Abstract

Malt is an important raw material in brewing beer. With the increasing development of craft beer, brewing malt has contributed diverse colours and abundant flavours to beer. While “malty” and “worty” were commonly used to describe the malt flavour of beer, they are still inadequate. This study focused on developing of a sensory lexicon and a sensory wheel for brewing malt. Here, a total of 22 samples were used for sensory evaluation. The panels identified 53 attributes to form the lexicon of brewing malt, including appearance, flavour, taste, and mouthfeel. After consulting with the experts from the brewing industry, 46 attributes were selected from the lexicon list to construct the sensory wheel. Based on the lexicon, rate-all-that-apply analysis was used to discriminate between six samples of different malt types. The principal component analysis results showed that malt types were significantly correlated with sensory features. To further understand the chemical origin of sensory attributes, partial least squares regression analysis was used to determine the association between the aroma compounds and sensory attributes. According to the colour range and malt types, 18 samples were used for sensory descriptive analysis and volatile compounds identification. Seven main flavours were selected from the brewing malt sensory wheel. 34 aroma compounds were identified by headspace solid phase microextraction gas chromatography-mass spectrometry-olfactometry. According to the partial least squares regression results, the aroma compounds were highly correlated with the sensory attributes of the brewing malt. This approach may have practical applications in the sensory studies of other products.

Similar content being viewed by others

Introduction

Beer is a drink that different cultures have appreciated for its variety of ingredients, processing methods, sensory properties, etc1. Beer, in particular, has abundant sensory characteristics, including appearance, flavour, taste, and mouthfeel, which can define the overall style of beer and even promote consumption trends2. The brewing industry has devoted much effort into the research and development of new technologies and innovations to diversify the flavour of craft beers in response to the increased consumer’s various demands3,4,5. With the increasing production and consumption of craft beer, malt, as an essential raw material in beer brewing, has attracted more attention6,7. It has played a key role in endowing beer with diverse colours and abundant flavours8,9. Even though “malty” and “worty” were used frequently to describe the malt flavour of beer, they are still inadequate to describe malt’s flavour which contributes a lot to beer10,11. Therefore, it is important to study the properties of beer malt alone.

There are two kinds of beer malt; base malts and specialty malts12. Base malts are made through a standard process of soaking, germinating, and drying, which provide the basic flavour of beer. Specialty malts are processed on basis of base malts and used for colouring and flavouring. They can be further categorised as High aroma, Biscuit, Caramel, Crystal, Chocolate, Coffee, Black, etc, which contain various flavour characteristics, like roasted, fruity, and caramel13. In the past, quality control techniques included visual colour and defects inspection, smelling for off or mould-like aromas, and chewing malt to determine acceptability. However, chewing alone cannot help to accurately describe malt flavour because some flavour active compounds can only be detected after extraction, as would occur in brewing14. The Brewing Association surveyed craft brewers and published a white paper “Malting Barley Characteristics for Craft Brewers” that reported malt flavour as a major gap in industry knowledge. Respondents consistently emphasised malt flavour as a priority over other parameters15. In response, the industry established several new tools that enable the description of malt flavour. In 2017, the American Society of Brewing Chemists developed and validated the Hot Steep Method, a quick and inexpensive way to extract malt flavour due to its wide accessibility, low material cost, and reproducibility across laboratories. According to Harmonie16, the Hot Steep Method has proved to be a highly effective tool, gaining significant popularity in western countries.

Malt flavour is complex because it can be influenced by the chemicals in the malt17,18. At the same time, the malt flavour is determined mainly by the malting process, where changes in moisture, temperature, airflow, and pH can affect the final content of non-volatile and volatile compounds19,20. The volatile compounds in brewing malts are mainly produced via a series of complex reactions during the germination, drying, and baking stages, such as the Millard reaction, caramelisation, Strecker degradation, and lipid peroxidation and degradation21,22. The Maillard Reaction Products (MRPs) are essential contributors to malt flavour and colour23,24,25. Small molecule MRPs, such as pyrazine, furfural and maltol, provide aromas like toasted, nutty, bread, and caramel25,26,27. A work by Sem demonstrated that the concentrations of pyrazine were the highest in roasted malt, such as 2,3-diethyl-5-methylpyrazine and 2-ethyl-3,5-dimethylpyrazine28. Furthermore, alcohols, aldehydes, ketones, organic acids, and lipids also contribute to malt flavour21,27,29. Dong30 indicated that benzaldehyde, benzeneacetaldehyde, hexanol, and ethyl acetate could be the key volatile compounds during the entire malting process.

Sensory evaluation is a crucial method to assess the sensory characteristics of food and beverages31. Among sensory evaluation methods, descriptive analysis (DA) has been widely used by researchers to describe the sensory features of food and beverage products32,33. In these methods, the sensory properties of the products are described quantitatively by sensory panel34,35. There has been a growing application of a series of novel sensory profiling methods, such as check all-that-apply (CATA), and rate-all-that-apply (RATA), which enables the use of untrained panellists or even consumers to obtain sensory profiles of food products36,37. However, the key to using those novel approaches is establishing an appropriate sensory lexicon based on panel input. Lawless and Civille38 provided an overview of the essential elements of a sensory lexicon, which should include a list of relevant products, along with all the attributes and their definitions and references. Recently, sensory wheels have been developed for a variety of beverages and foods, including chocolate39, Rakı40, potato cultivar41, soy sauce42, and coated tablets43. The attributes in a sensory wheel can be used to standardise training and aid education and discussion. Sensory wheels can also serve as a communication tool among industry members, including producers, retailers, exporters, importers, industry professionals, and consumers40.

Until now, there have been no detailed studies on the sensory properties of brewing malt. This study aimed to develop a sensory lexicon for brewing malt by sensory panel. Based on the sensory lexicon, the primary descriptors can be selected and visualised in the form of a sensory wheel. With the identification of the aroma-active compounds by gas chromatography-olfactometry (GC-O), the relationships between the aroma compounds and flavour attributes can be further explored.

Results and discussion

Lexicon and sensory wheel

Lexicon development included the following steps: identifying the broad product scope, generating the terms to characterise the products, and developing a final list of descriptors with references38. The 22 brewing malt samples represented the most likely sensory attributes to develop a brewing malt lexicon. In the beginning, the assessors generated a total of 214 sensory terms. Then, with further discussion, similar terms were combined by the consensus, and 92 preliminary descriptive terms were identified (Table 1). Some of the preliminary terms were then eliminated if their mention frequency was less than 5% before the final brewing malt lexicon was determined39,42. Finally, 53 attributes and their definitions and references were developed for the brewing malt lexicon. The final attributes list is shown in Table 2 and their definitions and references are shown in Supplementary Table 1. 53 attributes were then grouped into different categories, which was agreed upon by the panel, sensory research team, and the experts from the brewing industry. Overall, there were 9 categories in the lexicon, including 17 appearance attributes, 27 flavour attributes, and 9 taste and mouthfeel attributes.

A sensory wheel was generated according to the final attribute list from the brewing malt lexicon. These attributes were grouped to constitute different categories according to the inputs of the sensory research team. After consulting with the experts from the brewing industry and discussing among the sensory research team, 7 terms were dropped from the lexicon list (Table 2). A total of 46 specific attributes of brewing malt were illustrated in a three-circle sensory wheel, including 15 appearance attributes, 26 flavour attributes, and 5 taste and mouthfeel attributes (Fig. 1). The descriptors that made up the outer circle were the specific attributes, while the secondary descriptors that grouped certain attributes made up the second tier. The inner circle contained three primary sensory modalities: appearance, flavour, and taste and mouthfeel. In this study, a lexicon and sensory wheel for brewing malt were developed for the first time. The sensory lexicon and the sensory wheel specified a set of terms that defined the general properties of brewing malt for industrial and academic needs.

RATA analysis based on the flavour and taste attributes of brewing malt Lexicon

In order to validate whether the descriptors in the sensory wheel could help to distinguish between different malt samples, RATA analysis was conducted. Six brewing malt samples were selected from six different categories (High aroma, Biscuit, Caramel, Crystal, Chocolate, and Black) from Table 3. Fifteen attributes of flavour and 3 attributes of taste were chosen based on the common agreement of the laboratory panel. The attributes were mainly derived from flavour and taste, including toast, caramelised sweet potato, honey, red dates, cereal, caramel, biscuit, roasted, smoked, burnt, roasted nut, hazel, almond, black chocolate, coffee, sour, sweet, and bitter. The details are given in Supplementary Table 2. Principal component analysis (PCA) was used to evaluate the sensory data gathered from the six brewing malt samples by the Laboratory Panel. The results are shown in Fig. 2, and the variance is explained by the two principal components. The first principal component explained 54.91% of the variance, while the second principal explained 20.02%. It was shown that there were significant differences in the flavour attributes of the six brewing malt samples, which could be divided into three classes by PCA. Two of the samples, S6 and S11, were similar, displaying lower intensities of roasted, smoked, coffee, and black chocolate flavours and higher intensity levels of caramel, honey, and toasted flavours. The S7 and S14 samples were also similar, with prominent burnt, almond, biscuit, and roasted nut flavours. Furthermore, similarities were evident between the two remaining samples, S17 and S20, with roasted, smoked, coffee, and black chocolate flavours. Coghe21 indicated that a trained tasting panel detected a higher intensity of bitter and burnt flavours as the colour of the malt increased while the sweet flavour notes decreased. Chocolate and Black malt were processed with higher baking temperature and baking time than the other four malts, maximising the bitter, roasted, and smoky flavours. Based on the lexicon, RATA was used to discriminate between samples of different malt types (High aroma, Biscuit, Caramel, Crystal, Chocolate, and Black). The results of PCA show that malt type was significantly correlated with the sensory features.

Analysis of the aroma-active compounds

18 selected brewing malt samples, representing different colours and types (Base 3, High aroma 2, Biscuit 3, Caramel 2, Crystal 3, Chocolate 2, Coffee 1, and Black 2), were selected from Table 3 and determined by headspace solid phase microextraction gas chromatography-mass spectrometry (HS-SPME-GC-MS). A total of 76 volatile compounds were identified by HP-5MS columns, including 23 aldehydes, 15 heterocycles, 15 esters, 7 alcohols, 7 ketones, 2 phenols, 3 olefins, and 4 others (Supplementary Table 3). 7 brewing malt samples were selected from Table 3, representing 7 different categories (Basic, High aroma, Biscuit, Caramel, Crystal, Chocolate, and Black). GC-O analysis was used to determine the overall odour of aroma-active compounds. As shown in Table 4, 34 aroma compounds were detected in the samples, including 16 aldehydes, 11 heterocycles, 5 alcohols, 1 ketone, and 1 phenol. The results show that base malts and specialty malts had a diverse profile of aroma compounds. The content and quantity of aroma compounds in base malts were the lowest, and aldehydes were the most important. In contrast, the aroma compounds of specialty malts were more abundant and were affected by the malting process.

The volatile compounds in brewing malt are mainly produced by the Maillard reaction, caramelisation, Strecker degradation, and lipid peroxidation degradation21,22. Both caramelisation and the Maillard reaction are non-enzymatic Browning reactions, giving appealing flavours to malt under high temperature. Caramelisation is a process during which carbohydrate compounds dehydrate and degrade, producing volatile aldehydes and ketones. Overall, seven ketones were identified in the 18 brewing malts. It should be noted that geranylacetone (green) was a featured flavour compound found in the specialty malts but not in base malts. On the other hand, the Maillard reaction involves the violent collision and recombination of amino acids and reducing sugars in high-temperature conditions, yielding hundreds of compounds24,44. Base malts had the lowest degree of the Maillard reaction and thus produced only a small number of heterocyclic compounds. In contrast, the Maillard reaction of specialty malts produced more heterocyclic compounds. During the heating process, many N-heterocycles, O-heterocycles were produced, such as pyrazine, pyrrole, and furan. Studies have shown that MRPs are important compounds in malts, giving off roasted, coffee, nutty, caramel flavours21,25. Caramel malt and Crystal malt are prepared by multi-step roasting of green malt. Caramel malt and Crystal malt presented burnt flavour45, mainly from oxygen-containing heterocyclic compounds produced during baking46. Six O-heterocycles were identified in caramel and crystal malt samples, and five of them were aroma compounds, including furfural (red dates), furfuryl alcohol (coffee), 2-acetylfuran (earthy), 2-pentylfuran (earthy), and 5-methyl furfural (coffee and chocolate). In addition, furfural was found in all specialty malts samples and its content increased exponentially with the deepening of the malt colour. These results suggest that the furfural formation might require higher thermal energy than the other compounds. The High Aroma, Biscuit, chocolate, and black malt are all processed from base malts. As the baking process progressed, the EBC value gradually increased, while the quantity and content of MRPs also increased. Nitrogen-containing heterocyclic compounds such as pyrazine and pyrrole contributed significantly to the aroma of the dark malt. Nine N-heterocycles were identified in chocolate, coffee, and black malt samples, and six of them were aroma compounds, which were 2-ethyl-6-methylpyrazine (baked), 3,5-dimethyl-2-ethylpyrazine (nutty and baked), 2-methyl-3-isobutylpyrazine (sugar syrup), 2-pyrrolylcarboxaldehyde (burnt), and 1-furfurylpyrrole (nutty and cream). Aldehydes, alcohols, ketones, and esters are mainly related to lipid oxidation. Isovaleraldehyde (nutty), hexanal (green),benzaldehyde (plantule), trans-2-octenal(green), nonanal (honey), and decyl aldehyde (crisps) were identified in the 18 brewing malts. Basic malt contained the most esters, which could be gradually broken down during baking, so very few lipids were left in dark malt. In the previous research, trans-2-nonenal was found to be a vital aroma component in barely, malt, and beer47, which was mainly found in base malts. 2-methylbutyraldehyde (baked), and Cocal (fruity) were only identified in the specialty brewing malts. Maltols (caramellic) are crucial alcohol components. While this substance is a prominent aroma compound in the Caramel and Crystal Malt samples, they are also present in the Coffee, Chocolate, and Black malts.

The relationships between the main flavour attributes and aroma compounds

In this study, the Laboratory Panel using DA evaluated the selected 18 samples (Supplementary Table 4). Seven categories of flavour attributes in the sensory wheel were selected for evaluation: baking, smoky, nutty, fruity, caramel, grain, and green.

The brewing malt characteristics (both sensory and chemical) were expected to be interdependent and therefore it was difficult to analyse them independently. Therefore, multivariate statistical analysis was employed to establish mathematical models to clarify the relationship between the aroma compounds and the sensory properties48. To further understand the chemical origin of the sensory attributes, partial least squares (PLS) regression analysis was used to determine the association between the categories of flavour attributes (y variables, n = 7) and the significantly different aroma compounds (x variables, n = 34) in the 18 brewing malt samples. The performance of the PLS model was determined using cross-validation parameters. R2Y and Q2 represented the discussed variance and the predictive capability of the model, respectively. As a function for the goodness of fit, greater R2Y values indicated better modelling49. As an indicator of the prediction ability of the model, Q2 value >0.5 was admitted for good predictability50. Taking into account that a large discrepancy between R2Y and Q2 indicated an overfitting of the model through the use of too many components, the difference between R2Y and Q2 should be lower than 0.350. The concentration of the aroma compounds and the rating of categories of flavour attributes are shown in the correlation loading plot (Fig. 3). The value of R2Y was 0.728, and Q2 was 0.620, showing good fitness and predictability of the model. Therefore, the aroma compounds plotted in the vicinity of the sensory attributes were positively associated with those attributes.

The variable importance for projection (VIP) values were calculated from the PLS regression model of the sensory attributes and the aroma compounds (p < 0.05) of the 18 brewing malt samples. The VIP scores were above 1 for the 13 aroma compounds, which were furfural, 5-methyl furfural, 4-ethyl-2-methoxyphenol, 1-furfurylpyrrole, 2-pyrrolylcarboxaldehyde, trans-2-octenal, 3,5-dimethyl-2-ethylpyrazine, isovaleraldehyde, 2-ethyl-6-methylpyrazine, 2-phenyl-2-butenal, 4-methyl-2-phenyl-2-pentenal and 1-dodecanol. The presence of these aroma compounds was considered the primary reason for the flavour differences in brewing malt. Moreover, the “baked” and “smoky” flavours were associated with furfural, 1-furfurylpyrrole, 5-methyl furfural, 4-ethyl-2-methoxyphenol, 2-pyrrolylcarboxaldehyde, trans-2-octenal, 3,5-dimethyl-2-ethylpyrazine, decyl aldehyde, 2-methyl-3-isobutylpyrazine, and 2-ethyl-6-methylpyrazine. The heterocycles were the most important volatile constituents in the brewing malts. Their presence generally contributed to the roasted flavour notes of the baking products, which was consistent with the results of the PLS regression. The “caramel” flavour was related to cocal, 2-methylbutyraldehyde, isobutyraldehyde, 4-methyl-2-phenyl-2-pentenal, and furfuryl alcohol. The “nutty” and “grain” flavours were connected with 2-isopropyl-5-methyl-2-hexenal, phenylacetaldehyde, and 1-dodecanol. Previously, phenylacetaldehyde was considered as one of the key odorants during the whole malting process22. The “green” and “fruity” flavours displayed a close correlation with 1-octen-3-ol and trans-2-nonenal. In previous work by Akira51, it was demonstrated that 1-octen-3-ol and trans-2-nonenal contributed to the green note in malt whisky.

PLS regression analysis identified that the aroma compounds were highly correlated with the sensory attributes of the brewing malt. This was an essential strategy for identifying the critical aroma compounds that accounted for sensory differences and can be applied to optimise the parameters of malt brewing and beer production processes to improve product quality and flavour characteristics.

Methods

Experimental design

First, this study organised two sensory panels (Industry Panel and Laboratory Panel) in order to obtain a sensory lexicon for brewing malt. Next, a sensory wheel was constructed by selecting the most relevant terms according to their mention frequency. Using the reduced list of the sensory lexicon, the laboratory panel evaluated a total of six brewing malt samples with the rate-all-that-apply (RATA) method. Ultimately, sensory evaluation and headspace solid phase microextraction gas chromatography-mass spectrometry-olfactometry (HS-SPME-GC-MS-O) were used to analyse the relationship of flavour attributes and volatile compounds in 18 brewing malts.

Malt samples

When developing the sensory descriptors, it was important to cover the full range of the sensory profile in order to capture as many sensory descriptors as possible40. A total of 22 commercial brewing malt samples (denoted S1–S22) were selected as representative samples, which were gathered from 9 malt types and covered a wide colour scale (3 EBC to 1500 EBC) in order to explain all potential sensory attributes (Table 3). The malt samples were obtained from malt manufacturers or retail outlets, while their product classification information was taken from each one of the producers. Samples were stored at a constant temperature of 25 °C. For volatile compounds analysis and sensory analysis, wort samples were prepared according to the Hot Steep Method of the American Society of Brewing Chemists16. During a sensory evaluation, the wort samples were presented in a randomised order and served at 25 °C in odourless transparent cups with an adequate volume of 30 mL. There was a one-minute break between each sample to prevent fatigue. Water and plain crackers were available for palate cleansing.

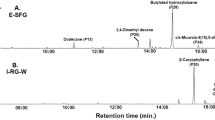

HS-SPME-GC-MS-O analysis of volatile compounds

Volatile compounds in the wort samples were detected using HS-SPME-GC-MS. 5 mL of the wort and 150 μL of 1,2,3-trichloropropane (10 mg/L in methanol, internal standard) were placed in a 20 mL glass vial sealed with an aluminium cover and Teflon septum. The samples were equilibrated for 20 min at 60 °C in the vials, and a 50/30 μm DVB/CAR/PDMS fibre (Supelco Ltd., Bellefonte, PA) was exposed to the sample headspace at 60 °C for 40 min. After extraction, the fibre was desorbed in a splitless inlet at 250 °C for 5 min. An Agilent 7890B/5977 A GC-MS (Agilent Technologies Inc., Santa Clara, CA) was used for GC-MS analysis, equipped with HP-5MS chromatographic columns (30 m × 0.25 mm i.d., 0.25 μm film thickness, J&W Scientific, Folsom, CA). Helium was used as the carrier gas, at a constant current of 1.20 mL/min. The GC programme was as follows: The original oven temperature was set at 35 °C for 5 min, gradually increased to 85 °C at a rate of 10 °C/min and held for 1 min, then raised to 200 °C at 4 °C/min and held for 3 min and finally raised to 200 °C at 10 °C/min and held for 3 min. The electron energy of MSD was 70 eV, the temperature of the ion source was 250 °C, and the scanning range was m/z 40–500. The volatile compounds were identified based on the NIST 2014 (National Institute of Standards and Technology, Gaithersburg, MD) and the retention index. Each examination was repeated three times. The relative content of each volatile compound was calculated according to the normalised scanning total ion current peak area using the internal standard, and the final result was the average value of the three replicate calculations.

Aroma-active compounds in the wort samples were directly detected by the sniffing port of the GC-MS-O (Sniffer 9000, Brechbuhler AG, Switzerland). The analysis conditions were the same as those for the GC-MS using the HP-5MS column, while the temperature of the sniffing port was set at 200 °C. During the GC operation, the panellists placed their noses close to the sniffer port and then recorded the smells. The compounds identified by more than three panellists were selected as flavour compounds for further analysis.

Panel

Sensory studies were performed by two independent groups, namely, the Industry Panel and the Laboratory Panel. The Industry Panel comprised 8 assessors (6 females and 2 males; aged range 26–40 years for both genders), with more than five years of both industrial and sensory analysis experience. The group consisted of R&D specialists from the Research and Development Centre of the COFCO Malt (Dalian) Co. Ltd and the sensory research team of COFCO NHRI Co. Ltd. Members of the R&D department were selected according to their regular participation in sensory evaluations for product development and quality control in industrial production. The sensory research team also regularly participated in sensory analysis research at the COFCO Sensory and Flavour Lab (CSFL). The Laboratory Panel comprised 15 assessors (12 females and 3 males; aged range 26–50 years for both genders), with more than two years of sensory analysis experience. They were recruited in compliance with ISO standards and were selected based on their abilities to identify and describe differences in malt samples. The study was reviewed and approved by the COFCO NHRI Co. Ltd. All assessors had provided informed consent before gathering in the CSFL testing room. For each sensory evaluation, the experiment was finished in separate compartments, under about 25 °C temperature and around 50% relative humidity. The panellists were instructed to observe, sniff, and taste the sample as many times as needed. The definitions of appearance (all the visible attributes of a substance or object), flavour (a complex combination of the olfactory, gustatory and trigeminal sensations perceived during tasting), taste, and mouthfeel (mixed experience derived from the taste organ or sensations in the mouth that relate to physical or chemical properties of a stimulus) were explained thoroughly to the panel52.

Development of the sensory lexicon and formation of the sensory wheel

The panel leader welcomed the assessors and explained that the aim of the experiments was to determine the sensory descriptors for brewing malts. The panel leader made sure to keep everyone engaged and focused on the task. Both of the sensory groups completed seven sessions (2 h each) in the sensory room. The first three sessions involved term generation based on all wort samples. In each session, seven or eight samples were served to the assessors. Panellists were individually presented with the samples and asked to write down the sensory attributes they found. Appearance, flavour, taste, and mouthfeel were evaluated based on their sensory perception. To describe the samples, they were instructed not to use hedonistic or quantitative terms, such as good, well, just right, and so forth. Assessors specified the attributes, definitions, and references through a consensual process38,53. In order to finalise the list of descriptive terms, the following sessions focused on attribute alignment with the use of references. The panel leader led several group discussions to reach a consensus on terminology. During the discussion, the panellists explained to each other the terms they would use to describe the samples, shared their understandings, and produced unified expressions. Finally, combining terms from the two different sensory groups, a total of 214 attributes were defined.

After that, the terms were reviewed and rationalised by assessors. The terms and references understood by more than two-thirds of the panellists were adopted as brewing malt descriptors42. Then, the descriptors with the same or similar meaning and redundant terms were eliminated. Only consensus attributes directly related to the samples were included in the preliminary descriptor list (n = 92). For practical purposes, the list was further consolidated based on how frequent the panellists used the terms. Attributes with low mention frequency (<5%) were removed38,39. The final list of the descriptors for brewing malt was then used to build the sensory wheel. They were divided into different categories based upon the inputs of the sensory research team. The sensory wheel was constructed using XLSTAT software.

Descriptive analysis of brewing malt samples

In the last decades, researchers have developed a number of rapid profiling methods, among which RATA was reported to be an effective method for providing the sensory characterisation of food products54,55. Recently, RATA has been successfully applied to differentiate the visual appearance of milk powders using trained sensory panels37. Vannier56 indicated that an efficient sensory profiling could be achieved with about 20 attributes. In this study, the Laboratory Panel applied RATA to evaluate six malt samples selected from six different categories (High aroma, Biscuit, Caramel, Crystal, Chocolate, and Black) after training. The panellists completed three sessions (2 h each). During the first session, a total of 18 attributes from the brewing malt sensory wheel were selected and agreed upon by the panellists. The second session was to evaluate six malt samples using RATA, and in the final session, the procedure above was repeated. Reference standards were prepared to aid the assessors. For each sample, the panellists were asked to respond “yes” to the attribute(s) they considered appropriate to describe the sample, and then rate the intensity of the attribute(s), using a 5-point scale (“very weak”, “weak”, “medium”, “strong”, and “very strong”). When testing, the absence of the attribute was scored as zero (0) and the intensity levels of the presence attributes were scored as 1, 2, 3, 4, or 5. The order in which the terms were presented was random for each product and participant. The samples were evaluated in duplicate to obtain reliable, consistent results.

Correlation analysis of the flavour attributes and the aroma compounds

Meanwhile, according to different categories (Base 3, High aroma 2, Biscuit 3, Caramel 2, Crystal 3, Chocolate 2, Coffee 1, and Black 2), 18 brewing malt samples were selected from Table 3. The Laboratory Panel used descriptive analysis (DA) to evaluate the samples.

Panellists completed a total of six sessions and assessed six samples per session, with two replicates for each malt sample. The seven categories of flavour attributes of the sensory wheel were selected as the evaluation attributes. The attribute intensity was scored using the continuous 5-point scale, ranging from 0 (lowest intensity) to 5 (highest intensity). To understand the chemical origin of the flavour attributes, PLS regression was employed to analyse the correlation between the categories of flavour attributes and the aroma compounds of 18 brewing malt samples.

Statistical analysis

Analysis of variance (ANOVA) was used for RATA and DA sensory data to determine the differences between the samples. The PCA was conducted to analyse the relationship between the malt samples and the sensory attributes. PLS regression was conducted to find out any correlation between the categories of flavour attributes and the aroma compounds. ANOVA, PCA, and PLS regression were run by XLSTAT software (Version 2019). Panel performance was monitored using PanelCheck Software (Version 1.3.2).

Reporting summary

Further information on research design is available in the Nature Research Reporting Summary linked to this article.

Data availability

The authors declare that all data supporting the findings of this study are available within the paper and supplementary information.

References

Maia, P., Baio, D., Silva, V., Miguel, M. & Pierucci, A. Microencapsulation of a craft beer, nutritional composition, antioxidant stability, and drink acceptance. LWT- Food Sci. Tech. 133, 110104 (2020).

Briggs, D. E., Brookes, P., Boulton, C. & Stevens, R. Brewing: Science and Practice Vol. 108 (Woodhead Publishing, 2004).

Yeo, H. Q. & Liu, S. Q. An overview of selected specialty beers: Developments, challenges, and prospects. Int. J. Food Sci. Technol. 49, 1607–1618 (2014).

Wang, O., Gellynck, X. & Verbeke, W. Chinese consumers and European beer: Associations between attribute importance, socio-demographics, and consumption. Appetite 108, 416–424 (2017).

Carvalho, N. B., Minim, L. A., Nascimento, M., de Castro Ferreira, G. H. & Minim, V. P. R. Characterization of the consumer market and motivations for the consumption of craft beer. Br. Food J. 120, 378–391 (2018).

De Schutter, D. P. et al. Characterization of volatiles in unhopped wort. J. Agric. Food Chem. 56, 246–254 (2008).

Fritsch, H. T. & Schieberle, P. Identification based on quantitative measurements and aroma recombination of the character impact odorants in a Bavarian Pilsner-type beer. J. Agric. Food Chem. 53, 7544–7551 (2005).

Andrés‐Iglesias, C., Montero, O., Sancho, D. & Blanco, C. A. New trends in beer flavour compound analysis. J. Sci. Food Agric. 95, 1571–1576 (2015).

Parker, D. Beer: Production, Sensory Characteristics, and Sensory Analysis (Elsevier, 2012).

Meilgaard, M. C., Dalgliesh, C. E. & Clapperton, J. F. Beer flavour terminology1. J. Inst. Brew. 85, 38–42 (1979).

Schmelzle, A. The beer aroma wheel. Updating beer flavor terminology according to sensory standards. Brew. Sci. 62, 26–32 (2009).

Boulton, C. Encyclopaedia of Brewing (John Wiley & Sons, 2013).

Coghe, S., Derdelinckx, G. & Delvaux, F. R. Effect of nonenzymatic browning on flavour, colour and antioxidative activity of dark specialty malts—a review. Monatsschr 57, 25–38 (2004).

Beal, A. D. & Mottram, D. S. Compounds contributing to the characteristic aroma of malted barley. J. Agric. Food Chem. 42, 2880–2884 (1994).

Association, B. Malting Barley Characteristics for Craft Brewers (Brewers Association, 2014).

ASBC. Methods of Analysis. Sensory Analysis 14. Hot Steep Malt Sensory Evaluation Method https://www.asbcnet.org/lab/webinars/Pages/sensoryvideos.aspx (2017).

Ferreira, I. M. & Guido, L. F. Impact of wort amino acids on beer flavour: A review. Fermentation 4, 23 (2018).

Clapperton, J. F., Dalgleish, C. E. & Meilgaard, M. C. Progress toward an international system of beer flavour terminology. J. Inst. Brew. 82, 7–13 (1976).

Brewing and Malting Barley Research Institute. Quality Factors in Malting Barley (Brewing and Malting Barley Research Institute, 2017).

Schwarz, P. & Li, Y. Malting and Brewing Uses of Barley (John Wiley & Sons, 2011).

Coghe, S., Martens, E., D’Hollander, H., Dirinck, P. J. & Delvaux, F. R. Sensory and instrumental flavour analysis of wort brewed with dark specialty malts. J. Inst. Brew. 110, 94–103 (2004).

Dong, L. et al. Analysis of volatile compounds from a malting process using headspace solid-phase micro-extraction and GC–MS. Food Res. Int. 51, 783–789 (2013).

Bettenhausen, H. M. et al. Variation in sensory attributes and volatile compounds in beers brewed from genetically distinct malts: An integrated sensory and non-targeted metabolomics approach. J. Am. Soc. Brew. Chem. 78, 136–152 (2020).

Carvalho, D. O., Gonçalves, L. M. & Guido, L. F. Overall antioxidant properties of malt and how they are influenced by the individual constituents of barley and the malting process. Compr. Rev. Food Sci. Food Saf. 15, 927–943 (2016).

Coghe, S., Adriaenssens, B., Leonard, S. & Delvaux, F. R. Fractionation of colored Maillard reaction products from dark specialty malts. J. Am. Soc. Brew. Chem. 62, 79–86 (2004).

Bettenhausen, H. M. et al. Influence of malt source on beer chemistry, flavor, and flavor stability. Food Res. Int. 113, 487–504 (2018).

Vandecan, S. M., Saison, D., Schouppe, N., Delvaux, F. & Delvaux, F. R. Optimisation of specialty malt volatile analysis by headspace solid-phase microextraction in combination with gas chromatography and mass spectrometry. Anal. Chim. Acta 671, 55–60 (2010).

Vandecan, S. M. G., Daems, N., Schouppe, N., Saison, D. & Delvaux, F. R. Formation of flavor, color, and reducing power during the production process of dark specialty malts. J. Am. Soc. Brew. Chem. 69, 150–157 (2011).

Guido, L. F. et al. Correlation of malt quality parameters and beer flavor stability: Multivariate analysis. J. Agric. Food Chem. 55, 728–733 (2007).

Dong, L. et al. Characterization of volatile aroma compounds in different brewing barley cultivars. J. Sci. Food Agric. 95, 915–921 (2015).

Stone, H. Example food: What are its sensory properties and why is that important? NPJ Sci. Food 2, 1–3 (2018).

Lawless, H. T. & Heymann, H. Sensory Evaluation of Food: Principles and Practices Vol. 2 (Springer, 2010).

Meilgaard, M. C., Carr, B. T. & Civille, G. V. Sensory Evaluation Techniques (CRC Press Taylor & Francis Group, 1999).

Djekic, I., Lorenzo, J. M., Munekata, P. E., Gagaoua, M. & Tomasevic, I. Review on characteristics of trained sensory panels in food science. J. Texture Stud. 52, 1–9 (2021).

Maheeka, W. N., Godfrey, A. J. R., Ellis, A. & Hort, J. Comparing temporal sensory product profile data obtained from expert and consumer panels and evaluating the value of a multiple sip TCATA approach. Food Qual. Prefer. 89, 104141 (2021).

Gunaratne, T. M. et al. Development of emotion lexicons to describe chocolate using the Check-All-That-Apply (CATA) methodology across Asian and Western groups. Food Res. Int. 115, 526–534 (2019).

Traill, R. M., Luckman, M. S., Fisk, N. A. & Peng, M. Application of the Rate-All-That-Apply (RATA) method to differentiate the visual appearance of milk powders using trained sensory panels. Int. Dairy J. 97, 230–237 (2019).

Lawless, L. J. & Civille, G. V. Developing lexicons: A review. J. Sens. Stud. 28, 270–281 (2013).

De Pelsmaeker, S., De Clercq, G., Gellynck, X. & Schouteten, J. J. Development of a sensory wheel and lexicon for chocolate. Food Res. Int. 116, 1183–1191 (2019).

Darıcı, M., Özcan, K., Beypınar, D. & Cabaroglu, T. Sensory lexicon and major volatiles of rakı using descriptive analysis and GC-FID/MS. Foods 10, 1494 (2021).

Sharma, C. et al. Development of a lexicon to describe the sensory characteristics of a wide variety of potato cultivars. J. Sens. Stud. 35, e12577 (2020).

Imamura, M. Descriptive terminology for the sensory evaluation of soy sauce. J. Sens. Stud. 31, 393–407 (2016).

Hofmanová, J., Mason, J. & Batchelor, H. Sensory attributes of coated tablets: Developing a formal lexicon and sensory wheel. Int. J. Pharm. 590, 119883 (2020).

Dack, R. E., Black, G. W. & Koutsidis, G. The effect of Maillard reaction products and yeast strain on the synthesis of key higher alcohols and esters in beer fermentations. Food Chem. 232, 595–601 (2017).

Fickert, B. & Schieberle, P. Identification of the key odorants in barley malt (caramalt) using GC/MS techniques and odour dilution analyses. Food/Nahr. 42, 371–375 (1998).

Yahya, H., Linforth, R. & Cook, D. J. Flavour generation during commercial barley and malt roasting operations: A time course study. Food Chem. 145, 378–387 (2014).

Svoboda, Z. et al. Optimization of modern analytical SPME and SPDE methods for determination of trans -2-nonenal in barley, malt and beer. Chromatographia 73, 157–161 (2011).

Yh, A. et al. Unraveling the chemosensory characteristics of strong-aroma type Baijiu from different regions using comprehensive two-dimensional gas chromatography–time-of-flight mass spectrometry and descriptive sensory analysis. Food Chem. 331, 127335 (2020).

Özdemir, İ. S. et al. Characterisation of the Turkish and Slovenian extra virgin olive oils by chemometric analysis of the presaturation 1H NMR spectra. LWT-Food Sci. Tech. 92, 10–15 (2018).

Zhu, M. T. et al. Prediction of fatty acid composition in camellia oil by 1H NMR combined with PLS regression. Food Chem. 279, 339–346 (2019).

Wanikawa, A., Hosoi, K., Kato, T. & Nakagawa, K. Identification of green note compounds in malt whisky using multidimensional gas chromatography. Flavour Fragr. J. 17, 207–211 (2002).

ISO. International Standard 5492. Sensory Analysis—Sensory Vocabulary. International Organization for Standardization (2008).

Chambers, E. IV et al. Development of a “living” lexicon for descriptive sensory analysis of brewed coffee. J. Sens. Stud. 31, 465–480 (2016).

Ares, G. et al. Evaluation of a rating-based variant of check-all-that-apply questions: Rate-all-that-apply (RATA). Food Qual. Prefer. 36, 87–95 (2014).

Gambetta, J. et al. Comparison of Rate-All-That-Apply (RATA) and descriptive analysis (DA) for the sensory profiling of wine. Am. J. Enol. Vitic. 69, 12–21 (2018).

Vannier, A., Brun, O. X. & Feinberg, M. H. Application of sensory analysis to champagne wine characterisation and discrimination. Food Qual. Prefer. 10, 101–107 (1999).

Author information

Authors and Affiliations

Contributions

X.S. and F.G. designed the study. X.S., M.Y., M.M., H.S., Q.B., and T.D. conducted experiments. X.S., M.Y., S.W., M.M., F.G., and Q.B. analysed data. X.S. and S.W. contributed to writing the manuscript. All authors read and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Su, X., Yu, M., Wu, S. et al. Sensory lexicon and aroma volatiles analysis of brewing malt. npj Sci Food 6, 20 (2022). https://doi.org/10.1038/s41538-022-00135-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41538-022-00135-5

This article is cited by

-

Identification of volatile compounds in chocolate malt

European Food Research and Technology (2023)