Abstract

Titanium and its alloys have been widely used for clinical applications because of their biocompatibility and exceptional chemical inertness, in addition to their outstanding osseointegration characteristics. They are well known to form a robust protective film on the surface that provides a high corrosion resistance with the surrounding environment. Although this passive state of titanium-based materials is often considered to be achieved very rapidly, even when damaged, and to be chemically stable in physiological environments, evidences of passivity breakdown and electron transfer reactions have been collected using high resolution microelectrochemical techniques. Thus, further optimizations are required for their forthcoming applications.

Similar content being viewed by others

Introduction

Biomaterials are generally defined as substances engineered to interact with biological systems to treat, evaluate, and replace any tissue, organ or function of the body1,2,3. In recent decades, a large number of biomaterials have been developed for applications in the health care field. They are primarily used for drug delivery, orthopedics, dental care, and tissue engineering of cardiovascular devices and skin4. Before any new biomaterial can be approved for use in the human body, several prerequisites recognized by the International Standards Organization (ISO) and The American Society for Testing and Materials (ASTM) must be met4. Biocompatibility is considered a vital requirement for the correct application of biomaterials. According to Williams’ definition of biocompatibility5, implanted biomaterials should not generate adverse and harmful reactions with the local physiological environment. However, implanted biomaterials are very susceptible to corrosion as they are exposed to harsh corrosive environments, such as blood and other types of extracellular fluids that contain chloride ions, proteins, and amino acids6,7,8. This emphasizes that implanted materials must exhibit high corrosion resistance as required by the ISO and ASTM. In fact, the implanted object can also suffer wear due to the micro-movement generated between it and the adjacent metal or bone9. This leads to the formation of wear debris that can develop undesirable interactions with living tissue10,11. Therefore, wear resistance and osseointegration characteristics are regarded as important factors for the longevity of implanted materials12.

Nowadays, biomaterials are made up of metals and alloys, polymers, ceramics, and composites. Among them, implanted materials made up from titanium are regarded the most useful as medical devices. In fact, titanium-based materials have been used in manufacturing of biomedical implants since the 1950’s. It is reported that more than 1000 tons of titanium are used each year in biomedical devices13. This is due to their biocompatibility and favorable mechanical properties such as low elasticity modulus, high tensile strength and low density. In addition, they are known for their exceptional osseointegration characteristics that operate in living tissues after implantation. This perspective will focus on the assumed stability and inertness of titanium-based materials for implant applications by providing some insights into the role and dynamics of surface passive oxide layers, and the impact of metal release as result of degradation mechanisms operating on those materials.

Passivity of titanium based materials

In general, it is known that under atmospheric conditions, a robust protective film can develop spontaneously on the surface of titanium objects. Its thickness is in the range of a few nanometers14. The protective oxide film is mainly composed of TiO2 mixed with some Ti2O3 and TiO14. TiO2 has a semiconductor characteristic with a wide bandgap of 3.2 eV15, which provides high corrosion resistance by attenuating the release of hazardous metal ions from the surface and inhibits electron transfer reactions with the local environment where it is implanted. When the titanium oxide-covered surface is damaged, the titanium metal reheals through the spontaneous formation of the passive film of titanium dioxide16, as illustrated by sketches a–c in Fig. 1. In this case, the broken film on the titanium biomaterial is rehealed fast and prevents corrosion from occurring on the surface of the biomaterial, which ultimately keeps the biological cell healthy. However, a different situation occurs in unhealed metals that result in corrosion occurrence as depicted by sketches d–f in Fig. 1. That is, corrosion initiates by the breakdown of the passive film on the titanium biomaterial, followed by oxidation of the titanium biomaterial promoted by corrosive species present in the surrounding electrolyte such as chlorides. While the electrons yielded by the oxidation reaction will be consumed by the oxidant present in the electrolyte, which is usually oxygen since its reaction is thermodynamically possible with titanium, this will result in the formation of reactive oxygen species at microcathode sites which will eventually lead to the damage of biological cells.

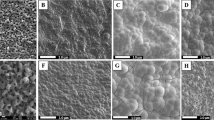

Since the surface of the implantable materials makes the close contact with living tissue, therefore the stability of the oxide film is a crucial factor for the success of the implantation treatment. In this context, various surface modification treatments are often carried out to improve the stability of the surface of the devices to be implanted, such as plasma assisted physical vapor deposition (PVD), nanograined (NG) and thermal oxidation (TO), among others17,18,19,20,21. Furthermore, the stability of passive oxide films can also be increased by using an appropriately selected amount of metal alloying additives during metallurgic preparation steps.

Extensive research is still underway to develop new titanium-based alloys with better mechanical and anti-corrosion properties. Ta, and Zr are the main metal alloying elements due to their non-toxic nature22 and their tendency to form very stable oxide films. However, under certain conditions, the protective film developed on titanium and its alloys is not completely stable. Breakdown of passivity and metastable nucleation of localized corrosion events have been observed in vitro on the micrometer scale for both titanium and its alloys23,24,25. The rarity of these localized rupture events and their minute spatial dimensions pose a challenge for their monitoring and investigation as they require improving the performance of experimental devices. Research is needed to determine metal release rates into the adjacent environment, as well as to discover the unknown mechanism. In fact, metal ions released from implanted titanium biomaterials have been detected in blood and urine26,27. The effects on living organisms of the most frequently released metals from medical devices are listed in Table 1.

Localised corrosion and metal release

The release of metal cations has been reported to harmfully affect wound healing in bone and surrounding tissue28. Significant wastage of material from an implanted device can change its mechanical properties and can weaken it, which can result in the loss of its supporting function29,30,31,32. In fact, the occurrence of localized corrosion and the release of metal cations are mainly the result of damage to the protective film on the metal surface of titanium due to the combined effect of chemical, electrochemical, and mechanical processes as sketched in Fig. 2)8. If this film takes longer time to fully heal after damage, the corrosive species in the electrolyte will enhance the rate of corrosion of the metal, leading to the onset of localized corrosion (cf. Fig. 1d–f). In fact, passive oxide films on titanium and on its alloys are generally believed to get immediately passivated. A few reports however, have addressed the self-healing kinetics of these biomaterials. Burstein and Souto reported on depassivation of titanium in the early stages of immersion in a physiological environment23. In their work, using electrochemical noise detection and chronoamperometry as measuring tools, transient depassivation of titanium in the presence of chlorides was observed, followed by a repassivation step. Later, the same authors reported a comparative study between pure titanium and Ti−6Al−4 V. They observed that the Ti−6Al−4 V is more susceptible to the depassavation feature even at ambient temperature. In an acidic environment this difference was more noticeable24. Soon after, they reported that the increase in temperature enhances the rate of metastable nucleation of pits on titanium25. Later on, Pust et al. correlated the higher pitting susceptibility exhibited by Ti−6Al−4 V with the biphasic microstructure of the material, as higher electron transfer rates occur for β-phase compared to α-phase33. On the other hand, Contu et al. examined the repassivation of the mechanically damaged surface of pure titanium and Ti−6Al−4 V immersed in inorganic buffer solutions34. In their work, the repassivation kinetics was investigated by measuring the open circuit potential of the testing samples before and after mechanically damaging the surface film. They proved that the self-healing process on the tested samples takes some minutes. More recently, Wang et al. studied the self-healing of different titanium alloys using in situ scratching35, whereas the repassivation rate was controlled using chronoamperometry. In their experiments, the test samples were polarized at 0.1 V (vs. a saturated calomel electrode (SCE)) for 600 s, followed by scratching the surface and monitoring the time needed for the current to reach the same value of the previously undamaged surface, and this was taken as the time of the self-healing. They demonstrated that the time needed for the self-healing of the tested titanium alloys varied between 10 and 150 s, depending on the composition of the alloy.

Passivity breakdown and repair

So far, the knowledge on the healing characteristics and corrosion resistance of the surface films formed on titanium and its alloys has been derived using chronoamperometry. Although this technique has provided valuable insights regarding the passivity breakdown process, it is not an adequate tool to determine the self-healing rate because it requires the prior formation of a protective surface film on the tested samples by electrochemical polarization, which effectively enhances the formation of the protective film. In addition, the kinetics of the self-healing process is greatly affected by the value of the imposed polarization36,37. For this reason, an in situ tool is demanded which can determine the rate of the self-healing of the passive films without applying any polarization to the investigated sample, that would remain effectively at its spontaneously developed open circuit corrosion potential (OCP). Therefore, Asserghine et al. chose scanning electrochemical microscopy (SECM) operated in the feedback mode for this purpose38, as it can be used as a non-destructive in situ tool for the characterization of the surface of materials with chemical resolution. In this way, they showed that after removal of the passive layer of titanium oxide from grade G4 (Ti-G4), the self-healing of the protective film is a time-dependent process, and it takes around 20 min for Ti-G4 to be completely passivated in a phosphate buffer solution (PBS). This was evidenced by monitoring electron transfer reactions on the surface of Ti-G4 by recording consecutive Z-approach curves using ferrocene methanol as a reversible redox mediator (FcMeOH), and their findings contradict the idea of an immediate (very fast) passivation of titanium. On the other hand, SECM was used by Izquierdo et al. to study the effect of zirconium addition as alloying element on the self-healing of the passive film on titanium in Ringer’s solution39. They proved that the presence of zirconium in 5 wt.% results in the formation of a thicker and more compact passive film in shorter times than those needed for the passive film formed in the case of 25 and 45 wt.% zirconium additions to titanium. In this way, their findings support the observation by Wang et al. that the rate of self-healing process depends on the metallurgical composition of the surface36.

Since after damage or breakdown it takes some time for the passive layer of titanium and its alloys to heal, chemical reactions are likely to occur on the unprotected surface during the healing process, and these can lead to the release of metal ions. Interestingly, the release of nickel and titanium ions has been documented for nitinol (45 wt.% Ni + 55 wt.% Ti)37, which is regarded as the most frequently employed titanium alloy biomaterial. Thus, nickel ions have been found in both neutral and acidic physiological environment and titanium was found only in acidic physiological environment40. The implications of this observation are important, since nickel ions are known to promote allergic reactions41. Asserghine et al. attempted to find the causes of metal ion release from nitinol using SECM in combination with atomic absorption spectroscopy analysis42. In this way, they observed that the passive oxide layer on nitinol is rather stable in a neutral simulated physiological environment (0.1 M NaCl solution), and the nickel ions detected in this environment are the result of the dissolution of nickel-rich inclusions present on the surface of the alloy. On the contrary, the passive film on nitinol immersed in an acid medium is not stable. Its breakdown was observed, while the repassivation process took 90 min to reform a stable and passive layer on the nitinol surface. In conclusion, these authors reported that nickel ions get in the fluid during the dissolution (breakdown) of the passive film on nitinol, while titanium is released during the subsequent self-healing process42.

In addition, ion release can also be investigated by measuring local pH changes that occur in the physiological environment in the vicinity of the metal surface. Thus, Asserghine and coworkers43 used a scanning probe made from antimony as a microelectrochemical pH sensor, showing that during the self-healing of titanium, the pH of the local environment shifts to the acidic direction due to the release of metal cations from the metal into the bulk of the electrolyte. This observation is of great importance from the point of view of cytotoxity, since the implanted materials are enveloped by biological cells. Therefore, the living cells can be affected during the self-healing process due local pH changes, eventually leading to their death44. On the other hand, during oxygen electroreduction at the associated microcathode sites, reactive oxygen species (ROS, including superoxides, hydroxyl radicals, hydrogen peroxide and singlet oxygen) can be generated (cf. Fig. 1d−f), which can seriously damage cells and even cause necrosis44,45,46.

Outlooks

This perspective draws awareness to the transient phenomena that take place during the early stages of repassivation in titanium biomaterials. During this, electron exchange reactions can precede with species present in the local environment, and the release of metal ions occur associated with local pH changes in the adjacent physiological environment. Therefore, for further application of titanium biomaterials, the following standpoints should be considered:

-

The kinetics of the self-healing process should be a feature to take into account for the evaluation of a biomaterial application.

-

Further research must be directed to investigate the self-healing of titanium and its alloys in human body fluids (human blood) and explore the effect of proteins and other bio-molecules on the repassivation of most commonly used titanium alloys such as nitinol and Ti−6Al−4 V, although the latter will require that these effects be explored for the α and β phases separately, as well as under galvanic coupling.

-

New metallurgical formulations or surface processing treatments must be developed to obtain fast self-healing and stable oxide films on titanium-based biomaterials.

-

New research must be undertaken to study in vitro and in vivo the cytotoxic effects produced in biological cells during self-healing of titanium biomaterials.

-

In situ microelectrochemical techniques are necessary for the characterization of biomaterials biocompatibility instead of using only conventional electrochemical techniques to evaluate their resistance to corrosion.

References

Griza, S., de Souza Sá, D. H. G., Batista, W. W., de Blas, J. C. G. & Pereira, L. C. Microstructure and mechanical properties of hot rolled TiNbSn alloys. Mater. Des. 56, 200–208 (2014).

Williams, D. F. Biocompatibility of clinical implant materials. In Biocompatibility of Clinical Impact Materials, vol. 1 (ed Williams, D. F.) 9–19 (CRC Press, 1981).

Geetha, M., Singh, A. K., Asokamani, R. & Gogia, A. K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 54, 397–425 (2009).

Brunette, M. D., Engvall, P. T., Textor, M. & Thomsen, P. Titanium in Medicine: Material Science, Surface Science, Engineering, Biological Responses, and Medical Applications. (Springer-Verlag, 2001).

Williams, D. F. The Williams Dictionary of Biomaterials. (Liverpool University Press, 1999).

Yu, F., Addison, O. & Davenport, A. J. A synergistic effect of albumin and H2O2 accelerates corrosion of Ti6Al4V. Acta Biomater. 26, 355–365 (2015).

Gilbert, J. Corrosion in the human body: metallic implants in the complex body environment. Corrosion 73, 1478–1495 (2017).

Hedberg, Y. S. Role of proteins in the degradation of relatively inert alloys in the human body. NPJ Mater. Degrad. 2, 26 (2018).

Géringer, J., Boyer, B. & Kim, K. Fretting corrosion in biomedical implants. In Tribocorrosion of Passive Metals and Coatings (eds Landolt, D. & Mischler, S.) 401–423 (Woodhead Publishing England, 2011).

Mas-Moruno, C. et al. Bioactive ceramic and metallic surfaces for bone engineering. In Biomaterials Surface Science (eds. Taubert, A., Mano, J. F. & Rodríguez-Cabello, J. C.) 337–374 (Wiley USA, 2013).

Arnholt, C. M. et al. Corrosion damage and wear mechanisms in long-term retrieved CoCr femoral components for total knee arthroplasty. J. Arthroplast 31, 2900–2906 (2016).

Tao, Z. –S. et al. A comparative study of zinc, magnesium, strontium-incorporated hydroxyapatite-coated titanium implants for osseointegration of osteopenic rats. Mater. Sci. Eng. C. 62, 226–232 (2016).

Addison, O. et al. Do ‘passive’ medical titanium surfaces deteriorate in service in the absence of wear? Interface 9, 3161–3164 (2012).

Schutz, R. W. Corrosion of titanium and titanium alloys. In ASM Handbook, Volume 13B: Corrosion: Materials (eds Cramer, S. D. & Covino Jr., B. S.) 252–299 (ASM International USA, 2005). https://doi.org/10.1361/asmhba0003822

Chen, X. & Mao, S. Titanium dioxide nanomaterials: synthesis, properties, modifications, and applications. Chem. Rev. 107, 2891–2959 (2007).

Hager, M. D., Greil, P., Leyens, C., van der Zwaag, S. & Schubert, U. S. Self-healing materials. Adv. Mater. 22, 5424–5430 (2010).

Oliveira, V. M. C. A., Aguiar, C., Vazquez, A. M., Robin, A. & Barboza, M. J. R. Improving corrosion resistance of Ti–6Al–4V alloy through plasma-assisted PVD deposited nitride coatings. Corros. Sci. 88, 317–327 (2014).

Wang, S., Liu, Y., Zhang, C., Liao, Z. & Liu, W. The improvement of wettability, biotribological behavior and corrosion resistance of titanium alloy pretreated by thermal oxidation. Tribol. Int. 79, 174–182 (2014).

Kulkarni, M. et al. Titanium nanostructures for biomedical applications. Nanotechnology 26, 062002 (2015).

Xu, G., Shen, X., Hu, Y., Ma, P. & Cai, K. Fabrication of tantalum oxide layers onto titanium substrates for improved corrosion resistance and cytocompatibility. Surf. Coat. Tech. 272, 58–65 (2015).

Lu, J. et al. Electrochemical corrosion characteristics and biocompatibility of nanostructured titanium for implants. Appl. Surf. Sci. 434, 63–72 (2018).

Niinomi, M. Recent research and development in titanium alloys for biomedical applications and health care goods. Sci. Technol. Adv. Mater. 4, 445–454 (2003).

Burstein, G. T. & Souto, R. M. Observations of localized instability of passive titanium in chloride solution. Electrochim. Acta 40, 1881–1888 (1995).

Souto, R. M. & Burstein, G. T. A preliminary investigation into the microscopic depassivation of passive titanium implant materials in vitro. J. Mater. Sci.: Mater. Med. 7, 337–343 (1996).

Burstein, G. T., Liu, C. & Souto, R. M. The effect of temperature on the nucleation of corrosion pits on titanium in Ringer’s physiological solution. Biomaterials 26, 245–256 (2005).

Sarmiento-González, A., Marchante-Gayón, J. M., Tejerina-Lobo, J. M., Paz-Jiménez, J. & Sanz-Medel, A. High-resolution ICP-MS determination of Ti, V, Cr, Co, Ni, and Mo in human blood and urine of patients implanted with a hip or knee prosthesis. Anal. Bioanal. Chem. 391, 2583–2589 (2008).

Nuevo-Ordónez, Y. et al. Titanium release in serum of patients with different bone fixation implants and its interaction with serum biomolecules at physiological levels. Anal. Bioanal. Chem. 401, 2747–2754 (2011).

Eliaz, N. Corrosion of metallic biomaterials: A review. Materials 12, 407 (2019).

Jacobs, J. J., Gilbert, J. L. & Urban, R. M. Corrosion of metal orthopaedic implants. J. Bone Jt. Surg. Am. 80, 268–282 (1998).

Yokoyama, K. I., Ichikawa, T., Murakami, H., Miyamoto, Y. & Asaoka, K. Fracture mechanisms of retrieved titanium screw thread in dental implant. Biomaterials 23, 2459–2465 (2002).

Virtanen, S. et al. Special modes of corrosion under physiological and simulated physiological conditions. Acta Biomater. 4, 468–476 (2008).

Hedberg, Y. S., Žnidaršič, M., Herting, G., Milošev, I. & Odnevall Wallinder, I. Mechanistic insight on the combined effect of albumin and hydrogen peroxide on surface oxide composition and extent of metal release from Ti6Al4V. J. Biomed. Mater. Res. B 107, 858–867 (2018).

Pust, S. E., Scharnweber, D., Nunes Kirchner, C. & Wittstock, G. Heterogeneous distribution of reactivity on metallic biomaterials: Scanning Probe microscopy studies of the biphasic Ti alloy Ti6Al4V. Adv. Mater. 19, 878–882 (2007).

Contu, F., Elsener, B. & Böhni, H. A study of the potentials achieved during mechanical abrasion and the repassivation rate of titanium and Ti6Al4V in inorganic buffer solutions and bovine serum. Electrochim. Acta 50, 33–41 (2004).

Wang, J. –L. et al. A closer look at the in vitro electrochemical characterisation of titanium alloys for biomedical applications using in-situ methods. Acta Biomater. 54, 469–478 (2017).

Zhu, R., Nowierski, C. Z., Noël, J. J. & Shoesmith, D. W. Insights into grain structures and their reactivity on grade-2 Ti alloy surfaces by scanning electrochemical microscopy. Chem. Mater. 19, 2533–2543 (2007).

Asserghine, A., Medvidović-Kosanović, M., Nagy, L., Souto, R. M. & Nagy, G. A study of the electrochemical reactivity of titanium under cathodic polarization by means of combined feedback and redox competition modes of scanning electrochemical microscopy. Sens. Actuators B Chem. 320, 128339 (2020).

Asserghine, A., Filotás, D., Nagy, L. & Nagy, G. Scanning electrochemical microscopy investigation of the rate of formation of a passivating TiO2 layer on a Ti G4 dental implant. Electrochem. Commun. 83, 33–35 (2017).

Izquierdo, J. et al. Electrochemical behaviour of ZrTi alloys in artificial physiological solution simulating in vitro inflammatory conditions. Appl. Surf. Sci. 313, 259–266 (2014).

Huang, H. –H. et al. Ion release from NiTi orthodontic wires in artificial saliva with various acidities. Biomaterials 24, 3585–3592 (2003).

Gitlitz, P. H., Sunderman, F. W. Jr. & Goldblatt, P. J. Aminoaciduria and proteinuria in rats after a single intraperitoneal injection of Ni(II). Toxicol. Appl. Pharmacol. 34, 430–440 (1975).

Asserghine, A., Medvidović-Kosanović, M., Nagy, L. & Nagy, G. In situ monitoring of the transpassivation and repassivation of the passive film on nitinol biomaterial by scanning electrochemical microscopy. Electrochem. Commun. 107, 106539 (2019).

Asserghine, A., Filotás, D., Németh, B., Nagy, L. & Nagy, G. Potentiometric scanning electrochemical microscopy for monitoring the pH distribution during the self-healing of passive titanium dioxide layer on titanium dental root implant exposed to physiological buffered (PBS) medium. Electrochem. Commun. 95, 1–4 (2018).

Pelicano, H., Carney, D. & Huang, P. ROS stress in cancer cells and therapeutic implications. Drug Resist. Update 7, 97–110 (2004).

Trachootham, D., Alexandre, J. & Huang, P. Targeting cancer cells by ROS-mediated mechanisms: A radical therapeutic approach? Nat. Rev. Drug Discov. 8, 579–591 (2009).

Asserghine, A. et al. In situ investigation of the cytotoxic and interfacial characteristics of titanium when galvanically coupled with magnesium using scanning electrochemical microscopy. ACS Appl. Mater. Interfaces 13, 43587–43596 (2021).

Jia, W. et al. Nickel release from orthodontic arch wires and cellular immune response to various nickel concentrations. J. Biomed. Mater. Res. B 48, 488–495 (1999).

Wever, D. J. et al. Electrochemical and surface characterization of a nickel–titanium alloy. Biomaterials 19, 761–769 (1998).

Bhat, S. V. Biomaterials. 36–38 (Narosa Publishing House, India, 2002).

Aksakal, B., Yildirim, Ö. S. & Gul, H. Metallurgical failure analysis of various implant materials used in orthopedic applications. J. Fail. Anal. Prev. 4, 17–23 (2004).

Rao, S., Okazaki, Y., Tateishi, T., Ushida, T. & Ito, Y. Cytocompatibility of new Ti alloy without Al and V by evaluating the relative growth ratios of fibroblasts L929 and osteoblasts MC3T3-E1 cells. Mater. Sci. Eng. C. 4, 311–314 (1997).

Piazza, S., Lo Biundo, G., Romano, M. C., Sunseri, C. & Di Quarto, F. In situ characterization of passive films on Al–Ti alloy by photocurrent and impedance. Corros. Sci. 40, 1087–1108 (1998).

Acknowledgements

This work was supported by the Hungarian Research Grant NFKI Nr 125244 (Budapest, Hungary), the International Visegrad Fund project number 22020140 (Bratislava, Slovakia), and jointly the University of La Laguna and the Spanish Ministry of Science, Innovation and Universities (Madrid, Spain) under contract No. 2022/0000586.

Author information

Authors and Affiliations

Contributions

A.A. and G.N. proposed the concept behind the study. A.A. and R.M.S. did the literature study and co-wrote the script. D.F., L.N., and G.N. revised the script, provided critical comments and supervised the work. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Asserghine, A., Filotás, D., Nagy, L. et al. Do titanium biomaterials get immediately and entirely repassivated? A perspective. npj Mater Degrad 6, 57 (2022). https://doi.org/10.1038/s41529-022-00270-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-022-00270-0