Abstract

Thermophysical properties of highly doped Si50Ge50 melt were measured contactlessly in the electromagnetic levitation facility ISS-EML on board the International Space Station. The sample could be melted, overheated by about 375 K, and cooled down in 350 mbar Argon atmosphere. A large undercooling of about 240 K was observed and a quasi-homogeneous nucleation on the droplet surface occurred. During the cooling phase, high-resolution videos were taken from the side and the top. The density and thermal expansion were evaluated with digital image processing; the viscosity and the surface tension were measured by means of the oscillating drop technique. Inductive measurements of the electrical resistivity were conducted by a dedicated electronics. All data were taken as a function of temperature T from the overheated melt down to the undercooled range. We found a nonlinear thermal expansion, suggesting a many body effect in the liquid beyond the regular pair interaction, an enhanced damping of surface oscillations likely related to an internal turbulent flow, and an increment of the electrical resistivity with decreased T in the undercooled range regarding a demixing of the components.

Similar content being viewed by others

Introduction

The semiconductors Si and Ge have been the workhorses for electronic hardware production for a long period of time. In addition, Si–Ge alloys and heterostructures using these alloys have come in the focus of interest due to their flexible electronic properties1,2,3,4. For productions and applications of materials, the knowledge of thermophysical properties of the melt is essential and they have to be measured accurately. For this purpose we started the ESA-project “SEMITHERM” (“Investigations of thermophysical properties of liquid semiconductors in the melt and the undercooled state under microgravity conditions”, ESA-AO-2000-068). The goals of the project include the precision measurements of the density, thermal expansion, surface tension, viscosity, and electrical resistivity of the liquid Ge and alloys Si1−xGex (x = 0.75, 0.5, and 0.25). Due to the strong reactivity of the high-temperature melts the experiments need to be performed contactlessly under low-gravity conditions. The Electromagnetic Levitator (ISS-EML) on board of the International Space Station (ISS) is the instrument of choice. For the preparation of these experiments, measurements on parabolic flights have been performed in a similar low-gravity electromagnetic levitation facility (TEMPUS)5. The results for Ge-rich Si–Ge alloys have been reported in a previous paper6.

Here we report about the measurements with an Si50Ge50 sample on board the ISS. Reports about other concentrations will follow. First, we give an overview of the general processing of the sample, followed by the presentation of the results of measurements of the viscosity, surface tension, density, thermal expansion, and electrical conductivity. All properties were measured in the melt as a function of temperature. In the last section an overview of the EML facility, the experimental details including the sample properties is given.

Results and discussion

Melting, cooling, undercooling, and solidification behavior

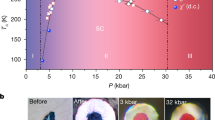

Eleven melting and cooling cycles of the Si50Ge50 sample (always the same sample) were successfully carried out on board the ISS. Table 1 gives an overview of the processing designed for each cycle, including values of overheat, achieved undercooling and cooling rates (in 350 mbar Ar) above and below the liquidus temperature Tl (1548 K). The overheat is about 375 K in average. Undercooling of about 45 ± 10 K was obtained from cycles #1–#5, jumping to 155 K in cycle #6 and then gradually rising up to 240 K for cycle #11. The result observed arises possibly from gradual melting of the surface oxide SiO2 at Tmax, which is close to the melting point (1986 K) of SiO27. In addition, silicon monoxide (SiO) may gradually form at high T via a decomposition reaction, SiO2 + Si ⇌ 2 SiO; SiO is volatile and can evaporate away by sublimation8.

As an example, Fig. 1a, b reveal time–temperature profiles T(t) measured by the radiation pyrometer for the cycles #1 and #10. The sample temperature T given here was calibrated using Wien’s law: 1/T = 1/Tp + (1/Tl −1/Tlp), where Tp is the pyrometer signal and Tl,p is the pyrometer signal at the liquidus temperature. In the beginning of the cycle the temperature reading of the solid sample rises quickly and reaches a plateau corresponding to the solidus temperature Ts (1383 K), where the sample starts to melt. The T(t)-profile approaching Ts shows no significant disturbances, indicating that in spite of a low electric conductivity the highly doped semiconductor can be well positioned in the EML facility. Because of the lower emissivity of the liquid, the temperature reading T(t) drops down during melting and subsequently reaches a minimum, which corresponds to the actual liquidus temperature Tl. The large fluctuation (ΔT ≈ 200 K) of the T(t)-profile in the two phase region arises from the different spectral emissivity of the solid (0.48) and the liquid (0.22) read by the pyrometer depending on the actual spot. The small fluctuation (ΔT ≈ 50 K) is due to changes in view factor caused by movement of the sample. During melting the sample becomes metallic, so that the force applied by the electromagnetic levitation field on the droplet grows and improves its positioning stability. As a consequence, the T(t)-profile in liquid state appears very smooth. Figure 1c, d is the video image of the sample obtained at the beginning of solidification from cycle #1 and #10. These show a strongly heterogeneous and a more homogeneous nucleation at the surface corresponding to small and large undercooling degrees indicated in Fig. 1a, b, respectively. The strongly heterogeneous nucleation is accompanied by a dendritic growth (Fig. 1c) and emerges mainly in cycles #1–#5, where residual SiO2 oxide impurities on the surface serve likely as a nucleus for solidification. Because of a low height of free energy barrier, the heterogeneous nucleation is in general more common than homogeneous nucleation.

a from cycle #1 and b from cycle #10, showing a small and a large undercooling, respectively. Solid and dashed lines show the voltages UP and UH controlling the electromagnetic fields for positioning and heating of the sample. b shows two pulses used for excitation of drop oscillations. c and d are images of the sample recorded at beginning of the solidification, showing strongly heterogeneous and more homogeneous nucleation at the surface associated with small and large undercooling shown in (a) and (b).

The rather homogeneous nucleation occurs for the first time in cycle #6, where the undercooling degree jumps up with no observable dendrite structure (Fig. 1d). The phenomenon can be contributed to the absence of the oxide impurities, which are obviously molten or evaporated during the processing in the first cycles, followed by a rise in undercooling (Table 1) in the subsequent cycles. Because of the homogeneous coverage of nuclei on the sample surface, the T(t)-profile now appears smooth at the beginning of the solidification and rises due to the exothermic nature of the process. The growth of the nuclei is accompanied by a volume expansion (volume anomaly6) and as a result, the liquid inside is partly pressured out, forming a bump on the surface. For this case, the T(t)-profile fluctuates regularly up and down upon the sample rotation.

Oscillating drop method

Figure 2 shows typical axial and radial images measured for Si50Ge50 at different points indicated in the relevant T(t)-profile in Fig. 2a. The artefacts stem from parts of the sample holder. The areas were excluded in the edge fitting procedure, yielding data of areas A and lengths of horizontal and vertical radii R1 and R2 as well as elliptical semiaxes a and b, used for evaluation of thermophysical properties via the oscillating drop method. To minimize errors, we introduce an average radius R calculated from R1, R2, a, b and reff, where reff is an effective radius extracted from the area A = π reff2. The normalized areas A/A0 and radii R/R0 with A0 and R0 denoted as their mean values are plotted in Fig. 2a, showing damped oscillations caused by switching off the electromagnetic heating field, which also squeezes the droplet, and short voltage pulses.

a Gives temperature (circles), voltage UH (dashed line) controlling the electromagnetic heating field with four short pulses used for exciting droplet oscillations, as well as normalized areas A/A0 (black) and radii R/R0 (gray). Relevant axial and radial images of the sample captured between heating-off and the first pulse (b), at the third pulse (c), and far away from the fourth pulse (d), respectively, involving elliptical semiaxes a, b (red), horizontal and vertical radii R1, R2 (green) as well as areas A surrounded by edge curves.

As illustrated in Fig. 2c, the short pulse squeezes the drop into a prolate shape along the perpendicular axis. The cross-section viewed from the top in axial direction becomes correspondingly small and in radial direction looked incomplete due to a hiding effect of the magnetic coil (its winding distance is 8 mm). The uniaxially deformed droplet relaxes to its equilibrium spherical shape, giving rise to surface oscillations. A similar behavior appears at Tmax by turning off the heating. In this case the uniaxial deformation is however much stronger than that induced by short pulses, giving rise to rotation of the droplet around an arbitrary axis with a period of about 1 Hz (see Fig. 3b). The overlap between rotation and oscillation makes the droplet temporarily aspherical (Fig. 2b) and lead to extra scattering of the experimental data (Fig. 5a). Only far away from heating-off or pulses, the droplet becomes quiet and well spherical, as shown in Fig. 2d. For this case, all length data R1, R2, a, and b are nearly identical and the scattering becomes smaller (Fig. 5b).

a T(t) profile of the cycle #10 with normalized axial areas A/A0 (black) and radii R/R0 (gray), revealing oscillations excited by heating-off und short pulses respectively and decayed with t in an exponential function e−λt (dashed lines), as well as abrupt changes occurring upon solidification (inset) regarding volume anomaly6. b (upper) Decayed oscillations of radial A/A0 from cycle #2 excited by heating-off, showing an extra low period of ~1 Hz caused by droplet rotations, (bottom) linear fitting of ln|A/A0−1| to get the decay constant λ. c Damping factors λ of the oscillations measured for 11 cycles. A linear fit gives λ = 0.5–3.5 × 10−4(T−Tl) s−1 (dashed line). The gray background indicates the scattering of ±0.2 s−1. The week T dependence is probably due to the influence of the turbulent flow effect.

Viscosity of the droplet

Typical oscillations of the levitated Si50Ge50 droplet excited at different T by start off and on heating pulses are presented as a function of the time t in Figs. 2a and 3a, b. The amplitude decays exponentially with t and approaches then the mean value A0 (or R0). The behavior can be fitted by f = f0 ± Δf·e−λt, here f/f0 is denoted as A/A0 or R/R0, Δf as their maximal amplitude. The fit provides the envelope of the oscillation as plotted in Fig. 3a, b (dashed line) and yields a matched decay factor λ, which can be referred as the magnitude of the viscosity, i.e. η = κλ9. Here the constant κ = \(\frac{{3M}}{{20r_0}}\) = 12.8 mPa s2 is calculated with M = 1.07 g and r0 = 4 mm.

The dashed lines in Fig. 3a illustrate the envelopes matched to oscillations (axial data of cycle #10) excited by heating off at 1940 K (Tmax) and two short pulses at 1480 and 1380 K. The relevant decay factors λ are found to be 0.25, 0.5, and 0.68 s−1, respectively, showing a temperature dependence. Figure 3b shows the oscillation of the droplet caused by heating off only (radial data of cycle #2). The impact from the rotation is visible. It creates a parasitic oscillation of about 1 Hz and disturbs the observation of the decay behavior, giving rise to additional errors. The dashed lines in Fig. 3b (upper part) present the fits with exponential function of e−λt, while the solid line in Fig. 3b (bottom) is simply obtained by linear fitting of the natural logarithm ln \(\left| {A/A_0 - 1} \right|\). Both calculations yield the same decay constant λ. In this case 0.3 s−1 by fitting the data up to t = 8 s.

Figure 3c gathers the damping factors λ of the oscillating droplet Si50Ge50 at different T from data of cycles #1 to #11. They are lower than the values measured in parabola flights6 and only weakly temperature dependent. Note the oscillation of cycle#1–#4 and #11 is excited by heating-off at Tmax only. The relevant decay constant λ was found to be within 0.15–0.31 s−1 (circles in Fig. 3c) and averaged at 0.23, which would correspond to a saturation value η of about 3.0 mPa s at high T. λ rises then slightly with decreasing T, passing through Tl without a remarkable change. At low T, it amounts to about 0.6 s−1, corresponding to η of about 8 mPa s.

For a discussion of the viscosity data measured here by the oscillating drop method the fluid flow in the sample plays a crucial role. In EML experiments even the positioning field in the cooling phase can lead to turbulent flow and therefore to an enhanced viscosity10. Qualitatively, the turbulent behavior can be observed by the movements of oxide particles, which exist on the surface in the first five cycles. Particles of about 50–100 µm in size could be tracked in the radial video images. They circulate or move chaotically on the droplet surface with maximum observed velocities v of about 0.12 m s−1. The Reynolds number Re, which is defined as the ratio of inertial force \(\frac{{\rho V^2}}{L}\) to viscous force \(\frac{{\eta V}}{{L^2}}\) (ρ is the density of the droplet and L its characteristic dimension), i.e. \(R_e = \frac{{\rho VL}}{\eta }\) 11, can be estimated to be Re ≥ 5700, taking ρ = 5.9 g cm−3, L = 8 mm (diameter of the sample) and the viscosity η assumed to be ≤1 mPa s as measured in experiments with an electrostatic levitator (ESL), where no turbulence should occur10,12,13. The high Re value of the Si50Ge50 droplet causes the flow instability and turbulent flow occurs.

An additional indication for the turbulent flow is the dynamical behavior of the surface of the melt showing self-excited oscillations during the whole cooling phase. For doped Ge, which is used in another EML-experiment, fluid flow modeling resulted in high Reynolds numbers of about 6500–70,000 indicating highly turbulent flow within the droplet in the whole temperature range14.

These findings lead to the conclusion that the measured damping factor λ may be dominated by the levitation force induced fluid flow and as a result, the relevant η may deviate from the molecular viscosity measured in other experiments on earth. The argumentation is supported by the smaller value of <1 mPa s measured for Si in an ESL by Zhou et al.12 and Li et al.13. In contrast to an EML, the levitation force does not drive convection in an ESL. For previous EML experiments on parabola flights with Ge-rich Si-Ge-samples6, we measured viscosity data of about 5–10 mPa s at high temperatures, higher than the actual values measured on ISS, which may be caused by very high positioning fields necessary in parabola flights and therefore enhanced fluid flow.

In addition, the molecular viscosity η may be estimated roughly by its relation to the surface tension γ as suggested by Egry15 and Brillo16, namely \(\frac{\gamma }{\eta } = 0.94\sqrt {\frac{{RT}}{W}}\). With the molar gas constant R = 8.314 J mol−1 K−1, the molecular weight W = 50.35 g mol−1 of Si50Ge50 and a measured value γ = 0.6 N m−1 near Tl (cf. Fig. 4a) we get a value η of about 1.2 mPa s in accordance with the measured values discussed. In principle, this form provides an opportunity to separate the temperature dependence of the damping into turbulent and laminar flow. On ther other hand it should be noted that the relation derived by Egry is not strictly applicable for Si50Ge50. It is only valid for pure elements and simple metallic liquids and should only be used for an estimate of the order of magnitude for the viscosity.

a Frequency spectra obtained from droplet oscillations induced by short pulses at 1810, 1645, and 1415 K, respectively. b Simulation of oscillations without and with droplet rotation. c Surface tension γ obtained (upper) from the cycles #1–#4 and #11, (bottom) from pulse cycles #5–#10, the lower values are indicated by arrows (here only for cycle #6) associated with relatively high droplet deformations at the beginning of excited oscillations.

Surface tension of the droplet

To determinate the surface tension γ of the droplet Si50Ge50, the frequency spectra were deduced by fast Fourier transform (FFT) of the oscillation data. Figure 4a exhibits the frequency spectra obtained from the droplet oscillations excited by short pulses at 1810, 1645, and 1415 K, respectively, exhibiting a resonance peak located at ν = 22 Hz and its higher harmonic peaks. A temperature dependence is here visible; the resonance peaks are shifted towards higher frequency for decreasing temperature. Since γ is a function of ν, namely γ =ξv2 (ref. 9) with ξ = \(\frac{{3\pi M}}{8}\) (M is the droplet mass), this result implies an increase of γ. Parasitic oscillations arising essentially from the rotation of the droplet (~1 Hz) are overlapped with the surface oscillation, leading to splitting of the resonance peaks (detailed see the inset in Fig. 4a, b) and have to be taken into account by the evaluation of the resonance frequency.

To minimize the impact from the parasitic oscillations, we have to operate the FFTs segmentally using a series of time segmentations, s1,s2, … as schematically illustrated in Fig. 4b. By means of a careful division, a data segmentation yields a frequency spectrum with a single resonance peak (though it may appear somehow slightly asymmetrical). A series of γ values as a function of the temperature were extracted in this manner and are plotted versus T in Fig. 4c (where dashed lines are drawn in view of the average). The results in Fig. 4c (upper part) are from the cycles #1–#4 and #11 (without additional pulses), in which the droplet oscillations are induced by heating-off at Tmax (cf. Fig. 3b) and driven by turbulent flow over whole temperatures until T < Tl. Since the surface resonance selects natural frequency of the droplet10, the self-excited oscillation enables the measurements of the surface tension in the whole T range with similar results obtained from the pulse cycles #5–#10 (see Fig. 4c, lower part).

In addition to the errors caused by splitting or asymmetrical behavior of the resonance peak regarding the droplet rotation, the deformation of the droplet may give rise to a frequency shift, as recently investigated by Xiao et al.17, using a molten nickel-based superalloy with a deformation amplitude δ up to 7%. They gave an equation, \(\frac{{\Delta v}}{v} = p_1\delta + p_2\delta ^2\), to describe the deformation induced frequency shift. Since the constant p1 and p2 are negative, the frequency shifts towards lower values. This nonlinear behavior is also visible here and even pronounced at the beginning of excited oscillations as indicated by arrows in Fig. 4c (lower part). The deformation amplitude δ of the molten Si50Ge50 can be estimated from the R/R0 data shown in Figs. 2 and 3a. It is about 15% at the beginning of the excited oscillations and decreases rapidly with t. After 1 or 2 s, δ < 10%. The δ value is somewhat above the limit reported in ref. 17. Nevertheless, the equation mentioned is valid for a qualitative discussion. An influence from oxide contamination (a few separated tiny particles) is insignificant, though it causes a small undercooling in the cycles #1–#5.

The measured surface tension is comparable to published data in the literature. In previous parabola flight experiments with undoped Si–Ge samples18 and doped Si–Ge samples with rich Ge content6, the values and the temperature dependences are similar. Measurements with an ESL also lie in the same range13. Experiments with the pendant drop method on earth show similar values19.

Thermal expansion

Figure 5a shows the normalized A/A0 and R/R0 for the cycle #1. Largely scattered data beyond 1 ± 0.2 for A/A0 (1 ± 0.1 for R/R0) arising from strong deformations of the droplet during the heating-off period (about 1 or 2 s) were removed. Since T is here mostly above Tl, the data represent behaviors of the overheated liquid. Figure 5b shows the data obtained from the deeply undercooled liquid (cycle #11 without a pulse). Due to a small deformation of droplet the scattering of the data is much smaller (1 ± 0.02), compared with those given in Fig. 5a.

a, b Radial data from cycle #1 and #11. c (bottom) Axial data from cycle #11 and (top) radial data from cycles #3 and #11, showing a nonlinear behavior, which can be fitted by a second-order polynomial. d Thermal expansion coefficients βA (area) and βR (radius) as a function of T with a slope in the order of magnitude of about 10−7 K−2.

Linear fitting these data yields coefficients βA = A−1 dA/dT (A = area) and βR = R−1dR/dT (R = radius) of area and linear thermal expansion in given temperature ranges. The error values in brackets shown in Fig. 5a, b give the uncertainty of the linear fit. As expected, βA is found here to be nearly equal to 2βR. More interestingly, we found the coefficients (βA = 10.0 × 10−5 K−1 and βR = 4.9 × 10−5 K−1) obtained from the highly overheated melt (Fig. 5a), being much higher than those (4.25 × 10−5 K−1 and 2.14 × 10−5 K−1) obtained from the deeply undercooled one (Fig. 5b). The result suggests a nonlinear thermal expansion of the liquid.

To show this in more detail, Fig. 5c exhibits relevant axial and radial video data, covering both overheating and undercooling temperature ranges. Note that the radial data of cycle #11 is combined here with the radial data of cycle #3, due to the limited data storage capacities on board the ISS and thus a restricted length (≤30 s) of radial image video data (400 Hz). In addition, to minimize the scattering the data plotted in Fig. 5c were smoothed by adjacent averaging. A nonlinear behavior of the droplet size with T is apparent, which can approximately be fitted by a second-degree polynomial as is demonstrated in Fig. 5c. The polynomial has the form

with constant αR,A close to 1. By differentiation of the Eq. (1), we get the thermal expansion coefficient as a linear function of T, namely

with βR,A0 ≈ 10−5 K−1 as initial value at T0 and 2βR,A′ ≈ 10−7 K−2 as the slope (see Fig. 5d). With the help of the Eq. (2), the βR value at the melting point Tl can be evaluated. Averaging over the cycles #1–#5, we get a mean βR of 3.40 × 10−5 K−1. It appears larger than that (2.90 × 10−5 K−1) averaged over cycles #6–#11, which, in contrast to the cycles #1–#5, possess more data of the deeply undercooled and spherical droplet. The difference arises therefore, on the one hand, from fitting errors depending on the data precision, but on the other hand, it mirrors again the nonlinear behavior of the thermal expansion. The mean value βR of 3.15 × 10−5 K−1 averaged using the values from all cycles represents the linear expansion coefficient of the Si50Ge50 melt near Tl. It, although partly contributed from deep undercooled melt, appears slightly above the value of βR = 3.0 × 10−5 K−1 measured by previous parabola flight experiments for overheated pure Ge (1275–1675 K)6. The result implies an impact of the composition. For the nonlinear term in the Eq. (1) we found 2βA′ = 2.43 × 10−7 K−2 and 2βR′ = 1.25 × 10−7 K−2 from the slopes in Fig. 5d. Again, a factor of ≈2 is found for βA′/βR′ (see above).

The density of the melts of Si and Ge was measured by a thermometric method by Glazov and Shcelikov20 about 20 years ago. They also found a nonlinear temperature dependence of the thermal expansion and discussed this behavior in terms of a decrease in the strength of interatomic bonds with increasing temperature. The experimental results are comparable to the behavior of the Si–Ge melts investigated here in the ISS-EML.

Kulkarni et al.21 performed ab initio MD simulations of Ge melts. They argue that at lower temperatures the structure factor shows a pronounced shoulder on the high k-side of the principal peak, which vanishes for high temperatures consistent with experimental scattering data in the literature. The coordination number increases with increasing temperature. This behavior of the structure factor is accompanied by an angle distribution function showing some tetrahedral arrangements at lower temperatures as well.

Following Kulkarni et al.22 our interpretation of the temperature dependence of the volume of the Si–Ge melt states that at very high temperatures the melt behaves like a simple metallic melt where a linear thermal expansion is expected22. With decreasing temperature, covalent, tetrahedral structure elements (small range order) begin to form and therefore the specific volume deviates from that of a simple liquid, which is characterized by a simple two body interatomic potential with linear thermal expansion, leading to the observed nonlinear temperature dependence.

In addition, the solidification of the melt is accompanied with an abrupt increase in A/A0 and R/R0 as illustrated in the inset of Fig. 3a. The phenomenon can be partly contributed to the volume expansion due to T rise, and partly to the volume anomaly of the substances Si and Ge, whose density in solid is lower than that in liquid6.

Electrical resistivity of the droplet

The temperature-dependent electrical resistivity ρ(T) is a sensitive indicator for structural changes in the melt. Generally, the electrical resistivity in liquid metals results from the scattering of the conduction electrons at the disordered metal ions. Accordingly, the decline of the temperature dependent density fluctuations in the melt with decreasing temperature results in the usually observed linear decrease of ρ22. In liquid alloys a formation of compact structures (clusters) with decreasing temperature, due to chemical short-range ordering processes of the components, may result in an increase of the scattering cross-section for the electrons and thus of the electrical resistivity23. Consequently, an onset of clustering phenomena in a liquid alloy may lead to a deviation of ρ(T) from the typical linear temperature dependence. The lower the temperature of the melt is the more pronounced this effect should show up.

This above assumption is confirmed by the present liquid Si50Ge50 sample. Figure 6 shows a plot of the resistivity data against the temperature measured during the cooling phase of cycle #11, where the undercooling of the liquid Si50Ge50 droplet was very high (cf. Figure 1b and Table 1).

The curve (black) is a fit of the resistivity model of Takeuchi and Endo23 to the data points, which agrees fairly well with the sliding average over 30 data points (gray line).

Assuming that the Si50Ge50 melt can be considered as a regular solution with a positive heat of mixing WSi,Ge > 024, meaning, that external heat is necessary to keep the liquid alloy components mixed, the unusual temperature behavior of the electrical resistivity can be described by the physical model of Takeuchi and Endo23

with xSi and xGe denoted as the concentrations of Si and Ge (presently xSi = xGe = 1/2), \(\rho _0^{\mathrm {Si,Ge}}(x_{\mathrm {Si}},x_{\mathrm {Ge}})\),\(\rho _1^{\mathrm {Si,Ge}}(x_{\mathrm {Si}},x_{\mathrm {Ge}})\) and \(\rho _2^{\mathrm {Si,Ge}}(x_{\mathrm {Si}},x_{\mathrm {Ge}})\) as temperature-independent constants. Corresponding to the conventional resistivity model, the Eq. (3) contains a constant term and a term which is linearly dependent on the temperature T. The last term finally considers the increase of the electrical resistivity with decreasing T due to the assumed increasing component demixing tendency in the melt, as discussed above. A weighted fit to the measured data points with ρ0Si,Ge = 1.9 × 10−5 Ω cm, ρ1Si,Ge = 2.2 × 10−8 Ω cm K−1, ρ2Si,Ge = 1.6 × 10−5 Ω cm, and WSi,Ge = 12 kJ mol−1 is shown in the diagram of Fig. 6. Even if the demixing assumption is too simple to explain the real structural development in the undercooled Si50Ge50 melt, Eq. (3) describes at least phenomenologically the measured temperature-dependent electrical resistivity of the Si50Ge50 melt fairly well. The structural evolution of the deeply undercooled Si50Ge50 melt may be also influenced by a liquid–liquid phase transition of the Si component and the reinforcement of its tetrahedral order25,26.

Methods

EML facility and sample description

The experiments were performed in the microgravity electromagnetic levitator ISS-EML on board the International Space Station (ISS). The facility applies two superposed, radio frequency electromagnetic fields on electrically conducting samples in its center (see Fig. 7). A quadrupole-like “positioning field” (150 kHz), generated by two oppositely directed RF coil currents, to containerlessly confine a liquid droplet at a dedicated place against external residual forces, and a homogeneous dipole-like “heating field” (400 kHz), generated by two RF coil currents in the same direction, to efficiently heat and melt the sample inductively.

The corresponding electrical circuits are powered by their own current supply. The actual EML circuits, basing on the superposition principle, differ in details from those shown above. The SCE electronics, used to determine inductively the temperature-dependent sample resistivity and dimension, is hooked up to the heating circuit.

Although originally designed for metallic materials only, the low residual forces in the microgravity environment enable processing of highly doped semiconductors in the facility. A more detailed description of the levitation principle can be found in ref. 27. For visual observation of the samples two high-resolution CCD-cameras are installed. An axial camera with a frame rate of 50 Hz (resolution 704 × 704 pixels) or 150 Hz (resolution 352 × 352 pixels) looking from the top along the symmetry axis of the magnetic fields on the sample. This camera is combined with a pyrometer for temperature measurements. A radial camera with a frame rate of 400 Hz and a resolution of 600 × 600 pixels is looking from the side on the sample. More details of the facility can be found in ref. 28.

The spherical Si50Ge50 sample used has a mass of M = 1.07 g and a radius of r0 = 4 mm. The raw material stems from a highly doped alloy crystal prepared by the Czochralski technique in the group of Abrosimov29 at the IKZ Berlin. The dopant is boron (B) with a concentration of about 1.9 × 1020 atoms cm−3, which corresponds to an electrical conductivity of about 1.7 × 103 Ω−1 cm−1 at 300 K. Due to the semiconducting behavior, the conductivity of the solid sample grows with T and jumps up to about 104 Ω−1 cm−1 (corresponding to a resistivity of about 10−4 Ω cm as given in Fig. 6) upon melting regarding to the semiconductor–metal phase transition caused by disordering.

The sample concentration was checked/confirmed by EDX analyses. The liquidus temperature Tl at 1548 K and solidus temperature Ts at 1383 K are taken from the literature30.

Ground test and parabola flight experiments

Relevant ground tests were made in advance by the Microgravity User Support Center (MUSC) at DLR, Cologne, Germany, to obtain the data of spectral emissivity ε required for the pyrometer, sample-coil coupling efficiency and the evaporation rate of the melt regarding the limits of dust generation. The measured spectral emissivity ε is 0.48 for the solid and 0.22 for the liquid phase. The inductive coupling efficiency is actually a measure for processability of the semiconductor sample in EML and was used for simulation of the planned melting cycles in ISS-EML. The coupling in the solid phase was found to be strong enough for a fast heating of the sample. In the liquid state, the sample is metallic and the coupling becomes enhanced by a factor of about 5.

The processability of highly doped semiconductors was verified by parabolic flight experiments provided by ESA and the DLR Institute of Material Physics in Space on board a Zero-G aircraft operated by Novespace, France using the similar EML setup TEMPUS5. The results indicated that the samples could be heated up in the solid phase, melted and positioned stable in liquid phase. Unfortunately, due to the short experiment time (~20 s) available and a relatively high Tl of the Si50Ge50 sample, only preliminary experiments could be performed.

ISS experimental details

Before the transport to ISS, the sample was cleaned with acetone and ethanol in ultrasound bath and integrated in a special transport container which was pumped down to 10−7 mbar and filled then with 1 bar Ar. During the end inspection, the sample was exposed to air and it is expected that the surface is covered with a natural thin passivation oxide layer, which prevented the sample from further oxidation.

The ISS experiments were performed during the vibration-free astronaut sleep period with 11 cycles (Table 1), consisting of heating and melting to maximal temperatures of up to Tmax ~1925 K and cooling down below Ts, as shown in Figs. 1a, b and 2a. At Tmax the heater was dimmed to its idle state, i.e. the heater control voltage was set to UH = 0 and the positioner control voltage UP decreased accordingly by about 2–3 V. During the following cooling phase, within which the disturbances by the electromagnetic force fields are just lowest, the different experiments with the sample were executed in an Argon gas atmosphere (350 mbar), which was necessary for a reduction of the evaporation rate (mass loss) of the overheated melt. A cycle took typically 1–2 min depending on the undercooling degree of the melt. A mass loss of about 0.1–0.2 mg per cycle was estimated from the evaporation experiments performed by MUSC as well as from the experience of the parabola flight experiments.

The surface tension γ and viscosity η of the melt were determined by the oscillating drop technique9,28. For this purpose, short pulses (triangle, 8 V, 0.05 s) in the heating field were set at different temperatures T in cycles #5–#10 (Figs. 1b, 2a, and 3a). The pulse squeezes the drop into a prolate shape along the heating field and results in damped surface oscillations to its equilibrium spherical shape. The exponential decay constant λ of the oscillation amplitude gives the viscosity of the sample, i.e. η = κλ with the proportional constant κ =\(\frac{{3M}}{{20\pi r_0}}\) (M is the mass and r0 is the radius of the sample), while the resonance frequency ν, which can be extracted from the fast Fourier transform (FFT) of the oscillation data, yields the surface tension γ = ξν2 with ξ = \(\frac{{3\pi M}}{8}\) (refs. 9,31). Unfortunately, the relaxation of the deformed drop is accompanied by a translational movement and a rotation (~1 Hz) of the droplet, which disturb the evaluation of the oscillation behavior and create extra scattering of the data. To minimize this disturbance, the melting cycles #1–#4 and #11 were done without pulses (cf. Table 1). However, at high temperatures near Tmax the oscillation caused by switching off the heating field is unavoidable, leading to a large scatter of image data in this regime. The droplet oscillations were monitored by the axial and radial video cameras and its images were analyzed with respect to the above described oscillating drop method using a dedicated software “TeVi” (SEA Datentechnik GmbH), which detects the edges of the sample from the image contrast. The edge cure is fitted with a polynomial of degree 9 (ref. 32) and yields areas, radii, and semiaxes of the droplet. From these data also the thermal expansion coefficients β of the sample could be determined.

The electrical resistivity of the liquid Si50Ge50 droplet is measured inductively. For this purpose the homogeneous radio frequency (RF) magnetic heating field can very well be used. This field, generated by an RF current I of angular frequency ω in the heating coil (see Fig. 7) induces eddy currents in the material, the strength of which depends on the electrical resistivity of the droplet. These eddy currents in turn generate an RF magnetization field depending on the resistivity and dimension of the sample. It induces an additional voltage U backwards in the coil, the strength and phase shift φ (relative to the current I) of which is determined by a dedicated measurement electronics (SCE). The data are monitored with a rate of 10 Hz and with a resolution of 16 Bit, for details see ref. 27.

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author upon reasonable request.

References

Cressler, J. D. & Niu, G. Silicon-Germanium Heterojunction Bipolar Transistors (Artech Hause, Boston, London, 2002).

King, R. R., Karam, N. H., & Haddad, M. Multijunction photovoltaic cells and panels using a silicon or silicon-germanium active substrate cell for space and terrestrial applications. US Patent US 6340788 B1 (2002).

Currie, M. T. et al. Carrier mobilities and process stability of strained Si n- and p-MOSFETs on SiGe virtual substrates. J. Vac. Sci. Technol. B19, 2268–2279 (2001).

Tanaka, T. et al. Upper limit of two-dimensional hole gas mobility in strained Ge/SiGe heterostructures. Appl. Phys. Lett. 100, 222102 (2012).

25th DLR Parabolic flight campaign, 20th–31st October 2014, Practical and Technical Information, DI-2014-ed1-en, Novespace, Bordeaux-Mérignac, Mars 2014. See also www.novespace.com.

Luo, Y. et al. Contactless processing of SiGe-melts in EML under reduced gravity. NPJ Microgravity 2, 1–9 (2016).

Haynes, W. M. (ed.). CRC Handbook of Chemistry and Physics 92nd edn. (CRC Press, Boca Raton, FL, 2011).

Wiberg, E., Wiberg, N. & Holleman, A. F. Inorganic Chemistry (Academic Press, San Diego; De Gruyter, Berlin, New York, 2001).

Egry, I., Lohöfer, G., Seyhan, I., Schneider, S. & Feuerbacher, B. Viscosity of eutectic Pd78Cu6Si16 measured by the oscillating drop technique in microgravity. Appl. Phys. Lett. 73, 462–463 (1998).

Hyers, R. W. Fluid flow effects in levitated droplets. Meas. Sci. Technol. 16, 394–401 (2005).

Reynolds, O. An experimental Investigation of the circumstances which determine whether the motion of water shall be direct or sinuous, and of the law of resistance in parallel channels. Philos. Trans. Roy. Soc. Lond. 174, 935–982 (1883).

Zhou, Z., Mukherjee, S. & Rhim, W. K. Measurement of thermophysical properties of molten silicon using an upgraded electrostatic levitator. J. Cryst. Growth 257, 350–358 (2003).

Li, J. J. Z., Rhim, W. K., Kim, C. P., Samwer, K. & Johnson, W. L. Evidence for a liquid–liquid phase transition in metallic fluids observed by electrostatic levitation. Acta Mat. 59, 2166–2171 (2011).

Bracker, G., et al. 12th International Workshop on Subsecond Thermophysics (IWSSTP 2019), 3–6 June 2019, Cologne, Germany.

Egry, I. On the relation between surface tension and viscosity for liquid metals. Scr. Met. Mat. 26, 1349 (1992).

Brillo, J. Thermophysical Properties of Multicomponent Liquid Alloys (DE Gruyter Oldenbourg, Walter de Gruyter GmbH, Berlin/Boston, 2016).

Xiao, X., Hyers, R. W., Wunderlich, R. K., Fecht, H. J. & Matson, D. M. Deformation induced frequency shifts of oscillating droplets during molten metal surface tension measurement. Appl. Phys. Lett. 113, 011903 (2018).

Chathoth, S. M., Damaschke, B., Samwer, K. & Schneider, S. Thermophysical properties of Si, Ge, and Si–Ge alloy melts measured under microgravity. Appl. Phys. Lett. 93, 071902 (2008).

Ricci, E. et al. Surface tension and density of Si-Ge melts. J. Chem. Phys. 140, 214704 (2014).

Glazov, O. V. & Shchelikov, M. D. Volume changes during melting and heating of silicon and germanium melts. High Temp. 38, 405–412 (2000).

Kulkarni, R. V., Aulbur, W. G. & Stroud, D. Ab initio molecular-dynamics study of the structural and transport propertiesof liquid germanium. Phys. Rev. B 55, 6896 (1997).

Takeuchi, S. & Endo, H. The electric resistivity of the metals in the molten state. Trans. Jim. 3, 30–35 (1962).

Takeuchi, S. & Endo, H. Theoretical and experimental studies on the resistivity of molten alloys. Trans. JIM 3, 35–41 (1962).

Olesinski, R. W. & Abbaschian, G. J. Ge-Si (Germanium-Silicon) system. Bull. Alloy Phase Diagr. 5, 180–183 (1984).

Krishnan, S. et al. The structures of normal and supercooled liquid silicon metal and SiGe alloy. J. Non-Cryst. Solids 353, 2975–2981 (2007).

Jakse, N. et al. Structural changes on supercooling liquid silicon. Appl. Phys. Lett. 83, 4734–4736 (2003).

Lohöfer, G. High-resolution inductive measurement of electrical resistivity and density of electromagnetically levitated liquid metal droplets. Rev. Sci. Instrum. 89, 124709 (2018).

Seidel, A., Soellner, W. & Stenzel, C. EML—an electromagnetic levitator for the International Space Station. J. Phys. Conf. Ser. 327, 012057 (2011).

Abrosimov, N. V., Rossolenko, S. N., Thieme, W., Gerhardt, A. & Schröder, W. Czochralski growth of Si- and Ge-rich SiGe single crystals. J. Cryst. Growth 174, 182–186 (1997).

Stohr, H. & Klemm, W. Über Zweistoffsysteme mit Germanium. I. Germanium/aluminium, germanium/zinn und germanium/silicium. Z. Anorg. Allgem. Chem. 241, 305–323 (1939).

Brillo, J., Lohöfer, G., Schmidt-Hohagen, F., Schneider, S. & Egry, I. Thermophysical property measurements of liquid metals by electromagnetic levitation. Int. J. Mat. Prod. Tech. 26, 247–273 (2006).

Keren, D. & Gotsman, C. Fitting curves and surfaces with constrained implicit polynomials. IEEE Trans. Pattern Anal. Mach. Intell. 21, 31–41 (1999).

Acknowledgements

The authors acknowledge the access to the ISS-EML, which is a joint undertaking of the European Space Agency (ESA) and the DLR Space Administration. The reported work was conducted in the framework of the ESA research project SEMITHERM (AO-2000-068). The authors acknowledge also the colleagues from DLR/MUSC in Cologne for the help with the realization of the experiments and N. Abrosimov et al. in Leibniz Institute for Crystal Growth in Berlin for sample material preparations. The work is financially supported by DLR Bonn via project 50WM1750.

Author information

Authors and Affiliations

Contributions

Experiment performance, data analysis and evaluations, as well as the manuscript preparation were done by Y.L., B.D., and G.L.; experiment idea and design and discussions of results by B.D., G.L., and K.S. All authors read, edited, and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Luo, Y., Damaschke, B., Lohöfer, G. et al. Thermophysical properties of a Si50Ge50 melt measured on board the International Space Station. npj Microgravity 6, 10 (2020). https://doi.org/10.1038/s41526-020-0100-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41526-020-0100-5

This article is cited by

-

Electromagnetic levitation containerless processing of metallic materials in microgravity: thermophysical properties

npj Microgravity (2023)

-

Thermophysical Properties Measurement of Al–22.5 wt pctCu in Reduced Gravity Using the ISS-EML

Metallurgical and Materials Transactions A (2023)

-

Impact of convection on the damping of an oscillating droplet during viscosity measurement using the ISS-EML facility

npj Microgravity (2021)