Abstract

The discovery of reactions is a central topic in chemistry and especially interesting if access to compound classes, which have not yet been synthesized, is permitted. N-Heterocyclic compounds are very important due to their numerous applications in life and material science. We introduce here a consecutive three-component reaction, classes of N-heterocyclic compounds, and the associated synthesis concept (regenerative cyclisation). Our reaction starts with a diamine, which reacts with an amino alcohol via dehydrogenation, condensation, and cyclisation to form a new pair of amines that undergoes ring closure with an aldehyde, carbonyldiimidazole, or a dehydrogenated amino alcohol. Hydrogen is liberated in the first reaction step and the dehydrogenation catalyst used is based on manganese.

Similar content being viewed by others

Introduction

Reaction discovery is a central topic in chemistry1 and especially interesting if access to classes of compounds, which have not yet been synthesized, can be provided. Unfortunately, concepts permitting a rational design of compound classes are rare. Iterative synthesis, the regeneration of the functional group(s) originally modified (Fig. 1A), is a suitable tool to introduce chemical diversity, which might be beneficial to address function or global challenges2. Recently, metal catalysed reactions have been in focus2 and used for automated C-C bond formation3 and selective olefin syntheses employing ethylene4. The ring closure of two functional groups generating a new pair of the same functional groups seems an option for synthesizing cyclic compounds (Fig. 1B)2,5,6,7. N-Heterocyclic compounds are very important fine and bulk chemicals due to their numerous applications in life and material sciences, for instance, as pharmaceuticals, agro chemicals, dyes, and conductive materials8. Classes of N-heterocyclic compounds might be accessible if the pair of functional groups that will be regenerated during cyclization are amines (Fig. 1C). We introduce here a catalytic consecutive three-component reaction and classes of N-heterocyclic compounds. Our reaction starts with a diamine, which reacts with an amino alcohol via dehydrogenation, condensation, and cyclisation to form a new pair of amines that undergoes ring closure with an aldehyde (Fig. 1C), carbonyldiimidazole or an amino alcohol. Hydrogen is liberated in the first reaction step9,10 and the dehydrogenation catalyst used is based on the Earth-abundant metal manganese11,12,13,14. Our reaction proceeds diastereoselectively, has a large scope, and many functional groups can be tolerated, including hydrogenation-sensitive examples, despite the presence of hydrogen and a hydrogenation catalyst15. Upscaling is easily accomplished and a catalytic amount of base is required. All N-heterocyclic compounds synthesized here have not yet been reported16.

A Regenerating the functional group again that has been modified originally (iterative synthesis) can lead to chemical diversity if different building blocks are used B Classes of (poly)cyclic compounds can be conceived via ring closure chemistry. The set of functional groups originally used has to be formed again during the ring closure reaction (regenerative cyclization). Repeating ring closure steps should lead to classes of (poly)cyclic compounds, which have not yet been synthesized, at some stage or modification degree. C N-Heterocyclic compounds introduced here with amines being the key functional groups, applying a modification degree of two, and a catalytic amino alcohol dehydrogenation-based ring closure reaction as the first step.

Results

Reaction optimization

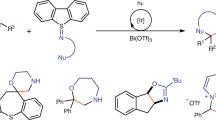

We started our investigations with an optimisation of the reaction conditions of the reaction of 1,8-diaminonaphthalene with 2-aminobenzyl alcohol to form the 2-(2,3-dihydro-1H-perimidin-2yl)aniline A1 (Fig. 2). The synthesis of 2,3-dihydro-1H-perimidines from 1,8-diaminonaphtalene and aldehydes is a classic reaction and has been reported already in 196417. Recently, the catalytic generation of the aldehyde for such a coupling via dehydrogenation catalysis employing a phosphine free manganese complex has been reported18. The key to our synthesis is the use of amino alcohols to regenerate the set of two amines and we started our investigation with 2-aminobenzyl alcohol. In case of amino alcohols, the corresponding aldehyde can undergo self-condensation and the catalytic generation via dehydrogenation catalysis seems an elegant way to address this issue. Different Earth-abundant metal (Mn, Fe, Co) complexes stabilized by pincer ligands were tested as precatalysts for the dehydrogenation step. Manganese catalysts stabilized by a PN5P-pincer ligand (Fig. 2. top right) showed the highest activity, determined by the yield of the product obtained under the given conditions. Such ligands are easy to synthesize from 2,6-diaminotriazines and dialkyl- or diarylphosphine chlorides. A significantly lower activity was observed if the ligand backbone of the manganese precatalysts was changed from a triazine (PN5P) to a pyridine (PN3P) moiety, (precatalysts Mn-VI, Mn-VII, Supplementary Table 1)19,20,21,22. Other reaction parameters, such as temperature, precatalyst loading, type and amount of solvent, and base were optimised—see Supplementary Tables 1–7 for details. The optimal reaction parameters for the synthesis of A1 (Fig. 2) were 1 mol% precatalyst [Mn-I], 30 mol% KOtBu, 3 mL 2-MeTHF at 100 °C with a reaction time of 2 h. The reaction proceeded in a tube with a bubble counter to facilitate the release of hydrogen during the dehydrogenation of the amino alcohol.

Substrate scope

Regarding the exploration of the functional group tolerance, we used 21 aminobenzyl alcohol derivatives and isolated the corresponding 2,3-dihydro-1H-perimidines A1-A21, referred to here as amino perimidines for simplification (Fig. 2). The model reaction led to the product A1 in an isolated yield of 90%. Single crystals were obtained via recrystallization from ethyl acetate/pentane (2:1) at −18 °C and analysed by X-ray diffraction confirming the molecular structure of A1 (Fig. 2; for more details, see Supplementary Data 1). The products A2-A6 were obtained in yields of 77–97%, demonstrating the tolerance of electron-donating groups on every position at the phenyl substituent. The tolerance of electron with-drawing substituents was shown by using fluoro- (A7-A10), chloro- (A13-A15), and bromo-aminobenzyl (A11, A12) alcohols. The corresponding products were isolated in yields ranging from 71–95%. The fluoro substituent was used as an example to show the tolerance at each position of the phenyl substituent. Substrates containing methoxy (A16), dimethoxy (A17), or trifluormethoxy (A18) groups were converted smoothly to the products desired and could be isolated in yields up to 82%. An amino perimidine bearing an acetal (A19) could be isolated in a yield of 69%. Using a polycyclic aromatic amino alcohol provided A20 in a yield of 77%. The use of a N-heterocyclic amino alcohol led to A21 in a nearly quantitative yield. The amino perimidines (A1-A24) were isolated as solids in colours from white to yellow. Each product was not described at that stage. The amino perimidines generally showed a good solubility in polar solvents, were air-stable, and easy to crystallize (e.g., in ethyl acetate/pentane).

The primary amine functionality of the modification degree 1 and its spatial distance to the NH-groups can be used for a second ring closure (modification degree 2). Aldehydes represent simple, easy-to-handle, inexpensive, diversely available and green or sustainable23,24 building blocks and can undergo condensation reactions with amines. This modification degree 2 leads to a class of compounds consisting of two six-membered N-heterocyclic ring systems (Fig. 3). We propose the name fertigines for this class of N-heterocycles. Keeping the synthesis procedure of the fertigines as simple as possible, we synthesized them via a consecutive multicomponent one-pot reaction using the conditions optimised for the synthesis of the amino perimidines followed by the addition of aldehyde (Fig. 3). The addition of benzaldehyde led to the fertigine B1a in an isolated yield of 93% after a reaction time of 15 h. B1a is a white solid that is soluble in polar solvents. Crystals for single crystal X-ray analysis were obtained by recrystallization of B1a (Fig. 3) in ethyl acetate/pentane at −18 °C. The molecular structure of B1a is shown in Fig. 3 (for more details, see Supplementary Data 2). The second ring closure proceeded smoothly to the products B1b-B1e in yields of 78–92%, indicating no significant influence of the position of electron-donating groups attached to the aminobenzyl alcohol moiety. Analogously, we investigated the position-dependent influence of electron-withdrawing groups on the outcome of the reaction. We chose the fluoro substituent and could not observe any significant impact on the second ring closure, obtaining the corresponding fertigines B1f-B1i in isolated yields of up to 87%. The use of further halogenated substrates, such as 5-bromo- (B1j), 6-chloro- (B1k), 4-chloro- (B1l) or 3-chloro-2-aminobenzyl alcohol (B1m), for fertigine synthesis led to the products desired in yields between 75 and 89%. B1n, bearing a trifluoromethoxy-group, could be obtained in an isolated yield of 70%. A fertigine with an acetal group (B1o) on the former amino alcohol moiety was isolated in a yield of 79%. Applying an amino alcohol with a polycyclic aromatic backbone provided the product B1p in an isolated yield of 73%. The use of 2-amino-pyridylmethanol resulted in the corresponding product B1q in an isolated yield of 86%.

We next investigated the substrate scope of fertigines by using various aldehydes (Fig. 4). After adding benzaldehydes with chloro-substituents in the para- and ortho-position, we obtained the corresponding fertigines (B2a—B2b) in isolated yields of 70 - 75%. Other halogenated benzaldehydes, such as para-fluorobenzaldehyde or ortho-bromobenzaldehyde, reacted smoothly to the corresponding products (B2c and B2d) and could be isolated in yields of 93 and 84%, respectively. The addition of 3-methylbenzaldehyde to the model reaction (Fig. 2) led to the product B2e in a yield of 87%. Methoxy-substituted benzaldehyde provided the corresponding fertigine B2f, respectively, in isolated yield of 78%. According to these results, no coherence between the electronic properties of the substituents on benzaldehyde and the efficiency of the second ring closure was observed. Using benzaldehydes for the synthesis of fertigine with a C–C double bond (B2g) or an acetoxy group (B2h) in the para-position, the yields decreased to 68 and 69%, respectively, but no notable side reactions occurred. We next investigated several aldehydes with heterocyclic moieties for the synthesis of the corresponding fertigines such as piperonal (B2i), thiophen-2-carbaldehyde (B2j), 2-formylpyridine (B2k) and 4-formylpyridine (B2l) and obtained those products in isolated yields up to 79%. The use of ortho-vanillin provided B2m in an isolated yield of 70%. We also tested an aldehyde based on a metal organic compound, namely, ferrocenaldehyde, and could isolate the fertigine B2n in a yield of 72%. The addition of aliphatic aldehydes to the reaction led to fertigines B2o and B2p in yields of 95 and 68%, respectively. The solubility properties of the fertigines changed using these aldehydes and a good solubility in pentane was observed. There was almost no limitation on the type of aldehyde that could be used for the second ring closure, indicating a very broad scope of our consecutive 3-component reaction. Using an aldehyde and an amino alcohol with a pyridine-backbone, we obtained the fertigine B3a in a yield of 90%. Double halogenated fertigines, such as B3b or B3c, could be isolated in yields of up to 78% by using the corresponding educts. The synthesis of fluorinated fertigines with an O-heterocycle (B3d) or a metal organic compound (B3e) proceeded in yields of 85 and 75%, respectively.

We next addressed the flexibility of the naphthalene diamine in order to achieve a high degree of functionalisation in the resulting fertigines (Fig. 5). Firstly, we investigated the influence of substituted 1,8-diaminonaphthalenes and isolated the resulting amino perimidines A22-A24 (Fig. 5). The use of 3,6-di-tert-butyl-1,8-diaminonaphthalene led to the corresponding product A22 in an isolated yield of 76%. Applying 5,6-diaminoacenaphthene for the catalytic step, an ethylene-bridged naphthalene moiety was achieved and the amino perimidine A23 was isolated in a yield of 86%. Using 2-chloro-1,8-naphthalenediamine, no decrease in the catalytic activity was observed and the product A24 was obtained in a yield of 91%. The second modification degree using this 1,8-diaminonaphthalene derivative (B4a-B4c; B5a-B5c) was achieved by adding the respective aldehyde after 6 h reaction time. The addition of benzaldehyde led to the products B4a-B4c desired in yields of up to 78%, observing no significant impact of the naphthalene substitution on the second ring closure. The yield of B4b decreased to 56% due to solvation problems. The products B5a-B5c were isolated in yields from 68–73%.

Reaction conditions: 1 mmol 1,8-diaminonaphthalene derivative, 1 mmol 2-aminobenzyl alcohol, 0.3 mmol KOtBu, 1 mol% [Mn-I] (0.01 mmol), 3 mL 2-MeTHF, 100 °C, 6 h, open system (anaerobic conditions). In order to synthesize the fertigines, 1 mmol aldehyde is added after 6 h. Isolated yields in brackets.

Upscaling experiments of the model reaction revealed similar yields for amino perimidine as well as fertigine synthesis, obtaining the products A1 and B1a desired in multigram scale (Supplementary Information Section 4).

We also examined the reaction of the amino perimidines starting from aliphatic amino alcohols to obtain amino alkyl perimidines (Fig. 6). For this, the reactions of L-alaninol or L-phenylalaninol with 1,8-diaminonaphthalene derivatives were carried out under the optimized conditions for the amino perimidines with only changing the solvent from 2-MeTHF to 1,4-dioxane. The resulting amino alkyl perimidines A25-A27 were obtained in yields of 91–94% as brown viscous oils and showed a good solubility in polar solvents. Compared to the amino perimidines A1-A21, the amino alkyl perimidines A25-A27 are not air stable. Afterwards it was not possible to perform a ring closure reaction between the amino alkyl perimidines A25-A27 and aldehydes. Therefore we used N,N’-carbonyldiimidazole (CDI) as coupling agent and C1 building block to achieve a five-membered N-heterocyclic ring. By using a base for the reaction of A25-A27 with CDI we obtained the corresponding kuenstlerines C1-C3 (Fig. 6). The optimized reaction parameters for the synthesis of C1-C3 are 30 mol% KOtBu, 1,4-dioxane as solvent, 1.15 eq. CDI at 130 °C with a reaction time of 2 h in a pressure tube (Supplementary Tables 8–13). We obtained the products desired in yields between 76–91% as light brown to reddish brown solids, which are air sensitive. After the second ring closure, diastereomers were obtained, which can be separated by column chromatography. The diastereomeric ratios varied between 71:29 (C1), 88:12 (C2), and 61:19 (C3). The amino alkyl perimidines A25-A27 and kuenstlerienes C1-C3 synthesized here have not yet been reported.

Reaction conditions: 2 mmol 1,8-diaminonaphthalene, 2.2 mmol amino alcohol, 0.6 mmol KOtBu, 1 mol% [Mn-I] (0.02 mmol), 12 mL 1,4-Dioxane, 100 °C (oil bath), 4 h, open system (anaerobic conditions). Isolated yields in brackets. bReaction conditions: 2 mmol perimidine A25-27, 2.3 mmol CDI, 0.6 mmol KOtBu, 10 mL 1,4-Dioxane, 130 °C (oil bath), 2 h, pressure tube (anaerobic conditions). Isolated yields in brackets.

We were also interested in the possibility of synthesizing amino fertigines, from which degree of modification 3 could be achieved. Therefore, we carried out the reactions without further optimization as consecutive one-pot reactions such as for the synthesis of the fertigines B1-B5, and used 2-aminobenzyl alcohols instead of aldehydes for the second ring closure step (Fig. 7). The amino fertigines B6a-B6c were obtained in yields of 38 – 79% as green solids, are poorly soluble in polar solvents and air-stable.

Mechanistic studies

The mechanism proposed for the catalytic cycle and the ring closure cascade is shown in Fig. 8. The catalyst [Mn-Ia] was obtained by adding KOtBu to the precatalyst complex [Mn-I]19,20. The triazine permits the deprotonation of the ligand backbone by strong metal bases, which has been shown to be beneficial in hydrogenation19,20 and dehydrogenation catalysis21,22. The manganese-catalysed dehydrogenation of 2-aminobenzyl alcohol proceeds via the liberation of one equivalent of hydrogen, as analysed by GC-analysis. In the absence of naphthalene diamine, self-condensation of the 2-aminobenzaldehyde generated in situ took place (Supplementary Fig. 19). We propose the formation of an imine with a subsequent intramolecular ring closure for the amino perimidine synthesis, as revealed by time-dependent 1H NMR studies. Interestingly, no reaction was observed in the absence of KOtBu, indicating a base-mediated cyclization (Supplementary Figs. 22–24). As the next step, we proposed the in situ deprotonation of one amino functionality of the aminoperimidine obtained by KOtBu (Fig. 8). A yellow crystalline solid (A1K) precipitated if KOtBu was added to the amino perimidine A1 in THF (Supplementary Figs. 25–27). If water was added to A1K, it was transformed back to the amino perimidine A1 accompanied by the formation of KOH (Supplementary Fig. 28). Time-dependent 1H NMR studies indicate that A1K is an intermediate of the second ring closure step (Fig. 8). A1K is able to react to the fertigine with benzaldehyde in the absence of KOtBu (Supplementary Figs. 29 and 30) and A1 doesn’t (under analogous conditions).

Conclusion

The regeneration of a set of diamines via cyclisation of the original set of diamines (regenerative cyclization) permits rational design and the synthesis of novel classes of N-heterocyclic compounds. Catalytic amino alcohol dehydrogenation via liberation of hydrogen seems a suitable protocol to accomplish regenerative cyclization of diamines extending the existing amino alcohol dehydrogenation based N-heterocycle syntheses, for instance, the synthesis of pyrroles25,26 and pyridines27,28. Recent work of cyclization of diamines employing methanol29 holds promises for the generalization of the concept introduced here.

Methods

General procedure for the synthesis 2-aminophenyl-2,3-dihydro-perimidines (1) and fertigines (2)

In a glovebox, 2 mmol 1,8-naphthalenediamin and 2 mmol 2-aminobenzyl alcohol derivatives are dissolved in 1 mL 2-MeTHF and added to a Schlenk tube. 0.5 mL of a 0.04 mmol/mL stock solution of the Mn-precatalyst Mn-I and 0.5 mL of a 1.2 mmol/mL KOtBu stock solution are added to the Schlenk tube. 1 mL 2-MeTHF is added, and the reaction mixture is heated at 100 °C using an open system consisting of a reflux condenser and a bubble counter. (1): After 2 h, the reaction is stopped by cooling down to room temperature and the addition of 2 mL H2O. Depending on the product, two different methods for purification were performed: 1. The mixture is extracted with dichloromethane (3 × 10 mL), the organic layers are dried with Na2SO4 and the solvent is removed in vacuo. The crude product is purified by column chromatography using Alox N as stationary phase. 2. H2O (5 mL) is added, the product is precipitated with pentane, filtrated, and washed with pentane. Finally, it is dried in vacuo. (2): After 2 h, 2 mmol of various aldehydes (dissolved in 0.5 mL 2-MeTHF) are added to the reaction. After 15 h, the reaction is stopped by cooling down to room temperature. The work-up depends on the substrates used. Usually, 2 mL H2O is added, and the reaction mixture is extracted with dichloromethane (3 × 10 mL). The organic layers were dried with Na2SO4 and the solvent is removed in vacuo. The crude product is purified by column chromatography using Alox N as stationary phase.

General procedure for the synthesis of 7,7a,8,9-tetrahydro-10H-imidazo[1,5-a]-perimidin-10-one derivatives

In a glovebox, 2 mmol perimidine derivatives, 30 mol% KOtBu (0.6 mmol, dissolved in 1.5 mL 1,4-dioxane), and 2.3 mmol carbonyldiimidazol (CDI) are added to a pressure tube, and dissolved in 8.5 mL 1,4-dioxane. The sealed pressure tube is heated at 130 °C for 2 h. After cooling down to room temperature 30 mL water is added and the product is extracted with diethyl ether (4 × 50 mL). The organic layers are dried with Na2SO4 and the solvent was removed in vacuo. The crude product is purified via gradient column chromatography using Alox N as stationary phase.

Data availability

Crystallographic data for compounds A1 and B1a are available free of charge from the Cambridge Crystallographic Data Centre under references CCDC 2084882 and CCDC 2083140, respectively. Materials and methods, experimental procedures, mechanistic studies, characterization data, and spectral data are available in the Supplementary Information. Correspondence and requests for materials should be addressed to R.K.

References

Pauling, L. Chemistry is the science of substances: their structure, their properties, and the reactions that change them into other substances. in General Chemistry (Courier Corporation, New York, 1988).

Lehmann, J., Blair, D. J. & Burk, M. D. Towards the generalized iterative synthesis of small molecules. Nat. Rev. Chem. 2, 0115 (2018).

Blair, D. J. et al. Automated iterative Csp3-C bond formation. Nature 604, 92–97 (2022).

Dietel, T., Lukas, F., Kretschmer, W. P. & Kempe, R. Elongation and branching of α-olefins by two ethylene molecules. Science 375, 1021–1024 (2022).

Mori, Y., Nogami, K., Hayashi, H. & Noyori, R. Sulfonyl-stabilized oxiranyllithium-based approach to polycyclic ethers. Convergent synthesis of the ABCDEF-ring system of yessotoxin and adriatoxin. J. Org. Chem. 68, 9050–9060 (2003).

Tonshoff, C. & Bettinger, H. F. Photogeneration of octacene and nonacene. Angew. Chem. Int. Ed. 49, 4125–4128 (2010).

Zhang, K., Cai, L., Jiang, X., Garcia-Garibay, M. A. & Kwon, O. Phosphine-mediated iterative arene homologation using allenes. J. Am. Chem. Soc. 137, 11258–11261 (2015).

Joule, J. A. & Mills, K. Heterocyclic Chemistry (Wiley, Chichester, UK, ed. 5, 2010).

Gunanathan, C. & Milstein, D. Applications of acceptorless dehydrogenation and related transformations in chemical synthesis. Science 341, 1229712–1229712 (2013).

Dobereiner, G. E. & Crabtree, R. H. Dehydrogenation as a substrate-activating strategy in homogeneous transition-metal catalysis. Chem. Rev. 110, 681–703 (2010).

Wang, Y., Wang, M., Li, Y. & Liu, Q. Homogeneous manganese-catalyzed hydrogenation and dehydrogenation reactions. Chem 7, 1180–1223 (2021).

Mukherjee, A. et al. Manganese-catalyzed environmentally benign dehydrogenative coupling of alcohols and amines to form aldimines and H2: A catalytic and mechanistic study. J. Am. Chem. Soc. 138, 4298–4301 (2016).

Mastalir, M. et al. Divergent coupling of alcohols and amines catalyzed by isoelectronic hydride MnI and FeII PNP pincer complexes. Chem. Eur. J. 22, 12316–12320 (2016).

Elangovan, S. et al. Efficient and selective N-alkylation of amines with alcohols catalysed by manganese pincer complexes. Nat. Commun. 7, 12641 (2016).

Kallmeier, F., Irrgang, T., Dietel, T. & Kempe, R. Highly active and selective manganese C=O bond hydrogenation catalysts: The importance of the multidentate ligand, the ancillary ligands, and the oxidation state. Angew. Chem. Int. Ed. 55, 11806–11809 (2016).

We consider compounds as “not reported” if they don’t yet have a CAS number.

Popp, F. D. & Catala, A. Synthesis of potential antineoplastic agents. XI. Some 2-aryl-2,3-dihydro-1H-perimidines and a perimidine mustard. J. Heterocycl. Chem. 1, 108–109 (1964).

Das, K., Mondal, A., Pal, D., Srivastava, H. K. & Srimani, D. Phosphine-free well-defined Mn(I) complex-catalyzed synthesis of amine, imine, and 2,3-dihydro-1H-perimidine via hydrogen autotransfer or acceptorless dehydrogenative coupling of amine and alcohol. Organometallics 38, 1815–1825 (2019).

Freitag, F., Irrgang, T. & Kempe, R. Mechanistic studies of hydride transfer to imines from a highly active and chemoselective manganate catalyst. J. Am. Chem. Soc. 141, 11677–11685 (2019).

Fertig, R., Irrgang, T., Freitag, F., Zander, J. & Kempe, R. Manganese-catalyzed and base-switchable synthesis of amines or imines via borrowing hydrogen or dehydrogenative condensation. ACS Catal. 8, 8525–8530 (2018).

Schlagbauer, M., Kallmeier, F., Irrgang, T. & Kempe, R. Manganese‐catalyzed β‐methylation of alcohols by methanol. Angew. Chem. Int. Ed. 59, 1485–1490 (2020).

Zhang, G., Irrgang, T., Schlagbauer, M. & Kempe, R. Synthesis of 1,3-diketones from esters via liberation of hydrogen. Chem. Catal. 1, 681–690 (2021).

Jönsson, L. J., Alriksson, B. & Nilvebrant, N.-O. Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol. Biofuels 6, 16 (2013).

Vispute, T. P., Zhang, H., Sanna, A., Xiao, R. & Huber, G. W. Renewable chemical commodity feedstocks from integrated catalytic processing of pyrolysis oils. Science 330, 1222–1227 (2010).

Michlik, S. & Kempe, R. A sustainable catalytic pyrrole synthesis. Nat. Chem. 5, 140–144 (2013).

Srimani, D., Ben-David, Y. & Milstein, D. Direct synthesis of pyrroles by dehydrogenative coupling of β-aminoalcohols with secondary alcohols catalyzed by ruthenium pincer complexes. Angew. Chem. Int. Ed. 52, 4012–4015 (2013).

Michlik, S. & Kempe, R. Regioselectively functionalized pyridines from sustainable resources. Angew. Chem. 125, 6450–6454 (2013). Angew. Chem. Int. Ed. 52, 6326-6329 (2013).

Srimani, D., Yehoshoa, B.-D. & Milstein, D. Direct synthesis of pyridines and quinolines by coupling of γ-amino-alcohols with secondary alcohols liberating H2 catalyzed by ruthenium pincer complexes. Chem. Commun. 49, 6632–6634 (2013).

Shao, Z., Yuan, S., Li, Y. & Liu, Q. Using methanol as a formaldehyde surrogate for sustainable synthesis of N-heterocycles via manganese-catalyzed dehydrogenative cyclization. Chin. J. Chem. 40, 1137–1143 (2022).

Acknowledgements

We thank Heidi Maisel and Felix Schreiner for their support in the lab. We acknowledge financial support of the DFG KE 756/31-2.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

R.K. conceived the concept. R.F., F.L.-K., T.I., and R.K. jointly devised the experimental program. T.I. supervised the experimental program. R.F. and F.L.-K. carried out the experimental program. All authors jointly wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interest.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fertig, R., Leowsky-Künstler, F., Irrgang, T. et al. Rational design of N-heterocyclic compound classes via regenerative cyclization of diamines. Nat Commun 14, 595 (2023). https://doi.org/10.1038/s41467-023-36220-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-023-36220-w

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.