Abstract

Selective conversion of methane (CH4) into value-added chemicals represents a grand challenge for the efficient utilization of rising hydrocarbon sources. We report here dimeric copper centers supported on graphitic carbon nitride (denoted as Cu2@C3N4) as advanced catalysts for CH4 partial oxidation. The copper-dimer catalysts demonstrate high selectivity for partial oxidation of methane under both thermo- and photocatalytic reaction conditions, with hydrogen peroxide (H2O2) and oxygen (O2) being used as the oxidizer, respectively. In particular, the photocatalytic oxidation of CH4 with O2 achieves >10% conversion, and >98% selectivity toward methyl oxygenates and a mass-specific activity of 1399.3 mmol g Cu−1h−1. Mechanistic studies reveal that the high reactivity of Cu2@C3N4 can be ascribed to symphonic mechanisms among the bridging oxygen, the two copper sites and the semiconducting C3N4 substrate, which do not only facilitate the heterolytic scission of C-H bond, but also promotes H2O2 and O2 activation in thermo- and photocatalysis, respectively.

Similar content being viewed by others

Introduction

Selective conversion of methane to liquid hydrocarbons represents a promising approach toward efficient utilization of natural gas1. The present industrial route for such conversions relies on a two-step process by first reforming methane to generate synthesis gas (CO and H2) at elevated temperatures (>500 °C), and then reacting CO with H2 to form methanol or other liquid products2,3. However, this process is energy-intensive and economically nonviable for distributed sources such as flare gas4. More robust technologies toward direct conversion of methane into condensed energy carriers are thus demanded to facilitate transportation and storage5.

Direct, partial oxidation of methane to methyl oxygenates has received intensive attention in recent years6,7. The studies on early days use transition copper exchanged zeolites to catalyze the reaction between CH4 and O2, and employ a two-step chemical looping process to subsequentially activate O2 and desorb the products8,9,10. Despite the achievement of high selectivities, these reactions are still suffering from the low CH4 conversions (typically < 0.03%) and reaction rates (<30 μmol gcata−1 h−1)11,12,13. Later on, partial oxidation of methane in a single step has been demonstrated by using non-O2 oxidizers such as oleum14), selenic acid15) and H2O216,17,18, but the cost associated with these oxidizing agents holds back their practical implementations19. More recent efforts have thus turned into in-situ generation of H2O2 from O2 by using selective oxygen reduction catalysts such as Au-Pd containing zeolites20. Alternatively, photoexcitation using visible light is proposed to be advantageous with near-room temperature activation of CH4, mitigating the concern of over oxidation to form CO2 upon heating21,22. But the reported photocatalytic oxidation of methane is still limited by relatively low methane conversions (<1%) and productivities (0.001~150 mmol gcata−1 h−1)22, as the commonly used photocatalysts have quite large bandgaps (e.g., ~3.2 eV for TiO223 and ~3.4 eV for ZnO)21 and may only activate methane via the Fenton or homolytic mechanisms that have relatively sluggish kinetics24. In this aspect, graphitic carbon nitride (g-C3N4) represents a promising photocatalytic substrate with a modest band gap in the range of 2.7-2.9 eV25,26,27. Its abundant nitrogen sites have been shown in many reports to be capable of anchor atomically dispersed transition metal sites28. It thus becomes interesting to investigate the potential coordination of active Cu sites on g-C3N4 and examine their synergies in partial oxidation of methane.

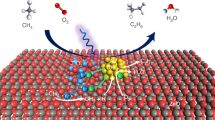

Here we report on Cu2@C3N4 as highly efficient catalysts for partial oxidation of methane. The dimeric copper catalysts were synthesized by supporting an (oxalato)(bipyridine)copper(II) complex, [Cu2(bpy)2(μ-ox)]Cl2, on g-C3N4 and then applying a mild thermal treatment in air (Fig. 1a). The derived catalysts contained dicopper-oxo centers anchoring on g-C3N4 via four Cu-N bonds (two for each copper atom), as characterized by using STEM, XPS and XAS, and also confirmed with atomistic simulations. The obtained copper-dimer catalysts were first evaluated for thermal oxidation of methane using H2O2 as the oxidizer, and then further applied for photocatalytic oxidation of methane with O2. Mechanisms governing the observed catalytic enhancements toward selective oxidation of methane were interpreted via combining computational simulation of the reaction pathways, spin-trapping EPR analysis of possible radical intermediates, and in situ XPS measurements under light irradiation.

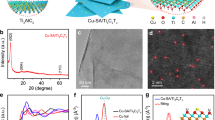

a Scheme illustration of synthetic route. b, c Characterization of the Cu-dimer precursor, [Cu2(bpy)2(μ-ox)]Cl2 complex, using FTIR (b) and UV-vis DRS (c). d Comparison of FTIR spectra for Cu2@C3N4 and g-C3N4. e–g Representative HAADF-STEM images of Cu2@C3N4, with the insets showing line-scanning intensity profiles of Cu dimers. h Statistical distribution of the Cu-Cu distance in the Cu dimers derived from the STEM images.

Results and discussion

Synthesis and characterization of Cu2@C3N4

The copper-dimer precursor [Cu2(bpy)2(μ-ox)]Cl2 was first prepared by a complexation reaction of copper chloride (CuCl2), 2,2,-bipyridine and oxalic acid29. The g-C3N4 substrate was grown by calcination of urea at 550 °C30. Cu2@C3N4 catalysts were synthesized by self-assembly of the dimeric copper complex on g-C3N431 and then treating the mixture in air at 250 °C to immobilize the copper species (Fig. 1a). The loading of Cu was determined to be 0.35 wt% by using inductively coupled plasma mass spectrometry (ICP-MS).

The complexation of pyridine, Cu2+ and oxalate (C2O42−) to form an organometallic compound was confirmed by using Fourier transform infrared spectroscopy (FTIR). The hydroxyl (O-H) and carbonyl (C = O) stretching features around 3450 and 1670 cm−1, respectively, associated with oxalic acid disappeared after the reaction. This was accompanied with the blue shift of the characteristic band (attributed to the asymmetric stretching of the pyridyl ring) of 2,2′-pyridine at ca. 1580 cm−1 to ca. 1650 cm−1, a consequence of its chelation with Cu2+ (Fig. 1b)32. Correspondingly, the d-d transition of Cu2+ at 650–700 nm had a blue shift of 48 nm in the ultraviolet-visible diffuse reflectance spectroscopy (UV-vis DRS) patterns (Fig. 1c). The FTIR spectra of g-C3N4 and Cu2@C3N4 exhibited the stretching vibration modes characteristic of the −NH group around 3180 cm−1, C-N heterocycles in the wavelength range of 1100–1650 cm−1 and the breathing mode of tri-s-triazine units at 810 cm−1 (Fig. 1d). Comparing to [Cu2(bpy)2(μ-ox)]Cl2, Cu2@C3N4 presented no more infrared features associated with the dimeric copper complex, indicating the complete removal of organic ligands during the immobilization process. This was further confirmed with thermogravimetric analysis (TGA) (Supplementary Fig. 1). The [Cu2(bpy)2(μ-ox)]Cl2/g-C3N4 mixture lost ~6% of its initial weight upon annealing in air at up to 250 °C, which is close to the expectation estimated based on the ligand content (~80 wt%) of [Cu2(bpy)2(μ-ox)]Cl2 and its ratio relative to the carbon nitride substrate (~8%) used in the synthesis. X-ray diffraction (XRD) patterns collected for the Cu2@C3N4 catalysts only show the (001) and (002) peaks associated with g-C3N4, with the absence of copper metal or oxide features indicating the highly dispersed nature of copper species (Supplementary Fig. 2). Atomic structures of the dimeric copper moieties were resolved by using aberration correction high angle annular dark field scanning transmission electron microscopy (HAADF-STEM) imaging (Fig. 1e-g). The collected STEM images exhibit a large number of adjacent, paired bright dots (labeled with red circles, <0.35 nm in size for each dot) distributed on a substrate of lower contrasts. These small bright dots can be attributed to atomically dispersed Cu considering their much higher Z contrast (M = 65 for Cu) than C3N4 (M = 12 or 14). Line-profile scanning for ~100 pairs of such bright dots give an average distance of 2.8 (±0.2 Å) (Fig. 1h). This is much shorter than the value (5.2 Å) for the two copper atoms within [Cu2(bpy)2(μ-ox)]Cl2, again confirming the reconstruction and condensation of the copper-dimer moieties as a result of the removal of organic ligands in the synthesis.

Chemical nature of the Cu dimers in Cu2@C3N4 was probed by using X-ray photoelectron spectroscopy (XPS) and X-ray absorption spectroscopy (XAS). The N 1 s XPS spectrum exhibits a broad feature with the binding energy ranging from 397 to 408 eV (Fig. 2a). This feature can be deconvoluted into four peaks centered at 398.6, 399.4, 401.0, and 404.5 eV, which can be assigned to pyridinic (C − N = C), tertiary (−N<), pyrrolic (−NH) nitrogen, and π-π* transition of C = N or uncondensed terminal amine groups in g-C3N4, respectively33,34. The Cu 2p spectrum shows two peaks at 932.5 eV and 952.3 eV, which are characteristic of Cu(I) or Cu0 (Supplementary Fig. 3)35. However, the XPS analysis (as well as the corresponding Auger electron spectrum, AES) was unable to explicitly determine the oxidation state of Cu due to the reduced signal-to-noise ratio associated with the low copper content in the catalysts. The copper oxidation state in Cu2@C3N4 was better resolved by using X-ray Absorption Near Edge Spectroscopy (XANES) (Fig. 2b). The Cu K edge spectrum exhibits a pre-edge transition at 8984 eV, which falls between the peaks associated with Cu2O (8983 eV) and CuO (8986 eV). This indicates an intermediate oxidation state between +1 and +2 for Cu in Cu2@C3N4. Noticeably, our results do not support the picture with a mixture of Cu(I) and Cu(II), as the 1 s → 3d transition at 8977 eV, a feature characteristic of Cu2+ (as shown for the references CuO and copper tetraphenylporphyrin (Cu-TPP) in Supplementary Fig. 4)35, is absent in the spectrum of Cu2@C3N4. The partial oxidation state (between +1 and +2) of Cu within the copper dimers supported on g-C3N4 can be viewed as a result of the semiconducting nature of the substrate. This is distinguished from the case for extensively studied copper exchanged zeolites, in which the dicopper-oxo centers ([Cu-O-Cu]2+) anchor on the Al sites with localized negative charges and have an oxidation state of +2 for both Cu atoms9,36,37.

a XPS spectrum at the N 1 s edge and the corresponding deconvolution. b XANES spectra and (c) k2-weighted EXAFS spectra at the Cu K edge, with Cu foil, Cu2O, CuO, and Cu-TPP (one Cu coordinated with for N atoms) as the reference. d Fitting of the EXAFS spectrum with consideration of both monomeric and dimeric Cu sites. e The simulated structure model of dicopper-oxo center. f Geometric parameters of the dicopper-oxo center determined for Cu2@C3N4.

The atomic structure of the Cu dimers was resolved by combining extended X-ray absorption fine structure (EXAFS) analysis and atomistic modeling based on DFT calculations. Figure 2c compares the k2-weighted Cu K edge EXAFS spectra for Cu2@C3N4, Cu foil, Cu2O, CuO, and Cu-TPP (with single-atom Cu2+ coordinating to four pyrrolic N, Supplementary Fig. 4). The Cu2@C3N4 catalyst exhibits first-shell scattering at 1.62 Å in R space (prior to phase correction), which is proximate to the values, 1.59 and 1.55 Å, found for Cu-TPP and CuO, respectively. This is distinct from the cases for Cu2O and Cu, the first-shell scattering of which locates at 1.50 and 2.30 Å, respectively. From these observations, we tentatively assign the primary scattering pair at 1.62 Å in the R-space spectrum of Cu2@C3N4 to be Cu-N or Cu-O bonding. To fit the EXAFS spectrum, a total of 9 possible Cu-dimer configurations was postulated, based on which DFT calculations were performed to relax the structures and determine bonding distances and angles (Supplementary Fig. 5 and Table 1). Considering the presence of minor Cu monomers observed in the STEM images (Fig. 1e–g), we have applied a linear combination of Cu monomers and dimers to fit the EXAFS spectrum. Various possible Cu-dimer configurations have been considered, with the corresponding EXAFS spectra compared to the experimental results to identify the best fit (Fig. 2d, e; also see Supplementary Figs. 6–7). It is estimated that 72.4% of the Cu atoms are in the dimeric configuration, close to the value (~70%) derived from statistical analysis of the STEM images. The determined copper-dimer structure comprises two Cu atoms bridged by an O atom, with the Cu-O bonds having lengths of 1.76 Å and 1.79 Å and an included angle (∠Cu-O-Cu) of 99.6o (Fig. 2f, Table 1). Each Cu atom is coordinated to two N atoms on the C3N4 framework, with the bonding distance varying from 1.90 to 1.99 Å and the bonding angle (∠N-Cu-N) being 82o for Cuα and 110o for Cuβ (Fig. 2f). Noticeably, the identified configuration with best fitting to the EXAFS spectrum also has the lowest (most negative) formation energy among the various configurations, in line with the expectation for stable atomic structures in the real catalysts (Supplementary Table 1). Our combined EXAFS analysis and DFT calculations resolved the Cu-Cu distance in the Cu dimers to be ~2.71 Å (Table 1), which is in agreement with the average Cu-Cu distance measured from the STEM images (Fig. 1h). It is noted that this value is much smaller than the Cu-Cu distance (4.10 Å) associated with the dicopper-oxo center ([Cu-O-Cu]2+) in Cu-ZSM-537. Furthermore, Bader charge analysis based on DFT calculation shows that the Cu atoms in the Cu dimers have oxidation states of +1.63 and +1.72 (Supplementary Fig. 7), resembling the results derived from XANES spectra (see the above discussion for Fig. 2b).

From the above discussion, we can see that the dimeric copper centers in Cu2@C3N4 have distinct atomic structures and electronic chemical properties form their counterparts confined in zeolites. We hypothesize that their non-integer oxidation state (intermediate between +1 and +2) and reduced cluster size (smaller Cu-Cu distance as compared to Cu-ZSM-5) would lend them exquisite catalytic performance for selective oxidation of methane36.

Thermocatalytic oxidation of methane with H2O2

The Cu2@C3N4 catalysts were first evaluated for the thermocatalytic oxidation of CH4 (Supplementary Figs. 8–12). This was conducted using a continuous stirred-tank reactor (CSTR) filled with 0.2 mM of H2O2 and 0.1 MPa of CH4 (see Experimental Methods in the Supplementary Materials). Methyl oxygenates (CH3OH and CH3OOH) were found to be the primary products, with the yield achieving 0.14% within 30 min of reaction at 30 °C (Fig. 3a). As previously reported, the generated CH3OOH can be facilely reduced to CH3OH under ambient conditions (Supplementary Fig. 12)19,38. The yield of methyl oxygenates increased to 0.37% at 70 °C, corresponding to the increase of productivity from 51.6 to 129.7 mmol gCu−1 h−1. Albeit the increase of reaction rate, the rise of reaction temperature is accompanied with the increase of CO2 selectivity from 0.8% at 30 °C to 5.0% at 70 °C (Supplementary Fig. 13). Similarly, elongated operations also led to the yield of more CO2 (Supplementary Fig. 13). The cyclability tests showed that the Cu2@C3N4 catalyst was stable throughout the methane oxidation reaction with H2O2. In five consecutive measurements by refilling CH4 and H2O2, the Cu2@C3N4 catalyst exhibited indiscernible change in reactivity and product distribution, with the productivity of methyl oxygenates found to be consistent at ~70 mmol gCu−1 h−1 at 50 °C (Supplementary Fig. 14). Furthermore, the atomic structure of dicopper-oxo centers was confirmed to remain intact after reaction by performing HADDF-STEM imaging and EXAFS analysis on the spent Cu2@C3N4 catalyst after 6 h of reaction (Supplementary Fig. 15 and Supplementary Table 2).

a Yields and productivity of methyl oxygenates at different reaction temperatures. b Comparisons of product yields and productivity over different catalysts. c Correlation between productivity of methyl oxygenates and gain factor for different catalysts. d Simulated pathways for the reaction between CH4 with H2O2 on the Cu2@C3N4 catalysts, with the middle inset illustrating the electron distribution of the CH4 molecule being activated on the bridging oxygen site. Energy barriers are also given for the associated molecular transformations. e The DFT calculated free energy diagram for the Cu2@C3N4-catalyzed partial oxidation of CH4 with H2O2. Three stages consisting of H2O2 activation, CH4 activation and methyl oxygenates formation are distinguished with different colors. The error bars presented in (a–c) indicate the statistical distribution derived from three independent measurements.

Considering that the bare g-C3N4 substrate is inactive for CH4 oxidation (Supplementary Fig. 16), the dicopper-oxo centers can be identified as the active sites in Cu2@C3N4. Considering that monomeric Cu in copper exchanged zeolites10,39,40 or metal−organic frameworks41 has also been discussed to be active for CH4 oxidation, we have performed comparative studies on a single-atom control (Cu1@C3N4) using the same g-C3N4 substrate. This catalyst was prepared by using a vapor-migration strategy42 with the Cu loading controlled to be also at ~0.35 wt%, with the single-atom dispersion confirmed by using XAS (Supplementary Fig. 17). Catalytic studies showed that Cu1@C3N4 was merely active for methane oxidation, delivering a yield of only 0.03% (versus 0.2% by Cu2@C3N4) for methyl oxygenates at 50 °C (Fig. 3b). The low reactivity of Cu1@C3N4 indicates that Cu monomers, if present in the Cu2@C3N4 catalysts, would not make significant contributions to the observed high methane partial oxidation activity, and also underlines the necessity of having dicopper-oxo centers for catalyzing the partial oxidation of methane. The activity of Cu2@C3N4 is also substantially enhanced as compared to copper exchanged zeolites. A comparative study of Cu-ZSM5 with a Si/Al ratio of 11.5 and full exchange (Cu/Al ~ 0.51) using similar reaction conditions only delivered a productivity of 25.5 mmol gCu−1 h−1 for methyl oxygenates at 50 °C, as compared to 74.4 mmol gCu−1 h−1 for Cu2@C3N4 at this temperature (Fig. 3b). Note that the copper species in this Cu-ZSM-5 catalyst is also predominantly present in the form of dicopper-oxo centers36, similar to that identified in Cu2@C3N4 (as shown in Fig. 2f). These results thus indicate that the dimeric Cu supported on carbon nitride is much more reactive for the oxidation of methane with H2O2 than their counterparts confined in zeolites.

In the partial oxidation of methane with H2O2, the efficiency of utilizing the peroxide oxidizer (instead of producing O2 through a disproportionation reaction) is an important metric for evaluating the performance of catalysts19,43. This is usually assessed by comparing the “gain factor” that is defined as the molar ratio between the produced methyl oxygenates (CH3OH and CH3OOH) and the consumed H2O219. Post-reaction titration of the concentration of residual hydrogen peroxide using cerium sulfate44 (Supplementary Fig. 18) showed that the Cu2@C3N4 catalyst had a gain factor of 0.19 (Fig. 3c and Supplementary Fig. 19). In comparison, the gain factor was determined to be only 0.03 and 0.06 for Cu1@C3N4 and Cu-ZSM5-11.5, respectively. It is interesting that the gain factor exhibited dependence on the copper loading in the dimer catalyst. A Cu2@C3N4 catalyst of reduced loading (0.25 wt%) had a gain factor of 0.12, which is lower than that for the normal catalyst with 0.35 wt% of copper. Moreover, correlation between the productivity of methyl oxygenates and the gain factor gives rise to a linear relationship, underscoring its meaning of describing the reactivity between methane and H2O2 on a given catalyst (Fig. 3c)19,45.

To understand the enhanced reactivity of Cu2@C3N4 for methane partial oxidation, we have performed DFT calculations to simulate the reaction pathways on the dicopper-oxo centers (Figs. 3d, e; also see Supplementary Fig. 20 and Supplementary Table 3). It is predicted that the reaction starts with sequential activation of two H2O2 molecules on the copper-dimer centers through radical mechanisms24,46,47. The first hydrogen peroxide molecule is dissociated via H2O2 → ‧OOH + *H, where the hydrogen adsorbs on the bridging oxygen and the ‧OOH radical migrates onto Cuα to become a peroxyl (*OOH) adsorbate. The second hydrogen peroxide undergoes H2O2 → ‧OH + *OH with the hydroxyl group adsorbing on Cuβ and the ‧OH radical recombines with the *H on the bridging oxygen site to form a H2O molecule. The involvement of ‧OOH and ‧OH in H2O2 activation was corroborated by the observation of these radicals in the electron paramagnetic resonance (EPR) spectroscopic studies by using 5,5′-Dimethyl-1-pyrroline-N-oxide (DMPO) as the radical trap (Supplementary Fig. 21)48. The generation of radicals is the rate limiting factor in both cases of H2O2 activation, which is predicted to have a kinetic barrier of 0.17 (for ‧OOH) or 0.56 (for ‧OH) eV. Noticeably, these barriers are substantially lower than the corresponding values found for the single-atom Cu sites (1.3 and 1.5 eV, Supplementary Fig. 22) and the dicopper-oxo centers confined in zeolites (0.58 and 0.81 eV in Cu-ZSM-5)7,49, in line with the higher gain factor and enhanced utilization of H2O2 as observed on the Cu2@C3N4 catalysts (Fig. 3c). The enhanced H2O2 activation on Cu2@C3N4 could be ascribed to the π-conjugated heterocyclic rings and the semiconducting nature of the C3N4 substrate, which is known for accommodation of charge transfer and able to supply electrons to the dicopper-oxo center for stabilization of the oxygenated adsorbates50,51,52,53. The C3N4 supported Cu dimers are thus believed to be more advantageous than their zeolitic counterparts for catalyzing the redox chemistries being examined here.

Following the activation of H2O2, methane is introduced to the dicopper-oxo center with one of the C-H bond attacked by the bridging oxygen (Fig. 3d, e). This C-H bond dissociation has a modest energy barrier of 0.61 eV (vs. ~0.71 eV in the case of Cu-ZSM-5)10,39,40. While the generated H adsorbs on the bridging oxygen, the methyl group migrates on to the adjacent Cu sites. Hereby the C-H bond dissociation is believed to be heterolytic instead of homolytic or the Fenton type, as no ‧CH3 radicals were observed using EPR (Supplementary Fig. 23)19,24,38. The heterolytic dissociation of C-H bond is believed to be essential for partial oxidation of methane at high selectivities, as the other two activation mechanisms via ‧CH3 radicals are typically accompanied with over oxidation to form substantial amounts of CO2. Compared to the case in Cu-ZSM-537, the Cu dimers supported on g-C3N4 have shorter Cu-O bond length (1.77 Å vs 1.88 Å) and smaller∠Cu-O-Cu (99.6° vs 135°), which are believed to sterically favor the heterolytic cleavage of the C-H bond and facilitate the transer of the -CH3 group. Noticeably, the -CH3 group can adsorb on either Cuα or Cuβ, where the reaction bifurcates into two possible pathways. On the one hand, *CH3 on Cuα recombine with the *OOH on this site to form *CH3OOH. On the other hand, it can also recombine with *OH on Cuβ to form *CH3OH. Desorption of these adsorbates gives rise to the corresponding methyl oxygenates. While the rate is limited by the *CH3 +*OH → *CH3OH recombination on Cuβ (with a barrier of 0.72 eV), the highest barrier for the CH3OOH pathway is found to be the desorption of *CH3OOH (0.52 eV). Overall, the CH3OOH pathway associated with Cuα is energetically more favorable than the CH3OH pathway with Cuβ, explaining the experimentally observed much higher yield of CH3OOH than CH3OH. The pathways as revealed in Fig. 3d emphasizes the synergy among the two Cu atoms and the bridging O in catalyzing the complex reaction involving multiple molecules (e.g., CH4 + 2H2O2 → CH3OOH + 2H2O), which is a unique feature of the carbon nitride supported dimeric copper centers. An analogous reaction mechanism was also proposed in the partial oxidation of methane with H2O2 catalyzed by Au-Pd colloids19.

Photocatalytic oxidation of methane with O2

Despite the selective oxidation of methane obtained with Cu2@C3N4, the thermocatalytic reaction still relies on the use of H2O2 as oxidant, which is not a readily available feeding in industry. Moreover, the low CH4 conversions (<1%) also limits the potential of this process for practical implementations. Considering that g-C3N4 is a semiconductor (with a bandgap of 2.7–2.9 eV25,26) with demonstrated photocatalytic applications27, we have turned to photocatalysis to overcome the limitation of thermocatalytic reactions. Photocatalytic oxidation of methane was carried out at 50 °C by applying near-edge excitation (300 W Xenon lamp equipped with a 420 nm bandpass filter) and using O2 as the oxidant (Supplementary Fig. 24). It is hypothesized that photoexcitation can efficiently activate O2 and generate the oxygenates (*OOH and *OH), mimicking and improving the role that H2O2 played in the reaction21,22,54.

The photocatalytic reaction gave much higher conversions of methane than the thermocatalytic process, reaching 1.3% at 1 h (Fig. 4a). The methane conversion increases with time, reaching ~13.1% at 6 h, where the products were found to be still dominated by CH3OOH and CH3OH (98.9% selectivity, Supplementary Fig. 25). The productivity of methyl oxygenates reached the peak value of 249.7 mmol gCu−1 h−1 at 2 h, representing an improvement factor of ~3.6 as compared to the thermocatalytic reaction. Further improvement of the productivity was obtained by raising the partial pressure of methane (PCH4). As PCH4 increased from 0.1 to 1 MPa (at PO2 = 0.1 MPa, while the total pressure was kept constant at 3 MPa), the productivity escalated from 184.3 to 709.8 mmol gCu−1 h−1, albeit with the methane conversion reducing from 13.1 to 5.1 (at 6 h, Fig. 4b and Supplementary Fig. 26). The improvement of productivity at higher PCH4 can be ascribed to the increased concentration of dissolved methane in the aqueous solution20. The low conversion of methane at high PCH4 was likely limited by the inadequacy of oxygen. At PO2 = 0.5 MPa and PCH4 = 1 MPa, a methane conversion of 10.1% was obtained with >98% selectivity toward methyl oxygenates, corresponding to an even higher productivity of 1399.3 mmol gCu−1 h−1. A comprehensive comparison to the literature results under similar reaction conditions indicate that this represents the highest activity for partial oxidation of methane, with improvement factors of at least >10 (Supplementary Table 4).

a Yields and productivity of methyl oxygenates as a function of reaction time at 0.1 MPa CH4 and 0.1 MPa O2. b CH4 conversions and productivity of methyl oxygenates at different CH4 and O2 partial pressures. c EPR spectra recorded for various control experiments using DMPO as the radical trapping agent. d, e In situ irradiation XPS spectra collected at the O 1 s (d) and N 1 s (e) edges. f Schematic illustration of the photocatalytic oxidation of CH4 with O2 catalyzed by Cu2@C3N4. The values “−1.45 and 1.31 eV” label the estimated position of dicopper-oxo states in the band structure of g-C3N4, as determined by performing the UV-vis DRS and UPS spectra analysis of Cu2@C3N4. The error bars shown in (a, b) indicate the statistical distribution derived from three independent measurements.

The photocatalytic oxidation of methane with O2 was confirmed by conducting control experiments under various conditions (Supplementary Table 5). In particular, the Cu2@C3N4 catalyst was found to be inactive in darkness (while the other conditions were kept the same), ruling out the involvement of thermocatalytic reaction between CH4 and O2 in the photocatalytic studies. The photocatalytic activity of bare g-C3N4 was also nearly negligible, underlining the role of Cu dimers in catalyzing the related molecular transformations. The generation of active peroxide species in situ during the photocatalytic reaction was confirmed by performing EPR spectroscopic studies by also using DMPO as the radical trapping agent (Fig. 4c). The spectra recorded under visible light irradiation, in both cases with and without methane, show the fingerprints of ‧OOH radicals, which can be assigned to the spin of unpaired electrons on oxygen21,45,54. Similar to the findings from photocatalytic studies, such signals were not observed from the controls in the absence of O2, Cu2@C3N4, or light. These ‧OOH radicals are likely derived from the thermal activation of H2O2 (as observed in the thermocatalytic studies, Supplementary Fig. 21), which was produced from photocatalytic reduction of O2 in situ55,56,57. It thus becomes evident that Cu2@C3N4 is not only a good thermocatalyst for partial oxidation of methane with H2O2, but also an exceptional photocatalyst when the oxidant is replaced by O2.

In addition to the reduction of O2 to peroxides, the photon excitation is also believed to enhance the methane activation. This was revealed by using in situ irradiation X-ray photoelectron spectroscopy (ISI-XPS)58 to examine charge transfer between the dimeric copper center and the C3N4 substrate (see the Experimental Methods in the Supplementary Materials). As shown in Fig. 4d, the XPS spectra collected on hydrated Cu2@C3N4 in darkness exhibited two O 1 s peaks at ca. 533.0 and 531.7 eV, which can be assigned to the oxygen binding to Cu, i.e., -Cu-OH and -Cu-O-Cu-, respectively59,60. Under light irradiation (400~500 nm), both of these two peaks had a blue shift of ~0.5 eV. Similar observations were obtained at the Cu 2p edge (Supplementary Fig. 27). Meanwhile, a red shift of the N 1 s peak associated with C3N4 was observed, from 398.8 eV in darkness to 398.2 eV under light irradiation (Fig. 4e). Such phenomena consistently point to the transfer of holes (rather than electrons) from the g-C3N4 substrate to the dicopper-oxo center, where CH4 is activated and oxidized to form *CH3. Meanwhile, the excited electrons in the g-C3N4 substrate lead to the reduction of O2 and formation of H2O2, which then migrates or diffuses onto the dicopper-oxo center and gets activated to form *OOH or *OH. In the following, these oxygen species recombine with *CH3 to form methyl oxygenates, as in the case of thermocatalytic reactions (Fig. 4f and Supplementary Figs. 28–29). Similar phenomena of charge transfer induced catalytic enhancements have previously been reported in photocatalysis using TiO2 based photocatalysts61,62,63.

In conclusion, we have developed new dimeric copper catalysts for partial oxidation of methane. These catalysts were synthesized by immobilization of a copper-dimer organometallic complex on graphitic carbon nitride, and dicopper-oxo centers were characterized to anchor on this substrate via Cu-N bonding. The derived Cu2@C3N4 catalysts were first examined for thermocatalytic oxidation of methane with H2O2, and then studied for photocatalytic reactions with O2 being used as the oxidant. Enhanced catalytic activities were demonstrated in both cases as compared to the other reported catalysts under similar reaction conditions, achieving improvement factors of more than an order of magnitude. Synergy of the bridging oxygen, the two copper sites, and the semiconducting C3N4 substrate has been revealed to promote H2O2 and O2 activation and the heterolytic scission of CH4. Our work highlights the great potential of carbon nitride supported dimeric copper centers in catalyzing redox chemical reactions.

Methods

Materials and Chemicals

The following chemicals were purchased and used as-received without further purification: Copper(II) chloride dihydrate (CuCl2·2H2O, ACS grade, Sigma Aldrich), 2,2,-bipyridine (C10H8N2, reagent grade, Sigma Aldrich), oxalic acid (HO2CCO2H, reagent grade, Alfa Aesar), urea (NH2CONH2, ACS grade, Sigma Aldrich), dicyandiamide (NH2C( = NH)NHCN, ACS grade, Sigma Aldrich), copper(II) acetylacetonate (Cu(acac)2, ACS reagent, Sigma Aldrich), oleylamine (CH3(CH2)7CH = CH(CH2)8NH2, ≥ 98%, Sigma Aldrich), ethanol (C2H5OH, HPLC grade, Fisher Scientific), methanol (CH3OH, HPLC grade, Fisher Scientific), deionized water (18.2 MΩ) was collected from an ELGA PURELAB flex apparatus.

Synthesis of copper dimer complex

Solutions A, B, and C were prepared by ultrasonically dispersion method, respectively. The detailed preparation process was as follows: Solution A: 1.6 mmol 272 mg CuCl2·2H2O was ultrasonically dispersed in 20 mL deionized water; Solution B: 1.6 mmol 248 mg 2,2,-bipyridine was ultrasonically dispersed in 10 mL methanol; Solution C: 0.8 mmol 100 mg oxalic acid was ultrasonically dispersed in 10 mL deionized water; Subsequently, Adding solution B and solution C to solution A drop by drop respectively and kept stirring for 1 h. Finally, the light-blue solid was obtained by centrifugation, washing with water and methanol for three times and drying in vacuum29.

Synthesis of g-C3N4

20 g of urea was placed to an alumina crucible (100 mL). Subsequently, the crucible was sealed with multiple layers of tin foil and put into a muffle furnace with the heating program from 50 °C to 550 °C for 2 h at the rate of 20 °C min−1. The obtained powder was further repeated the above calcination operation, the difference was that the heating rate was kept at 5 °C min−1 and the retention time at 550 °C was 3 h. Finally, the yellowish-white powder was obtained.

Synthesis of Cu2@C3N4

Solution A: 0.5 g g-C3N4 was ultrasonically dispersed in 50 mL methanol solution; Solution B: 42 mg copper dimer was ultrasonically dispersed in 5 mL methanol solution; Solution B was drop-wisely added to solution A and was stirred at room temperature for 24 h, and the obtained solid was calcined in muffle furnace with the heating program from 50 °C to 250 °C for 10 h at the rate of 2 °C min−1. Finally, the blue-yellow solid was got.

Synthesis of Cu1@g-C3N4

64 3 g dicyandiamide and 340 mg CuCl2·2H2O were grounded to be-well mixed, then spread in an alumina crucible (100 mL) with a cap covered. The crucibles were places in a muffle furnace, and gradually heated to 550 °C for 8 h with the ramping rate of 5 °C min−1 and then cool down.

Material characterization

X-Ray Diffraction (XRD) patterns were obtained from a PANalytical X’Pert3 X-ray diffractometer equipped with a Cu Kα radiation source (λ = 1.5406 Å). Nitrogen adsorption measurements were measured on a Micromeritics ASAP 2010 instrument with the samples degassed under vacuum at 300 °C for 4 h. Specific surface area (SSA) was calculated using the Brunauer-Emmett-Teller (BET) theory. The Cu contents were determined by inductively coupled plasma mass spectrometry (ICP-MS) using a PerkinElmer Elan DRC II Quadrupole ICP-MS after dissolution of the samples in aqua regia. High angle annular dark field (HAADF) STEM images were acquired using a JEOL TEM/STEM ARM 200CF (equipped with an Oxford X-max 100TLE windowless X-ray detector) at a 22 mrad probe convergence angle and a 90 mrad inner-detector angle. The analysis of surface elements was performed on X-ray photoelectron spectroscopy (XPS), Thermo Fisher Scientific Escalab 250Xi spectrometer with Al Kα radiation as the excitation source. Fourier Transform Infrared Spectroscopy were carried out on ThermoNicolet Nexus 670. Diffuse reflectance ultraviolet-visible (UV-Vis) spectra were collected on a Shimadzu UV-2450 spectrometer equipped with an integrating sphere attachment using BaSO4 as the reference. FTIR Spectrometer Ultraviolet photoelectron spectroscopy (UPS) measurements were performed on an ESCALAB 250 UPS instrument with a He Iα gas discharge lamp operating at 21.22 eV and a total instrumental energy resolution of 90–120 meV.

XAS experiments were performed at the 10-BM beamline at the Advanced Photon Source (APS) at Argonne National Laboratory. Samples were pressed into a stainless-steel sample holder. All measurements were performed at the Cu K edge (8.9789 keV) in transmission mode in fast scan from 250 eV below the edge to 800 eV above the edge. Spectra processing, including background removal and normalization were performed on ATHENA module in Demeter package. The extraction of structural parameters and fitting of the DFT optimized models of fresh and spent Cu2@C3N4 samples were performed on ARTEMIS module. For the optimized structure, EXAFS data were fit from k = 2.7 to 10 Å−1 (dk = 2) and R = 1–3.2 Å with a Hanning window.

Electron Paramagnetic Resonance (EPR) measurements were performed on a Bruker EMX EPR spectrometer at X-band frequency (9.46 GHz). 5,5’-Dimethyl-1-pyrroline-N-oxide (DMPO) was used as the spin-trapping agent, which can capture the radicals •CH3, •OOH and •OH. As for the detection of •OOH and •OH, methanol and DI H2O were used respectively, due to the DMPO-OOH is not stable in H2O, would be quickly converted to DMPO-OH.

The in-situ irradiation X-Ray photoelectron spectroscopy (ISI-XPS) was carried out on AXIS SUPRA (Kratos Analytical Inc, Shimadazu) coupled with a continuous tunable wavelength light optical fiber (PLS-EM 150, Beijing Perfectlight Co. Ltd.). The wavelength of irradiation light was set at 400–500 nm to mimicking the visible light. The measurement setup is developed to monitor the photoelectron transfer process. Before measurement, the hydrated Cu1@g-C3N4 was obtained by pretreatment of fresh Cu1@g-C3N4 by water.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information file. The data generated in this study for main manuscript are provided in the Source Data file. Other raw data of the presented figures and tables are available from the corresponding authors upon request. Source data are provided with this paper.

References

Nisbet, E. G., Dlugokencky, E. J. & Bousquet, P. Methane on the rise-again. Science 343, 493–495 (2014).

Choudhary, T. V. & Choudhary, V. R. Energy-efficient syngas production through, catalytic oxy-methane reforming reactions. Angew. Chem. Int. Ed. 47, 1828–1847 (2008).

Tang, P., Zhu, Q. J., Wu, Z. X. & Ma, D. Methane activation: the past and future. Energ. Environ. Sci. 7, 2580–2591 (2014).

Buzcu-Guven, B. & Harriss, R. Extent, impacts and remedies of global gas flaring and venting. Carbon Manag 3, 95–108 (2012).

Julian-Duran, L. M., Ortiz-Espinoza, A. P., El-Halwagi, M. M. & Jimenez-Gutierrez, A. Techno-economic assessment and environmental impact of shale gas alternatives to methanol. ACS Sustain. Chem. Eng. 2, 2338–2344 (2014).

Farrell, B. L., Igenegbai, V. O. & Linic, S. A viewpoint on direct methane conversion to ethane and ethylene using oxidative coupling on solid catalysts. ACS Catal. 6, 4340–4346 (2016).

Hammond, C. et al. Direct catalytic conversion of methane to methanol in an aqueous medium by using copper-promoted Fe-ZSM-5. Angew. Chem. Int. Ed. 51, 5129–5133 (2012).

Pappas, D. K. M. et al. The nuclearity of the active site for methane to methanol conversion in cu-mordenite: a quantitative assessment. J. Am. Chem. Soc. 140, 15270–15278 (2018).

Groothaert, M. H. S., Smeets, P. J., Sels, B. F., Jacobs, P. A. & Schoonheydt, R. A. Selective oxidation of methane by the bis(m-oxo)dicopper core stabilized on ZSM-5 and mordenite zeolites. J. Am. Chem. Soc. 127, 1394–1395 (2005).

Woertink, J. S. et al. A [Cu2O]2+ core in Cu-ZSM-5, the active site in the oxidation of methane to methanol. P. Natl Acad. Sci. 106, 18908–18913 (2009).

Narsimhan, K., Iyoki, K., Dinh, K. & Roman-Leshkov, Y. Catalytic oxidation of methane into methanol over copper-exchanged zeolites with oxygen at low. Temp. ACS Cent. Sci. 2, 424–429 (2016).

Dinh, K. T. et al. Continuous partial oxidation of methane to methanol catalyzed by diffusion-paired copper dimers in copper-exchanged zeolites. J. Am. Chem. Soc. 141, 11641–11650 (2019).

Koishybay, A. & Shantz, D. F. Water is the oxygen source for methanol produced in partial oxidation of methane in a flow reactor over Cu-SSZ-13. J. Am. Chem. Soc. 142, 11962–11966 (2020).

Palkovits, R., Antonietti, M., Kuhn, P., Thomas, A. & Schuth, F. Solid catalysts for the selective low-temperature oxidation of methane to methanol. Angew. Chem. Int. Ed. 48, 6909–6912 (2009).

Jones, C. J. et al. Selective oxidation of methane to methanol catalyzed, with C-H activation, by homogeneous, cationic gold. Angew. Chem. Int. Ed. 43, 4626–4629 (2004).

Shan, J. J., Li, M. W., Allard, L. F., Lee, S. S. & Flytzani-Stephanopoulos, M. Mild oxidation of methane to methanol or acetic acid on supported isolated rhodium catalysts. Nature 551, 605–608 (2017).

Sushkevich, V. L., Palagin, D., Ranocchiari, M. & van Bokhoven, J. A. Selective anaerobic oxidation of methane enables direct synthesis of methanol. Science 356, 523–527 (2017).

Grundner, S. et al. Single-site trinuclear copper oxygen clusters in mordenite for selective conversion of methane to methanol. Nat. Commun. 6, 7546 (2015).

Agarwal, N. et al. Aqueous Au-Pd colloids catalyze selective CH4 oxidation to CH3OH with O2 under mild conditions. Science 358, 223–226 (2017).

Jin, Z. et al. Hydrophobic zeolite modification for in situ peroxide formation in methane oxidation to methanol. Science 367, 193–197 (2020).

Song, H. et al. Direct and selective photocatalytic oxidation of CH4 to oxygenates with O2 on Cocatalysts/ZnO at room temperature in water. J. Am. Chem. Soc. 141, 20507–20515 (2019).

Song, H., Meng, X. G., Wang, Z. J., Liu, H. M. & Ye, J. H. Solar-energy-mediated methane conversion. Joule 3, 1606–1636 (2019).

Song, H. et al. Selective photo-oxidation of methane to methanol with oxygen over dual-cocatalyst-modified titanium dioxide. ACS Catal. 10, 14318–14326 (2020).

Szecsenyi, A., Li, G. N., Gascon, J. & Pidko, E. A. Mechanistic complexity of methane oxidation with H2O2 by single-site Fe/ZSM-5 catalyst. ACS Catal. 8, 7961–7972 (2018).

Wen, J. Q., Xie, J., Chen, X. B. & Li, X. A review on g-C3N4-based photocatalysts. Appl. Surf. Sci. 391, 72–123 (2017).

Xu, Y. & Gao, S. P. Band gap of C3N4 in the GW approximation. Int. J. Hydrog. Energ. 37, 11072–11080 (2012).

Su, F. Z. et al. mpg-C3N4-catalyzed selective oxidation of alcohols using O2 and visible light. J. Am. Chem. Soc. 132, 16299–16301 (2010).

Shi, Z. S., Yang, W. Q., Gu, Y. T., Liao, T. & Sun, Z. Q. Metal-nitrogen-doped carbon materials as highly efficient catalysts: progress and rational design. Adv. Sci. 7, 2001069 (2020).

Reinoso, S., Vitoria, P., Lezama, L., Luque, A. & Gutierrez-Zorrilla, J. M. A novel organic-inorganic hybrid based on a dinuclear copper complex supported on a keggin polyoxometalate. Inorg. Chem. 42, 3709–3711 (2003).

Martin, D. J. et al. Highly efficient photocatalytic H2 evolution from water using visible light and structure-controlled graphitic carbon nitride. Angew. Chem. Int. Ed. 53, 9240–9245 (2014).

Zhao, Y. Y. et al. Stable iridium dinuclear heterogeneous catalysts supported on metal-oxide substrate for solar water oxidation. Proc. Natl Acad. Sci. 115, 2902–2907 (2018).

Gerasimova, T. P. & Katsyuba, S. A. Bipyridine and phenanthroline IR-spectral bands as indicators of metal spin state in hexacoordinated complexes of Fe(II). Ni(II) Co.(II). Dalton. T. 42, 1787–1797 (2013).

Mane, G. P. et al. Highly ordered nitrogen-rich mesoporous carbon nitrides and their superior performance for sensing and photocatalytic hydrogen generation. Angew. Chem. Int. Ed. 56, 8481–8485 (2017).

Chen, Z. P. et al. Stabilization of single metal atoms on graphitic carbon nitride. Adv. Funct. Mater. 27, 1605785 (2017).

Fox, E. B. et al. Characterization of CeO2-supported Cu-Pd bimetallic catalyst for the oxygen-assisted water-gas shift reaction. J. Catal. 260, 358–370 (2008).

Xie, P. F. et al. Bridging adsorption analytics and catalytic kinetics for metal-exchanged zeolites. Nat. Catal. 4, 144–156 (2021).

Tsai, M. L. et al. [Cu2O]2+ active site formation in Cu-ZSM-5: geometric and electronic structure requirements for N2O activation. J. Am. Chem. Soc. 136, 3522–3529 (2014).

Ab Rahim, M. H. et al. Oxidation of methane to methanol with hydrogen peroxide using supported gold-palladium alloy nanoparticles. Angew. Chem. Int. Ed. 52, 1280–1284 (2013).

Kulkarni, A. R., Zhao, Z. J., Siahrostami, S., Norskov, J. K. & Studt, F. Cation-exchanged zeolites for the selective oxidation of methane to methanol. Catal. Sci. Technol. 8, 114–123 (2018).

Yashnik, S. A., Boltenkov, V. V., Babushkin, D. E., Taran, O. P. & Parmon, V. N. Methane oxidation by H2O2 over different Cu-species of Cu-ZSM-5 catalysts. Top. Catal. 63, 203–221 (2020).

Zheng, J. et al. Selective methane oxidation to methanol on Cu-Oxo dimers stabilized by zirconia nodes of an NU-1000 metal-organic framework. J. Am. Chem. Soc. 141, 9292–9304 (2019).

Qu, Y. T. et al. Direct transformation of bulk copper into copper single sites via emitting and trapping of atoms. Nat. Catal. 1, 781–786 (2018).

Ravi, M. et al. Misconceptions and challenges in methane-to-methanol over transition-metal-exchanged zeolites. Nat. Catal. 2, 485–494 (2019).

Lu, Z. Y. et al. High-efficiency oxygen reduction to hydrogen peroxide catalysed by oxidized carbon materials. Nat. Catal. 1, 156–162 (2018).

Xing, Y. C. et al. Fe/Fe3C boosts H2O2 utilization for methane conversion overwhelming O2 generation. Angew. Chem. Int. Ed. 60, 2–9 (2021).

Szecsenyi, A., Li, G. N., Gascon, J. & Pidko, E. A. Unraveling reaction networks behind the catalytic oxidation of methane with H2O2 over a mixed-metal MIL-53(Al,Fe) MOF catalyst. Chem. Sci. 9, 6765–6773 (2018).

Osadchii, D. Y. et al. Isolated Fe sites in metal organic frameworks catalyze the direct conversion of methane to methanol. ACS Catal. 8, 5542–5548 (2018).

Schneider, J. T., Firak, D. S., Ribeiro, R. R. & Peralta-Zamora, P. Use of scavenger agents in heterogeneous photocatalysis: truths, half-truths, and misinterpretations. Phys. Chem. Chem. Phys. 22, 15723–15733 (2020).

Hori, Y., Shiota, Y., Tsuji, T., Kodera, M. & Yoshizawa, K. Catalytic performance of a dicopper-Oxo complex for methane hydroxylation. Inorg. Chem. 57, 8–11 (2018).

Zhou, P. et al. Strengthening reactive metal-support interaction to stabilize high-density Pt single atoms on electron-deficient g-C3N4 for boosting photocatalytic H2 production. Nano Energy 56, 127–137 (2019).

Xiao, X. D. et al. A promoted charge separation/transfer system from Cu single atoms and C3N4 layers for efficient photocatalysis. Adv. Mater. 32, 2003082 (2020).

Guo, Y. Q. et al. A strategy for enhancing the photoactivity of g-C3N4 based single-atom catalysts via sulphur doping: a theoretical study. Phys. Chem. Chem. Phys. 23, 6632–6640 (2021).

Tong, T., He, B. W., Zhu, B. C., Cheng, B. & Zhang, L. Y. First-principle investigation on charge carrier transfer in transition-metal single atoms loaded g-C3N4. Appl. Surf. Sci. 459, 385–392 (2018).

Luo, L. H. et al. Water enables mild oxidation of methane to methanol on gold single-atom catalysts. Nat. Commun. 12, 1218 (2021).

Shiraishi, Y. et al. Highly selective production of hydrogen peroxide on graphitic carbon nitride (g-C3N4) photocatalyst activated by visible light. ACS Catal. 4, 774–780 (2014).

Moon, G. H. et al. Eco-friendly photochemical production of H2O2 through O2 reduction over carbon nitride frameworks incorporated with multiple heteroelements. ACS Catal. 7, 2886–2895 (2017).

Rao, P. S. & Hayon, E. Redox potentials of free-radicals. IV. superoxide and hydroperoxy radicals single bond ‧O2- and single bond ‧HO2. J. Phys. Chem. 79, 397–402 (1975).

Zhang, P. et al. Photogenerated electron transfer process in heterojunctions: In Situ Irradiation XPS. Small Methods 4, 2000214 (2020).

Akhavan, O., Azimirad, R., Safa, S. & Hasani, E. CuO/Cu(OH)2 hierarchical nanostructures as bactericidal photocatalysts. J. Mater. Chem. 21, 9634–9640 (2011).

Bojestig, E., Cao, Y. & Nyborg, L. Surface chemical analysis of copper powder used in additive manufacturing. Surf. Interface Anal. 52, 1104–1110 (2020).

Dong, F. et al. In situ construction of g-C3N4/g-C3N4 metal-free heterojunction for enhanced visible-light photocatalysis. ACS Appl. Mater. Inter. 5, 11392–11401 (2013).

Wang, D., Sheng, T., Chen, J. F., Wang, H. F. & Hu, P. Identifying the key obstacle in photocatalytic oxygen evolution on rutile TiO2. Nat. Catal. 1, 291–299 (2018).

Xie, J. J. et al. Highly selective oxidation of methane to methanol at ambient conditions by titanium dioxide-supported iron species. Nat. Catal. 1, 889–896 (2018).

Wu, Q. et al. Cu@g-C3N4: an efficient single-atom electrocatalyst for NO electrochemical reduction with suppressed hydrogen evolution. J. Phys. Chem. C. 123, 31043–31049 (2019).

Acknowledgements

P.X. acknowledges support by the Natural Science Foundation of Zhejiang Province (LR22B060002). C.W. acknowledges support by the Advanced Research Projects Agency – Energy (ARPA-E), Department of Energy (DOE) and the Petroleum Research Fund, American Chemical Society. P.Z. acknowledges support by National Natural Science Foundation of China (51972287, U2004172). J.D., Z.Y. and S.D. acknowledge support by The Funds for National Natural Science Foundation of China (21706131, 22008211, and 22178309). R. S.-Y. acknowledges financial support from National Science Foundation award DMR-1809439.

Author information

Authors and Affiliations

Contributions

C.W. and P.X. contributed to the idea and experimental design. P.X., J.D., and J.Z. conducted the synthesis of control samples, catalytic evaluation. T. Pu performed spectroscopic analysis. N.Z-F, H.Z., and S.D. conducted the EPR characterization and NMR analysis. C.W., Z.H. and R. S-Y. performed the high resolution microscopy. Z.Y. and S.D. contributed to the simulation analysis. P.Z. conducted the in-situ irradiation X-Ray photoelectron spectroscopy characterization. C.W. and P.X. wrote the paper and all authors commented on the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the other anonymous reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xie, P., Ding, J., Yao, Z. et al. Oxo dicopper anchored on carbon nitride for selective oxidation of methane. Nat Commun 13, 1375 (2022). https://doi.org/10.1038/s41467-022-28987-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-28987-1

This article is cited by

-

Spherical cationic polymer networks with porphyrin photosensitizer for sustainable and efficient photocatalysis

Nano Research (2024)

-

High-rate CH4-to-C2H6 photoconversion enabled by Au/ZnO porous nanosheets under oxygen-free system

Science China Chemistry (2024)

-

Visible Light-Induced Photocatalysis: Self-Fenton Degradation of p-ClPhOH Over Graphitic Carbon Nitride by a Polyethylenimine Bifunctional Catalyst

Transactions of Tianjin University (2024)

-

Current Status and Perspectives of Dual-Atom Catalysts Towards Sustainable Energy Utilization

Nano-Micro Letters (2024)

-

Photocatalytic nonoxidative coupling of methane to ethylene over carbon-doped ZnO/Au catalysts

Science China Chemistry (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.