Abstract

Thin, soft, and skin-integrated electronic system has great advantages for realizing continuous human healthcare monitoring. Here, we report an ultra-thin, flexible, and garment-based microelectronics powered by sweat-activated batteries (SABs) and applications of powering biosensors and microelectronic systems for real time sweat monitoring. The SAB cell is ultra-thin (1.25 mm) with excellent biocompatibility. The SAB has good electricity output with high capacity (14.33 mAh) and maximum power density (3.17 mW cm−2) after being activated by the sweat volume of 0.045 mL cm−2, which could continuously power 120 light emitting diodes over 3 h. The outputs could maintain stable after repeatable bending. Wireless microelectronics system could be continuously powered by the SABs for 3 h to monitor sweat and physiological information, including sweat Na+ concentration, pH, and skin impedance. The reported integrated system provides a potential for solving the power issues of flexible wearable electronics and realizing personalized medicine.

Similar content being viewed by others

Introduction

Wearable devices with the advances in small size, light weight, and on body features, associating with flexible electronic technologies have attracted great attention in the fields of healthcare monitoring, entertainment, and human-machine interfaces1,2,3,4,5,6,7,8,9,10. Human body, as a remarkable biological system with complex organized physiological processes, associates with lots of biochemical and biophysical signals that could reflect the health status6,11,12. Developing wearable sensors is extremely essential to realize the personalized on-patient healthcare because they can continuously monitor individuals’ physiological biomarkers. Sweat is a typical body fluid containing information of multiple biomarkers such as pH, inorganic ion concentration, and moisture, that can be used as natural testing samples in daily life, since changes in the concentration of these biomarkers are closely related with human physical condition13,14,15. The traditional sweat testing methods associate with collecting sweat samples from skin by gauze pads and then analyzed by benchtop instrument, which is time consuming and may cause the sample pollution16,17. Recent advances in wearable sweat sensors highlights the importance of this field18,19,20,21,22. While many efforts have been focused on developing sweat sensors with high sensitivity and wearing comfortability. There are still some critical issues needed to be addressed for wearable sweat monitoring systems, such as portable power sources and data transmission modules.

Power source as the most important component in wearable electronics; however, is still an obstacle restricting the miniaturization, flexibility, and integration of wearable electronics. Up to now, the most common used powering strategies for wearable devices mainly rely on (a) energy storage components, i.e., lithium-ion battery and super-capacitor23,24,25,26,27,28,29, and (b) energy harvesting and self-powered devices, such as triboelectric nanogenerators, solar cells, and biofuel cells30,31,32,33,34,35,36,37,38. For the energy storage components, batteries and super-capacitors are typically based on rigid and bulky devices, which is not appropriate for wearable electronics. In addition, the electrolytes of commercial rechargeable batteries are strong acid or base, which raises safety concerns during usage. For self-powered devices, the electrical outputs are too low to power and operate microcontrollers for achieving the continuous data collection, processing, and transmission. These devices typically require supercapacitors as energy storage for intermittent operation. Very recently, the concept of sweat-activated battery (SAB) and demonstrations in soft electronics offer a new strategy for power management in wearable electronics for continuous sweat monitoring17,39. Nevertheless, there are still some problems need to be solved for SABs, especially the dimension in thickness, flexibility, and power outputs.

Here, we report a class of materials and devices of wearable sweating sensing electronic system based on ultra-thin, soft, skin-integrated SAB and state of art flexible sweat sensors. The reported SAB could produce sufficient electricity to power the microcontroller (MCU) for continuously data acquisition, processing, and storage of multiplexed monitoring of key metabolic biomarkers in sweat (e.g., sodium ion (Na+) concentration, pH values, and skin impedance) in a wireless data transmission way, and thus allows intelligent dehydration prevention and health monitoring during exercise. The SAB unit cell (3.5 cm × 1 cm) with optimized architecture, materials, and mechanics designs exhibits ultra-thin in thickness of 1.25 mm, great outputs with an open circuit voltage of 1.54 V and a short circuit current of 16.91 mA, and a capacity of 14.33 mAh and a maximum power density (MPD) of 3.17 mW cm−2, that could continuously light 120 light-emitting diodes (LEDs) over 3 h. Excellent flexibility of the SAB allows stable and robust performance under mechanical deformations, with no performance degradation over hundreds of cycles bending at 180°. The demonstration of the SAB associates with powering a multiplexed sweat sensors patch and a near field communication (NFC) based microelectronics for continuous monitoring sweat and skin impedance for 3 h, indicating the possibility of next generation self-powered wearable sweat sensors.

Results

SABs powered microelectronics system for wireless sensing

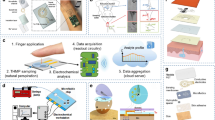

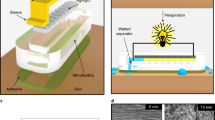

Figure 1a shows the schematic illustrations of the SAB-powered flexible microelectronics system (SMS), which consists of an ultra-thin powering components based on SABs, and a flexible sweating sensing devices with the integration of biosensors for physiological related information detection in sweat and a NFC-based wireless microelectronic device for data collection, processing, and wireless communications. The thin, soft features of the SAB and NFC electronic sensing device allow the SMS to be easily integrated with cloth and thus to be attached onto various parts of body in wearable formats, such as headbands sport braces to wear on heads, elbows, and knees for sweat monitoring. Considering the biocompatibility and performance issues, magnesium (Mg)/oxygen (O2) based reaction principle was selected as the powering option for the SABs, as which is a kind of emerging green power sources with considerable capacity, low cost, and good biocompatibility40,41,42. Figure 1b shows the schematic diagram of the ultra-thin, flexible SAB, which is comprised by a porous tape with releasing layer (thickness, 0.3 mm) for good air breathing and immobilizing inner components, a Graphene coated paper (size, 1 cm × 3 cm; thickness, 0.15 mm) as the cathode, a thin Mg foil (size, 1 cm × 3 cm; thickness, 0.09 mm) as the anode, a thin cotton layer (thickness, 0.8 mm) with potassium chloride (KCl) powders insides serving as rapid sweat absorption layer and thus serves as electrolyte. Noted, the materials selected in the SABs are all low-cost and safe to skin, and environmental friendly. After collecting sweat in the cotton layer and forming liquid environment, Mg foil could react with O2 and water (H2O) to produce magnesium hydrate (Mg(OH)2) (Eq. 1). Therein, the Mg anode could be oxidized and release electrons (Eq. 2). At the same time, O2 could be reduced in the Graphene cathode and obtain electrons (Eq. 3). As a result, an electron transport circuit could be formed between the anode and cathode. Here, for improving the output performance of the SAB, the graphene-coated absorbent paper is utilized for catalyzing oxygen reduction and adsorbing electrolyte43,44,45.

a Schematic illustrations of the skin integrated electronic system. b Schematic illustrations of the ultra-thin SAB. c Optical images of the SAB mounted on human forearm and the enlarged details of side views with the Cartoon shape of a Baymax. d Optical images of the electrodes for the SAB. e SEM image of graphene-coated absorbent paper. f Optical images of the microelectronics system integrated with multiplexed biosensor patch and flexible circuit. g Optical images of the microelectronics system embedded into a head band. h System-level block diagram of the electronic module for the whole system.

Figure 1e shows the scanning electron microscopy (SEM) images of the Graphene coated absorbent paper, where adequate Graphene flakes can be found on the paper. Compared with the neat absorbent paper without any materials coating (Supplementary Fig. 1), it is obvious that graphene has been evenly covered on the surface of the paper, which could significantly enhance the catalytic efficiency. The target of the system is to integrate with cloth, and the format of the SAB should be in an ultrathin architecture, therefore we adopted an in-plane structure for the SAB where the anode and cathode are designed as the side by side structure (Fig. 1d and Supplementary Fig. 2). As demonstrated in Fig. 1c, the ultra-thin format (overall thickness, 1.25 mm), lightweight (0.65 g), and great flexibility allows the SAB convenient to interface with human skin for long-term use and also could be designed as various expected shapes for aesthetics. Supplementary Fig. 3 shows the good biocompatibility of the SAB as there is not any skin irritation reaction after wearing 3 h. The SAB could be stored in vacuum seal bags before using, that effectively prevent the performance degradation caused by the active chemical property of Mg (Supplementary Fig. 4).

The SMS was designed by well-established flexible electronics technologies46,47,48, which is compatible with flexible print circuit board (FPCB) manufacturing processes, and thus capable of achieving high reliability and low cost manufacture. As shown in Fig. 1f, the integrated SMS including the detachable multiplexed biosensor patch, an NFC chip, and electronic components is built on an ultra-soft and thin polyimide (PI, 130 μm) substrate, that offers excellent flexibility with stable performance under bending at a board range of angles, and thus could be entirely embedded into cloth and affixed to the skin for sweat monitoring during exercise (Fig. 1g). A small amount of sweat generated by a short time of activities would activate the SAB for powering the wearable SMS to continuously monitor biomarkers of Na+ concentration, pH values of sweat as well as the skin impedance. The NFC-based MCU is used for data acquisition, processing, and storage. The wireless data transmission happened when a smartphone approaches the SMS, where the stored data of the continuous monitored period of time could be displayed on the graphic user interface (GUI) of the smartphone (Fig. 1h).

Performance characterization of the SABs

Figure 2 shows the electrical characteristics of the SAB as functions of various several parameters, including distance between cathode and anode (Fig. 2a), thickness of the Mg foil (Fig. 2b), and ambient temperature (Fig. 2c), which are directly associating with the device size, operation time and output performance. It is found that longer distance between the electrodes (Fig. 2a) and thinner Mg foil (Fig. 2b) tend to decrease the operation duration of the SAB with smaller average short-circuit current. At a constant Mg foil thickness of 90 µm and ambient temperature of 25 °C, the working duration of the SAB and the corresponding average short-circuit current drops from 3.52 h and 14.98 mA as the distance between electrodes increases from 0.5 to 2.5 cm, where the result is owing to the increase of the inner impedance of the battery (Fig. 2a). From the short-circuit current versus Mg foil thickness shown in Fig. 2b, it can be found that thicker Mg electrode contributes positive effect on the duration and short-circuit current. Specifically, SABs with 30 µm thick Mg electrode yield operating duration of 0.73 h with average short-circuit current of 16.24 mA, while SABs with 90 µm thick Mg electrode exhibits the performance of 3.52 h and 16.91 mA. As a result, the performance of the SABs can be simply optimized by adjusting the distance between electrodes and Mg electrode thickness.

a Short-circuit current of the SABs with three different electrode distances of 0.5, 1.5, and 2.5 cm, as a function of time. b Short-circuit current of the SABs with three different Mg foil thickness, 30, 60, and 90 μm, as a function of time. c Influences of ambient temperature on the SABs’ capacity. Discharging current, 1 mA cm−2. d Open-circuit voltage of the SABs. e Polarization curve of the SABs. f Power density curve of the SABs. g Electrical response of the SABs as a function of time with increasing injected sweat volume. h Electrical output response of the SABs bended as 90° and 180° as a function of time. i Electrical output response of the SABs bendeing over 600 times as a function of time.

Next, we measured the discharging capacity of the SABs and the influences of the electrolyte and ambient temperatures on battery capacity. Supplementary Fig. 5 shows the capacity of the SABs can reach to 14.33 mAh when KCl is used as the electrolyte and salt bridge. Other electrolyte materials including magnesium chloride (MgCl2) and calcium chloride (CaCl2) were also adopted to compare the SAB performance, where the capacity of the SABs using MgCl2 and CaCl2 as electrolyte was only 2.99 mAh and 1.47 mAh, demonstrating KCl electrolyte is the best candidate in this type of SABs. Figure 2c shows the capacity differences of the SABs under different ambient temperatures, where it can be found the energy capacity decreases with the increase of ambient temperature from 14.33 mAh at 25 °C to 6.82 mAh at 45 °C. The results can be explained as the increases of evaporation rates under low-flow-rate conditions, resulting in increased internal resistance (Fig. 2c)17,49. Figure 2d shows the open-circuit voltage as a function of time of a representative SAB cell after absorbing sweat, where the voltage can stabilize at 1.54 V for over 5 h. The polarization data shown in Fig. 2e shows that the maximum current density (MCD) could reach 3.88 mA cm−2. Accordingly, the MPD is calculated as 3.17 mW cm−2 (Fig. 2f). To investigate the influence of the absorbed sweat volume on the electrical performance of the SABs, we measured the open-circuit voltage of the batteries by gradually increasing artificial sweat volume from 0 to 0.045 mL cm−2, as shown in Fig. 2g. It is obvious that the battery can be activated with a very small amount of sweat volume of 0.021 mL cm−2, with an open-circuit voltage of 0.59 V. This small amount of sweat can be easily collected during daily activities, which allows our SABs to exhibit an extremely short activation time (30 s) during activities (Supplementary Table 1). Benefited from the advances in mechanics, the SABs are capable of maintaining stabilized open-circuit voltage around 1.52 V with negligible fluctuations under bending in a broad range from 90° to 180° (Fig. 2h). In addition, the voltage outputs of the SABs stabilize between 1.45 and 1.59 V during repeatable bending test, and exhibit negligible degradation after 600 bending cycles at a constant angle and frequency of 90° and 2.8 Hz (Fig. 2i).

Multiplexed biosensor patch characterization

To verify the performance of the SABs, a load of a 120 green LEDs array was connected to a SAB cell activated by 0.135 mL to test the lighting duration, where it came out the LED array can be continuously lighted over 3 h with high brightness, demonstrating the great capacity and output energy of the SABs (Supplementary Fig. 6 and Supplementary Movie). Encouraged by the excellent performance of the SABs, we next integrated the SABs with the SMS to power multiplexed biosensors for garment-embedded electronics to monitor sweat during exercise (Fig. 3). Figure 3a shows the sensor array with Na+, pH and impedance sensors we developed on PI substrate, where we can see the size of the integrated sensor array patch is very small, similar to the size of our fingertips. The pH sensor associates with the polyaniline (PANI) electrodeposited on the gold (Au) electrode as the sensing layer. The Na+ sensor adopts the method of ion-selective electrode (ISE) based on Au substrate for Na+ concentration detection. The pH sensor shares the same corresponding silver (Ag)/silver chloride (AgCl) reference electrode with the Na+ sensor, and couples with a thin polyvinyl butyral (PVB) coating layer to maintain a stable potential in solutions with different ionic strengths. On the top of the sensor array patch, a pair of Au electrodes serves as the impedance sensor to get the skin impedance in a constant distance. Combining with the detachable multiplexed sensor patch, the integrated SMS could be easily embedded with sport wears, i.e., the head bands, elbow pads, and knee pads for sweat monitoring during exercise (Fig. 3b–d).

a Optical images of the multiplexed biosensor patch. b–d Optical images of SMS embedded in the head band, elbow pad, and knee pad. e, f Calibration curve of the Na+ sensor and pH sensor. g The skin impedance changes as a function of time after dropping 10 μL water. h, i Anti-interference characterization of the Na+ sensor and pH sensor. j Results comparison of the skin impedance and commercial hydration instrument.

The performance of each type of sensor was characterized and optimized as shown in Fig. 3e–j. Supplementary Figs. 7 and 8 show the representative open circuit voltage responses of the Na+ and pH sensors for the physiologically relevant concentrations of 10–100 mM Na+ concentration and 2–8 pH value, respectively50,51. The plots in Fig. 3e, f show good linear relationships between the voltage outputs and the logarithm of ion concentration for both the Na+ sensors and pH sensors. The determination coefficient (R2) of Na+ sensors and pH sensors could reach to 0.993 and 0.998, respectively, indicating great sensitivities of these two biomarkers. Figure 3h, i shows the selectivity study results, and the data indicates excellent anti-interference ability of the Na+ sensors and pH sensors. It is clear that the Na+ sensor is not sensible for other cations besides Na+, as the introduction of additional potassium chloride (KCl) and ammonium chloride (NH4Cl) doesn’t cause any electrical responses, while obvious responses only happened as sodium chloride (NaCl) added in, demonstrating the sensor exhibiting good specificity for Na+ (Fig. 3h). Figure 3i shows the anti-interference study of the pH sensors, where the study associates with adding neutral chemicals of KCl and NaCl, as well acid step by step. We can find that adding KCl and NaCl wouldn’t influence the voltage outputs of the pH sensor, while the sensor is only responsive to the change of H+ concentration. The characterization of the impedance sensors associates with measuring the skin impedance changes with different hydration levels by simply smearing water. Figure 3g shows the skin impedance measured by the impedance sensors could reasonably increase with the water evaporation, demonstrating the feasibility of this method to detect skin impedance. Moreover, a commercial skin hydration meter (Supplementary Fig. 9, Real Bubee Ltd. UK) is used to calibrate the skin impedance sensor, as the hydration value is inversely proportional to the impedance. Figure 3j exhibits the comparison results between commercial hydration meter and the impedance sensor, demonstrating that the skin impedance and hydration on different body locations are different, as well as the usability and stability of the impedance sensor.

On-body real-time health monitoring and wireless data transmission

With the sensitive, stable, and robust performance of the sensor array, as well as the great capacity of the SAB, we next conducted the system level test of the SMS to demonstrate the potential in practical applications. Figure 4a shows a testing subject wears a SMS embedded elbow pad and jogs. The enlarge image in Fig. 4a clearly shows that the multiplexed sensor patch could perfectly attach to the skin for sweat monitoring. When the subject begins to perspire, 2 SAB cells connected in series could be activated quickly and power the microelectronics system and sweat sensors. The signals obtained by the sensor patch would be converted to digital signals by 12-bit ADCs inside the MCU, and then these signals will be stored in a 2 M electrically erasable programmable read-only memory (EEPROM) via I2C. When the phone is approaching, the NFC chip detects an electromagnetic field nearby, then it will send a signal to the MCU, so that the MCU will enter the interrupt, start reading the data stored in the EEPROM through the I2C, and transfer these data to the phone through the NFC chip. The app in the smart phone will display and automatically store the received data for further analysis. Supplementary Fig. 10 demonstrates that the energy output by SABs could continuously support the normal work of the microelectronics system around 3 h. Supplementary Fig. 11 shows the working stability of NFC-based microelectronics device. The normal peak frequency of the NFC system is 13.56 MHz, while that would shift to 13.53 and 13.495 MHz when bended at 30° and 60°. According to the NFC technical protocol of ISO 15693, the NFC communication system can work normally in the frequency range of 13.56 ± 0.07 MHz6,52,53. So, the NFC-based microelectronics device could transfer data normally during activities.

a Optical images of the jogging subject wearing SMS embedded in the elbow pad and the phone interface that illustrates wireless communication and data acquisition. b The real-time monitoring results of the sweat Na+ concentration, pH value and skin impedance during jogging. c–e The comparison of data changes of Na+ concentration, pH value, and skin impedance during exercise on heads of three different subjects. f–h The comparison of data changes of Na+ concentration, pH value, and skin impedance during exercise for three different body locations, including head, elbow, and knee.

Continuous physiological monitoring is performed on a subject over 0.5 h jogging to demonstrate the real time monitoring concept. As shown in Fig. 4b, while the subject is jogging, the Na+ in sweat would increase at the beginning, and then stabilize over time because of the increase of sweat volume could dilute the concentration. There is minor fluctuation for the sweat pH ranging from 3.98 to 4.99 during exercising. As for the skin impedance, the impedance of the skin surface would keep decreasing because of the increase of skin moisture caused by perspiration, while the ion concentration in sweat has little effect on the change tendency of skin impedance. All the results demonstrate that the subject’s physical condition stays stable at the early exercise stage, which is consistent with previous study results12,35,47,50. In Fig. 4c–e, the sweat Na+ concentration, pH, and skin impedance of three different subjects after continuous exercise are compared with the initial levels. It is clear that the sweat Na+ concentration would increase a lot; the pH value slightly increase and impedance would decrease for every subject. Figure 4f–h demonstrates changes of sweat composition and skin impedance in different body locations before and after exercise, which is also consistent with the change trends mentioned previous. These results all prove that general change trends of sweat and skin impedance caused by exercise as well as the feasibility and the stability of the SMS.

Discussion

In summary, we developed an ultra-thin, flexible, and fully integrated flexible electronic system powered by SABs, that can be used for sweat monitoring in real time with wireless transmission capability. The ultra-thin SABs with high output power density and long duration could cling to the skin, be activated by a slight sweat volume, and light 120 LEDs over 3 h. Flexible and sensitive biosensors are able to detect the sweat Na+ concentration, pH value, and skin impedance for dehydration prevention and healthcare monitoring during exercise. Powered by the SABs, signals of sensors could be continuously stored and processed by the microelectronics system, and wirelessly transmitted to the user interface by NFC. As wearable electronics, the whole SMS exhibits good conformal properties on skin surface. It can be assumed that the proposed integrated system would have wide application prospects in fields of wearable electronics and health monitoring.

Methods

Fabrication of SAB

As exhibited in the Supplementary Fig. 12, the first step for fabricating SAB was to cut absorbent paper and Mg sheet into the fixed size (3 cm × 1 cm). And then immersing the obtained absorbent paper into graphene well-dispersed aqueous solution and drying at 100 °C for 10 min, which ensures the uniform distribution of graphene on the surface of absorbent paper. Next, putting obtained graphene/paper and Mg sheet side by side on the air-permeable. Finally, attaching a thin cotton layer containing KCl powders onto electrodes to form the SAB.

Fabrication of microelectronics and multiplexed biosensor patch

Pattern and circuit were fabricated by flexible printed circuit board processing techniques of copper (thickness 10 μm) plated with gold (thickness 50 nm) on PI substrate. Then, an insulating layer was covered onto the exposing circuit for preventing short circuit. All components, including microcontroller (MSP430FR5969, TI), NFC receiver (NT3H2211, NXP), EEPROM (M24M02-DR, STMicroelectronics), and LDO (TPS76933, TI) were all bonded and electrically connected by Low-temperature solder joints all of the components.

For the fabrication of the multiplexed biosensors patch, the electrode substrate was obtained by the similar process with microelectronics. The top two Au electrodes could be used as the impedance sensor. For the preparation of Na+ sensor, PEDOT:PSS was the first layer needed to electrodeposited on the Au electrode, which was obtained by constant current electrodeposition (0.2515 mA, 1800 s) in the mixed solution of 0.01 M 3,4-Ethylenedioxythiophene (EDOT) and 0.1 M polystyrene sulfonate (NaPSS). And then 5 μL Na+ sensitive cocktail was drop-casted on the PEDOT:PSS layer and dried overnight in a 4 °C refrigerator. To prepare the Na+ sensitive cocktail, 100 mg mixture of Na ionophore X (1% w/w), sodium tetrakis [3,5-bis(trifluoromethyl)phenyl] borate (Na-TFPB, 0.55% w/w), polyvinyl chloride (PVC, K-value 72–1, 33% w/w), and bis(2-ethylehexyl) sebacate (DOS, 65.45% w/w) was dissolved in 610 μL of tetrahydrofuran17. For the pH sensor, the sensitive layer of PANI was obtained by electrodeposition in the mixture solution of 0.1 M aniline and 1 M H2SO4 through 50 cycles of cyclic voltammetry (−0.2 to 1 V at a scan rate of 0.1 V s−1). For the fabrication of Ag/AgCl reference electrode, an Ag layer (100 nm) was firstly sputtering on the Au electrode. And then, 10 μL 0.1 M FeCl3 was drop-casted onto the Ag for 30 s to form Ag/AgCl. For the reference electrode of Na+ sensor, 5 μL extra polyvinyl butyral (PVB) cocktail (79.1 mg of PVB, 50 mg of NaCl, 1 mg of block polymer PEO-PPO-PEO, and 0.2 mg of carbon nanotubes in 1 ml of methanol) was drop-casted on the Ag/AgCl electrode.

Characterization

The SEM images were obtained by FEI Quanta 250. The open circuit was measured by the data acquisition (DAQ)/multimeter system (PowerLab 16/35, AD Instruments). Short circuit current was calculated by measuring the voltage of a 2.5 Ω resistance as the load. Polarization curve measurement, chronopotentiometry, constant current electrodeposition, and CV were achieved by the electrochemical work station of CHI 660E. The current density was calculated through the reaction area of electrodes (3 cm2) and the power density was the product of voltage and current density. The battery capacity was the product of discharging current and discharging time.

Ethical information for studies involving human subjects

All experiments involving human subjects were approved by Research Committee of City University of Hong Kong and conducted in compliance with the guidelines. All participants for the studies were fully voluntary and submitted the written informed consents to take part in the study. The device is attached on the subjects’ body and thus the necessary but limited identifiable images must be used. All identifiable information was totally consented by the user.

Data availability

All data are contained within the manuscript. Raw data are available from the corresponding authors upon reasonable request.

References

Deng, J. et al. Electrical bioadhesive interface for bioelectronics. Nat. Mater. 20, 229–236 (2021).

Liu, C. et al. Wireless, skin-interfaced devices for pediatric critical care: Application to continuous, noninvasive blood pressure monitoring. Adv. Health. Mater. 10, 2100383 (2021).

Zhao, H. et al. Compliant 3D frameworks instrumented with strain sensors for characterization of millimeter-scale engineered muscle tissues. Proc. Natl Acad. Sci. USA 118, 19 (2021).

Chun, K. S. et al. A skin-conformable wireless sensor to objectively quantify symptoms of pruritus. Sci. Adv. 7, eabf9405 (2021).

Yu, X. et al. Skin-integrated wireless haptic interfaces for virtual and augmented reality. Nature 575, 473–479 (2019).

Bandodkar, A. J. et al. Battery-free, skin-interfaced microfluidic/electronic systems for simultaneous electrochemical, colorimetric, and volumetric analysis of sweat. Sci. Adv. 5, eaav3294 (2019).

Song, E. et al. Miniaturized electromechanical devices for the characterization of the biomechanics of deep tissue. Nat. Biomed. Eng. 5, 759–771 (2021).

Liu, Y. et al. Electronic skin from high-throughput fabrication of intrinsically stretchable lead zirconate titanate elastomer. Research 2020, 1085417 (2020).

Li, D. et al. Miniaturization of mechanical actuators in skin-integrated electronics for haptic interfaces. Microsyst. Nanoeng. 7, 85 (2021).

Wong, T. H. et al. Tattoo-like epidermal electronics as skin sensors for human-machine interfaces. Soft Sci. 1, 10 (2021).

Li, D., Yao, K., Gao, Z., Liu, Y. & Yu, X. Recent progress of skin-integrated electronics for intelligent sensing. Light.: Adv. Manuf. 2, 1–20 (2021).

Gao, W. et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 529, 509–514 (2016).

Oncescu, V., O’Dell, D. & Erickson, D. Smartphone based health accessory for colorimetric detection of biomarkers in sweat and saliva. Lab Chip 13, 3232–3238 (2013).

Kim, J., Campbell, A. S., de Avila, B. E. F. & Wang, J. Wearable biosensors for healthcare monitoring. Nat. Biotechnol. 37, 389–406 (2019).

Smith, T. W. Blood, sweat, and tears: Exercise in the management of mental and physical health problems. Clin. Psychol.-Sci. Pr. 13, 198–202 (2006).

Huang, X. et al. Epidermal self-powered sweat sensors for glucose and lactate monitoring. Bio-Des. Manuf. 5, 201–209 (2022).

Bandodkar, A. J. et al. Sweat-activated biocompatible batteries for epidermal electronic and microfluidic systems. Nat. Electron. 3, 554–562 (2020).

Bandodkar, A. J. et al. Epidermal tattoo potentiometric sodium sensors with wireless signal transduction for continuous non-invasive sweat monitoring. Biosens. Bioelectron. 54, 603–609 (2014).

He, W. et al. Integrated textile sensor patch for real-time and multiplex sweat analysis. Sci. Adv. 5, eaax0649 (2019).

Sonner, Z. et al. The microfluidics of the eccrine sweat gland, including biomarker partitioning, transport, and biosensing implications. Biomicrofluidics 9, 031301 (2015).

Koh, A. et al. A soft, wearable microfluidic device for the capture, storage, and colorimetric sensing of sweat. Sci. Transl. Med. 8, 366ra165 (2016).

Choi, J. et al. Skin-interfaced microfluidic systems that combine hard and soft materials for demanding applications in sweat capture and analysis. Adv. Health. Mater. 10, 4 (2021).

Wang, L., Zhang, Y., Pan, J. & Peng, H. S. Stretchable lithium-air batteries for wearable electronics. J. Mater. Chem. A 4, 13419–13424 (2016).

Liu, Z. X. et al. Towards wearable electronic devices: A quasi-solid-state aqueous lithium-ion battery with outstanding stability, flexibility, safety, and breathability. Nano Energy 44, 164–173 (2018).

Pu, X. et al. A self‐charging power unit by integration of a textile triboelectric nanogenerator and a flexible lithium‐ion battery for wearable electronics. Adv. Mater. 27, 2472–2478 (2015).

Zhao, K., Yang, Y., Liu, X. & Wang, Z. L. Triboelectrification-enabled self-charging lithium-ion batteries. Adv. Energy Mater. 7, 21 (2017).

Bae, J. et al. Fiber supercapacitors made of nanowire-fiber hybrid structures for wearable/flexible energy storage. Angew. Chem. Int. Ed. 50, 1683–1687 (2011).

Gopi, C. V. V. M., Vinodh, R., Sambasivam, S., Obaidat, I. M. & Kim, H. J. Recent progress of advanced energy storage materials for flexible and wearable supercapacitor: From design and development to applications. J. Energy Storage 27, 101035 (2020).

Sun, J. F. et al. Recent progress of fiber-shaped asymmetric supercapacitors. Mater. Today Energy 5, 1–14 (2017).

Huang, X. et al. Wearable biofuel cells based on the classification of enzyme for high power outputs and lifetimes. Biosens. Bioelectron. 124-125, 40–52 (2019).

Pan, S. et al. Wearable solar cells by stacking textile electrodes. Angew. Chem. Int. Ed. Engl. 53, 6110–6114 (2014).

Yin, S., Jin, Z. & Miyake, T. Wearable high-powered biofuel cells using enzyme/carbon nanotube composite fibers on textile cloth. Biosens. Bioelectron. 141, 111471 (2019).

Liu, Y. M., Wang, L. Y., Zhao, L., Yu, X. G. & Zi, Y. L. Recent progress on flexible nanogenerators toward self-powered systems. InfoMat 2, 318–340 (2020).

Yu, Y. et al. Biofuel-powered soft electronic skin with multiplexed and wireless sensing for human-machine interfaces. Sci. Robot. 5, eaaz7946 (2020).

Tan, P., Zou, Y., Fan, Y. & Li, Z. Self-powered wearable electronics. Wearable Technol. 1, E5 (2020).

Wu, M. et al. Self-powered skin electronics for energy harvesting and healthcare monitoring. Mater. Today Energy 21, 100786 (2021).

Wu, M. et al. Thin, soft, skin-integrated foam-based triboelectric nanogenerators for tactile sensing and energy harvesting. Mater. Today Energy 20, 100657 (2021).

Jeerapan, I., Sempionatto, J. R. & Wang, J. On‐body bioelectronics: wearable biofuel cells for bioenergy harvesting and self‐powered biosensing. Adv. Funct. Mater. 30, 1906243 (2020).

Wu, H. et al. Enhanced power generation from the interaction between sweat and electrodes for human health monitoring. ACS Energy Lett. 5, 3708–3717 (2020).

Zhang, T., Tao, Z. & Chen, J. Magnesium-air batteries: From principle to application. Mater. Horiz. 1, 196–206 (2014).

Li, C. S., Sun, Y., Gebert, F. & Chou, S. L. Current progress on rechargeable magnesium-air battery. Adv. Energy Mater. 7, 1700869 (2017).

Chawla, N. Recent advances in air-battery chemistries. Mater. Today Chem. 12, 324–331 (2019).

Byon, H. R., Suntivich, J. & Shao-Horn, Y. Graphene-based non-noble-metal catalysts for oxygen reduction reaction in acid. Chem. Mater. 23, 3421–3428 (2011).

Ma, J. L. et al. Effect of functionalized graphene on performance of magnesium/air battery. Mater. Res Express 6, 085528 (2019).

Kim, H. & Ahn, J. H. Graphene for flexible and wearable device applications. Carbon 120, 244–257 (2017).

Oh, Y. S. et al. Battery-free, wireless soft sensors for continuous multi-site measurements of pressure and temperature from patients at risk for pressure injuries. Nat. Commun. 12, 5008 (2021).

Song, Y. et al. Wireless battery-free wearable sweat sensor powered by human motion. Sci. Adv. 6, eaay9842 (2020).

Park, Y. et al. Wireless, skin-interfaced sensors for compression therapy. Sci. Adv. 6, eabe1655 (2020).

Li, L. & Manthiram, A. Dual-electrolyte lithium-air batteries: Influence of catalyst, temperature, and solid-electrolyte conductivity on the efficiency and power density. J. Mater. Chem. A. 1, 5121–5127 (2013).

Bariya, M., Nyein, H. Y. Y. & Javey, A. Wearable sweat sensors. Nat. Electron. 1, 160–171 (2018).

Nyein, H. Y. Y. et al. A wearable electrochemical platform for noninvasive simultaneous monitoring of Ca2+ and pH. ACS Nano 10, 7216–7224 (2016).

Gutruf, P. et al. Wireless, battery-free, fully implantable multimodal and multisite pacemakers for applications in small animal models. Nat. Commun. 10, 5742 (2019).

Hajiaghajani, A. et al. Textile-integrated metamaterials for near-field multibody area networks. Nat. Electron. 4, 808–817 (2021).

Acknowledgements

This work was supported by City University of Hong Kong (Grants No. 9667199, 9667221, 9680322), Research Grants Council of the Hong Kong Special Administrative Region (Grant No. 21210820, 11213721), Shenzhen Science and Technology Innovation Commission (Grant No. JCYJ20200109110201713).

Author information

Authors and Affiliations

Contributions

X.H., Y.L., and J.Z. contributed equally to this work. X.H., Y.L., and X.Y. conceived the ideas and designed the experiments. X.H., Y.L., S.N., T.W., H.L., Y.H., and X.Y. wrote the manuscript. X.H., Y.L., J.Z., C.Y., W.P., J.L., L.Z., J.S., and K.Y. performed experiments, X.H., Y.L., Z.G., M.W., D.L., J.L., and R.S. analyzed the experimental data. J.Z., C.Y., and W.P. designed the electrical circuits.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Huang, X., Liu, Y., Zhou, J. et al. Garment embedded sweat-activated batteries in wearable electronics for continuous sweat monitoring. npj Flex Electron 6, 10 (2022). https://doi.org/10.1038/s41528-022-00144-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41528-022-00144-0

This article is cited by

-

Promising applications of human-derived saliva biomarker testing in clinical diagnostics

International Journal of Oral Science (2023)

-

Wearable flexible microfluidic sensing technologies

Nature Reviews Bioengineering (2023)

-

Large-scale fully printed “Lego Bricks” type wearable sweat sensor for physical activity monitoring

npj Flexible Electronics (2023)