Abstract

The protection of marine materials against corrosion using marine bacterial biofilms is a promising strategy. However, little is known about the mechanisms of this attractive corrosion prevention method. In this work, the corrosion behaviors of X80 carbon steel (CS) in the presence of three different marine Vibrio species were studied. The results demonstrated that all the three Vibrio spp. displayed significant corrosion protection with a weight loss reduction of up to 68%. Moreover, their corrosion prevention performance was tightly related to their abilities to form biofilms, which was in the order of Vibrio sp. EF187016 > Vibrio alginolyticus > Vibrio parahaemolyticus. To further investigate the corrosion prevention mechanism caused by marine biofilms, the extracellular polymeric substances (EPS) of Vibrio sp. EF187016 was extracted and added to 3.5 wt% NaCl for abiotic corrosion testing. The results suggested that the EPS inhibited corrosion, which means EPS can play a significant role in corrosion protection by biofilm.

Similar content being viewed by others

Introduction

Steel is one of the most widely used structural materials in marine equipment for the transportation of oil and natural gas because of its low cost, high strength, toughness, weldability, and other characteristics1,2,3,4. However, corrosion of steel is a critical issue that causes huge economic losses in the aggressive marine environment. Indeed, the high saline content and microorganisms can cause the decay of materials performance, and thus greatly reduce their expected service lifespan. Traditional strategies for corrosion control are expensive, environmentally problematic, and sometimes inefficient. Through exploring the natural mechanisms of microorganisms and sessile cells in protecting themselves against the harsh attack from external environments5, several biogenic organic substances associated with a variety of microbes6,7,8,9 were reported to possess corrosion inhibition effects on many materials, such as carbon steel (CS)10,11,12, aluminum13,14,15, and copper16,17. It is known that bacteria can significantly change the chemical, physical, and electrochemical characteristics of the surrounding environments18. In most cases, bacteria reside on surfaces by forming a biofilm, which might act as a physical barrier to inhibit corrosion. It is known that an aerobic biofilm consumes O2 and greatly reduces the O2 concentration in the biofilm19. For instance, Pseudomonas cichorii6 and Pseudomonas flava7 biofilms are able to significantly reduce the corrosion rates of mild steel. Biofilm has a three-dimensional architecture that is composed of extracellular polymeric substances (EPS) with embedded sessile bacterial cells. EPS have been reported to impact the interaction between microorganisms and the substrate and the surrounding environment20, which may lead to microbiologically influenced corrosion inhibition (MICI)21.

EPS are mainly composed of extracellular polysaccharides, proteins, lipids, and nucleic acids22. These polymeric macromolecules have certain viscosities and can tightly adhere to a solid surface to form a biofilm, which blocks the diffusion of aggressive ions and other chemical species in the surrounding environment. Previously, Masoumeh et al.23,24 discovered a novel bacterium, Vibrio neocaledonicus sp., whose EPS bond to iron to form Fe-N-acetyl hexosamine complexes, exhibiting an excellent corrosion inhibition efficiency. Liu et al.12 reported corrosion inhibition effects of EPS produced by iron-oxidizing bacteria, and explored the concentration and culture-cycle dependency effects of EPS on corrosion inhibition.

Vibrio spp. widespread marine bacteria, which are able to form dense biofilms on solid surfaces25,26. This work elucidated the MICI mechanisms of three representative Vibrio spp. on X80 CS. Vibrio parahaemolyticus, Vibrio alginolyticus, and Vibrio sp. EF187016 were isolated from the South China Sea, Xiamen, China. The MICI performances of these three bacteria were characterized by an array of electrochemical and surface analysis techniques. In addition, the EPS of Vibrio sp. EF187016 were isolated and tested to further investigate the MICI mechanisms. The systematic study on the MICI mechanisms of the marine Vibrio spp. provided a theoretical foundation for the application of beneficial biofilms as a green and sustainable method for corrosion inhibition.

Results and discussion

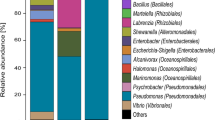

Biofilm characterization

The morphologies of V. parahaemolyticus, V. alginolyticus, and Vibrio sp. EF187016 on the surfaces of X80 CS samples were characterized using field emission scanning electron microscopy (FESEM) and confocal laser scanning microscopy (CLSM) after 7- and 14-d incubation periods. As shown in Fig. 1, after 7-d incubation, microbes were embedded in EPS and formed dense biofilm patches on X80 CS surfaces. The biofilms were denser after 14-d incubation. Figure 2 displays the 3D-CLSM images of biofilms after fluorescence staining. The viable cells, showing up as green dots, formed strong and dense biofilms on X80 CS samples after 7- and 14-d incubation periods. Red dots are hardly seen in Fig. 2b, d, f, indicating virtually no dead cells after 14 d of incubation. The order of the biofilm thickness was Vibrio sp. EF187016 (71.1 μm) > V. alginolyticus (63.6 μm) > V. parahaemolyticus (50.8 μm).

Weight loss and pitting corrosion

Weight loss tests, which directly represent uniform or general corrosion rate, were performed for each X80 CS sample. Figure 3a displays the weight loss data of each sample after incubation in different culture media. The results indicated that the three Vibrio spp. all caused significant decreases in corrosion of X80 CS. After 14-d incubation, the weight loss of X80 CS was 5.45 mg cm−2 in the abiotic medium as a result of O2 corrosion. However, it decreased to 2.59, 2.46, and 1.76 mg cm−2 in the presence of V. parahaemolyticus, V. alginolyticus, and Vibrio sp. EF187016, respectively. The highest inhibition efficiency of 68% was achieved by Vibrio sp. EF187016. In this work, the acid attack was not a contributing factor in corrosion because the culture medium pH values in all groups were above 7 during the entire 14-d incubation period (Supplementary Fig. 1). The highest broth pH was 8.6 at the end of the 14-d incubation (for Vibrio sp. EF187016), which is significantly higher than the corresponding pH 7.8 in the sterile medium. However, the higher biotic pH was unlikely behind the large observed weight loss reduction offered by Vibrio sp. EF187016 here. This is because, in the pH range of 4–10, abiotic iron corrosion rate in aerated seawater is known to be constant27.

The corrosion pits on each coupon were characterized with CLSM imaging (Fig. 3b) after the weight loss tests. After 14-d incubation in the sterile medium, the maximum pit depth was 7.3 µm and the average maximum pit depth was 4.9 ± 0.3 µm (Supplementary Table 1). Much shallower pits were observed for the coupons with biofilm protection. The average maximum pit depth decreased significantly to 3.1 ± 0.5, 3.0 ± 0.3, and 2.2 ± 0.1 µm in the presence of V. parahaemolyticus, V. alginolyticus, and Vibrio sp. EF187016, respectively. The pit depth data clearly demonstrated that Vibrio spp. significantly inhibited both the general and pitting corrosion process of X80. The results of biofilm characterization, weight loss and surface analysis implied that the corrosion protection effect of Vibrio spp. had a positive correlation with the thickness of the biofilm.

Open circuit potential and linear polarization resistance

Figure 4a shows the variation of EOCP (open circuit potential) for X80 immersed in different culture media. The EOCP of X80 immersed in the sterile medium fluctuated over the 14-d period, which could be the result of the buildup and loss of corrosion products28. In Fig. 4a, the abiotic coupon has the most negative EOCP, indicating the highest tendency for corrosion without biofilm protection.

The variation of the linear polarization resistance (Rp) over time is shown in Fig. 4b. The Rp values in the sterile medium were significantly lower than those in the presence of Vibrio spp. biofilms. According to the Stern-Geary equation, a higher Rp corresponds to a lower corrosion rate. Thus, Rp trends can be qualitatively used to analyze corrosion inhibition trends. The Rp values in this work were in the order of Vibrio sp. EF187016 > V. alginolyticus > V. parahaemolyticus, representing their ability to inhibit corrosion. The Rp data here were consistent with the weight loss and pit depth data trends.

In order to further explore the effects of the three Vibrio spp. on the corrosion kinetics of X80, potentiodynamic polarization scans were performed at the end of 14-d incubation (Fig. 4c). Compared with the sterile control, the presence of Vibrio spp. caused the decrease of both cathodic reaction and anodic reaction rates. The decrease in the cathodic reaction was due to the fact that less O2 reaching X80 in the presence of the biofilm protection. The corresponding fitted electrochemical parameters are displayed in Fig. 4d. X80 in the sterile medium had a corrosion current density (icorr) of 0.73 ± 0.03 µA cm−2. In the presence of Vibrio spp., icorr decreased. The icorr was in the following order: V. parahaemolyticus (0.40 ± 0.11 µA cm−2) > V. alginolyticus (0.35 ± 0.09 µA cm−2) > Vibrio sp. EF187016 (0.32 ± 0.01 µA cm−2), indicating Vibrio sp. EF187016 as the most effective strain in corrosion protection.

Electrochemical Impedance Spectroscopy (EIS) test

Nyquist and Bode plots were recorded for the X80 specimens immersed in the different culture media at 1, 4, 7, and 14 days. For the sample immersed in the sterile medium, the smaller diameter of the semi-circles in the Nyquist plots suggested lower corrosion resistance (Supplementary Fig. 2a). The diameter of Nyquist plot increased with the incubation time, indicating the formation of a corrosion protection film29. Larger diameters in Nyquist plots were observed for the samples immersed in the biotic media (Supplementary Fig. 2c, e, g), indicating the increased impedance for corrosion. Furthermore, compared with the sterile condition (Supplementary Fig. 2b), the |Z | value in the presence of different Vibrio spp. at the low-frequency region (Supplementary Fig. 2d, f, h) were significantly higher, suggesting higher corrosion resistance for X80 under these conditions.

The EIS spectra were curve-fitted satisfactorily (Σχ2 < 10−3) with equivalent circuits (Supplementary Fig. 3b), which yielded corresponding electrochemical parameters (Supplementary Table 2). In the presence of Vibrio spp., the Rct + Rf value at each time point was higher than that in the sterile medium, suggesting corrosion protection offered by the biofilms. The highest Rct + Rf value at the 14th day (8.0 × 104 Ω cm2) occurred in the presence of Vibrio sp. EF187016, confirming that its biofilm offered the best protection among the three biofilms.

Corrosion products

The high-resolution XPS (X-ray photoelectron spectroscopy) spectra of Fe 2p of X80 samples after 14-d incubation in different culture media are shown in Fig. 5a−d, and the corresponding chemical species were identified (Supplementary Table 3). The main corrosion product peaks detected by XPS for different groups were Vibrio sp. EF187016 (FeO), V. alginolyticus (Fe3O4), V. parahaemolyticus (Fe3O4 and Fe2O3), and sterile medium (Fe2O3), respectively, indicating a sequence of more oxidized Fe in the iron oxides30,31,32,33. Among them, Fe2O3 is an Fe(III) oxide, which is the most oxidized form of Fe. FeO is an Fe(II) oxide, which is the least oxidized. Fe3O4 is a mixture of FeO and Fe2O3 or an Fe(II)/Fe(III) oxide32,34,35,36. The increasing oxidation state for Fe in the corrosion products above agreed well with the increasing corrosion weight loss sequence of Vibrio sp. EF187016 < V. alginolyticus < V. parahaemolyticus < sterile medium. This confirmed that the corrosion was caused by O2 attack, and Vibrio sp. EF187016 was the most protective among all the three Vibrio spp. because less O2 reached the X80 surface.

Effect of EPS on the abiotic corrosion behavior of X80 CS

Vibrio spp. gradually covered the surfaces of X80 CS with a dense biofilm during the 14-d incubation. Vibrio sp. EF187016 on the surfaces of X80 produced a large number of EPS (Supplementary Fig. 4). It has been reported that EPS are involved in biofilm formation and stability, influencing the properties and functions of microbial biofilms22. However, the effect of EPS on corrosion prevention is unclear. In order to clarify the role of EPS in the corrosion inhibition mechanism, EPS from Vibrio sp. EF187016 were isolated and evaluated for corrosion protection.

Figure 6 displays the FESEM images for X80 exposed to 3.5 wt% NaCl solution containing different concentrations of EPS after 72 h immersion. It can be clearly seen that the X80 surfaces were covered with a layer of EPS. Moreover, the EPS density on the X80 CS surfaces increased as the EPS concentration increased. A dense EPS layer was present for 3 g L−1 Vibrio sp. EF187016 EPS (Fig. 6c). This was in agreement with other researchers’ observation that EPS can attach to material surfaces to form a uniform layer37,38.

Figure 7 shows the weight loss results of X80 after immersion in 3.5 wt% NaCl solutions containing different concentrations of Vibrio sp. EF187016 EPS. After 72 h immersion, a weight loss of 4.03 mg cm−2 was detected in the control group with 0 g L−1 EPS. The weight losses were 3.69, 3.12, and 2.43 mg cm−2 for additions of 1, 2, and 3 g L−1 EPS, respectively. The weight-loss trend suggested that a higher concentration of EPS inhibited corrosion better.

In order to clarify the role of EPS in abiotic corrosion protection, electrochemical tests were conducted using different concentrations of Vibrio sp. EF187016 EPS in 3.5 wt% NaCl solutions. In Fig. 8a, all the EOCP values shifted toward the more positive direction during the test, and no obvious difference is seen at the end of 72 h immersion for 1–3 g L−1 EPS samples. It is known that OCP does not always reflect corrosion trends, especially in MIC because OCP only reflects the thermodynamic tendency for corrosion but the actual corrosion outcome depends on the corrosion kinetic process. Kinetic electrochemical tests need to be conducted39. In this work, the addition of Vibrio sp. EF187016 EPS caused the increase of Rp, and a larger EPS concentration led to a higher Rp (Fig. 8b). Moreover, Rp gradually increased with immersion time, suggesting the accumulation of EPS on an X80 surface offered corrosion protection. In Fig. 8c, potentiodynamic polarization curves at 72 h in different solutions are exhibited. Tafel analysis was carried out to obtain electrochemical parameters. Figure 8d shows that the addition of EPS caused a significant decrease of icorr, from 13.3 µA cm−2 for the control solution (0 g L−1 EPS) to 4.40, 3.89, and 2.72 µA cm−2 for 1, 2, and 3 g L−1 EPS, respectively. An icorr reduction-based corrosion protection efficiency of 80% was achieved with the addition of 3 g L−1 EPS.

In general, the diameters of the Nyquist plots in the presence of EPS were much larger than that in the control solution at each time point (Supplementary Fig. 5), which indicated higher impedance and lower corrosion. Moreover, the diameters increased with the EPS concentration. The diameters of Nyquist plots also increased over the immersion time, which suggested a gradual accumulation of EPS on X80 surfaces. In the Bode plots (Supplementary Fig. 5b, d, f), after 48 h immersion, the peak heights increased with the concentration of the EPS, indicating the formation of a protective film which gave a more capacitive response40. Furthermore, even though the curve shape remained the same, an increase in the impedance at low frequency was observed with an increase in EPS concentration. This indicated an increment in the protection of X80 with the adsorption of EPS on the surface41,42.

The EIS data for EPS addition were fitted using equivalent circuits (Supplementary Fig. 3) and the electrochemical parameters were obtained (Supplementary Table 4). Within the 72 h immersion, Rct of X80 CS in the control group decreased over time, indicating corrosion rate increase. However, with the EPS addition, Rct increased gradually with the increase of EPS concentration, suggesting that EPS acted as a corrosion inhibitor. The results above confirmed that Vibrio sp. EF187016 EPS was able to form a protective layer on the X80 surface, and provided good corrosion inhibition.

In summary, this study proved that the Vibrio spp. biofilms could attach to the surfaces of X80 CS and inhibit its corrosion. It was found the corrosion inhibition efficiency of Vibrio spp. increased with the thickening of the biofilms. Among the three tested Vibrio spp., Vibrio sp. EF187016 exhibited the best corrosion inhibition performance, reaching a weight loss-based inhibition efficiency of 68%. By extracting and evaluating Vibrio sp. EF187016 EPS, it was further confirmed that EPS played a key role in corrosion protection by the biofilm. XPS results indicated that biofilms of Vibrio spp. decreased the Fe oxidation state in the main corrosion products of various iron oxides, indicating that O2 attack was behind the corrosion. Therefore, the corrosion protection by the biofilms came from two aspects. One was aerobic respiration consumption of O2 by both planktonic and sessile cells, which reduced the O2 amount reaching the surface. The other was the adsorbed EPS on X80 acting as a barrier for corrosive species such as O2 and chloride ions, which was demonstrated in the abiotic EPS corrosion protection tests. Figure 9 illustrates the proposed corrosion inhibition mechanism of X80 CS by Vibrio spp. This study provided a theoretical basis for using biofilms as an eco-friendly corrosion inhibitor for carbon steels in the marine environment.

Methods

Materials

The elemental composition (wt%) of X80 CS used in this study was: 0.07 C, 1.82 Mn, 0.19 Si, 0.045 S, 0.045 P, 0.17 Ni, 0.01 Mo, 0.026 Cr, and balance Fe. A X80 CS ingot was cut into square-shaped coupons of 10 × 10 × 5 mm. For electrochemical tests, a copper wire was soldered to the back of an X80 coupon before the coupon was embedded in Epoxy. For corrosion product analysis, coupons with dimensions of 10 × 10 × 2 mm were used. Each coupon’s exposed surface (1 cm2) was polished with silicon carbide metallurgical papers to 1000 grit, ultrasonically rinsed in absolute alcohol for 15 min, and sterilized with ultraviolet light for 30 min before immersion tests.

Microbial cultivation and EPS extraction

The Vibrio spp. isolated from the South China Sea were cultured in 2216E culture medium purchased from Qingdao Hope Bio-technology Co, Qingdao, China43. Before inoculation, the medium was autoclaved at 121 °C for 20 min. The EPS were extracted from 1000 mL of Vibrio sp. EF187016 broth after for 3-d incubation at 28 °C. The broth was aliquoted into 50 mL portions and centrifuged at 1.07 × 104 g at 4 °C for 20 min. The supernatant was filtered three times through a 0.22 µm membrane filter (Millex-GP, MilliporeSigma, Burlington, MA, USA) to remove bacterial cells. EPS in the filtered solution was separated by adding two volumes of pure isopropanol and keeping the liquid overnight at 4 °C to precipitate EPS. The liquid was then centrifuged again at 25 °C for 5 min to get an EPS precipitate. After air-drying the pooled-together precipitates at room temperature, the extracted EPS product was preserved at 4 °C until use.

Biofilm characterization

The biofilms on X80 samples were characterized using a field emission scanning electron microscope (FESEM, Ultra Plus, Zeiss, Germany). Confocal laser scanning microscopy (CLSM, C2 Plus, Nikon, Japan) was used to observe live and dead cells in the biofilms after staining. Specific methods are described in the Supplementary information.

Weight loss test and characterization of corrosion morphology

The biofilm and corrosion products on the sample surfaces were removed according to the Chinese National Standards (CNS) GB/T10125-2012. After 14-d immersion in different culture media, coupons were sonicated in absolute ethanol for 15 min to remove the surface impurities, and then dried in air. The weights of coupons were measured using an analytical balance with 0.01 mg readability (Shimadzu-AUW220D, Japan). Three replicate coupons were used for a single weight loss data point. The pit morphology on the coupon surfaces was observed and recorded using a CLSM (LSM 710, Zeiss, Germany) as previously reported44.

Electrochemical tests

Electrochemical tests were performed with a three-electrode system45. EIS tests were operated at stable OCP, and the sinusoidal amplitude was 5 mV in the frequency range of 105–10−2 Hz. The EIS data were analyzed with the ZsimpWin software (Princeton Applied Research, USA). The potential was swept in the range of −5 to 5 mV (vs. EOCP) at a scan rate of 0.125 mV s−1 for the Rp measurement. The potentiodynamic polarization curve was scanned at a constant sweep rate of 0.166 mV s−1. The glass cells were kept at 28 °C in a thermostatic bath during the 14-d tests.

Corrosion products

After incubation in different culture media in biotic tests or immersion in 3.5 wt% NaCl in abiotic EPS tests for 14 d, the corrosion products on the coupon surfaces were analyzed with XPS (ESCALAB 250, Thermo VG, USA). Pass energy of 50 eV and a step size of 0.1 eV were used.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Abd El-Lateef, H. M., Abo-Riya, M. A. & Tantawy, A. H. Empirical and quantum chemical studies on the corrosion inhibition performance of some novel synthesized cationic gemini surfactants on carbon steel pipelines in acid pickling processes. Corros. Sci. 108, 94–110 (2016).

Salgar-Chaparro, S. J., Darwin, A., Kaksonen, A. H. & Machuca, L. L. Carbon steel corrosion by bacteria from failed seal rings at an offshore facility. Sci. Rep. 10, 12287 (2020).

Hou, Y., Pojtanabuntoeng, T. & Iannuzzi, M. Use of electrochemical current noise method to monitor carbon steel corrosion under mineral wool insulation. npj Mater. Degrad. 4, 1–9 (2020).

Al-Sodani, K. A. A., Maslehuddin, M., Al-Amoudi, O. S. B., Saleh, T. A. & Shameem, M. Efficiency of generic and proprietary inhibitors in mitigating corrosion of carbon steel in chloride-sulfate environments. Sci. Rep. 8, 11443 (2018).

Videla, H. A. & Herrera, L. K. Understanding microbial inhibition of corrosion. A comprehensive overview. Int. Biodeterior. Biodegrad. 63, 896–900 (2009).

Chongdar, S., Gunasekaran, G. & Kumar, P. Corrosion inhibition of mild steel by aerobic biofilm. Electrochim. Acta 50, 4655–4665 (2005).

Gunasekaran, G., Chongdar, S., Gaonkar, S. N. & Kumar, P. Influence of bacteria on film formation inhibiting corrosion. Corros. Sci. 46, 1953–1967 (2004).

Finkenstadt, V., Cote, G. & Willett, J. Corrosion protection of low-carbon steel using exopolysaccharide coatings from Leuconostoc mesenteroides. Biotechnol. Lett. 33, 1093–1100 (2011).

Li, K., Whitfield, M. & Van Vliet, K. Beating the bugs: roles of microbial biofilms in corrosion. Corros. Rev. 31, 73–84 (2013).

Li, Z. et al. Marine biofilms with significant corrosion inhibition performance by secreting extracellular polymeric substances. ACS Appl. Mater. Interfaces 39, 47272–47282 (2021).

Ghafari, M. D., Bahrami, A., Rasooli, I., Arabian, D. & Ghafari, F. Bacterial exopolymeric inhibition of carbon steel corrosion. Int. Biodeterior. Biodegrad. 80, 29–33 (2013).

Liu, H., Gu, T., Asif, M., Zhang, G. & Liu, H. The corrosion behavior and mechanism of carbon steel induced by extracellular polymeric substances of iron-oxidizing bacteria. Corros. Sci. 114, 102–111 (2017).

Li, H. et al. The influence of additives (Ca2+, Al3+, and Fe3+) on the interaction energy and loosely bound extracellular polymeric substances (EPS) of activated sludge and their flocculation mechanisms. Bioresour. Technol. 114, 188–194 (2012).

Ruan, X., Li, L. & Liu, J. Flocculating characteristic of activated sludge flocs: interaction between Al3+ and extracellular polymeric substances. J. Environ. Sci. 25, 916–924 (2013).

Nardeli, J. V. et al. Tannin: A natural corrosion inhibitor for aluminum alloys. Prog. Org. Coat. 135, 368–381 (2019).

Torres Bautista, B. E. et al. Influence of extracellular polymeric substances (EPS) from Pseudomonas NCIMB 2021 on the corrosion behaviour of 70Cu–30Ni alloy in seawater. J. Electroanal. Chem. 737, 184–197 (2015).

Jayaraman, A. & Mansfeld, F. B. Axenic aerobic biofilms inhibit corrosion of copper and aluminum. Appl. Microbiol. Biotechnol. 52, 787–790 (1999).

Zuo, R. Biofilms: strategies for metal corrosion inhibition employing microorganisms. Appl. Microbiol. Biotechnol. 76, 1245–1253 (2007).

Flemming, H.-C., Schaule, Dr. G., Mcdonough, R. & Ridgway, H. Biofouling and biocorrosion in industrial water systems. Eff. Extent Biofilm Accumul. Membr. Syst. 5, 2132 (1993).

Jefferson, K. K. What drives bacteria to produce a biofilm? FEMS Microbiol. Lett. 236, 163–173 (2004).

Dubiel, M., Hsu, C., Chien, C., Mansfeld, F. & Newman, D. Microbial iron respiration can protect steel from corrosion. Appl. Environ. Microbiol. 68, 1440–1445 (2002).

Shi, Y. et al. Exploiting extracellular polymeric substances (EPS) controlling strategies for performance enhancement of biological wastewater treatments: an overview. Chemosphere 180, 396–411 (2017).

Moradi, M., Song, Z. & Tao, X. Introducing a novel bacterium, Vibrio neocaledonicus sp., with the highest corrosion inhibition efficiency. Electrochem. Commun. 51, 64–68 (2015).

Moradi, M., Song, Z. & Xiao, T. Exopolysaccharide produced by Vibrio neocaledonicus sp. as a green corrosion inhibitor: Production and structural characterization. J. Mater. Sci. Technol. 34, 2447–2457 (2018).

Frischkorn, K., Stojanovski, A. & Paranjpye, R. Vibrio parahaemolyticus type IV pili mediate interactions with diatom-derived chitin and point to an unexplored mechanism of environmental persistence. Environ. Microbiol. 15, 1416–1427 (2013).

Chalkiadakis, E. et al. Partial characterization of an exopolysaccharide secreted by a marine bacterium, Vibrio neocaledonicus sp. from New Caledonia. J. Appl. Microbiol. 114, 1–11 (2013).

Melchers, R. E., Moan, T. & Gao, Z. Corrosion of working chains continuously immersed in seawater. J. Mar. Sci. Technol. 12, 102–110 (2007).

Shaban, M. M. et al. Novel trimeric cationic pyrdinium surfactants as bi-functional corrosion inhibitors and antiscalants for API 5L X70 carbon steel against oilfield formation water. J. Mol. Liq. 305, 112817 (2020).

Lv, M., Du, M., Li, X., Yue, Y. & Chen, X. Mechanism of microbiologically influenced corrosion of X65 steel in seawater containing sulfate-reducing bacteria and iron-oxidizing bacteria. J. Mater. Res. Technol. 8, 4066–4078 (2019).

Ghods, P., Burkan Isgor, O., Bensebaa, F. & Kingston, D. Angle-resolved XPS study of carbon steel passivity and chloride-induced depassivation in simulated concrete pore solution. Corros. Sci. 58, 159–167 (2012).

Yuan, S. J. & Pehkonen, S. O. Microbiologically influenced corrosion of 304 stainless steel by aerobic Pseudomonas NCIMB 2021 bacteria: AFM and XPS study. Colloids Surf. B Biointerfaces 59, 87–99 (2007).

Briggs, D. Handbook of X-ray photoelectron spectroscopy. Surf. Interface Anal. 3, 432 (1981).

Powell, C. J. et al. NIST data resources for surface analysis by X-ray photoelectron spectroscopy and Auger electron spectroscopy. J. Electron Spectrosc. Relat. Phenom. 114–116, 1097–1102 (2001).

Buckley, A. N. & Woods, R. The surface oxidation of pyrite. Appl. Surf. Sci. 27, 437–452 (1987).

Giacovazzo, C. et al. Fundamentals of Crystallography. (Oxford Univ. Press, 2011).

Jung, R.-H., Tsuchiya, H. & Fujimoto, S. XPS characterization of passive films formed on Type 304 stainless steel in humid atmosphere. Corros. Sci. 58, 62–68 (2012).

Dong, Z. H., Liu, T. & Liu, H. F. Influence of EPS isolated from thermophilic sulphate-reducing bacteria on carbon steel corrosion. Biofouling 27, 487–495 (2011).

Su, Y., Qian, C., Rui, Y. & Feng, J. Exploring the coupled mechanism of fibers and bacteria on self-healing concrete from bacterial extracellular polymeric substances (EPS). Cem. Concr. Compos. 116, 103896 (2021).

Jia, R. et al. Effects of ferrous ion concentration on microbiologically influenced corrosion of carbon steel by sulfate reducing bacterium Desulfovibrio vulgaris. Corros. Sci. 153, 127–137 (2019).

Singh, A., Shukla, S., Singh, M. & Quraishi, M. Inhibitive effect of ceftazidime on corrosion of mild steel in hydrochloric acid solution. Mater. Chem. Phys. 129, 68–76 (2011).

Fernandes, C. M. et al. Green synthesis of 1-benzyl-4-phenyl-1H-1,2,3-triazole, its application as corrosion inhibitor for mild steel in acidic medium and new approach of classical electrochemical analyses. Corros. Sci. 149, 185–194 (2019).

Liu, T. et al. Marine bacteria provide lasting anticorrosion activity for steel via biofilm-induced mineralization. ACS Appl. Mater. Interfaces 10, 40317–40327 (2018).

Gao, Y. et al. Inhibiting corrosion of aluminum alloy 5083 through Vibrio species biofilm. Corros. Sci. 180, 109188 (2021).

Jia, R. et al. Effects of biogenic H2S on the microbiologically influenced corrosion of C1018 carbon steel by sulfate reducing Desulfovibrio vulgaris biofilm. Corros. Sci. 130, 1–11 (2018).

Liu, D. et al. Biofilm inhibition and corrosion resistance of 2205-Cu duplex stainless steel against acid producing bacterium Acetobacter aceti. J. Mater. Sci. Technol. 35, 2494–2502 (2019).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. U2006219, 51871050, and 51901039), the Natural Science Foundation of Liaoning Province (No. 20180510041), the Liaoning Revitalization Talents Program (No. XLYC1907158), the Fundamental Research Funds for the Central Universities (No. N2120007), and the Fundamental Research Funds for the Central Universities of the Ministry of Education of China (Nos. N180205021, N180203019, and N2002019).

Author information

Authors and Affiliations

Contributions

Y.G.: Conceptualization, additive manufacturing, methodology, investigation, formal analysis, writing. M.Z.: Additive manufacturing, investigation, writing—review and editing. Y.F.: Additive manufacturing, writing—review and editing. Z.L.: Additive manufacturing, writing—review and editing. P.C.: Analysis of the electrochemical data. X.C.: Writing—review and editing. D.X.: Supervision, funding acquisition. F.W.: Supervision. T.G.: Technical advice, data analysis, review and editing

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gao, Y., Zhang, M., Fan, Y. et al. Marine Vibrio spp. protect carbon steel against corrosion through secreting extracellular polymeric substances. npj Mater Degrad 6, 6 (2022). https://doi.org/10.1038/s41529-021-00212-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-021-00212-2

This article is cited by

-

Biodegradation of materials: building bridges between scientific disciplines

npj Materials Degradation (2023)