycles are performed. After 30 days of storage, the uncoated fruit has been reported to have a weight loss of around 15% whereas the coated one has only had a weight loss of 7.6%47. Compared to the uncoated counterpart, the coated one has also been found to be 15.23 % higher in its firmness47. All these illustrate the effectiveness of self-healable packaging materials in preserving different types of food products.

Despite the practical potential of self-healable packaging materials as mentioned above, till now self-healable films and coatings reported in the literature have been examined mostly in fruit and vegetable packaging. This may be partially because fruits and vegetables are fragile products with high water content. Along with the fact that changes in their quality can be easily detected based on their appearance and weight change, fruits and vegetables serve as favourite models in evaluating the performance of a food packaging film. Over the last several decades, different films possessing self-healing capacity have been exploited to package fruits and vegetables. For instance, by using a 3-layered film consisting of CS and CMC to coat lemon fruits (Citrus aurantifolia Swingle), the pectinase enzyme activity (as well as the loss of vitamin C) of the coated fruits has been shown to be much lower than that of the uncoated ones80. The application potential of self-healable polymeric films and coatings in postharvest preservation of fruits has been further demonstrated by the case of the smart edible coating generated from CS and beeswax-pollen grains81. During coating preparation, beeswax, glycerol, pollen grains and tween 80 are added to an acetic acid solution containing CS, glycerol and calcium chloride dihydrate81. The presence of edible hydrophobic components such as beeswax and pollen grains help improve the physical and barrier properties of the CS-based coating81. Once the coating is damaged, calcium ions can diffuse along the interface of the cut points and help re-establish dynamic supramolecular interactions (including electrostatic interactions and hydrogen bonding interactions) to heal the damaged area81. The self-healing efficiency of the coating is estimated to be around 80–90%81. By using Le Conte pears as a model, the weight loss percentage of the coated fruits under cold storage conditions has been found to be much less than that of the uncoated counterparts81. Owing to the ability of the coating to restrict gas exchange through the peel and to inhibit ethylene gas generation, the coated pears are more resistant to decay as compared to the uncoated ones81. The coating can also inhibit water loss and the activity of pectin-degrading enzymes81. This retards the rate of fruit softening. Compared to the uncoated pears or those coated with either CS or a mixture of beeswax and pollen grains, those coated with both CS and beeswax-pollen grains exhibit better appearance and an increase in the total soluble solid percentage (Fig. 5)81.

a Scanning electron microscopic images of the CS-beeswax/pollen grains coating at various magnification scales. The scale bar in (i), (ii), (iii) and (iv) represents 1 mm, 200 µm, 30 µm and 10 µm, respectively. b Appearance of (i) uncoated pears, (ii) pears coated with CS alone, (iii) pears coated with a mixture of beeswax and pollen grains, and (iv) pears coated with both CS and beeswax-pollen grains. The pears have been stored at 0 ± 1 °C for 105 days and at 23 ± 2 °C for 1 week. Reproduced from 80 with permission from Royal Society of Chemistry.

Recently, one multi-layered coating showing self-healing capacity has been developed to extend the shelf life of fruits44. During coating formation, a substrate is repeatedly immersed in an acetic acid solution of CS and an aqueous solution of SA44. Molecules of CS and SA in the coating are linked to each other via both hydrogen bonds and ionic bonds44. Microscopic examination reveals that the coating has a smooth surface, with the hydrophobicity of the coating depending largely on the properties of the outer layer but not on the interactions between SA and CS44. In addition, the degree of mobility of the polyelectrolyte multilayer is influenced by the number of deposition cycles during coating formation44. Healing of the coating can be initiated upon the addition of water, which can accelerate the movement of molecules between layers of the coating. This enables the mechanical strength, oxygen barrier capacity and water vapour barrier properties of a damaged coating to be recovered44. The performance of the coating in fruit preservation has been evaluated by using strawberries as a model. Five days after the coating process, spoilage has been found to be lower in coated strawberries than in the uncoated ones. This is partly due to the antibacterial activity of CS. The coating has also been shown to inhibit water loss from the strawberries, and to lower the content of malondialdehyde (MDA), which is a secondary end-product of membrane lipid peroxidation and can serve as an indicator of oxidative stress82. Importantly, while damage of the coating can lead to an increase in the water vapour permeability and oxygen permeability and hence an accumulation of MDA, such effects have been successfully reduced upon the healing of the coating.

Opportunities and challenges for practical applications

When films and coatings are generated, various additives may be added to manipulate the properties and to increase the functionality. For example, CNCs have been extracted from cotton textile waste and modified with methacrylamide (MAM)83. Composite films, consisting of cellulose acetate and poly(vinyl chloride), have been found to show higher mechanical and UV barrier properties upon the incorporation of MAM-CNCs83. After chlorination, MAM-CNCs also enable the composite films to act against both Staphylococcus aureus ATCC 6538 and Escherichia coli K1283. Recently, incorporation of quaternized CNCs into PVA films as nanofillers has been reported to give the films higher tensile strength and higher antibacterial activity84. Apart from nanofillers as mentioned above, plasticizers can be added to help weaken intermolecular interactions among polymer chains85, thereby reducing the tension of deformation exhibited by the film, improving the polymer chain flexibility86,87,88,89,90 and increasing the resistance of the generated film to fracture85. Examples of commonly used plasticisers include polyols (e.g., sorbitol, polyethylene glycol, and glycerol) and lipids85. Despite the possible use of these agents in improving film properties, migration of these chemicals from a packaging film to a food product may lead to not only concerns on toxicity but also changes in the sensory attributes and quality of the food. Migration is defined as the mass transfer of substances from the packaging material to the packaged food91. It is one of the major safety concerns in food packaging. As stated by the European Union (EU) regulations, there should be no constituent of a food contact material that can transfer to the packaged food in an amount that can either endanger the health of the consumer or deteriorate the organoleptic features of the food91. In order to determine the safety profile of a packaging film and coating, migration tests can be conducted. However, such tests are time-consuming and laborious91. The accuracy of such tests is also hampered when proper analytical methods to determine the migrant are lacking92. This problem is compounded by the fact that compounds added to the film and coating may react with other packaging material constituents or food components, leading to formation of new chemical entities that are overlooked when detecting potential migrants. In addition, different food compositions and storage conditions may cause changes in the level of migration of substances from the packaging material to the packaged food91. All these make eradication of safety concerns on the generated films and coatings difficult, thereby impeding the practical use of those films and coatings in practice. To enhance the accuracy of migration tests, apart from using the actual conditions of storage of the real food product as the experimental conditions used in migration tests, the food model adopted should be the same as the food product to be packaged by using the film and coating under investigation. More sophisticated methods have to be developed to predict products formed via possible reactions between packaging material constituents and food components. Efforts are also needed to be paid to the development of analytical techniques with high sensitivity and specificity.

Apart from examining the safety of plasticizers, it is important to determine the number of tolerable damage-repair cycles that can be undertaken by a self-healable packaging material before the material is applied to package real products. However, most of the studies in the literature reporting the development of a self-healable polymeric food packaging material have only examined the efficiency of single-time healing. The capacity in multi-time healing has rarely been determined. This may be because, in the current approach to evaluate the self-healing performance, a cut on the material is often created manually by using scalpels or blades. The width and depth of the cut can hardly be precisely controlled, not to mention the difficulty of making the same cut in exactly the same position multiple times. This impedes the generated self-healable material to be translated from a laboratory to routine food packaging applications. Light to solve this problem has been shed recently by the emergence of colloidal lithography, which makes the generation of repeatable cuts with precisely controllable depth, width, shape, and location possible93. This approach has been reported to successfully generate cuts in the form of nanorods, nanowells, and microstripes on a self-healable PEI/PAA film93, enabling the limitation of a self-healable film and coating undergoing repeated damage to be studied.

Last but not least, right now most of the self-healable films and coatings reported in the literature have been evaluated only by using fruits and vegetables as the models. Here it is worth noting that films and coatings generated by using components (e.g., CS and CMC) of many of those self-healable counterparts have in fact been shown to be applicable to package many other food products. For example, CS films incorporated with Cinnamodendron dinisii Schwanke essential oil-loaded zein have been reported to successfully stabilize the deterioration reactions in ground beef94. Farsi gum-CMC films containing Ziziphora clinopodioides essential oil and lignocellulose nanofibers have also been exploited as packaging materials to extend the shelf life of fresh minced beef meat95. Although these packaging materials are not self-healable films and coatings, their success in packaging food products other than vegetables and fruits implicates the worth of exploiting the packaging performance of self-healable materials beyond mere fruit and vegetable preservation.

Concluding remarks and future outlook

Self-healable packaging materials can maintain their protection of the packaged food even upon damage, and hence show practical values in both food product development and food preservation. In sections above, the latest status of the design and applications of self-healable films and coatings for food packaging have been presented. While several issues (including the development of more effective strategies to evaluate film migration and to determine the number of tolerable damage-repair cycles) have to be addressed to enhance practical translation of the generated films and coatings, some unmet needs in current research on self-healable packaging materials are also worth noting for future research. For example, at the moment the self-healing capacity of packaging materials have been evaluated in the literature predominately by using only simple qualitative approaches, in which the healing time and healing efficiency are determined simply under a microscope. Along with the fact that the depth, width and position of a cut made on the films and coatings in different studies are different, a fair comparison of the self-healing capacity of different reported packaging materials is basically impossible.

For future research, development of a more standardized and quantitative procedure to examine the self-healing performance is desired. This allows films and coatings generated in different laboratories to be fairly compared, thereby enabling more effective candidates to be selected for further development. In addition, at the moment self-healing of the reported food packaging materials largely requires the use of an external stimulus (ranging from humidity to elevated temperature) as a trigger. This implies that, if those films and coatings are used in a real situation, the self-healing process will function well only when any damage imposed on the films and coatings can be identified in real time and be immediately treated. This is obviously impractical. Development of films and coatings that can undergo automatic self-healing is, therefore, a direction that is worth exploration in future research. Clearly there is still some way to go before self-healable films and coatings can be routinely adopted in food packaging, but with the increasing sophistication of techniques in chemical synthesis and film optimization96,97,98,99,100,101, along with the merit brought about by the self-healing property, it is anticipated that self-healable materials will continue to contribute to food preservation in the forthcoming decades.

Data availability

Data sharing is not applicable. This is a review article and no new datasets were generated or analyzed during this article.

References

Lai, W. F. Design of polymeric films for antioxidant active food packaging. Int. J. Mol. Sci. 23, 12 (2021).

Xie, Q. W. et al. Active edible films with plant extracts: a updated review of their types, preparations, reinforcing properties, and applications in muscle foods packaging and preservation. Crit. Rev. Food Sci. 27, 1–23 (2022).

Pietrosanto, A., Scarfato, P., Di Maio, L. & Incarnato, L. Development of eco-sustainable pbat-based blown films and performance analysis for food packaging applications. Materials 13, 5395 (2020).

Najwa, I. S. N. A., Yusoff, M. M. & Hanani, Z. A. N. Potential of silver-kaolin in gelatin composite films as active food packaging materials. Food Packag. Shelf Life 26, 100564 (2020).

Montes-de-Oca-Avalos, J. M. et al. Physical and structural properties of whey protein concentrate—Corn oil—TiO2 nanocomposite films for edible food-packaging. Food Packag. Shelf. Life 26, 100590 (2020).

Mahuwala, A. A. et al. Synthesis and characterisation of starch/agar nanocomposite films for food packaging application. IET Nanobiotechnol 14, 809–814 (2020).

Avila, L. B. et al. Carrageenan-based films incorporated with jaboticaba peel extract: an innovative material for active food packaging. Molecules 25, 5563 (2020).

Humbert, S., Rossi, V., Margni, M., Jolliet, O. & Loerincik, Y. Life cycle assessment of two baby food packaging alternatives: glass jars vs. plastic pots. Int. J. Life Cycle Ass. 14, 95–106 (2009).

Idumah, C. I., Zurina, M., Ogbu, J., Ndem, J. U. & Igba, E. C. A review on innovations in polymeric nanocomposite packaging materials and electrical sensors for food and agriculture. Compos. Interface 27, 1–72 (2020).

Huang, T. Q., Qian, Y. S., Wei, J. & Zhou, C. C. Polymeric antimicrobial food packaging and its applications. Polymers 11, 560 (2019).

Vasile, C. Polymeric nanocomposites and nanocoatings for food packaging: a review. Materials 11, 1834 (2018).

Opran, C. G., Grosu, E. & Enachescu, M. Research regarding the mechanical properties of some biodegradable polymeric composites for food packaging products. Mater. Plast. 55, 498–501 (2018).

Lai, W. F. & Wong, W. T. Edible clusteroluminogenic films obtained from starch of different botanical origins for food packaging and quality management of frozen foods. Membranes 12, 437 (2022).

Lai, W. F., Zhao, S. & Chiou, J. Antibacterial and clusteroluminogenic hypromellose-graft-chitosan-based polyelectrolyte complex films with high functional flexibility for food packaging. Carbohydr. Polym. 271, 118447 (2021).

Lai, W. F., Yip, W. & Wong, W. T. UV-shielding and clusteroluminogenic cellulose-based films with tuneable wettability and permeability for dually self-indicating food packaging. Adv. Mater. Technol. 6, 2100120 (2021).

Min, T. T. et al. Electrospun functional polymeric nanofibers for active food packaging: a review. Food Chem. 391, 133239 (2022).

Kathuria, A. & Zhang, S. J. Sustainable and repulpable barrier coatings for fiber-based materials for food packaging: a review. Front. Mater. 9, 929501 (2022).

Iversen, L. J. L. et al. The emergence of edible and food-application coatings for food packaging: a review. Molecules 27, 5604 (2022).

Gupta, V., Biswas, D. & Roy, S. A comprehensive review of biodegradable polymer-based films and coatings and their food packaging applications. Materials 15, 5899 (2022).

Lai, W. F. Development of hydrogels with self-healing properties for delivery of bioactive agents. Mol. Pharm. 18, 1833–1841 (2021).

Wang, L. et al. Poly(N,N-dimethyl)acrylamide-based ion-conductive gel with transparency, self-adhesion and rapid self-healing properties for human motion detection. Soft Matter 18, 6115–6123 (2022).

Wang, J. T. et al. Enhanced delivery of neuroactive drugs via nasal delivery with a self-healing supramolecular gel. Adv. Sci. 8, e2101058 (2021).

Li, X. et al. Flexible and self-healing aqueous supercapacitors for low temperature applications: polyampholyte gel electrolytes with biochar electrodes. Sci. Rep. 7, 1685 (2017).

Hao, M. et al. Stretchable, self-healing, transient macromolecular elastomeric gel for wearable electronics. Microsyst. Nanoeng. 5, 9 (2019).

White, S. R. et al. Autonomic healing of polymer composites. Nature 409, 794–797 (2001).

Hu, Z. et al. Efficient intrinsic self-healing epoxy acrylate formed from host-guest chemistry. Polymer 164, 79–85 (2019).

Zhu, M., Ying, D., Zhang, H., Xu, X. & Chang, C. Self-healable hydrophobic films fabricated by incorporating natural wax into cellulose matrix. Chem. Eng. J. 446, 136791 (2022).

Dou, Y. B. et al. Humidity-triggered self-healing films with excellent oxygen barrier performance. Chem. Commun. 50, 7136–7138 (2014).

Yesilyurt, V. et al. Injectable self-healing glucose-responsive hydrogels with ph-regulated mechanical properties. Adv. Mater. 28, 86–91 (2016).

Yu, H., Wang, Y., Yang, H., Peng, K. & Zhang, X. Injectable self-healing hydrogels formed via thiol/disulfide exchange of thiol functionalized F127 and dithiolane modified PEG. J. Mater. Chem. B 5, 4121–4127 (2017).

Qu, J., Zhao, X., Ma, P. X. & Guo, B. pH-responsive self-healing injectable hydrogel based on N-carboxyethyl chitosan for hepatocellular carcinoma therapy. Acta Biomater. 58, 168–180 (2017).

Auepattana-Aumrung, K. & Crespy, D. Self-healing and anticorrosion coatings based on responsive polymers with metal coordination bonds. Chem. Eng. J. 452, 139055 (2023).

Ghanian, M. H., Mirzadeh, H. & Baharvand, H. In situ forming, Cytocompatible, and self-recoverable tough hydrogels based on dual ionic and click cross-linked alginate. Biomacromolecules 19, 1646–1662 (2018).

Ye, X. et al. Self-healing pH-sensitive cytosine- and guanosine-modified hyaluronic acid hydrogels via hydrogen bonding. Polymer 108, 348–360 (2017).

Zhang, E. et al. A highly efficient bionic self-healing flexible waterborne polyurethane elastic film based on a cyclodextrin-ferrocene host-guest interaction. Polym. Chem. 12, 831–842 (2021).

Owusu-Nkwantabisah, S., Gillmor, J. R., Switalski, S. C. & Slater, G. L. An autonomous self-healing hydrogel based on surfactant-free hydrophobic association. J. Appl. Polym. Sci. 134, 44800 (2017).

Guo, W., Li, X., Xu, F., Li, Y. & Sun, J. Transparent polymeric films capable of healing millimeter-scale cuts. ACS Appl. Mater. Interfaces 10, 13073–13081 (2018).

Huang, W. et al. On-demand dissolvable self-healing hydrogel based on carboxymethyl chitosan and cellulose nanocrystal for deep partial thickness burn wound healing. ACS Appl. Mater. Interfaces 10, 41076–41088 (2018).

Karimi, A. R. & Khodadadi, A. Mechanically robust 3D nanostructure chitosan-based hydrogels with autonomic self-healing properties. ACS Appl. Mater. Interfaces 8, 27254–27263 (2016).

Xu, C. et al. Self-healing chitosan/vanillin hydrogels based on Schiff-base bond/hydrogen bond hybrid linkages. Polym. Test. 66, 155–163 (2018).

Ren, J. et al. Adherent self-healing chitosan/dialdehyde starch coating. Colloids Surf. A Physicochem. Eng. Asp. 586, 124203 (2020).

Sharma, S. et al. Development of a novel chitosan based biocompatible and self-healing hydrogel for controlled release of hydrophilic drug. Int. J. Biol. Macromol. 116, 37–44 (2018).

Liu, X. et al. Anti-oxidative and antibacterial self-healing edible polyelectrolyte multilayer film in fresh-cut fruits. J. Nanosci. Nanotechnol. 18, 2592–2600 (2018).

Du, Y. et al. Fabrication of novel self-healing edible coating for fruits preservation and its performance maintenance mechanism. Food Chem. 351, 129284 (2021).

Zhu, Y., Xuan, H., Ren, J. & Ge, L. Self-healing multilayer polyelectrolyte composite film with chitosan and poly(acrylic acid). Soft Matter 11, 8452–8459 (2015).

Yang, H. et al. Facile preparation of a high-transparency zwitterionic anti-fogging poly(SBMA-co-IA) coating with self-healing property. Prog. Org. Coat. 165, 106764 (2022).

Yang, Y., Ren, J., Luo, C., Yuan, R. & Ge, L. Fabrication of l-menthol contained edible self-healing coating based on guest-host interaction. Colloids Surf. A Physicochem. Eng. Asp. 597, 124743 (2020).

Calderon-Castro, A. et al. Effect of extrusion process on the functional properties of high amylose corn starch edible films and its application in mango (Mangifera indica L.) cv. Tommy Atkins. J. Food Sci. Technol. 55, 905–914 (2018).

Zhang, W., Li, X. & Jiang, W. Development of antioxidant chitosan film with banana peels extract and its application as coating in maintaining the storage quality of apple. Int. J. Biol. Macromol. 154, 1205–1214 (2020).

Zhang, W., Shu, C., Chen, Q., Cao, J. & Jiang, W. The multilayer film system improved the release and retention properties of cinnamon essential oil and its application as coating in inhibition to penicillium expansion of apple fruit. Food Chem. 299, 125109 (2019).

Valero, D. et al. Effect of alginate edible coating on preserving fruit quality in four plum cultivars during postharvest storage. Postharvest Biol. Technol. 77, 1–6 (2013).

Antoniewski, M. N., Barringer, S. A., Knipe, C. L. & Zerby, H. N. Effect of a gelatin coating on the shelf life of fresh meat. J. Food Sci. 72, 382–387 (2007).

Fadini, A. L. et al. Mechanical properties and water vapour permeability of hydrolysed collagen-cocoa butter edible films plasticised with sucrose. Food Hydrocoll. 30, 625–631 (2013).

Hu, B. A. et al. Layer-by-layer assembly of polysaccharide films with self-healing and antifogging properties for food packaging applications. ACS Appl. Nano Mater. 1, 3733–3740 (2018).

Abbott, A. P., Capper, G., Davies, D. L., Rasheed, R. K. & Tambyrajah, V. Novel solvent properties of choline chloride/urea mixtures. Chem. Commun. 2003, 70–71 (2003).

Zdanowicz, M., Staciwa, P., Jedrzejewski, R. & Spychaj, T. Sugar alcohol-based deep eutectic solvents as potato starch plasticizers. Polymers 11, 1385 (2019).

Depoorter, J. et al. Fully biosourced materials from combination of choline chloride-based deep eutectic solvents and guar gum. ACS Sustain. Chem. Eng. 7, 16747–16756 (2019).

Smirnov, M. A. et al. Self-healing films based on chitosan containing citric acid/choline chloride deep eutectic solvent. Polym. Test. 97, 107156 (2021).

Carissimi, M., Flores, S. H. & Rech, R. Effect of microalgae addition on active biodegradable starch film. Algal Res 32, 201–209 (2018).

Manabe, K., Koyama, E. & Norikane, Y. Cephalopods-inspired rapid self-healing nanoclay composite coatings with oxygen barrier and super-bubble-phobic properties. ACS Appl. Mater. Interfaces 13, 36341–36349 (2021).

Hernandez-Montelongo, J. et al. Electrostatic immobilization of antimicrobial peptides on polyethylenimine and their antibacterial effect against Staphylococcus epidermidis. Colloids Surf. B Biointerfaces 164, 370–378 (2018).

Ramaiah, D., Neelakandan, P. P., Nair, A. K. & Avirah, R. R. Functional cyclophanes: promising hosts for optical biomolecular recognition. Chem. Soc. Rev. 39, 4158–4168 (2010).

Schaich, K. Transition metals: multifaceted catalysts of lipid oxidation and degradation of food quality. Abstr. Pap. Am. Chem. Soc. 258, 1155 (2019).

Penicaud, C., Guillard, V., Peyron, S. & Gontard, N. Oxygen transfer coupled to oxidation reactions: numerical tool for optimising nutritional quality of food. Czech J. Food Sci. 27, S28–S28 (2009).

Nawaz, A. et al. Protein oxidation in muscle-based products: effects on physicochemical properties, quality concerns, and challenges to food industry. Food Res. Int. 157, 111322 (2022).

Pan, C. et al. Inhibitory effect of cinnamaldehyde on Fusarium solani and its application in postharvest preservation of sweet potato. Food Chem. 408, 135213 (2023).

Li, Y. X. et al. Antimicrobial mechanisms of spice essential oils and application in food industry. Food Chem. 382, 132312 (2022).

Yang, K. L. et al. Dysfunction of FadA-cAMP signalling decreases Aspergillus flavus resistance to antimicrobial natural preservative Perillaldehyde and AFB1 biosynthesis. Environ. Microbiol. 24, 1590–1607 (2022).

Hidalgo, F. J. Lipid oxidation and the formation of processing-induced toxicants in foods: acrylamide and heterocyclic aromatic amines. J. Am. Oil Chem. Soc. 98, 97–97 (2021).

Olson, J., Miyazawa, T. & Schaich, K. Are lipid oxidation products consumed in foods toxic? If so, where? J. Am. Oil Chem. Soc. 98, 96–96 (2021).

Decker, E. Why does lipid oxidation in foods continue to be such a challenge? J. Am. Oil Chem. Soc. 98, 6–6 (2021).

Guillen, M. D. & Goicoechea, E. Formation of oxygenated alpha,beta-unsaturated aldehydes and other toxic compounds in sunflower oil oxidation at room temperature in closed receptacles. Food Chem. 111, 157–164 (2008).

Barden, L. & Decker, E. A. Lipid oxidation in low-moisture food: a review. Crit. Rev. Food Sci. Nutr. 56, 2467–2482 (2016).

Brewer, M. S. Natural antioxidants: sources, compounds, mechanisms of action, and potential applications. Compr. Rev. Food Sci. Food Saf. 10, 221–247 (2011).

Tian, F., Decker, E. A. & Goddard, J. M. Controlling lipid oxidation of food by active packaging technologies. Food Funct. 4, 669–680 (2013).

Kim, J. K., Choi, B. & Jin, J. Transparent, water-stable, cellulose nanofiber-based packaging film with a low oxygen permeability. Carbohyd. Polym. 249, 116823 (2020).

Hosseinkhanli, H., Sharif, A., Aalaie, J., Khalkhali, T. & Akhlaghi, S. Oxygen permeability and the mechanical and thermal properties of (low-density polyethylene)/poly (ethylene-co-vinyl acetate)/organoclay blown film nanocomposites. J. Vinyl Addit. Techn. 19, 132–139 (2013).

Borreani, G. & Tabacco, E. Low permeability to oxygen of a new barrier film prevents butyric acid bacteria spore formation in farm corn silage. J. Dairy Sci. 91, 4272–4281 (2008).

Sai, F. et al. Multifunctional waterborne polyurethane films: Amine-response, thermal-driven self-healing and recyclability. Appl. Surf. Sci. 573, 151526 (2022).

Sultan, M., Hafez, O. M. & Saleh, M. A. Quality assessment of lemon (Citrus aurantifolia, swingle) coated with self-healed multilayer films based on chitosan/carboxymethyl cellulose under cold storage conditions. Int. J. Biol. Macromol. 200, 12–24 (2022).

Sultan, M., Hafez, O. M., Saleh, M. A. & Youssef, A. M. Smart edible coating films based on chitosan and beeswax-pollen grains for the postharvest preservation of Le Conte pear. RSC Adv. 11, 9572–9585 (2021).

Nguyen, V. T. B., Nguyen, D. H. H. & Nguyen, H. V. H. Combination effects of calcium chloride and nano-chitosan on the postharvest quality of strawberry (Fragaria x ananassa Duch.). Postharvest Biol. Technol. 162, 111103 (2020).

Huang, S., Li, S., Lu, X. & Wang, Y. Modification of cellulose nanocrystals as antibacterial nanofillers to fabricate rechargeable nanocomposite films for active packaging. ACS Sustain. Chem. Eng. 10, 9265–9274 (2022).

Meng, L. et al. Improved mechanical and antibacterial properties of polyvinyl alcohol composite films using quaternized cellulose nanocrystals as nanofillers. Compos. Sci. Technol. 232, 109885 (2023).

Espitia, P. J. P., Du, W. X., Avena-Bustillos, R. D. J., Soares, N. D. F. F. & McHugh, T. H. Edible films from pectin: physical-mechanical and antimicrobial properties—A review. Food Hydrocoll. 35, 287–296 (2014).

Syafiq, R. M. O., Sapuan, S. M., Zuhri, M. Y. M., Othman, S. H. & Ilyas, R. A. Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films. Nanotechnol. Rev. 11, 423–437 (2022).

Koker, H. S., Ersan, H. Y. & Aytac, A. The characterization of polyethylene/sodium caseinate films with different plasticizers produced by extrusion and its biodegradability. Kaut Gummi Kunst 74, 48–55 (2021).

Guo, S. X., Fu, Z. Q., Sun, Y., Wang, X. Y. & Wu, M. Effect of plasticizers on the properties of potato flour films. Starch-Starke 74, 2100179 (2022).

Caicedo, C., Diaz-Cruz, C. A., Jimenez-Regalado, E. J. & Aguirre-Loredo, R. Y. Effect of plasticizer content on mechanical and water vapor permeability of maize starch/pvoh/chitosan composite films. Materials 15, 1274 (2022).

Arifin, H. R. et al. Improved properties of corn starch-based bio-nanocomposite film with different types of plasticizers reinforced by nanocrystalline cellulose. Int. J. Food Prop. 25, 509–521 (2022).

Sanches Silva, A., Cruz, J. M., Sendon Garcı'a, R., Franz, R. & Paseiro Losada, P. Kinetic migration studies from packaging films into meat products. Meat Sci. 77, 238–245 (2007).

Begley, T. et al. Evaluation of migration models that might be used in support of regulations for food-contact plastics. Food Addit. Contam. 22, 73–90 (2005).

Chen, H., Cheng, F., Chen, C. & Li, H. Study on self-healing behavior of the layer-by-layer assembled polyethylenimine/poly(acrylic acid) film. J. Appl. Polym. Sci. 137, 49169 (2020).

Xavier, L. O. et al. Chitosan packaging functionalized with Cinnamodendron dinisii essential oil loaded zein: a proposal for meat conservation. Int. J. Biol. Macromol. 169, 183–193 (2021).

Bahari, R., Shahbazi, Y. & Shavisi, N. Effect of gamma irradiation on physico-mechanical and structural properties of active Farsi gum-CMC films containingZiziphora clinopodioidesessential oil and lignocellulose nanofibers for meat packaging. J. Food Sci. 85, 3498–3508 (2020).

Todhanakasem, T., Panjapiyakul, S. & Koombhongse, P. Novel pineapple leaf fibre composites coating with antimicrobial compound as a potential food packaging. Packag. Technol. Sci. 35, 97–105 (2022).

Zhou, M. L. et al. Hematite nanoparticle decorated MIL-100 for the highly selective and sensitive electrochemical detection of trace-level paraquat in milk and honey. Sens. Actuat. B Chem. 376, 132931 (2023).

Zhang, P., Luo, S. L. & Gao, D. Effects of poly(butylene adipate-co-terephthalate)/TiO2 nanocomposite antimicrobial films on chilled pork quality. Packag. Technol. Sci. 34, 709–715 (2021).

Lee, D. S., Wang, H. J., Jaisan, C. & An, D. S. Active food packaging to control carbon dioxide. Packag. Technol. Sci. 35, 213–227 (2022).

Shi, M. J. et al. Redox-active polymer integrated with mxene for ultra-stable and fast aqueous proton storage. Adv. Funct. Mater. 33, 2209777 (2022).

Fernandes, F. G., Grisi, C. V. B., Araujo, R. C., Botrel, D. A. & Sousa, S. Active cellulose acetate-oregano essential oil films to conservation of hamburger buns: Antifungal, analysed sensorial and mechanical properties. Packag. Technol. Sci. 35, 175–182 (2022).

Author information

Authors and Affiliations

Contributions

The author is the sole contributor.

Corresponding author

Ethics declarations

Competing interests

The author declares no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lai, WF. Design and application of self-healable polymeric films and coatings for smart food packaging. npj Sci Food 7, 11 (2023). https://doi.org/10.1038/s41538-023-00185-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41538-023-00185-3

This article is cited by

-

Tailoring of Polymer and Metal Nanobiocomposites Corroborated with Smart Food Packaging Systems—A Review

Food and Bioprocess Technology (2024)