Abstract

Martensitic transformation with good structural compatibility between parent and martensitic phases are required for shape memory alloys (SMAs) in terms of functional stability. In this study, first-principles-based materials screening is systematically performed to investigate the intermetallic compounds with the martensitic phases by focusing on energetic and dynamical stabilities as well as structural compatibility with the parent phase. The B2, D03, and L21 crystal structures are considered as the parent phases, and the 2H and 6M structures are considered as the martensitic phases. In total, 3384 binary and 3243 ternary alloys with stoichiometric composition ratios are investigated. It is found that 187 alloys survive after the screening. Some of the surviving alloys are constituted by the chemical elements already widely used in SMAs, but other various metallic elements are also found in the surviving alloys. The energetic stability of the surviving alloys is further analyzed by comparison with the data in Materials Project Database (MPD) to examine the alloys whose martensitic structures may cause further phase separation or transition to the other structures.

Similar content being viewed by others

Introduction

Shape-memory alloys (SMAs) constitute an important class of materials in industrial use because of their shape-memory effect and pseudoelasticity.1 Already various kinds of SMAs have been well known. Ni–Ti (Nitinol) alloys are now widely used because of its working range around room temperature, good pseudoelastic property, phase stability, and so on.2 The Ni–Ti alloys, however, suffer from large thermal hysteresis unless additional elements are included.3 Toxicity of Ni in these alloys is also problematic for bioapplications.4 Cu-based SMAs such as Cu–Zn, Cu–Al, and their multicomponent alloys are commercially available because of their low price, but they also have disadvantages, such as instability of martensitic phase, brittleness,5 and poor thermomechanical performance.6 Discovery of new SMAs are therefore still needed for better functional stability,7,8,9 design of working temperature,10,11 and other special purposes such as nontoxic biomaterials4 and ferromagnetic (FM) SMAs.12

To design SMAs, their working temperature and functional stability (reversibility of the shape-memory effect) may be the most important engineering properties. The working temperature is critical particularly to design high-temperature SMAs (HTSMAs). The functional stability is also important to improve the reliability of SMAs. The working temperature is expected to be related to the energetic stability of the martensitic phase relative to that of the parent phase (see the subsection “SMAs reported in experiments”). Meanwhile, some reports have found that better structural compatibility between the parent and the martensitic phases results in smaller thermal hysteresis, which gives better functional stability.13,14 We can therefore expect that appropriate energy difference and good structural compatibility between the parent and the martensitic phases are essential factors when we try to design SMAs.

We can adjust working temperature and functional stability of SMAs by replacing their constituent elements with others. The working temperature of Ni–Ti alloys can be much increased to the range of 400–1200 K by the total or partial replacement of Ni and Ti with the same group elements, namely Pd or Pt15,16 and Zr or Hf,17 respectively. These reports imply that the martensitic phases become energetically more stable than the parent phases at low temperature by replacing constituent elements. Meanwhile, better functional stability, which is associated with smaller thermal hysteresis and functional fatigue can be achieved by adding Cu14 or Pd13 in Ni–Ti alloys and Cr in Ti–Pd alloys.9

To discover new materials by modifying their constituent elements, computational research is useful because of its efficiency compared with experimental search. Especially, materials screening based on systematic first-principles calculations prior to experimental synthesis is useful to limit the searching space. Thanks to the recently improved computational machine power, now we can perform systematic first-principles calculations for various combinations of chemical elements with various crystal structures for searching new materials. Indeed, many different materials systems have been investigated in this manner.18,19,20,21 Hautier et al.18 and Hinuma et al.19 have identified new ternary-oxide and zinc-nitride semiconductors, respectively, using the “prototype” crystal structures of Inorganic Crystal Structure Database.22 Carrete et al.20 have reported the semiconductors with the half-Heusler structure that show low thermal conductivity. Greeley et al.21 have reported the binary surface alloys to show a good electrocatalytic property.

There have been theoretical researches on the martensitic transformation by the first-principles calculations. Most of them have been mainly focused on the properties of the specific SMAs, such as the crystal and electronic structures of the martensitic structures,23,24,25 the transformation path and energy profile of the martensitic transformation,23,26,27 and the phase diagram obtained by quasi-harmonic approximation.28 However, investigation on various combinations of chemical elements have been rarely reported to the authors’ knowledge.

In this study, we perform the first-principles screening to identify intermetallic compounds possessing the energetic and dynamical stabilities of the martensitic phase, as well as the structural compatibility between the parent and the martensitic phases, which is expected to be related to the functional stability. We initially consider 6627 alloys, and 187 survive after the screening. We investigate which elements mainly participate in the surviving alloys. Finally, the energetic stability of surviving alloys are further analyzed by comparison with the first-principles data in Materials Project Database (MPD)29 to examine the alloys which may occur phase separation or transition.

Results and Discussion

Elements and crystal structures of investigated alloys

We consider binary and ternary alloys with the B2, D03, or L21 structure as the parent phase at their stoichiometric composition ratios. These parent-phase structures are derived from the body-centered cubic (bcc) structures30 as described in Fig. 1. We investigate combinations of the 48 metallic elements between Li and Bi shown in Fig. 2; specifically, we consider 1128 (=48 C 2) XY, 2256 (=48 P 2) X 3 Y, and 3243 (=3X 47 C 2) X 2 YZ (X = Ti, Cu, Zn) alloys with the B2, D03, and L21 parent-phase structures, respectively. For the martensitic phases, we consider the orthorhombic 2H (or B19 for the binary alloys with the B2 parent phase) and monoclinic 6M [in the Otsuka notation,31,32 which will be used hereafter to correctively refer to 9R (for B2) and 18R (for D03 and L21) in the Ramsdell notation33] structures. Both the 2H and 6M martensitic-phase structures have the close-packed basal plane, but they have different stacking orders: “AB” for the 2H structure and “ABCBCACAB” for the 6M structure. Figure 3a shows the crystal structures of the 2H and 6M for ternar X 2 YZ alloys with the L21 parent phase. The structure of the 2H is explicitly calculated in this study, while the structure of the 6M is estimated from that of the 2H as described later. The space-group type of the 2H structure is Pmma for the B2-parent XY alloys and Pnma for the D03-parent X 3 Y and for the L21-parent X 2 YZ alloys.

a Crystal structures of the 2H and the 6M martensitic phases for the ternary alloys with the L21 parent phase. b Transformation between the parent and the martensitic phases. Small black arrows on spheres denote the atomic movement, and the rectangle denotes the unit cell of the 2H crystal structure

The lattice basis for the 2H martensitic structure is given as

where a 2H, b 2H, and c 2H are the lattice constants of the 2H structure. The unit cell of the parent phase that changes to L 2H after the martensitic transformation may be given as

and

where a p, b p, and c p are the lattice basis of the conventional unit cell for the parent phase structures, and a p is their lattice constant. The deformation gradient34 F 2H is then obtained as

Figure 3b describes the martensitic transformation between the L21 parent and its 2H martensitic phases. It should be emphasized that the martensitic transformation path is similar to the Burgers path35,36 for pure metals, which describes the transformation between the bcc and the hexagonal close-packed structures.

In order to reduce computational costs, the crystal structure of the 6M is estimated from that of the 2H as follows. We first assume that their basal-plane structure and layer distance along the stacking direction are the same for both the 2H and 6M. We further assume that the stacking position of each layer is different exactly by a 2H/3 along a 2H. Then, the lattice basis for the 6M structure is given as

The unit cell of the parent phase that changes to the L 6M after the martensitic transformation may be given as

and

The deformation gradient F 6M is then obtained as

Materials-screening conditions

Figure 4 shows the flowchart of the materials screening.

Flowchart of the materials screening. The number of surviving alloys at each step is shown in blue. Conditions 1–3, 4–5, and 6 are related to the energetic stability of the martensitic phase, the structural compatibility between parent and martensitic phases, and the dynamical stability of the martensitic phase, respectively. The lists of 187 surviving alloys with the 2H and 6M martensitic structures are given in Tables 2 and 3

Firstly, we check whether or not the space-group type of the optimized structure of the 2H martensitic phase (G m opt) is the same as the expected one (G p init). For many investigated alloys, the 2H structure is optimized to the parent-phase structure or to some other structures. Such alloys are excluded from the screening because they cannot have the assumed martensitic structure. The space-group types of the optimized structures are checked using the SPGLIB library inside the PHONOPY code.37,38

Secondly, we investigate the energetic stability. Here we check whether the energy of the martensitic phase (E m) is smaller than that of the parent phase (E p). Only the alloys satisfying ΔE m − p ≡ E m − E p < 0 survive. We also guarantee that the 2H martensitic phase is energetically more stable than pure metals as references. Here, the formation energy of the martensitic phase relative to those of pure metals in their most stable crystal structures, E f m, must be smaller than zero.

Thirdly, the structural compatibility between the parent and the martensitic phases is considered. For this purpose, we use the transformation stretch tensors34 U 2H and U 6M, which are positive-definite and symmetric matrices. These matrices are obtained from F 2H and F 6M using the polar decomposition as

and

where R 2H and R 6M are rotation matrices. James et al. have shown using their model that when the second largest eigenvalue λ 2 of U (hereafter the U 2H or U 6M are collectively referred to as U) is equal to one, the two phases can make a distortionless interface,34 which is intuitively expected as an advantage for showing better functional stability. Indeed, several SMAs with small thermal hysteresis and functional fatigue are found by modifying the composition ratios to realize λ 2 close to one.8,9,13,39 Based on these reports, we adopt |λ 2 − 1| < 0.01 as a screening condition. We also consider the volume difference between the parent and the martensitic phases, because the large volume difference is expected to cause huge stress between the two phases and to result in low functional stability.39 Actually, several materials systems such as lithium-ion batteries, whose applications are related to their phase transitions, are known to have good advantage of reliability when they show small volume differences.40 The relative difference between the volume of the parent (V p) and the martensitic (V m) phases are obtained as det(U), and hence we adopt |det(U) − 1| < 0.01 as another screening condition.

Lastly, the dynamical stability of the martensitic phase is investigated. For this purpose, we analyze the phonon frequencies of the martensitic phases ω ph m and elastic modulus matrix (C) of the martensitic phases. The alloys with imaginary phonon frequencies, i.e., {ω ph m}2 < 0 for some phonon modes, are screened out, because the existence of the imaginary phonon frequencies indicates that the crystal structure is dynamically unstable. Phonon dispersion curves and density of states are used to confirm the dynamical stability of martensitic phase by the existence of the imaginary phonon frequencies. We also screen out the alloys whose elastic modulus matrices are not positive definite according to Born’s elastic stability criteria.41 Note that the dynamical stability of the 6M martensitic structure is assumed to be the same as that of the 2H martensitic structure.

SMAs reported in experiments

Prior to the materials screening, we first investigate ΔE m − p for 13 alloys that were reported to show the shape-memory effect near the stoichiometric composition ratios in experiments. Table 1 summarizes the experimental transformation temperature T c and the computed ΔE m − p for the 13 SMAs, and Fig. 5 shows their correlation. Here T c is determined as the average over the reported characteristic martensitic transformation temperatures A s, A f, M s, and M f in experiments.8,12,15,16,42,43,44,45,46,47 When some SMAs were reported to have different martensitic structures from 2H in experiments or theoretical calculations, the energies of these crystal structures are additionally calculated to obtain ΔE m − p. Among 13 alloys, Ni2MnGa and Co2NiGa are known as the FM alloys with the Curie temperatures of 376 K48 and 377 K,49 respectively. The experimental martensitic transformation temperatures of these alloys are below their Curie temperatures. Our calculations confirm that both the parent-phase and the martensitic-phase structures of these two alloys are more than 0.04 eV/atom energetically more stable in the FM state than in the NM state.

Relationship of computed ΔE m − p and experimental transformation temperature T c of 13 SMAs near the stoichiometric composition ratios in experiments. In addition to the 2H structure (star purple symbols), martensitic-phase structures in the parentheses (triangle orange symbols), which are reported in experiments or simulations, are also investigated. The computed ΔE m − p and experimental T c show strong correlation with the linear correlation coefficient (r) of −0.92

We can derive three results from the obtained data. Firstly, the martensitic phases have lower energies than the parent phase for all the 13 investigated SMAs. Since the first-principles calculations give the energies at 0 K, this result supports the experimental fact that the martensitic phases are found at lower temperature than the parent phase for the 13 SMAs. Secondly, most of the energy differences among various martensitic phases are less than 0.01 eV/atom, which are much smaller than the energy differences between the parent and the martensitic phases. This guarantees that the energy of the 2H structure can be used as the representative value among the various martensitic phases for the screening procedure using ΔE m − p. Thirdly, the computed ΔE m − p shows strong correlation with the experimental T c. Specifically, the SMAs with large |ΔE m − p| show high T c. The linear correlation coefficient between ΔE m − p and T c is −0.92. This implies that ΔE m − p can be used to roughly but efficiently estimate T c for various kinds of alloys. For example, the ΔE m − p of −0.05 eV/atom corresponds to T c of 400 K.

Figures 6 and 7 show the phonon dispersion curves of parent and martensitic phases, respectively, for the 13 SMAs. For the martensitic phases, we investigate energetically the most stable crystal structure for each of the 13 SMAs. These martensitic structures do not show any imaginary modes, indicating that they are dynamically stable. These martensitic structures also show the elastic stability confirmed by the positive definite elastic modulus matrices. This satisfies our screening condition that the martensitic structures should be dynamically stable. In contrast, the parent phases of the most of the 13 SMAs show imaginary frequencies in a wide range of wave vectors. This indicates that they are dynamically unstable under the harmonic approximation. The anharmonic phonon effects,50,51 which is significant particularly at high temperature, is probably essential to make the parent phases dynamically stable.

Phonon dispersion curves for the parent-phase structures of the 13 SMAs with stoichiometric composition ratios. The space-group type of the structure is also shown in each panel. The band paths in the Brillouin zones are set based on the space-group type of the structure.75 Most of the parent phases of 13 SMAs show imaginary modes

Phonon dispersion curves for the martensitic-phase structures of the 13 SMAs with stoichiometric composition ratios. The space-group type of the structure is also shown in each panel. The band paths in the Brillouin zones are set based on the space-group type of the structure.75 All of the martensitic phases of 13 SMAs do not show any imaginary modes

According to these results, we expect that the screening conditions for the energetic and dynamical stabilities described in subsection “Materials-screening conditions” are suitable to find intermetallic compounds which possibly cause a martensitic transformation. Later we will also discuss the structural compatibility of the 13 investigated alloys.

Energetic and structural properties of the martensitic phase of intermetallic compounds

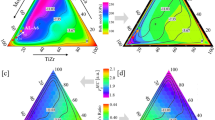

In order to identify the intermetallic compounds whose martensitic phase is energetically and dynamically stable and shows good structural compatibility with the parent phase, we apply the screening conditions described in subsection “Materials-screening conditions” and Fig. 4 to 6627 alloys. Figure 8 shows the correlations among four quantities, ΔE m − p, E f m, det(U) − 1, and λ 2 − 1, for 3997 alloys in the set-1. Gaussian kernel density estimation52 is used to put colors in the plots. There are no strong correlations among the four quantities. The maximum magnitude of the linear correlation coefficient is only 0.42, found between ΔE m − p and det(U) − 1. This indicates that these four screening conditions work almost independently. The screening conditions are also indicated in Fig. 8 as gray vertical and horizontal lines. Although our screening conditions are rather tight especially for det(U)−1 and λ 2 − 1, as many as 187 alloys survive because of the high density of alloys within the screening-condition slot. The lists of surviving alloys with the 2H and 6M martensitic structures are given in Tables 2 and 3, respectively. Among 187 alloys, 54 and 133 alloys correspond to the 2H and 6M martensitic structures, respectively. The surviving alloys tend to have the 6M martensitic structure more than the 2H.

Scatter plots between the quantities associated with the screening conditions for 3997 alloys in the set-1 in Fig. 4. The gray lines denote the boundary of screening-condition slot. The color scale represents the relative density of points generated by Gaussian kernel density estimation. Blue and red colors correspond to higher and lower densities, respectively. r shown in each panel is the linear correlation coefficient. There are no strong correlations among the four quantities, which indicates that these four screening conditions work almost independently

It is interesting that the 13 SMAs analyzed in previous subsection are not included in the list of surviving alloys. We confirm that they satisfy the screening condition for the energetic and dynamical stability of the martensitic phase. However, they do not satisfy the remaining two screening conditions related to the structural compatibility (|λ 2 − 1| < 0.01 and |det(U) − 1| < 0.01). Their low structural compatibility implies their low functional reliability. Actually, the experimental reports (Table 1) show that the thermal hysteresis of these alloys, except for Zn2AuCu, is larger than 20–30 K, which is not small.3,53 The larger thermal hysteresis should result in the worse functional stability. It is worth referring to the experimental reports that some of these alloys reduce their thermal hysteresis by deviating their composition ratios from the stoichiometric and/or adding dopant elements; Zn–Au–Cu shows low thermal hysteresis of ~2 K by adjusting its composition ratio,8 Ti–Ni reduces the thermal hysteresis by doping Pd, Pt, Cu, or Au,3,13,14 and Ti–Pd achieves less than 5 K of thermal hysteresis by doping Cr.9 These reports indicate the possibility to control the functional stability of SMAs by introducing nonstoichiometric composition ratios and/or dopant elements.

Figure 9 shows the chemical combinations of 111 surviving binary alloys. The ternary X 2 YZ alloys are excluded for this analysis because in this study the X component for the ternary is restricted to three elements, i.e., Ti, Cu, and Zn.

Combinations of chemical elements in the 111 surviving binary alloys with the composition of a XY and b X 3 Y. Upward and downward triangles classify the type of martensitic-phase structure, and red and blue colors of the triangles classify ΔE m − p. Almost half of the surviving binary alloys (53 out of 111) include some chemical elements in the groups 10–14, while the other 58 surviving binary alloys are found in various combinations of groups

The alloys composed of the elements from the same combination of groups tend to have the same type of martensitic structures. Two or more X 3 Y alloys survive in 24 group-combinations, and among them, 20 combinations have the same type of martensitic structures. This tendency may be related to the same number of valence electrons of the alloys formed by chemical elements in the same combinations of groups in the periodic table.

All the surviving ten XY alloys include at least one chemical element in the groups 10–13. Among 101 combinations of X 3 Y alloys, 28 alloys are only composed of the chemical elements in the groups 10–12. Other 15 alloys are formed by the combinations of a chemical element in the group 3 or 4 as X and the other one in the groups 10–14 as Y. Thus, almost half of the surviving binary alloys (53 out of 111) include some chemical elements in the groups 10–14. On the other hand, the other 58 surviving X 3 Y binary alloys are found in various combinations of groups. It is therefore difficult to categorize them into some specific combinations of the groups in the periodic table.

Hence, next the surviving binary alloys are analyzed from the element-resolved viewpoint. Among the 48 chemical elements, Cu, Zn, Ag, Au, and Pd are the most frequently included elements in the descending order. The result is reasonable since many Cu-based alloys are known to exhibit the shape-memory effects. Cu–Zn-based SMAs are found in the form of either binary alloys of 60–64 at.% Cu54 or ternary alloys incorporating Al, Si, Ga, and Mn.5 Cu–Al-based SMAs are found in the form of ternary alloys incorporating Ni,55 Mn,56 Be,57 and Zn.5 Cu–Sn-based binary alloys also show the shape-memory effect for 74–91 at.% Cu.5 Note that these alloys are not included in the 13 SMAs analyzed in previous subsection because their shape-memory effect were reported in experiments only for the off-stoichiometric composition ratios.

Besides these popular alloy systems, many other elements and their combinations are found in the surviving alloys. Among such elements, Li and Sc have been rarely used as the constituent elements of the SMAs reported in experiments. Only recently, the Mg80Sc20 alloy was discovered as a SMA having technological advantages with its light weight.58 The In–Tl nanowire was also reported to exhibit the shape-memory effect.59 These reports support that it is possible to make the alloys which cause a martensitic transformation from the less popular elements.

According to several review papers,10,11 the SMAs with the T c above 370–400 K are categorized in HTSMAs. Since the ΔE m − p of −0.05 eV/atom approximately corresponds to the T c of 400 K as described in previous subsection, it may be interesting to classify the surviving alloys at ΔE m − p = −0.05 eV/atom. Among the 111 surviving binary alloys, 60 alloys show ΔE m − p < −0.05 eV/atom, which are shown in blue in Fig. 9. Al, Sc, Ti, Zn, Hf, and Pt are found five or more times in the surviving alloys with ΔE m − p < −0.05 eV/atom. These chemical elements, except for Zn, are not so much included in the alloys with −0.05 eV/atom < ΔE m − p < 0. This indicates that these elements are preferable to show T c over ~400 K. Indeed, Pt-rich alloys such as Pt–Al and Pt–Ga60 are used for HTSMAs.

Finally, energetic stability of the 187 surviving alloys is examined. The stability is already examined by the formation energy E f m with respect to pure metals as described in the subsection “Materials-screening conditions”. Besides E f m, the energy of the alloys can be compared with the convex-hull energy for the corresponding binary and ternary systems. Since the construction of the convex-hull energy for many systems is computationally laborious, we refer to the data of the MPD,29 which were obtained under similar computational conditions with the present study. The convex-hull energy of the corresponding chemical composition relative to pure metals in MPD, E f conv(MPD), is compared to the present E f m. Tables 2 and 3 show the difference E f m − E f conv(MPD), together with the corresponding phases for the given composition. Most of the 2H and 6M structures for the 187 surviving alloys are missing in MPD, and therefore the structure on the convex hull in the MPD and that of the present martensitic phase are different for these alloys. The small absolute value of E f m − E f conv(MPD) less than ~0.1 eV/atom may be ascribed to either the difference of the structures or the difference of computational conditions. It may be, however, still reasonable to say that if the E f m − E f conv(MPD) exceeds ~0.1 eV/atom, the alloy may be difficult to be formed or susceptible to the phase separation or transition.

In this study, we considered only the nonmagnetic (NM) and the FM states for each system. If any antiferromagnetism takes place, the energetic stability may be affected. In this study, the 2M martensitic-phase structure (L10 in the Strukturbericht symbol and 3R (for B2) and 6 R (for D03 and L21) in the Ramsdell notation) is not considered because it requires tetragonal elongation and is therefore mathematically impossible to simultaneously satisfy λ 2 − 1 = 0 and det(U) − 1 = 0. The inverse Heusler structure is not considered as the parent-phase structure because the L21 regular Heusler structure is much often found as the parent-phase structure of SMAs.8,56,61 Note that in the cases of X = Fe, Co, Ni, Ru, Rh, Pd, Os, Ir and Pt in the X 2 YZ combinations, it is reported that only 27 combinations among 810 is energetically more stable in the inverse Heusler structure than both in L21 and constituting elements.62,63 The B19′ structure is not considered as the martensitic-phase structure because of the following reasons. Firstly, this structure is expected to give poor structural compatibility with the parent phase. The lattice constants of binary nearly-equiatomic Ti–Ni show poor structural compatibility between the parent B2 and the martensitic B19′ structures in experiments.64,65 Secondly, the B19′ structure has been found in experiments only for Ti–Ni-based alloys.23,64,65 Although some Ti–Ni-based ternary alloys with off-stoichiometric composition and doping such as Ti50.2Ni34.4Cu12.3Pd3.1 7 and Ti54Ni34Cu12 66 are reported to show low functional fatigue, their martensitic-phase structures are not B19′ but B19. It should be also pointed out that the lattice constants and monoclinic angles of the B19′ structures have strong dependence on computational conditions67 and the constituting chemical elements.23

In conclusion, we perform the first-principles-based materials screening to find the intermetallic compounds which possibly cause a martensitic transformation. As the screening conditions, we consider the energetic and dynamical stabilities of the crystal structure in the martensitic phase as well as the structural compatibility of the crystal structures between the parent and the martensitic phases. The B2, D03, and L21 crystal structures are considered as the parent phase, while the 2H and the 6M structures are considered as the martensitic phase.

We screen 6627 alloys with binary and ternary combinations of chemical elements, resulting in 187 alloys. The surviving alloys are composed of various chemical combinations, indicating that the elements in the wide range in the periodic table should be investigated to discover the alloys with a martensitic transformation. The formation energies of the surviving candidates are further compared with those of the first-principles data in the MPD to screen out the alloys whose martensitic structure may cause phase separation or transition to other structures.

We also examine the correlation between the martensitic transformation temperature T c in experiments and the ΔE m − p obtained from the first-principles calculations for the 13 SMAs with nearly stoichiometric composition ratios. Strong correlation is found between the experimental T c and the computed ΔE m − p. This implies that ΔE m − p can be used to roughly estimate the working temperature range as SMAs.

The findings in this study may also help the discovery of SMAs that overcome the problems of costs, toxicity, and poor functional stability. Although in this study we focus on only the alloys with stoichiometric composition ratios, this study may be a good starting point for investigation also on the alloys with off-stoichiometric composition ratios and provides useful fundamental data. Actually, the off-stoichiometric Zn45Au30Cu25 alloy shows smaller thermal hysteresis and functional fatigue than the stoichiometric Zn2AuCu alloy,8 and hence such composition dependence must be also very interesting.

Method

The first-principles calculations are performed by the projector augmented wave (PAW) method68,69 implemented in the Vienna ab-initio simulation package (VASP)70,71 within the framework of the generalized gradient approximation of Perdew–Burke–Ernzerhof form.72 The cutoff energy is set to 400 eV. k-space sampling mesh for each investigated structure is summarized in Table 4, and the Methfessel-Paxton scheme73 with a smearing width of 0.4 eV is employed. The volume and shape of the cells and internal atomic coordinates are fully relaxed until residual forces acting on atoms reach below 0.005 eV/Å. The structure optimization is performed for a primitive-cell model to reduce computational costs. Both the NM and the FM states are calculated for each system, and the lower-energy states are investigated in the subsequent materials screening.

The phonon calculations are performed under the harmonic approximation on the lattice Hamiltonian by using the PHONOPY code.37,38 To calculate phonon frequencies, in this study we combine the supercell approach and density functional perturbation theory.74 Force constants of an alloy are calculated by applying density functional perturbation theory at the Γ point to the supercell model of the alloy. Phonon frequencies are then calculated from the force constants. The supercell size in the phonon calculation for each investigated structure is summarized in Table 4.

We upload the input files of VASP code and optimized crystal structures of surviving compounds as the supplemental information.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper, and the computational conditions for VASP code and crystal structures for surviving 187 alloys are available in its supplementary information files.

References

Jani, J. M., Leary, M., Subic, A. & Gibson, M. A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 56, 1078–1113 (2014).

Otsuka, K. & Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 50, 511–678 (2005).

Zhang, Z., James, R. D. & Müller, S. Energy barriers and hysteresis in martensitic phase transformations. Acta Mater. 57, 4332–4352 (2009).

Biesiekierski, A., Wang, J., Abdel-Hady Gepreel, M. & Wen, C. A new look at biomedical Ti-based shape memory alloys. Acta Biomater. 8, 1661–1669 (2012).

Dasgupta, R. A look into Cu-based shape memory alloys: present scenario and future prospects. J. Mater. Res. 29, 1681–1698 (2014).

Huang, W. On the selection of shape memory alloys for actuators. Mater. Des. 23, 11–19 (2002).

Zarnetta, R. et al. Identification of quaternary shape memory alloys with near-zero thermal hysteresis and unprecedented functional stability. Adv. Funct. Mater. 20, 1917–1923 (2010).

Song, Y. et al. Enhanced reversibility and unusual microstructure of a phase-transforming material. Nature 502, 85–88 (2013).

Xue, D. et al. Design of high temperature Ti-Pd-Cr shape memory alloys with small thermal hysteresis. Sci. Rep. 6, 28244 (2016).

Ma, J., Karaman, I. & Noebe, R. D. High temperature shape memory alloys. Int. Mater. Rev. 55, 257–315 (2013).

Van Humbeeck, J. High temperature shape memory alloys. J. Eng. Mater. Technol. 121, 98–101 (1999).

Ullakko, K., Huang, J. K., Kokorin, V. V. & O’Handley, R. C. Magnetically controlled shape memory effect in Ni2MnGa intermetallics. Scr. Mater. 36, 1133–1138 (1997).

Chen, X., Srivastava, V., Dabade, V. & James, R. D. Study of the cofactor conditions: conditions of supercompatibility between phases. J. Mech. Phys. Solids 61, 2566–2587 (2013).

Cui, J. et al. Combinatorial search of thermoelastic shape-memory alloys with extremely small hysteresis width. Nat. Mater. 5, 286–290 (2006).

Wadood, A. & Yamabe-Mitarai, Y. Recent research and developments related to near-equiatomic titanium-platinum alloys for high-temperature applications. Platin. Met. Rev. 58, 61–67 (2014).

Atli, K. C. et al. Improvement in the shape memory response of Ti50.5Ni24.5Pd25 high-temperature shape memory alloy with scandium microalloying. Metall. Mater. Trans. A 41, 2485–2497 (2010).

Zarinejad, M. & Liu, Y. Dependence of transformation temperatures of NiTi-based shape-memory alloys on the number and concentration of valence electrons. Adv. Funct. Mater. 18, 2789–2794 (2008).

Hautier, G. et al. Finding nature’s missing ternary oxide compounds using machine learning and density functional theory. Chem. Mater. 22, 3762–3767 (2010).

Hinuma, Y. et al. Discovery of earth-abundant nitride semiconductors by computational screening and high-pressure synthesis. Nat. Comm. 7, 11962 (2016).

Carrete, J. et al. Finding unprecedentedly low-thermal-conductivity half-Heusler semiconductors via high-throughput materials modeling. Phys. Rev. X 4, 011019 (2014).

Greeley, J. et al. Computational high-throughput screening of electrocatalytic materials for hydrogen evolution. Nat. Mater. 5, 909–913 (2006).

Belsky, A., Hellenbrandt, M., Karen, V. L. & Luksch, P. New developments in the Inorganic Crystal Structure Database (ICSD): Accessibility in support of materials research and design. Acta Crystallogr. Sect. B 58, 364–369 (2002).

Huang, X., Ackland, G. J. & Rabe, K. M. Crystal structures and shape-memory behaviour of NiTi. Nat. Mater. 2, 307–311 (2003).

Huang, X., Rabe, K. M. & Ackland, G. J. First-principles study of the structural energetics of PdTi and PtTi. Phys. Rev. B 67, 024101 (2003).

Hickel, T. et al. Ab Initio-based prediction of phase diagrams: application to magnetic shape memory alloys. Adv. Eng. Mater. 14, 547–561 (2012).

Wagner, M. F. X. & Windl, W. Lattice stability, elastic constants and macroscopic moduli of NiTi martensites from first principles. Acta Mater. 56, 6232–6245 (2008).

Hatcher, N., Kontsevoi, O. Y. & Freeman, A. J. Role of elastic and shear stabilities in the martensitic transformation path of NiTi. Phys. Rev. B 80, 144203 (2009).

Dutta, B. et al. Ab initio prediction of martensitic and intermartensitic phase boundaries in Ni-Mn-Ga. Phys. Rev. Lett. 116, 025503 (2016).

Jain, A. et al. Commentary: The Materials Project: a materials genome approach to accelerating materials innovation. Appl. Phys. Lett. Mater. 1, 011002 (2013).

De Graef, M. & McHenry, M. E. Structure of Materials: An Introduction to Crystallography, Diffraction and Symmetry, 2nd edn (Cambridge University Press, 2012).

Otsuka, K., Ohba, T., Tokonami, M. & Wayman, C. M. New description of long period stacking order structures of martensites in β-phase alloys. Scr. Metall. Mater. 29, 1359–1364 (1993).

Delaey, L. & Chandrasekaran, M. Comments on “New description of long period stacking order structures of martensites in β-Phase alloys” by K. Otsuka, T. Ohba, M. Tokonami and C. M. Wayman. Scr. Metall. Mater 30, 1605–1610 (1994).

Nishiyama, Z. Martensitic Transformation, 1st edn (Academic, 1978).

James, R. D. & Hane, K. F. Martensitic transformations and shape-memory materials. Acta Mater. 48, 197–222 (2000).

Grimvall, G., Magyari-Köpe, B., Ozoliņš, V. & Persson, K. A. Lattice instabilities in metallic elements. Rev. Mod. Phys. 84, 945–986 (2012).

Burgers, W. G. On the process of transition of the cubic-body-centered modification into the hexagonal-close-packed modification of zirconium. Physica 1, 561–586 (1934).

Togo, A., Chaput, L., Tanaka, I. & Hug, G. First-principles phonon calculations of thermal expansion in Ti3SiC2, Ti3AlC2, and Ti3GeC2. Phys. Rev. B 81, 174301 (2010).

Togo, A., Oba, F. & Tanaka, I. First-principles calculations of the ferroelastic transition between rutile-type and CaCl2-type SiO2 at high pressures. Phys. Rev. B 78, 134106 (2008).

James, R. D. & Zhang, Z. A way to Search for Multiferroic Materials with “Unlikely” Combinations of Physical Properties. In Magnetism and Structure in Functional Materials (eds. Planes, A., Mañosa, L. & Saxena, A.) (Springer, 2005).

Nishijima, M. et al. Accelerated discovery of cathode materials with prolonged cycle life for lithium-ion battery. Nat. Comm. 5, 4553 (2014).

Born, M. & Huang, K. Dynamics Theory of Crystal Lattices (Oxford University Press, 1954).

Nakanishi, N. Lattice softening and the origin of SME. In Shape Memory Effects in Alloys (ed. Perkins, J.) (Springer, 1975).

Wilkes, K. E. & Liaw, P. K. The fatigue behavior of shape-memory alloys. JOM 52, 45–51 (2000).

Craciunescu, C., Kishi, Y., Lograsso, T. A. & Wuttig, M. Martensitic transformation in Co2NiGa ferromagnetic shape memory alloys. Scr. Mater. 47, 285–288 (2002).

Chai, Y. W., Kim, H. Y., Hosoda, H. & Miyazaki, S. Interfacial defects in Ti–Nb shape memory alloys. Acta Mater. 56, 3088–3097 (2008).

Padula, S. I. et al. Challenges and progress in the development of high-temperature shape memory alloys based on NiTiX compositions for high-force actuator applications. In International Conference on Shape Memory and Superelastic Technologies, 787–801 (eds. Berg, B., Mitchell, M. R. & Proft, J.) (ASM International, Pacific Grove, CA, 2006).

Yamabe-Mitarai, Y., Hara, T., Miura, S. & Hosoda, H. Mechanical properties of Ti-50(Pt,Ir) high-temperature shape memory alloys. Mater. Trans. 47, 650–657 (2006).

Webster, P. J., Ziebeck, K. R. A., Town, S. L. & Peak, M. S. Magnetic order and phase transformation in Ni2MnGa. Philos. Mag. B 49, 295–310 (2006).

Entel, P. et al. Phase diagrams of conventional and inverse functional magnetic Heusler alloys: New theoretical and experimental investigations. In Disorder and Strain-induced Complexity in Functional Materials (eds. Kakeshita, T., Fukuda, T., Saxena, A. & Planes, A.) (Springer, 2013).

Hellman, O., Abrikosov, I. A. & Simak, S. I. Lattice dynamics of anharmonic solids from first principles. Phys. Rev. B 84, 180301 (2011).

Souvatzis, P., Eriksson, O., Katsnelson, M. I. & Rudin, S. P. Entropy driven stabilization of energetically unstable crystal structures explained from first principles theory. Phys. Rev. Lett. 100, 095901 (2008).

Scott, D. W. Multivariate Density Estimation: Theory, Practice and visualization, 1st edn (Wiley, 1992).

Tang, W. & Sandström, R. Property database on shape memory alloys for engineering design. In Computerization and Networking of Materials Databases (eds. Sturrock, C. P. & Begley, E. F.) (ASTM International, 1995).

Schroeder, T. A. & Wayman, C. M. The formation of martensite and the mechanism of the shape memory effect in single crystals of Cu-Zn alloys. Acta Metall. 25, 1375–1391 (1977).

Otsuka, K. et al. Superelasticity effects and stress-induced martensitic transformations in CuAlNi alloys. Acta Metall. 24, 207–226 (1976).

Kainuma, R., Takahashi, S. & Ishida, K. Thermoelastic martensite and shape memory effect in ductile Cu-Al-Mn alloys. Metall. Mater. Trans. A 27, 2187–2195 (1996).

Montecinos, S., Moroni, M. O. & Sepúlveda, A. Superelastic behavior and damping capacity of CuAlBe alloys. Mater. Sci. Eng. A 419, 91–97 (2006).

Ogawa, Y., Ando, D., Sutou, Y. & Koike, J. A lightweight shape-memory magnesium alloy. Science 353, 368–370 (2016).

Zheng, H. et al. Reversible phase transformations in a shape memory alloy In–Tl nanowires observed by in situ transmission electron microscopy. Mater. Lett. 70, 109–112 (2012).

Biggs, T., Cortie, M. B., Witcomb, M. J. & Cornish, L. A. Platinum alloys for shape memory applications. Platin. Met. Rev. 47, 142–156 (2003).

Chernenko, V. A., Cesari, E., Kokorin, V. V. & Vitenko, I. N. The development of new ferromagnetic shape memory alloys in Ni-Mn-Ga system. Scr. Metall. Mater. 33, 1239–1244 (1995).

Gilleßen, M. & Dronskowski, R. A combinatorial study of full Heusler alloys by first-principles computational methods. J. Comput. Chem. 30, 1290–1299 (2009).

Gilleßen, M. & Dronskowski, R. A combinatorial study of inverse Heusler alloys by first-principles computational methods. J. Comput. Chem. 31, 612–619 (2010).

Otsuka, K., Sawamura, T. & Shimizu, K. Crystal structure and internal defects of equiatomic TiNi martensite. Phys. Status Solidi A 5, 457–470 (1971).

Kudoh, Y., Tokonami, M., Miyazaki, S. & Otsuka, K. Crystal structure of the martensite in Ti-49.2 at.%Ni alloy analyzed by the single crystal X-ray diffraction method. Acta Metall. 33, 2049–2056 (1985).

Chluba, C. et al. Ultralow-fatigue shape memory alloy films. Science 348, 1004–1007 (2015).

Holec, D., Friák, M., Dlouhý, A. & Neugebauer, J. Ab initio study of pressure stabilized NiTi allotropes: Pressure-induced transformations and hysteresis loops. Phys. Rev. B 84, 224119 (2011).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Methfessel, M. & Paxton, A. T. High-precision sampling for Brillouin-zone integration in metals. Phys. Rev. B 40, 3616–3621 (1989).

Baroni, S., Giannozzi, P. & Testa, A. Green’s-function approach to linear response in solids. Phys. Rev. Lett. 58, 1861–1864 (1987).

Aroyo, M. I. et al. Brillouin-zone database on the Bilbao Crystallographic Server. Acta Crystallogr. Sect. A 70, 126–137 (2014).

Acknowledgements

This work was supported by Grant-in-Aid for Scientific Research (A) and Grant-in-Aid for Scientific Research on Innovative Areas “Nano Informatics” (Grant No. 25106005) from the Japan Society for the Promotion of Science (JSPS), and Support program for starting up innovation hub on Materials research by Information Integration” Initiative from Japan Science and Technology Agency. J.L. acknowledges Grant-in-Aid for International Research Fellow of JSPS (Grant No. 2604376) and JSPS fellowships. Y.I. acknowledges Grant-in-Aid for Young Scientist (B) of JSPS (Grant No. 16K18228). Funding by the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan, through Elements Strategy Initiative for Structural Materials (ESISM) of Kyoto University, is also gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

J.L. and Y.I. proposed the idea for computational works and analyzed theoretical data. J.L. carried out the first principles calculations. I.T. advised the strategy of the research. All authors discussed the results and wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing financial interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lee, J., Ikeda, Y. & Tanaka, I. First-principles screening of structural properties of intermetallic compounds on martensitic transformation. npj Comput Mater 3, 52 (2017). https://doi.org/10.1038/s41524-017-0053-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41524-017-0053-8