Abstract

Copper (Cu)-based catalysts generally exhibit high C2+ selectivity during the electrochemical CO2 reduction reaction (CO2RR). However, the origin of this selectivity and the influence of catalyst precursors on it are not fully understood. We combine operando X-ray diffraction and operando Raman spectroscopy to monitor the structural and compositional evolution of three Cu precursors during the CO2RR. The results indicate that despite different kinetics, all three precursors are completely reduced to Cu(0) with similar grain sizes (~11 nm), and that oxidized Cu species are not involved in the CO2RR. Furthermore, Cu(OH)2- and Cu2(OH)2CO3-derived Cu exhibit considerable tensile strain (0.43%~0.55%), whereas CuO-derived Cu does not. Theoretical calculations suggest that the tensile strain in Cu lattice is conducive to promoting CO2RR, which is consistent with experimental observations. The high CO2RR performance of some derived Cu catalysts is attributed to the combined effect of the small grain size and lattice strain, both originating from the in situ electroreduction of precursors. These findings establish correlations between Cu precursors, lattice strains, and catalytic behaviors, demonstrating the unique ability of operando characterization in studying electrochemical processes.

Similar content being viewed by others

Introduction

Electrocatalytic CO2 reduction reaction (CO2RR) provides a versatile means of storing energy in chemical bonds while closing the anthropogenic carbon cycle1. Although significant progress has been made in the generation of single-carbon (C1) products (e.g., carbon monoxide, formate, methane, and methanol), in which a product selectivity of above 80% and an industrial-level current density have been achieved2,3,4,5, the production of valuable multicarbon (C2+) products (e.g., ethylene, ethanol, and n-propanol) using CO2RR has remained a challenge6.

To date, Cu-based catalysts are the main force for the production of C2+ products, owing to the *CO adsorption energy on Cu that favors the C–C coupling. Derived Cu catalysts, formed from the in situ reactions of oxides, hydroxides, or other oxidized Cu precursors under the reducing potentials of CO2RR, have attracted significant attention because they typically exhibit high selectivities toward C2+ products7,8,9. Although the Pourbaix diagram of Cu indicates that oxidized Cu precursors should be readily reduced to Cu(0) at negative potentials10, some experimental and theoretical studies have stated that Cu+ species or mixed oxidation states of Cu (e.g., Cu2+, Cu+, and Cu) are present in oxide- or hydroxide-derived Cu electrodes and are responsible for their high C2+ selectivity8,11,12,13,14,15,16. For example, Nilsson et al. combined spectroscopy and microscopy techniques to unravel the presence of residual oxygen in oxide-derived Cu electrocatalysts under CO2RR conditions17,18,19. In contrast, many other studies have demonstrated the full reduction of oxidized Cu precursors to Cu(0) and attributed the enhanced C2+ selectivity to structural and morphological effects20,21, specific crystal facet exposure7,22, or grain boundary and low-coordinated sites23,24. These inconsistent conclusions indicate that identifying the active species of derived Cu catalysts and the origin of their high C2+ selectivity remains controversial.

Lattice strain can modulate the activity and selectivity of electrocatalysts by breaking the linear scaling relationship25. Using density functional theory (DFT), Mavrikakis et al. first correlated metal lattice strain, d-band center shift, and adsorption energy to explain catalytic behaviors26. Various approaches have been employed to induce strain in Cu catalysts, including the formation of bimetallic nanoparticles27,28, epitaxial growth of thin films29,30, and crystal morphology engineering31. However, few studies have investigated strain effects in derived Cu catalysts for CO2RR. Li et al. observed microstrains in oxide-derived Cu, but they did not correlate them with CO2RR activity or selectivity32. Moreover, the influence of precursor materials on the catalytic performance of derived Cu catalysts has not been investigated. A better understanding of these aspects would facilitate the rational design of catalysts to achieve higher C2+ product selectivity.

Owing to the high sensitivity of Cu species to O2 and their immediate re-oxidation when the reducing potential is lifted33, operando characterizations are essential for probing the active species and dynamic evolution of Cu-based catalysts during CO2RR34. Particularly, some operando techniques, such as Raman spectroscopy, can detect the intermediates and products of CO2RR in real time, which has significantly facilitated the investigation of the reaction mechanism and catalyst optimization35,36. However, using operando characterization techniques that are relying on high energy beamlines (e.g., X-ray diffraction (XRD) and X-ray absorption spectroscopy) has been restricted by the limited access to synchrotron radiation facilities. The feasibility of using in-house laboratory XRD for an operando investigation of CO2RR has not been fully explored.

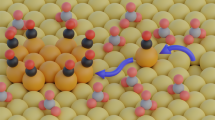

In this study, we investigate the structural and compositional evolution of three Cu-based catalysts derived from Cu2(OH)2CO3, Cu(OH)2 and CuO during CO2RR with an operando XRD platform that uses a laboratory-scale X-ray to analyze the phase transformation of the catalyst crystals (Fig. 1a) and operando Raman spectroscopy to detect the surface species (Fig. 1b). It is revealed that the three oxidized Cu precursors are all completely reduced to Cu(0) when delivering their maximum Faradaic efficiencies (FE) for C2+ products (\({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2+}}\)), whereas CuO shows faster electroreduction kinetics than Cu2(OH)2CO3 and Cu(OH)2. The three derived Cu catalysts exhibit significantly higher \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2+}}\) compared to bulk Cu, which is attributed to their small grain sizes (~11 nm). Operando XRD discovers that Cu(OH)2- and Cu2(OH)2CO3-derived Cu exhibit obvious tensile strains, while CuO-derived Cu is almost strain-free. This finding offers a method to induce lattice strain in Cu nanocrystals by using the appropriate precursor and explains the difference in CO2RR activity relative to hydrogen evolution among the three derived Cu catalysts. Therefore, lattice strain has been identified as another factor promoting the CO2RR activity of derived Cu catalysts in addition to grain boundaries and high-index facets associated with the small grain size. These important insights cannot be gained by ex situ characterization because Cu nanocrystals undergo rapid surface oxidation and strain relaxation once electroreduction conditions are lifted. This study highlights the importance and necessity of operando characterizations in probing the evolution of electrocatalysts, and provides a technical solution for achieving this goal in ordinary laboratories.

Results

Precursor characterization

The XRD characterization revealed that the three synthesized precursors, Cu2(OH)2CO3, Cu(OH)2, and CuO, are all phase pure (Supplementary Fig. 1a), and their Raman spectra were perfectly matched with the reported standard spectra (Supplementary Fig. 2a, b)36,37,38,39. Scanning electron microscopy (SEM) revealed that Cu2(OH)2CO3 consisted of agglomerated nano-sized square rods (Supplementary Fig. 3a), whereas Cu(OH)2 exhibited a flower-like morphology, formed by the radial stacking of rectangular nanosheet bundles (Supplementary Fig. 3b). As the CuO sample was synthesized by heating the as-prepared Cu2(OH)2CO3, it retained the morphology of the parent material (Supplementary Fig. 3c) but had smaller grains, which could be attributed to the 60% atomic loss during conversion. The mean crystallite (grain) sizes of the Cu2(OH)2CO3, Cu(OH)2, and CuO nanocrystals estimated from the XRD data using the Scherrer equation were 24.7 ± 3.5, 19 ± 0.5, and 10 ± 0.5 nm, respectively (Supplementary Table 1).

CO2RR performance

We evaluated the CO2RR performance of the three Cu based catalysts with an H-type cell by analyzing the gas and liquid products at different applied potentials in CO2-saturated 0.1 M KHCO3 aqueous solution in ambient conditions. The maximum \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2+}}\) of Cu2(OH)2CO3-, Cu(OH)2-, and CuO-derived Cu catalysts were 73.0, 71.9, and 68.6% at −1.05, −1.08, and −1.16 VRHE, respectively, substantially higher than the \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2+}}\) obtained on electropolished Cu foil (13% at −1.12 VRHE; Fig. 2a). The main C2+ products of the systems included C2H4, C2H5OH, n-C3H7OH, C2H5CHO, CH3CHO, and C2H6 (sequenced by decreasing FE, see Supplementary Fig. 4a–c for the detailed product distribution). The three catalysts exhibited similar C2+ partial current densities (\({{j}}_{{{{\mathrm{C}}}}_{2+}}\)) within the tested potential window, reaching −20 to −30 mA cm−2 at ~−1.2 VRHE. In contrast, the maximum \({{j}}_{{{{\mathrm{C}}}}_{2+}}\) value obtained on the Cu foil was −4.1 mA cm−2 at ~−1.12 VRHE (Fig. 2b). The observed high C2+ selectivities and activities of Cu(OH)2- and CuO-derived Cu are consistent with findings in previous studies7,8,40, whereas this is the first report on the high selectivity and activity of Cu2(OH)2CO3-derived Cu toward C2+ production during CO2RR.

Comparison of a Faradaic efficiency of C2+ products and b C2+ partial current density for Cu2(OH)2CO3, Cu(OH)2, and CuO nanocrystals and Cu foil. Data are normalized using the geometric surface area. c Comparison of Faradaic efficiencies for overall CO2RR (\({{{\mathrm{FE}}}}_{{{{\mathrm{CO}}}}_{2}{{{\mathrm{RR}}}}}\)) and HER (\({{{\mathrm{FE}}}}_{{{{\mathrm{H}}}}_{2}}\)) between Cu2(OH)2CO3, Cu(OH)2, and CuO nanocrystals. All CO2RR experiments were performed in an H-type cell using CO2-saturated 0.1 M KHCO3 as the electrolyte for 1.5 h. Error bars represent the standard deviation of three independent measurements.

The overall FEs for CO2RR (\({{{\mathrm{FE}}}}_{{{{\mathrm{CO}}}}_{2}{{{\mathrm{RR}}}}}\)) of the three catalysts followed the order of Cu2(OH)2CO3 ≈ Cu(OH)2 > CuO (Fig. 2c). Specifically, Cu2(OH)2CO3- and Cu(OH)2-derived Cu exhibited ~75% \({{{\mathrm{FE}}}}_{{{{\mathrm{CO}}}}_{2}{{{\mathrm{RR}}}}}\) at a relatively low potential of ~−0.83 VRHE, whereas the \({{{\mathrm{FE}}}}_{{{{\mathrm{CO}}}}_{2}{{{\mathrm{RR}}}}}\) of CuO was only ~47% at this potential. Correspondingly, the competing hydrogen evolution reaction (HER) occurred to a significantly higher degree on CuO-derived Cu than on the other two catalysts over the tested potential range. The three catalysts exhibited a similar trend: as the potential became more negative, the FE for hydrogen (\({{{\mathrm{FE}}}}_{{{{\mathrm{H}}}}_{2}}\)) first decreased and then increased. The minimum \({{{\mathrm{FE}}}}_{{{{\mathrm{H}}}}_{2}}\) (i.e., the maximum \({{{\mathrm{FE}}}}_{{{{\mathrm{CO}}}}_{2}{{{\mathrm{RR}}}}}\)) was reached at ~−1.1 VRHE, where the difference in CO2RR activity (or HER activity) between CuO and the other two catalysts became less significant but still discernible (Fig. 2c).

Redox behaviors

To further examine the catalyst evolution during CO2RR, we first investigated the redox behaviors of the three oxidized Cu precursors by performing Cyclic Voltammetry (CV) in 0.1 M KOH aqueous solution and Linear Sweep Voltammetry (LSV) in Ar-saturated 0.1 M of KHCO3 aqueous solution. The results revealed that, in both KOH and KHCO3 environments, the three samples undergo the same electroreduction pathway (i.e., complete reduction to Cu via the formation of Cu2O); however, more negative potentials are required for the electroreduction of Cu2(OH)2CO3 and Cu(OH)2 compared to CuO (see Supplementary Note and Supplementary Fig. 5 for the detailed analysis).

Operando XRD

We then performed time-resolved operando XRD in a customized flow cell to investigate the structural transitions of the three oxidized Cu precursors during CO2RR (Supplementary Figs. 6 and 7). When Cu2(OH)2CO3 was at its optimal C2+ production potential (−1.05 VRHE), its characteristic (20-1) peak at 31.3° gradually faded during the first 45 min of the reaction, while the fingerprint (111) and (200) peaks of metallic Cu emerged with increasing intensity after the first 15 min (Fig. 3a). No diffraction peaks related to Cu hydroxides or oxides were detected during the entire process, suggesting that these species, if present, did not form crystalline phases. Further analysis of operando XRD data collected at different potentials revealed the potential-dependent electroreduction kinetics of Cu2(OH)2CO3: the required reduction time from Cu2(OH)2CO3 to Cu decreased with an increase in the negativity of the applied potential (Supplementary Fig. 8a, b). Similar to Cu2(OH)2CO3, Cu(OH)2 underwent a relatively slow process before the complete reduction to metallic Cu, during which no crystalline CuO or Cu2O phase was detected. At its optimal potential for \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2+}}\) (−1.08 VRHE), the strongest (130) peak at 39.8° vanished completely after 60 min of CO2RR, even though metallic Cu emerged in the first 15 min (Fig. 3b). In contrast, CuO was rapidly and completely converted to metallic Cu within the first 15 min of CO2RR (Fig. 3c), implying faster electroreduction kinetics compared to Cu2(OH)2CO3 and Cu(OH)2. On the other hand, although the grain sizes of the starting materials were different (Supplementary Table 1), the Cu derived from the three precursors had similar grain sizes (~11 nm; estimated from the XRD data; Supplementary Table 1). The smaller mean grain sizes of the derived Cu relative to those of the parent materials could be attributed to the combined effect of the volume shrinkage of the unit-cell and crystal fragmentation7. We therefore concluded that the three oxidized Cu precursors, despite the differences in their chemical components and electroreduction kinetics, were completely reduced to metallic Cu with similarly small grain sizes while (or before) delivering enhanced C2+ selectivity under the CO2RR conditions.

Time-resolved operando XRD patterns (upper panel) and the corresponding quantitative peak analysis (lower panel) of a Cu2(OH)2CO3, (b) Cu(OH)2, and c CuO nanocrystals during the CO2RR at their optimum potential for C2+ production. Spectra were collected every 15 min. For the quantitative peak analysis, the integrated and normalized intensities of Cu2(OH)2CO3(20-1), Cu(OH)2(130), CuO(11-1) and Cu(111) were used. d Comparison of Cu(111) (left panel) and Cu(200) (right panel) diffraction peak position of various derived Cu and Cu foil measured from operando XRD experiments. Vertical lines indicate the standard diffraction peak positions.

Interestingly, Cu nanocrystals derived from Cu2(OH)2CO3 exhibited shifted XRD peaks relative to the Cu foil as a standard sample, implying the presence of lattice strain. Specifically, at −1.05 VRHE, the Cu(111) and Cu(200) diffraction peaks were shifted by ~0.25° and ~0.39° to the low-angle direction (Fig. 3d), corresponding to the tensile strains of 0.55% and 0.72%, respectively (Supplementary Table 2). This phenomenon was reproduced in measurements at different potentials, whereas the degree of strain slightly varied with the potential (Supplementary Table 2). Similarly, Cu nanocrystals derived from Cu(OH)2 possessed significant (0.42%−0.47%) tensile strains under CO2RR conditions, according to the shift in the Cu(111) diffraction peak (Fig. 3d and Supplementary Table 2). In contrast, Cu derived from CuO displayed negligible peak shifts relative to the standard regardless of the applied potential, although it had a grain size similar to the other two derived Cu samples (Fig. 3d and Supplementary Table 2). The operando XRD data were all corrected based on the results of a standard sample to eliminate liquid-induced peak shift effects (Supplementary Fig. 9).

Operando Raman spectroscopy

Time-resolved operando Raman spectroscopy was performed in a customized flow cell to explore the oxidation state evolution of the catalyst surface during CO2RR (Supplementary Figs. 10 and 11). When the measurement of Cu2(OH)2CO3 was conducted at −0.84 VRHE, some areas of the electrode surface gradually changed from the initial turquoise color (the color of Cu2(OH)2CO3 nanocrystals) to brown after 90 min of CO2RR (Fig. 4a, right panel). Three types of Raman spectra were observed in different regions of the electrode surface, including the characteristic spectrum of Cu2(OH)2CO3 from the remaining shiny crystals and two distinct spectra from the newly formed brown area (Fig. 4a, left panel). Further analysis revealed that the red-circled region corresponded to Cu2O, as evidenced by the fingerprint Raman bands at 149, 528, and 620 cm−136,41. The spectrum acquired from the blue-circled region revealed three intense bands at 283, 368, and 530 cm−1 and a shoulder band at 498 cm−1. According to recent studies, the bands at 283 and 368 cm−1 correspond to the frustrated rotational mode of *CO (P1) and the Cu(0)–CO stretching vibration (P2), respectively35,41, and the bands at 498 and 530 cm−1 originate from C-containing adsorbates42,43,44. Interestingly, once the negative potential of CO2RR was lifted, these four bands disappeared, whereas the fingerprint pattern of Cu2O emerged (Supplementary Fig. 12a), confirming their association with the binding intermediates to the Cu surface. These results taken together indicate that the catalyst in the blue-circled region was fully reduced to Cu(0), and the Raman bands at 283, 368, 498 (shoulder), and 530 cm−1 can be regarded as indicators for the formation of Cu(0) and its participation in the CO2RR process.

a Time-resolved light microscopy (right panel) images of the Cu2(OH)2CO3 electrode surface during the CO2RR process at −0.84 VRHE, and the operando Raman spectra (left panel) acquired from three different areas (circled in different colors) on the Cu2(OH)2CO3 electrode surface after 90 min of the reaction. Time-resolved operando Raman spectra (left panel) and light microscopy (right panel) images of the b Cu2(OH)2CO3, (c) Cu(OH)2, and d CuO nanocrystals at their optimum potential for C2+ production during CO2RR. The circles indicate the locations of the laser spot with a theoretical diameter of 858 nm. Spectra were collected every 15 min.

Given that the shiny crystals were confirmed to be unreduced Cu2(OH)2CO3, subsequent analyses were performed on the brown region of the electrode. At a more negative potential (e.g., −1.05 VRHE in Fig. 4b, and −1.2 VRHE in Supplementary Fig. 13), the color change of the electrode surface was faster, and few shiny crystals remained on the electrode after 30 min. Moreover, most acquired Raman spectra exhibited a similar pattern (283, 368, 498 (shoulder), and 530 cm−1), suggesting the predominance of Cu(0) during CO2RR at such negative potentials. Slight deviations within 280 to 284 and 368 to 388 cm−1 for the Cu(0)–CO signals can be attributed to the dynamic change in the Cu surface during CO2RR45. The other two characteristic Raman bands also shifted within 486 to 500 and 526 to 536 cm−1, presumably due to the variation in the C-containing species binding to the Cu surface.

Operando Raman measurements indicated that, similar to Cu2(OH)2CO3, Cu(OH)2 also underwent gradual and uneven electroreduction under CO2RR conditions (Fig. 4c). In contrast, CuO exhibited a much faster electroreduction rate. The original black electrode surface turned completely brown within the first 5 min. The Raman bands of CuO vanished within 15 min, while Cu(0) dominated the electrode surface (Fig. 4d). These observations are consistent with the bulk behaviors of the three precursors revealed through operando XRD.

In summary, the operando Raman spectroscopy echoes and complements the operando XRD analysis. Both methods demonstrate that the three oxidized Cu precursors (bulk and surface) are fully reduced to metallic Cu when delivering their maximum \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2+}}\) and that CuO exhibits faster reduction kinetics than the other two. Another interesting finding is that Raman signals associated with the CO2RR intermediates and signals of Cu2(OH)2CO3, Cu(OH)2, CuO, or Cu2O do not appear in the same region simultaneously. Given that XRD can only detect crystalline phases and Raman effect is weak and localized, the present data cannot completely rule out the possible presence of metastable, short-lived, amorphous oxidized Cu species in the derived Cu catalysts16,46.

Discussion

Importance and necessity of Operando characterizations

Operando characterizations provide otherwise unavailable information on the inherent states of catalysts and intermediates under reaction conditions and are particularly important for systems involving susceptible species, such as Cu. In this study, the Raman bands, which are relevant to the binding of CO2RR intermediates to Cu(0) (i.e., 283, 368, 498 (shoulder), and 530 cm−1), could not be observed through ex situ measurements due to the inevitable rapid surface oxidation of Cu (Supplementary Fig. 12a). In other words, without operando Raman spectroscopy, we would not have been able to determine the lack of co-occurrence of CO2RR intermediates and oxidized Cu species, which is crucial for determining the catalytic active species (ubi infra).

Likewise, significant tensile strains in Cu2(OH)2CO3 and Cu(OH)2-derived Cu could only be probed using operando XRD. When the electrodes containing derived Cu nanocrystals were removed from the electrochemical systems and characterized using conventional (ex situ) XRD, the Cu(111) and Cu(200) diffraction peaks appeared at their standard positions without a shift (Supplementary Fig. 12b). Moreover, a broad peak emerged at ~36.62°, which could be assigned to Cu2O formed through surface oxidation. We surmise that the surface oxidation of Cu nanocrystals leads to the relaxation of the lattice strain. These results demonstrate the unique ability of operando characterization to capture the true states of catalysts under reaction conditions.

In addition, the time-resolved operando characterizations revealed that the electroreduction kinetics of CuO are faster than those of Cu2(OH)2CO3 and Cu(OH)2. We note that the electroreduction behaviors of Cu2(OH)2CO3 and Cu(OH)2 under the CO2RR conditions have not been previously investigated using operando techniques, while the conclusions of several earlier studies on Cu oxides41,47 are consistent with the observations of the CuO sample in this work.

Determination of active species in derived Cu catalysts

The operando XRD and operando Raman spectroscopy results collectively suggest that, despite the difference in chemical components and electroreduction kinetics, the three oxidized Cu precursors were reduced to metallic Cu while (or before) delivering enhanced C2+ selectivity under CO2RR conditions. For Cu2(OH)2CO3 and Cu(OH)2 with slow electroreduction kinetics, the temporary presence of mixed Cu oxidation states (Cu2+ from Cu2(OH)2CO3 or Cu(OH)2, Cu+ from Cu2O, and metallic Cu) was observed; however, Raman signals related to CO2RR intermediates (283, 368, 498 (shoulder), and 530 cm−1) were only observed in regions without Raman fingerprints of Cu2(OH)2CO3, Cu(OH)2, CuO, or Cu2O. These results rule out the participation of these oxidized Cu species in CO2RR; thus, we conclude that Cu(0) is the catalytic active site responsible for enhanced C2+ selectivity.

Based on this understanding, we speculate that, at the initial stage of the reaction, CuO is more selective for C2+ products than Cu2(OH)2CO3 because CuO can be reduced to Cu(0) in a shorter time. To verify this speculation, we re-examined the Cu2(OH)2CO3 and CuO systems by monitoring the C2+ production rate during the CO2RR at optimal potentials. Because C2H4 was the main component among the C2+ products in these systems, we used \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2}{{{\mathrm{H}}}}_{4}}\) as the indicator for C2+ selectivity. The results revealed that the \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2}{{{\mathrm{H}}}}_{4}}\) plateau was achieved faster in the CuO system than in the Cu2(OH)2CO3 system, although the final \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2}{{{\mathrm{H}}}}_{4}}\) values of the two systems were similar. At sampling points of 10, 15, and 20 min, CuO exhibited a higher \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2}{{{\mathrm{H}}}}_{4}}\) than Cu2(OH)2CO3 (Supplementary Fig. 14). This result agrees with the expectation, confirming that Cu(0) plays a key role in enhancing C2+ selectivity.

If Cu(0) is indeed the origin of high C2+ selectivity and oxidized Cu precursors are reduced to metallic Cu during CO2RR, the marked variation in the performance of various Cu catalysts reported in the literature need to be understood. For instance, why do hydroxide- or oxide-derived Cu catalysts generally exhibit higher C2+ selectivity than bulk Cu catalysts (e.g., Cu foil)? In a previous study, we demonstrated that an oxidation–reduction cycle resulted in the fragmentation of original Cu material into smaller irregular grains7, leading to the exposure of a variety of grain boundaries and high-index facets promoting C–C couplings for high \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2+}}\)32,48,49,50,51,52,53. We therefore postulate that the C2+ selectivity is roughly related to the mean grain (crystallite) size of the Cu catalyst, and is benefited from grains that are more irregular with a decreased size.

In this study, the three derived Cu catalysts with similar grain sizes (~11 nm) indeed exhibited similar \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2+}}\) (68%–73%). To further verify the correlation between the Cu grain size and C2+ selectivity, two additional Cu samples were prepared: Cu nanowires and electropolished polycrystalline Cu foil (Supplementary Figs. 1b and 3d–f). The mean grain size of the Cu nanowires estimated by XRD was ~29 nm, and the transmission electron microscopy revealed that the Cu foil comprised micron-sized grains (Supplementary Fig. 3e). The CO2RR performance of Cu nanowires and electropolished polycrystalline Cu foil was also evaluated (Supplementary Fig. 4d–e). Comparisons of the maximum \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2+}}\) and the mean grain sizes of the five tested catalysts confirmed a negative correlation between these two factors; that is, the C2+ selectivity increased with a decreasing Cu grain size (Fig. 5a). Another consequence of reducing the Cu grain size is an increase in the electrochemically active surface area of the electrode (Supplementary Table 1), which typically results in enhanced apparent activity in terms of current density per unit electrode area54.

a Maximum Faradaic efficiencies for C2+ products and the crystal sizes of the derived Cu (from Cu2(OH)2CO3, Cu(OH)2, and CuO nanocrystals), Cu nanowires, and polycrystalline Cu foil. b Different tensile strain values of the derived Cu (along the [111] direction) and the corresponding Faradaic efficiencies for H2, C1, CH4, C2+ products, and the overall CO2RR at ~−1.1 VRHE. Samples with 0.06%, 0.43%, and 0.55% tensile strains represent the Cu derived from CuO, Cu(OH)2, and Cu2(OH)2CO3, respectively. Error bars represent the standard deviation of three independent measurements.

Strain effects

Although the three derived Cu catalysts exhibited similar C2+ selectivity, a discernible difference exists in the overall Faradaic efficiency for CO2RR (\({{{\mathrm{FE}}}}_{{{{\mathrm{CO}}}}_{2}{{{\mathrm{RR}}}}}\)) between CuO and the other two catalysts (CuO < Cu2(OH)2CO3 ≈ Cu(OH)2; Fig. 2c). Moreover, CuO-derived Cu is strain-free, whereas the other two derived Cu samples show significant tensile strains under CO2RR conditions (Fig. 3d). This coincidence led to wondering whether lattice strain is another factor affecting the catalytic performance of Cu in addition to grain boundaries and high-index facets associated with the small grain size.

According to the d-band theory, lattice strain can trigger a shift of the d-band center of the metal and tailor its catalytic activity25,26,29,30. We performed DFT calculations to investigate how tensile strain affects the d-band center of Cu and the consequent binding energy (Ebinding) of *CO on its surface, using Cu(111) and Cu(100) with different strain values as model structures (see the computational details in the Methods). The calculations revealed that for both structures, the d-band center shifts up toward the Fermi Level with increasing tensile strain, thus leading to a continuous increase in the Ebinding of *CO. This conclusion holds for both low (Fig. 6a–d) and high (Supplementary Fig. 15a–c) *CO surface coverages. These results imply that strained Cu has a greater promoting effect on *CO adsorption than unstrained Cu, which has been experimentally verified using a recently reported method based on Raman band analysis (Supplementary Fig. 16a–d)55.

Projected density of states (PDOS) of the d-band for a Cu(111) and b Cu(100) without strain. The horizontal black dashed lines indicate positions of the d-band center (referenced to the Fermi level). The Fermi level was set as zero. Insets are top views of the corresponding crystal structure slabs. Calculated d-band centers and binding energies of *CO for c Cu(111) and d Cu(100) with different strain values (0.0%, 0.5%, 1.0%, 1.5% and 2.0%). For Cu(111), the *CO coverage is 0.25 monolayer (ML) with a cross-sectional area of 9.15 × 10−15 cm2; for Cu(100), the *CO coverage is 0.11 ML with a cross-sectional area of 1.20 × 10−14 cm2. e Reaction pathway for the formation of CH4 and typical C2+ products during CO2RR. The calculated Gibbs free energies of formation (ΔGformation) of *CHO, *COH, *COCO, and *COCOH on f Cu(111) and g Cu(100) with different strain values. The vertical grey dashed lines indicate the experimental tensile strain of 0.55% for Cu(111) and 0.72% for Cu(100). All the DFT calculations were performed at the GGA/PBE level of theory.

According to the widely accepted CO2RR mechanism56,57,58,59, *CHO/*COH and *COCO/*COCOH are the primary intermediates for the formation of CH4 and C2+ products, respectively (Fig. 6e), while the Gibbs free energies of formation (ΔGformation) of these intermediates are indicators of the ease of the corresponding pathways. The introduction of 0.5% tensile strain slightly reduces the ΔGformation of *CHO, *COH, *COCO, and *COCOH on Cu(111) by 0.02, 0.02, 0.04, and 0.03 eV, respectively; further increases in strain do not monotonically decrease their ΔGformation on Cu(111) but lead to fluctuations (Fig. 6f and Supplementary Fig. 17). Introducing 0.5−1.0% tensile strain leads to a decrease in ΔGformation for *CHO, *COH, and *COCO on Cu(100), and further increasing the strain causes their ΔGformation to first increase and then decrease. For *COCOH on Cu(100), the ΔGformation slightly increases when the tensile strain increases from 0.0% to 1.5%, followed by a sudden drop at 2.0% strain (Fig. 6g and Supplementary Fig. 17).

Moreover, we explored the strain effect on the HER by calculating the adsorption free energy of *H (ΔG*H) and water dissociation activation barriers. Regardless of strain degree and surface type, the ΔG*H is uphill whereas the H2 removal is downhill, implying that the HER on Cu is limited by the *H formation (Supplementary Fig. 18a, b). For Cu(111), although the ΔG*H decreases with increasing tensile strain, it remains considerably positive at large strain values (e.g., 0.07 eV at 2.0% strain). For Cu(100), tensile strain does not affect the ΔG*H. The influence of tensile strain on the water dissociation activation barrier is marginal for both surfaces (Supplementary Fig. 18c, d).

In summary, the calculations indicate that the introduction of tensile strain in Cu significantly promotes the adsorption of *CO and also slightly facilitates the subsequent hydrogenation and C–C coupling, while hardly affecting the HER. Therefore, Cu with tensile strain is expected to exhibit higher overall CO2RR selectivity and suppressed HER, compared to unstrained Cu. Figure 5b displays the product distributions on the three catalysts at ~−1.1 VRHE, in which the differences in the production of H2, CH4, and C1 compounds between strained (Cu(OH)2- and Cu2(OH)2CO3-derived) and unstrained (CuO-derived) Cu are clearly illustrated. In comparison with the unstrained Cu, the strained Cu exhibited higher \({{{\mathrm{FE}}}}_{{{{\mathrm{CO}}}}_{2}{{{\mathrm{RR}}}}}\), primarily contributed by the enhanced production of C1 compounds (e.g., CH4), and lower \({{{\mathrm{FE}}}}_{{{{\mathrm{H}}}}_{2}}\). This result is consistent with expectations from DFT calculations, corroborating the important role that lattice strain in Cu may play in CO2RR.

It is not fully understood why Cu nanocrystals derived from Cu(OH)2 or Cu2(OH)2CO3 have greater tensile strain than Cu nanocrystals derived from CuO. One possible reason is that the former nanocrystals undergo more drastic shrinkage in unit-cell volume (74% for Cu2(OH)2CO3, 71% for Cu(OH)2, and 42% for CuO; Supplementary Table 3) and more pronounced elimination of components than the latter nanocrystals during the phase transition. With this hypothesis, the degree of lattice strain in Cu crystals can be tuned by the precursors, offering an effective strategy for strain engineering.

Although the promoting effect of tensile strain on C-C coupling and suppression on the competing HER have been demonstrated theoretically60,61, a controversy exists in the literature on how the tensile strain in Cu affects the C1 products during the CO2RR. For instance, a recent study reported that tensile strain in Cu is unfavorable for the formation of C1 products29, which is inconsistent with our observations and the conclusions of other studies31,61. Another study concluded that tensile strain has different effects on the production of CH4, depending on the thickness of the Cu layer30. These discrepancies imply that the lattice strain is not the primary factor determining CO2RR selectivity, and its effect may be overwhelmed by other coexisting factors, such as crystal size, grain boundary, and alloying effect. In this study, the high C2+ selectivity of derived Cu catalysts is primarily attributed to the grain boundaries and high-index facets due to the size effect, while the overall CO2RR selectivity (influenced by the competition between C1 production and HER) can be further improved by introducing tensile strain through the choice of precursors.

In summary, the as-prepared Cu2(OH)2CO3, Cu(OH)2, and CuO nanocrystals delivered an \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2+}}\) of 73.0%, 71.9%, and 68.6%, respectively, at approximately −1.1 VRHE during the CO2RR. The time-resolved operando XRD, which uses a laboratory-scale X-ray source for characterizing CO2RR electrocatalysts, and operando Raman spectroscopy confirmed the full reduction of the precursors to Cu(0) while (or before) delivering enhanced C2+ selectivity under CO2RR conditions, and revealed that the electroreduction kinetics of Cu2(OH)2CO3 and Cu(OH)2 were significantly slower than those of CuO. The results collectively demonstrated that the active species responsible for the enhanced C2+ selectivity of the derived Cu electrodes was Cu(0), rather than oxidized Cu species. This conclusion was further verified by the faster reduction of CuO to Cu and the corresponding higher \({{{\mathrm{FE}}}}_{{{{\mathrm{C}}}}_{2}{{{\mathrm{H}}}}_{4}}\) at the initial stage of CO2RR compared to that of Cu2(OH)2CO3. However, it is worth noting that the possible presence of dynamic amorphous oxidized Cu species in the catalyst cannot be completely excluded due to the inherent limitations of XRD and Raman characterization.

A negative correlation between the Cu grain size and C2+ selectivity was established and the small grain size of the derived Cu (~11 nm), which resulted in an increased exposure of grain boundaries and high-index facets to facilitate the C–C coupling reaction, was considered as the primary factor for achieving high C2+ selectivity. Operando XRD revealed remarkable tensile strains in Cu nanocrystals derived from Cu(OH)2 and Cu2(OH)2CO3 but not in Cu nanocrystals derived from CuO. Theoretical calculations indicate that tensile strain in the Cu lattice helps promote the hydrogenation of *CO and C–C coupling, enhancing the overall CO2RR selectivity and suppressing HER, which explains the diverse performance of the three derived Cu catalysts. Reducing crystallite size and inducing lattice strain were therefore identified as two effective approaches to enhancing the performance of Cu catalysts for CO2RR.

The findings of this study highlight the significant role of operando characterization techniques in probing catalyst evolution during CO2RR, and the customized operando platforms can be readily adapted to other important electrochemical reactions, including but not limited to hydrogen/oxygen evolution, nitrogen reduction, and methane oxidation.

Methods

Precursor preparation

Cu 2 (OH) 2 CO 3 nanocrystals and CuO nanocrystals

First, aqueous solutions of 10 mL of 0.5 M CuSO4 (Sigma–Aldrich, 98%) and 12 mL of 0.5 M Na2CO3 (Sigma–Aldrich, ≥ 99.0%) were prepared at room temperature using Milli-Q water (18.2 MΩ·cm−1). Subsequently, the Na+ solution was added to the Cu2+ solution, and the mixture was continuously stirred. After 15 min, the mixture was heated at 60 °C and stirred for another 15 min. Afterward, the mixture was allowed to stand until fully precipitated. Then, the Cu2(OH)2CO3 nanocrystals were obtained via vacuum filtration. The final product was dried in a vacuum oven overnight at 30 °C. The as-prepared Cu2(OH)2CO3 nanocrystals were heated in a vacuum oven for 4 days at 250 °C to synthesize CuO nanocrystals.

Cu(OH) 2 nanocrystals

First, 50 mL of 0.05 M aqueous solution of Cu(NO3)2 was prepared at room temperature. Subsequently, 1 mL of 25% ammonia solution was slowly added into the solution, followed by 1 mL of 0.01 M NaOH aqueous solution under stirring. The mixture was heated to 60 °C for 15 min and then cooled to room temperature. Then, the mixture was subjected to centrifugation and copious washing with water to a neutral pH to obtain the resulting bluish Cu(OH)2 nanocrystals. The final product was dried in a vacuum oven overnight at 30 °C.

Cu nanowires and electropolished Cu foil

The Cu nanowires were sequentially prepared by mixing 20 mL of 15 M NaOH, 1 mL of 0.1 M Cu(NO3)2, 0.15 mL of ethylenediamine, and 0.025 mL of 35 wt% hydrazine under continuous stirring. Subsequently, the mixture was heated to 80 °C for 60 min, and the product was collected by centrifugation and washed with a 3 wt% aqueous hydrazine solution. The Cu nanowires were dried in a vacuum oven overnight at 30 °C and stored under an Ar atmosphere to minimize oxidation. Polycrystalline Cu foil was electropolished in 85% phosphoric acid (Scharlau, 85% in water) at 3.0 V vs. another Cu foil for 5 min.

Ex situ material characterization

The chemical compositions of the precursors were investigated using powder XRD (Bruker, D8 Advance) with a Cu Kα radiation wavelength of 0.154184 nm. The obtained peaks were indexed using standard patterns (PDF#00-004-0836 for Cu, PDF#00-048-1548 for CuO, PDF#04-009-4366 for Cu(OH)2, and PDF#00-002-0345 for Cu2(OH)2CO3). The mean crystallite sizes of the precursors were estimated using the Scherrer equation (\(\tau=K\lambda /\beta {\cos }\theta\), where τ is the mean size of the crystalline domains, K is the dimensionless shape factor (0.89), λ is the X-ray wavelength, β is the line broadening at half the maximum intensity (full width at half maximum), and θ is the Bragg angle). Ex situ Raman spectra of the samples were recorded using a WITec apyron system equipped with a 633 nm laser. Considering that the three compounds were easily reduced to Cu2O under the Raman laser (Supplementary Fig. 19)36, a low magnification objective lens (Zeiss EC Epiplan–Neofluar Dic 10X/0.25) was used and the laser power was set to 20 mW to prevent the laser-induced thermo-reduction of the samples. The surface morphologies of the samples were characterized using SEM (FEI, Magellan) at a working distance of 4 mm. All samples were coated with a layer of 3 nm of Ir prior to SEM imaging to eliminate charging caused by their poor conductivity.

Electrode preparation

First, 20 mg of the as-prepared precursor powder was mixed with 50 µL of Nafion solution and 3 mL of ethanol. Subsequently, the mixture was sonicated for at least 30 min to obtain a homogenous ink. Next, the electrodes were prepared by airbrushing the precursor ink onto a glassy carbon substrate with an area of 1.0 × 0.5 cm2. For operando characterizations, carbon paper (Freudenberg H14C9, Fuel Cell Store) was used as the substrate. The mass loading of the precursor was approximately 0.6 mg cm−2.

Electroreduction of CO2

The electrochemistry experiments were performed in a gas-tight H-type cell using a CHI 760e workstation. The cathode and anode compartments were separated using a Nafion 117 membrane (Fuel Cell Store). A Pt foil was used as the counter electrode, and an Ag/AgCl electrode filled with saturated KCl solution (CHI, 111) was used as the reference electrode. All potentials measured against Ag/AgCl were converted to the reversible hydrogen electrode (RHE) scale using ERHE = EAg/AgCl + 0.197 V + 0.0591 × pH. The cell resistance was determined using a current-interrupt method, and the potential was manually corrected after each measurement. In addition, a 0.1 M KHCO3 (Honeywell, 99.5% to 101.0% (acidimetric)) aqueous solution was used as the electrolyte and was saturated with CO2 prior to each CO2RR experiment. The pH value of the cell measured using an Orion 5 star benchtop multiparameter (Thermo Scientific) was 6.8. During the CO2RR experiment, 5.0 sccm of CO2 was continuously purged into the cell, and the gaseous products were routed into an online gas chromatography (GC) system (Kechuang GC2002).

Product analysis

Gaseous products were detected using the online GC equipped with three detectors: one thermal conductivity detector for detecting H2, one flame ionization detector for detecting hydrocarbons, and another flame ionization detector coupled with a methanizer (Kechuang) for detecting CO. Quantitative determination was conducted using calibration curves from standard gases.

Liquid products were analyzed using proton nuclear magnetic resonance (NMR, Bruker, 600 MHz) with a presaturation sequence for suppressing the water peak. Calibration curves were developed using commercial chemicals with 1.67 ppm dimethyl sulfoxide (Sigma–Aldrich, 99.9%) as the internal standard. In addition, FE was calculated using \({FE}=([A]\cdot V\cdot ({nF}))/Q\), where [A] is the analyte concentration determined using quantitative NMR, V represents the NMR sample volume (typically, 600 μL), n denotes the molar ratio of the transferred electrons, F indicates the Faraday constant, and Q denotes the total charge passed.

Operando XRD

Operando XRD measurements were performed using a Bruker D8 Discover XRD spectrometer equipped with an IµS microfocus X-ray source and Eiger 2D detector. A 2 mm collimator was used to enhance the X-ray intensity on a small spot on the electrode. The 2D detector was vertically positioned to enable the coverage of 21.7° (2θ) in the still scan mode to cover the desired diffraction angle range at a high resolution (Supplementary Fig. 20). In addition, an optical laser-video camera system was incorporated to enable easy and accurate sample positioning and system alignment. A customized electrochemical cell (Supplementary Fig. 6) was used with a Pt wire and an Ag/AgCl electrode (CHI 111; saturated KCl solution) as the counter and reference electrodes, respectively. The cathode and anode compartments were separated using a Fumasep FKB-PK-130 membrane (Fuel Cell Store). The precursors were airbrushed onto one side of the carbon paper and positioned close to the glassy carbon on the cell to function as the working electrode. The electrolyte (50 mL of 0.1 M KHCO3) was saturated with CO2 while circulating through the cell at 1 mL min−1. During the measurements, the cell was fastened on the stage using psi tilted to 30° for the better release of in situ formed bubbles from the electrode surface. For the Cu2(OH)2CO3 nanocrystals, the measurements were conducted at −0.84, −1.05, and −1.2 VRHE. For Cu(OH)2 and CuO nanocrystals, the potential was set to −1.08 and −1.16 VRHE, respectively. The 2D diffraction patterns were collected in the still scan mode at an integration time of 900 s. The raw data were integrated using DIFFRAC.EVA software, and the background was removed for improved peak identification.

Strain determination

The tensile strain values of derived Cu samples were calculated using the equation:

where d is the d-spacing of a given reflection (e.g., Cu(111) or Cu(100)) determined from the XRD pattern and d0 is the corresponding d-spacing in the standard Cu sample.

For the operando XRD experiments, the theta angle was set to 20.28° for still scan mode to achieve the desired diffraction angle range (30°−51.7°, 2θ) at a high resolution. Under such conditions, the illuminated area on the electrode is an ellipse of ~4.7 mm2. The obtained strain value is the average result of the illuminated area.

Operando Raman spectroscopy

Operando Raman spectra were recorded using a WITec apyron system with a water-immersion objective lens (Zeiss W Plan-Apochromat 63X/1) and a 633 nm laser beam. A low laser power of 0.8 mW was used to prevent the irradiation-induced modification on the precursor surface. The measurements were conducted in a customized electrochemical cell (Supplementary Fig. 10) with a Pt wire and an Ag/AgCl electrode (CHI 111; saturated KCl solution) as the counter and reference electrode, respectively. The cathode and anode compartments were separated using a Fumasep FKB-PK-130 membrane (Fuel Cell Store). The electrolyte (50 mL of 0.1 M KHCO3) was saturated with CO2 while circulating at 1 mL min−1 above the electrode surface to remove bubbles produced in situ. The Raman signals were collected in a back-scattering geometry every 15 min along the CO2RR process. The raw data were recorded and processed using WITec Control Five software, and the background was removed to enable improved peak identification.

Computational methods

The DFT calculations were conducted using the projector-augmented wave method, as implemented in Vienna Ab initio Simulation Package code62,63. The generalized gradient approximation with the Perdew–Burke–Ernzerhof exchange-correlation functional was used. A uniform 6 × 6 × 6 k-mesh grid in the Brillouin zone was employed to optimize the crystal structure of bulk Cu, and the resulting lattice parameter was a = 3.635 Å. The Cu slab model with five atomic layers had a (2 × 2) and a (3 × 3) lateral periodicity with (111) and (100) exposed surfaces, respectively, and the slab replica was separated by ∼20 Å of vacuum. The lattice parameters were set to a = 3.653 Å, 3.671 Å, 3.690 Å, and 3.708 Å for Cu(111) and Cu(100) slabs to mimic 0.5%, 1.0%, 1.5%, and 2.0% tensile strain, respectively. A 2 × 2 × 1 k-mesh was used for all Cu(111) and Cu(100) slab structures. The plane-wave basis set cutoffs of the wave functions were set at 500 eV for the bulk and 450 eV for slab structures without and with molecular adsorption. The atomic positions of all structures were fully relaxed until the forces on each atom were less than 0.01 eV/Å.

The Gibbs free energy values were calculated using the following equations:

where \({E}_{{DFT}}\) denotes the energy calculated by DFT, \({E}_{{ZPE}}\) represents the vibrational zero-point energy, \({\int }_{0}^{298.15}{C}_{v}{dT}\) indicates the heat capacity, and S is the entropy, respectively. In addition, ℎ is the Planck constant, kB denotes the Boltzmann constant, and v represents the vibrational frequency. Only vibrational modes were considered for calculating the entropy due to the scarce contribution from translational and rotational modes. The Gibbs free energy of formation (ΔGformation) for *COCOH is calculated as ΔGformation(*COCOH) = G*COCOH – (G*CO+*CO + GH2/2). In addition, ΔGformation for *COH is calculated as ΔGformation(*COH) = G*COH – (G*CO + GH2/2), ΔGformation for *CHO is calculated as ΔGformation(*CHO) = G*CHO – (G*CO + GH2/2), and ΔGformation for *COCO is calculated as ΔGformation(*COCO) = G*COCO – (G*CO + GCO). The thermodynamic parameters for calculating Gibbs free energies are given in Supplementary Tables S4–S13.

The hydrogen adsorption free energy G*H is calculated as G*H = E (slab + H) – E(slab) – E(H2)/2 + ΔEZPE – TΔS, where E (slab + H) and E(slab) are the total energies of the Cu(111) or Cu(100) slab with and without H adsorption; E(H2) is the total energy of a H2 molecule; ΔEZPE is the difference in the zero-point energy between gas phase of H2 and the adsorbed H atom; and ΔS is the difference in entropy. To determine the transition state (TS) for the water dissociation on the Cu(111) and Cu(100) surfaces, the climbing image nudged elastic band (NEB) method was employed, and the force convergence tolerance on each atom was set to be 0.05 eV/Å during the search of the minimum energy path.

Data availability

The data supporting the findings of this study are provided in the Supplementary Information/Source Data file. The input and output files for the DFT calculations are available in the IoChem-BD database (https://iochem-bd.bsc.es/browse/review-collection/100/215881/6ca411524a36a3f2c1194679). Additional data are available from the corresponding authors on request. Source data are provided with this paper.

Code availability

Vienna ab initio simulation package (VASP) for the DFT calculations is available at https://www.vasp.at/.

References

Gao, D. F., Arán-Ais, R. M., Jeon, H. S. & Roldan Cuenya, B. Rational catalyst and electrolyte design for CO2 electroreduction towards multicarbon products. Nat. Catal. 2, 198–210 (2019).

Xia, C. et al. Continuous production of pure liquid fuel solutions via electrocatalytic CO2 reduction using solid-electrolyte devices. Nat. Energy 4, 776–785 (2019).

Zheng, T. T. et al. Large-scale and highly selective CO2 electrocatalytic reduction on nickel single-atom catalyst. Joule 3, 265–278 (2019).

Lu, L. et al. Highly efficient electroreduction of CO2 to methanol on palladium-copper bimetallic aerogels. Angew. Chem. Int. Ed. Engl. 57, 14149–14153 (2018).

Wang, Y. S., Chen, J. X., Wang, G. X., Li, Y. & Wen, Z. H. Perfluorinated covalent triazine framework derived hybrids for the highly selective electroconversion of carbon dioxide into methane. Angew. Chem. Int. Ed. 57, 13120–13124 (2018).

Fan, L. et al. Strategies in catalysts and electrolyzer design for electrochemical CO2 reduction toward C2+ products. Sci. Adv. 6, eaay3111 (2020).

Lei, Q. et al. Investigating the Origin of Enhanced C2+ Selectivity in Oxide-/Hydroxide-Derived Copper Electrodes during CO2 Electroreduction. J. Am. Chem. Soc. 142, 4213–4222 (2020).

Lee, S. Y. et al. Mixed copper states in anodized Cu electrocatalyst for stable and selective ethylene production from CO2 reduction. J. Am. Chem. Soc. 140, 8681–8689 (2018).

Liang, Z. Q. et al. Copper-on-nitride enhances the stable electrosynthesis of multi-carbon products from CO2. Nat. Commun. 9, 3828 (2018).

Van Muylder, J. Electrochemical Materials Science Ch. 1 (Springer US: Boston, MA, 1981).

Mistry, H. et al. Highly selective plasma-activated copper catalysts for carbon dioxide reduction to ethylene. Nat. Commun. 7, 12123 (2016).

Fan, Q. K. et al. Manipulating Cu nanoparticle surface oxidation states tunes catalytic selectivity toward CH4 or C2+ products in CO2 electroreduction. Adv. Energy Mater. 11, 2101424 (2021).

Yang, P. P. et al. Protecting copper oxidation state via intermediate confinement for selective CO2 electroreduction to C2+ Fuels. J. Am. Chem. Soc. 142, 6400–6408 (2020).

Liu, C. et al. Stability and effects of subsurface oxygen in oxide-derived Cu catalyst for CO2 reduction. J. Phys. Chem. C. 121, 25010–25017 (2017).

Favaro, M. et al. Subsurface oxide plays a critical role in CO2 activation by Cu(111) surfaces to form chemisorbed CO2, the first step in reduction of CO2. Proc. Natl Acad. Sci. USA 114, 6706–6711 (2017).

Dattila, F., García-Muelas, R. & López, N. Active and selective ensembles in oxide-derived copper catalysts for CO2 reduction. ACS Energy Lett. 5, 3176–3184 (2020).

Eilert, A. et al. Subsurface oxygen in oxide-derived copper electrocatalysts for carbon dioxide reduction. J. Phys. Chem. Lett. 8, 285–290 (2017).

Cavalca, F. et al. Nature and distribution of stable subsurface oxygen in copper electrodes during electrochemical CO2 reduction. J. Phys. Chem. C. 121, 25003–25009 (2017).

Wang, H. Y. et al. Direct evidence of subsurface oxygen formation in oxide-derived Cu by X-ray photoelectron spectroscopy. Angew. Chem. Int. Ed. 61, e202111021 (2022).

Scholten, F., Nguyen, K. C., Bruce, J. P., Heyde, M. & Roldan Cuenya, B. Identifying structure-selectivity correlations in the electrochemical reduction of CO2: A comparison of well-ordered atomically clean and chemically etched copper single-crystal surfaces. Angew. Chem. Int. Ed. Engl. 60, 19169–19175 (2021).

Kim, T. et al. Enhancing C2–C3 production from CO2 on copper electrocatalysts via a potential-dependent mesostructure. ACS Appl. Energy Mater. 1, 1965–1972 (2018).

Jiang, K. et al. Metal ion cycling of Cu foil for selective C-C coupling in electrochemical CO2 reduction. Nat. Catal. 1, 111–119 (2018).

Möller, T. et al. Electrocatalytic CO2 reduction on CuOx Nanocubes: Tracking the evolution of chemical state, geometric structure, and catalytic selectivity using Operando spectroscopy. Angew. Chem. Int. Ed. Engl. 59, 17974–17983 (2020).

Velasco-Velez, J. J. et al. Revealing the active phase of copper during the electroreduction of CO2 in aqueous electrolyte by correlating in situ X-ray spectroscopy and in situ electron microscopy. ACS Energy Lett. 5, 2106–2111 (2020).

Jansonius, R. P., Reid, L. M., Virca, C. N. & Berlinguette, C. P. Strain engineering electrocatalysts for selective CO2 reduction. ACS Energy Lett. 4, 980–986 (2019).

Mavrikakis, M., Hammer, B. & Nørskov, J. K. Effect of strain on the reactivity of metal surfaces. Phys. Rev. Lett. 81, 2819–2822 (1998).

Liu, F. Z., Wu, C. & Yang, S. C. Strain and Ligand Effects on CO2 Reduction Reactions over Cu-Metal Heterostructure Catalysts. J. Phys. Chem. C. 121, 22139–22146 (2017).

Monzó, J. et al. Enhanced electrocatalytic activity of Au@Cu core@shell nanoparticles towards CO2 reduction. J. Mater. Chem. A 3, 23690–23698 (2015).

Kim, T., Kumar, R. E., Brock, J. A., Fullerton, E. E. & Fenning, D. P. How Strain Alters CO2 Electroreduction on Model Cu(001) Surfaces. ACS Catal. 11, 6662–6671 (2021).

Du, M. S., Zhao, X., Zhu, G., Hsu, H. Y. & Liu, F. Elastic strain controlling the activity and selectivity of CO2 electroreduction on Cu overlayers. J. Mater. Chem. A 9, 4933–4944 (2021).

Liu, S. G. & Huang, S. P. Structure engineering of Cu-based nanoparticles for electrochemical reduction of CO2. J. Catal. 375, 234–241 (2019).

Li, C. W., Ciston, J. & Kanan, M. W. Electroreduction of carbon monoxide to liquid fuel on oxide-derived nanocrystalline copper. Nature 508, 504–507 (2014).

Chen, C. J. et al. The in situ study of surface species and structures of oxide-derived copper catalysts for electrochemical CO2 reduction dagger. Chem. Sci. 12, 5938–5943 (2021).

Li, X., Wang, S., Li, L., Sun, Y. & Xie, Y. Progress and perspective for in situ studies of CO2 reduction. J. Am. Chem. Soc. 142, 9567–9581 (2020).

Jiang, S., Klingan, K., Pasquini, C. & Dau, H. New aspects of operando Raman spectroscopy applied to electrochemical CO2 reduction on Cu foams. J. Chem. Phys. 150, 041718 (2019).

Deng, Y. L., Handoko, A. D., Du, Y. H., Xi, S. B. & Yeo, B. S. In situ Raman spectroscopy of copper and copper oxide surfaces during electrochemical oxygen evolution reaction: Identification of CuIII oxides as catalytically active species. ACS Catal. 6, 2473–2481 (2016).

Marucci, G., Beeby, A., Parker, A. W. & Nicholson, C. E. Raman spectroscopic library of medieval pigments collected with five different wavelengths for investigation of illuminated manuscripts. Anal. Methods-UK 10, 1219–1236 (2018).

Frost, R. L., Martens, W. N., Rintoul, L., Mahmutagic, E. & Kloprogge, J. T. Raman spectroscopic study of azurite and malachite at 298 and 77 K. J. Raman Spectrosc. 33, 252–259 (2002).

Wang, W. et al. A simple wet-chemical synthesis and characterization of CuO nanorods. Appl. Phys. A 76, 417–420 (2003).

Cheng, D. et al. The nature of active sites for carbon dioxide electroreduction over oxide-derived copper catalysts. Nat. Commun. 12, 395 (2021).

Dutta, A. et al. CO2 electrolysis - Complementary operando XRD, XAS and Raman spectroscopy study on the stability of CuxO foam catalysts. J. Catal. 389, 592–603 (2020).

Ren, D., Gao, J., Zakeeruddin, S. M. & Grätzel, M. New insights into the interface of electrochemical flow cells for carbon dioxide reduction to ethylene. J. Phys. Chem. Lett. 12, 7583–7589 (2021).

Moradzaman, M. & Mul, G. In situ Raman study of potential-dependent surface adsorbed carbonate, CO, OH, and C species on Cu electrodes during electrochemical reduction of CO2. Chemelectrochemistry 8, 1478–1485 (2021).

Shan, W. et al. In situ surface-enhanced Raman spectroscopic evidence on the origin of selectivity in CO2 electrocatalytic reduction. ACS Nano 14, 11363–11372 (2020).

Schmitt, K. G. & Gewirth, A. A. In situ surface-enhanced Raman spectroscopy of the electrochemical reduction of carbon dioxide on silver with 3,5-Diamino-1,2,4-Triazole. J. Phys. Chem. C. 118, 17567–17576 (2014).

Liu, G. et al. CO2 reduction on pure Cu produces only H2 after subsurface O is depleted: Theory and experiment. Proc. Natl Acad. Sci. USA 118, e2012649118 (2021).

Scott, S. B. et al. Absence of Oxidized Phases in Cu under CO Reduction Conditions. ACS Energy Lett. 4, 803–804 (2019).

Feng, X., Jiang, K., Fan, S. & Kanan, M. W. A direct grain-boundary-activity correlation for CO electroreduction on Cu nanoparticles. ACS Cent. Sci. 2, 169–174 (2016).

Handoko, A. D. et al. Mechanistic Insights into the selective electroreduction of carbon dioxide to ethylene on Cu2O-derived copper catalysts. J. Phys. Chem. C. 120, 20058–20067 (2016).

Jung, H. et al. Electrochemical fragmentation of Cu2O nanoparticles enhancing selective C-C coupling from CO2 reduction reaction. J. Am. Chem. Soc. 141, 4624–4633 (2019).

Velasco-Vélez, J. J. et al. On the activity/selectivity and phase stability of thermally grown copper oxides during the electrocatalytic reduction of CO2. ACS Catal. 10, 11510–11518 (2020).

Lum, Y. W., Yue, B. B., Lobaccaro, P., Bell, A. T. & Ager, J. W. Optimizing C-C Coupling on Oxide-Derived Copper Catalysts for Electrochemical CO2 Reduction. J. Phys. Chem. C. 121, 14191–14203 (2017).

Chen, Z. Q. et al. Grain-Boundary-rich copper for efficient solar-driven electrochemical CO2 reduction to ethylene and ethanol. J. Am. Chem. Soc. 142, 6878–6883 (2020).

Nitopi, S. et al. Progress and Perspectives of Electrochemical CO2 Reduction on Copper in Aqueous Electrolyte. Chem. Rev. 119, 7610–7672 (2019).

Zhan, C. et al. Revealing the CO Coverage-Driven C-C Coupling Mechanism for Electrochemical CO2 Reduction on Cu2O Nanocubes via Operando Raman Spectroscopy. ACS Catal. 11, 7694–7701 (2021).

Zheng, Y. et al. Understanding the Roadmap for Electrochemical Reduction of CO2 to Multi-Carbon Oxygenates and Hydrocarbons on Copper-Based Catalysts. J. Am. Chem. Soc. 141, 7646–7659 (2019).

De Luna, P. et al. Catalyst electro-redeposition controls morphology and oxidation state for selective carbon dioxide reduction. Nat. Catal. 1, 103–110 (2018).

Kortlever, R., Shen, J., Schouten, K. J. P., Calle-Vallejo, F. & Koper, M. T. M. Catalysts and Reaction Pathways for the Electrochemical Reduction of Carbon Dioxide. J. Phys. Chem. Lett. 6, 4073–4082 (2015).

Birdja, Y. Y. et al. Advances and challenges in understanding the electrocatalytic conversion of carbon dioxide to fuels. Nat. Energy 4, 732–745 (2019).

Sandberg, R. B., Montoya, J. H., Chan, K. & Nørskov, J. K. CO-CO coupling on Cu facets: Coverage, strain and field effects. Surf. Sci. 654, 56–62 (2016).

Chen, Z. Z., Zhang, X. & Lu, G. Overpotential for CO2 electroreduction lowered on strained penta-twinned Cu nanowires. Chem. Sci. 6, 6829–6835 (2015).

Kresse, G. & Hafner, J. Ab-Initio Molecular-Dynamics for Open-Shell Transition-Metals. Phys. Rev. B 48, 13115–13118 (1993).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Acknowledgements

The financial support for this work was provided by KAUST Catalysis Center CCF Fund (FCC/1/1974-16-01) to Y.H. and Baseline Funds (BAS/1/1413-01-01) to X.L. from King Abdullah University of Science and Technology. This work is partially supported by National Key Research and Development Project of China (2022YFE0113800). This research used resources from the Core Laboratories of King Abdullah University of Science and Technology. J.Y. acknowledges financial support from the Hong Kong Polytechnic University (grant P0042930).

Author information

Authors and Affiliations

Contributions

Q.L. and Y.H. crafted the experimental plan and analyzed all the data. Q.L. performed the precursor synthesis, CO2RR performance evaluation, and the operando XRD. Q.L., L.H., K.X.Y., X.W., Z.W., and Y.H. analyzed the CO2RR results. Q.L., B.D., and Y.Y. designed and implemented the operando XRD characterization platform. Q.L. and L.H. implemented and performed the operando Raman spectroscopy characterization under the guidance of X.L. J.Y. performed the theoretical calculations and analyzed the computational data. X.D. implemented the online gas chromatography system. Y.H. guided the research. Q.L., Y.H., and X.L. wrote the manuscript. All the authors discussed the results and reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the other anonymous reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lei, Q., Huang, L., Yin, J. et al. Structural evolution and strain generation of derived-Cu catalysts during CO2 electroreduction. Nat Commun 13, 4857 (2022). https://doi.org/10.1038/s41467-022-32601-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-32601-9

This article is cited by

-

Superexchange-stabilized long-distance Cu sites in rock-salt-ordered double perovskite oxides for CO2 electromethanation

Nature Communications (2024)

-

Dynamics of bulk and surface oxide evolution in copper foams for electrochemical CO2 reduction

Communications Chemistry (2024)

-

Combined effects of sea urchin-like structure and mixed Cu+/Cu0 states on promoting C2 formation in electrocatalytic CO2 reduction

Frontiers of Chemical Science and Engineering (2024)

-

Unraveling the synergistic effects of Cu-Ag tandem catalysts during electrochemical CO2 reduction using nanofocused X-ray probes

Nature Communications (2023)

-

Stabilizing ruthenium dioxide with cation-anchored sulfate for durable oxygen evolution in proton-exchange membrane water electrolyzers

Nature Communications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.