Abstract

One-step adsorptive purification of ethylene (C2H4) from four-component gas mixtures comprising acetylene (C2H2), ethylene (C2H4), ethane (C2H6) and carbon dioxide (CO2) is an unmet challenge in the area of commodity purification. Herein, we report that the ultramicroporous sorbent Zn-atz-oba (H2oba = 4,4-dicarboxyl diphenyl ether; Hatz = 3-amino-1,2,4-triazole) enables selective adsorption of C2H2, C2H6 and CO2 over C2H4 thanks to the binding sites that lie in its undulating pores. Molecular simulations provide insight into the binding sites in Zn-atz-oba that are responsible for coadsorption of C2H2, C2H6 and CO2 over C2H4. Dynamic breakthrough experiments demonstrate that the selective binding exhibited by Zn-atz-oba can produce polymer-grade purity (>99.95%) C2H4 from binary (1:1 for C2H4/C2H6), ternary (1:1:1 for C2H2/C2H4/C2H6) and quaternary (1:1:1:1 for C2H2/C2H4/C2H6/CO2) gas mixtures in a single step.

Similar content being viewed by others

Introduction

Ethylene (C2H4) is a feedstock for the production of plastics, detergents and coatings and its production, now approaching 200 million tons per year, continues to grow1. The energy footprints for purification of C2H4 and propylene (C3H6), also one of the highest volume products of the chemical industry, account for ca. 0.3% of the global energy demand2. The presence of impurities is a consequence of the steam pyrolysis process used to produce C2H4, which in turn results in acetylene (C2H2), carbon dioxide (CO2), ethane (C2H6) and other downstream products including propylene (C3H6), propane (C3H8), hydrogen (H2), C4 and higher light hydrocarbons3,4, which are easily separated by the difference of boiling points. Polymer-grade (>99.95% purity) C2H4 is generated by stepwise removal in downstream purification processes: CO2 is removed using caustic soda; C2H2 is eliminated via catalytic hydrogenation with noble-metal catalysts at high temperature and pressure; cryogenic distillation is typically employed to remove C2H65.

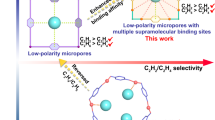

To mitigate the high energy footprint of C2H4 production, researchers have typically focused upon the development of a new generation of physisorbents that exhibit affinity for one gas over others in a gas mixture. The promise of physisorbents lies with their relatively low energy consumption compared to distillation processes thanks to facile regeneration/recycling6. However, physisorbents tend to be unsuitable for ethylene purification because the kinetic diameter of C2H4 (4.1 Å) sits between CO2 (3.3 Å), C2H2 (3.3 Å) and C2H6 (4.4 Å), precluding the possibility of molecular sieving by pore size engineered physisorbents7. Since the quadrupole moment of C2H4 (1.5 × 10−26 esu cm2) also lies between CO2 (4.3 × 10−26 cm2), C2H2 (7.2 × 10−26 esu cm2) and C2H6 (0.65 × 10−26 esu cm2)8, one-step purification of C2H4 by thermodynamics (selective binding) has thus far proven to be elusive. Metal organic materials (MOMs)9, also called metal-organic frameworks (MOFs)10,11 or porous coordination polymers (PCPs)12, have promising applications as C2 and CO2 selective physisorbents for several binary mixtures, including C2H2/C2H4, C2H4/C2H6, C2H6/C2H4, C2H2/CO2 and CO2/C2H213,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34 There are also examples of physisorbents that are effective against ternary C2 and C2-CO2 mixtures such as C2H2/C2H4/C2H6 and C2H2/C2H4/CO235,36,37,38,39,40,41. Certain classes of physisorbents are amenable to systematic fine-tuning of pore chemistry and pore size42,43 and have resulted in “second generation” sorbents with > one order of magnitude improvement in performance18,24,44,45,47. Nevertheless, we are aware of only one report of C2H4 purification from quaternary mixtures using physisorbents as reported by us in 2019 by introducing the synergistic sorbent separation technology (SSST)46 concept, which enables one-step production of high-purity ethylene from a quaternary C2H2-C2H4-C2H6-CO2 mixture by exploiting three benchmark sorbents, Zn-atz-ipa, SIFSIX-3-Ni, and TIFSIX-2-Cu-i. These sorbents were tandem-packed in a single column to sequentially remove C2H6, CO2, and C2H2, respectively (Fig. 1). Unfortunately, the interplay of packing sequence and gas mass transfer in SSST can make industrial-scale processes infeasible and, as illustrated in Fig. 1, a single sorbent that coadsorbs C2H2, C2H6, and CO2 would be desirable for quaternary gas separations such as the purification of C2H4 from a C2H2-C2H4-C2H6-CO2 mixture. Herein we report that the challenge of one-step C2H4 purification from a quaternary mixture (C2H2-C2H4-C2H6-CO2) is achieved by a single physisorbent, the ultramicroporous coordination network Zn-atz-oba.

Results

Synthesis and characterization of Zn-atz-oba

Zn-atz-oba was synthesized following a previously reported protocol (for details see Methods section)47. The bulk phase purity of crystalline samples was confirmed by powder X-ray diffraction, PXRD (Fig. 2c). As shown in Fig. 2a, b, Zn(II) cations are linked by atz− anions to form 2D undulating layers with dinuclear Zn(II) clusters as nodes. These layers are further cross-linked via oba2− ligands to form a pcu topology network. As revealed by thermogravimetric analysis (Supplementary Fig. 1), activated Zn-atz-oba is fully desolvated and stable until ca. 673 K. As calculated by PLATON48, the void space of Zn-atz-oba is 35.9%.

Views of (a) the pore structure and (b) the Connolly surface of Zn-atz-oba when viewed along the a- and c-axis, respectively. H-atoms are omitted for clarity. (c) PXRD patterns confirm the bulk phase purity of Zn-atz-oba. (d) Adsorption enthalpy profiles (Qst) for Zn-atz-oba. (e) Gas sorption isotherms of Zn-atz-oba at 298 K. (f) Binary 1:1 (v/v) IAST selectivity of Zn-atz-oba at 298 K. color codes for (a) and (b): carbon = gray; nitrogen = blue; oxygen = red; Zn polyhedra in (a) = tyrian purple; Connolly surface in (b) = purple.

The pore volume, Langmuir and Brunauer−Emmett−Teller (BET) specific surface area for Zn-atz-oba are 0.287 cm3 g−1, 783.1 m2 g−1, and 710.7 m2 g−1, respectively, as calculated from its cryogenic (77 K) N2 adsorption isotherm (Supplementary Figs. 2–4). Both parameters are in agreement with the crystal structure derived pore volume (0.283 cm3 g−1) and the Langmuir surface area calculated therefrom (755 m2 g−1), respectively. Horvath-Kawazoe model (pore geometry: slit) based pore size distribution analysis revealed the aperture distribution to be ultramicroporous between 0.32 and 0.44 nm (Supplementary Fig. 5).

Adsorption isotherm, selectivity, and enthalpy

The C2H2, C2H4, C2H6, and CO2 adsorption isotherms of activated Zn-atz-oba were recorded at 298 and 273 K (Fig. 2e and Supplementary Fig. 6). Interestingly, C2H2, C2H6, and CO2 exhibited higher adsorption uptakes at 298 K across the entire pressure range tested, 0–100 kPa, especially in the low-pressure region, 0–20 kPa. These uptakes suggest selective adsorption of C2H2, CO2, and C2H6 over C2H4 by Zn-atz-oba. Low-coverage isosteric adsorption enthalpies were determined by virial fit of the isotherm data (see Methods section, Supplementary Note 2: Adsorption enthalpy calculation, and Supplementary Figs. 7–10) and the trends (Fig. 2d) correlate well with their low-pressure (until 20 kPa) saturation uptake capacities as follows: Qst(C2H6) (30.0 kJ mol−1) > Qst(CO2) (29.0 kJ mol−1) > Qst(C2H2) (27.5 kJ mol−1) > Qst(C2H4) (27.0 kJ mol−1). We also note that the adsorption enthalpies of all four gases are below 35 kJ mol−1, an indication that Zn-atz-oba should exhibit a relatively low energy footprint for regeneration27,45.

Adsorption selectivity is also a key indicator of separation performance. The adsorption selectivities of Zn-atz-oba for C2H2/C2H4, C2H6/C2H4, and CO2/C2H4 were calculated using Ideal Adsorbed Solution Theory49 (IAST) after fitting the single-component adsorption isotherms to the Langmuir-Freundlich model (Supplementary Figs. 11–14 and Supplementary Table 1). As shown in Fig. 2f, at 298 K and 100 kPa, the selectivities are 1.43 (C2H2/C2H4), 1.27 (C2H6/C2H4), and 1.33 (CO2/C2H4). C2H6/C2H4 and C2H2/C2H4 selectivities for Zn-atz-oba are comparable to the current benchmark sorbents that enable C2H4 purification from C2H2/C2H4/C2H6 1:1:1 ternary mixtures (1.2 and 1.8 for TJT-10035, 1.46 and 1.09 for Azole-Th-136, 1.32 and 1.4 for NPU-139, 1.4 and 1.07 for UPC-612 and 1.5 and 1.4 for UPC-61341, respectively) (Supplementary Table 3). The selectivity for CO2/C2H4 is also comparable to that of C2H6/C2H4 and C2H2/C2H4. Grand canonical Monte Carlo (GCMC) simulations of binary mixtures containing 1:1 C2H2/C2H4, C2H6/C2H4, and CO2/C2H4 in Zn-atz-oba confirmed that these selectivities are greater than 1 at 298 K and 1 atm (Supplementary Table 5). These selectivities and relatively close adsorption enthalpies suggest that Zn-atz-oba might coadsorb the preferred sorbates C2H2, C2H6, and CO2 when subjected to a mixture feed.

Mechanism of gas adsorption by GCMC simulations

GCMC simulations were conducted upon Zn-atz-oba at 273 and 298 K and afforded C2H4 and CO2 uptakes that are in good agreement with the corresponding experimental measurements at low pressure (≤0.2 atm), but are slightly higher than experimental values at higher pressures (Fig. 3). Moreover, it can be observed that the simulated uptakes for C2H2 and C2H6 significantly overestimate their corresponding experimental values for most of the state points considered. Since polarization contributes to less than 10% of the total energy for simulations of all four gases in Zn-atz-oba (see Supplementary Fig. 21), the overestimation of the theoretical uptakes compared with experiment might be attributable to the partial charges (Supplementary Data 1) and/or the repulsion/dispersion parameters (Supplementary Data 2) that were used for the MOF atoms (for crystallographic distances between MOF atoms see Supplementary Data 3; further details of the modeling study are provided in Supplementary Note 3: Modeling Study). Future work could exploit multiple MOF force field parameters for the simulations and investigate their effect upon the reliability of gas uptakes in this material. Although the simulated uptakes in Zn-atz-oba are inconsistent with experimental data, the simulations still properly predicted that this material exhibits the lowest uptake for C2H4 within the considered pressure range at 273 and 298 K. In addition, according to the simulations, Zn-atz-oba was expected to display higher uptake for C2H6 within the low-pressure region (<0.1 atm) compared to the other three gases. This is also consistent with the finding that this MOF exhibited the highest initial Qst value toward C2H6 according to both experiment and simulation (Fig. 2d and Supplementary Table 4).

The primary adsorption sites of (a) C2H2, (b) C2H4, (c) C2H6, and (d) CO2 in Zn-atz-oba. Adsorbed gas molecules are presented in space-filling mode. color codes: C (Zn-atz-oba and CO2): gray; C (C2 gases): orange; H: white; O: red; N: blue; Zn: silver. Experimental (solid lines with circles) and simulated (squares) adsorption isotherms for C2H2 (green), C2H4 (red), C2H6 (blue), and CO2 (black) at (e) 273 K and (f) 298 K and pressures up to 1 atm in Zn-atz-oba.

Molecular simulations revealed that the most favorable binding site for all adsorbates lies within the confined region enclosed by four atz linkers and three oba linkers (Fig. 3). In this region, C2H2 interacts with the –NH2 group of atz with N···H–C distances of 2.34 Å (Fig. 3a). C2H4, C2H6, and CO2 exhibit different orientations than C2H2, which allow them to make multiple contacts with the surrounding atoms of the framework. Most sorbent–sorbate interaction distances are longer for C2H4 versus C2H6 and CO2, indicating weaker interactions between C2H4 and the pores of Zn-atz-oba (Fig. 3b–d). The GCMC-calculated initial Qst values were determined and exhibit the following trend: C2H6 > CO2 > C2H2 > C2H4 (see Supplementary Table 4). The greater Qst value for C2H6 versus CO2 in Zn-atz-oba is supported by shorter interactions between C2H6 and Zn-atz-oba, perhaps because of the larger molecular dimensions of C2H6 and repulsive interactions between the negatively charged O atoms of CO2 and the surrounding electronegative N atoms of the atz linkers at the binding site. Further, the close N···H–C interactions exhibited by C2H2 are shorter than those of C2H4. Overall, the modeling studies support the experimental finding that C2H4 forms weaker interactions with Zn-atz-oba than the other three gases.

Breakthrough experiments of Zn-atz-oba

The gas separation performance was determined by dynamic column breakthrough experiments performed with Zn-atz-oba. In a typical breakthrough test at 298 K and ambient pressure, C2H4/C2H6, C2H2/C2H4/C2H6, and C2H2/C2H4/C2H6/CO2 mixtures (equimolar mixtures, total gas pressure = 100 kPa) were passed through a packed column and the effluent streams were monitored by gas chromatography. In accordance with the pure gas sorption results and the molecular simulations derived understanding of the binding sites, the Zn-atz-oba fixed-bed column eluted C2H4 with ultra-high purity in a single step from all three gas mixtures. As shown in Fig. 4a–c, C2H4 breaks through first at ca. 236, 177, and 130 min, respectively, and the impurities (C2H6, C2H2, and CO2) break through 14, 12, and 10 min later, respectively. Before breakthrough of C2H6, C2H4 of polymer grade purity (>99.95%) was collected at the outlet, revealing that Zn-atz-oba achieved one-step purification of C2H4 by the coadsorption of C2H2, C2H6, and CO2 from C2H2/C2H4/C2H6/CO2 (>99.95% C2H4 productivity, 0.106 mmol g−1). To explore the recycling performance of Zn-atz-oba, ten cycles of four-component breakthrough experiments were conducted. There was no loss of C2H4 retention time (Fig. 4d). In industrial C2 hydrocarbon gas streams, C2H2 only constitutes ~1% of the total flow50. We also tested a C2H2/C2H4/C2H6/CO2 (1/33/33/33) mixture under dynamic breakthrough using 7.4 g Zn-atz-oba packed in a fixed-bed. As shown in Fig. S25, polymer-grade ethylene was harvested from 1/33/33/33 gas mixture, followed by C2H6, CO2, and C2H2. As a typical contaminant in downstream feedstocks, water vapor is present in the industrially produced C2-CO2 stream51, so breakthrough experiments in the presence of water vapor were conducted. As revealed by Fig. 4e, fractional pressure reduction of C2H2, C2H4, C2H6, and CO2 in the presence of water vapor reduced the adsorption capacity of Zn-atz-oba. This is reflected in a reduced C2H4 breakthrough time, from c.a. 170 min to c.a. 150 min. 4-component C2H2/C2H4/C2H6/CO2 (1:1:1:1) breakthrough experiments in the presence of water vapor (relative humidity 52%) also resulted in a reduced retention time but a consistent gas outflow sequence. Nevertheless, C2H4 with effluent purity >99.95% was collected at the column outlet. We attribute the shorter retention time under 52% humidity to the presence of water vapor in the breakthrough pipeline and competing sorption of water with the other four gases. After ambient air exposure for 30 days or water immersion for 10 days, PXRD patterns (Fig. 4f) and N2 isotherms at 77 K (including pore distribution, Supplementary Figs. 26 and 27) of regenerated Zn-atz-oba indicated that it is stable to both humid air and liquid water. Temperature-programmed desorption of the fully adsorbed column was conducted after achieving full saturation and revealed that the Zn-atz-oba bed could be regenerated within 50 min at 333 K under He flow (30 cm3 min−1). Even under ambient conditions (298 K and 100 kPa), regeneration was achieved within 140 min under He flow of 20 cm3 min−1 (Supplementary Fig. 23), confirming that there is indeed a relatively low energy footprint for Zn-atz-oba regeneration.

(a)–(c) Experimental breakthrough curves at 298 K for C2H4/C2H6 (1:1) (a), C2H2/C2H4/C2H6 (1:1:1) (b), and C2H2/C2H4/C2H6/CO2 (1:1:1:1) (c) separations (equimolar mixtures; total gas pressure 100 kPa; total gas flow 1.4, 2.1 and 2.8 cm3 min−1, respectively) based on Zn-atz-oba (6.3 g) packed column (C: Outlet gas concentration, C0: Inlet gas concentration). (d) Dynamic breakthrough data obtained with Zn-atz-oba fixed-bed in 1st, 5th, and 10th cycle when subjected to four-component C2H2/C2H4/C2H6/CO2 (1:1:1:1) mixture. e Four-component (1:1:1:1) breakthrough experiment in the presence of water vapor at 288 K and 100 kPa based on Zn-atz-oba (7.0 g) packed column (total gas flow of 2.8 cm3 min−1). (f) PXRD patterns of Zn-atz-oba after being subjected to air exposure and water immersion stability test conditions.

Discussion

If one compares the performances of previously reported physisorbents in the context of ethylene purification from binary mixtures15,16,17,18,19,20,22,23,24,25,26,27,28,29,30,32,46 (C2H2/C2H4, C2H6/C2H4, and C2H4/CO2) and ternary mixtures35,36,39,40,41 (C2H2/C2H4/C2H6, C2H2/C2H4/CO2, and C2H6/C2H4/CO2), it is evident that Zn-atz-oba represents a benchmark in terms of its performance parameters (Fig. 5). Specifically, Zn-atz-oba coadsorbs three gases, C2H2, C2H6, and CO2, to produce polymer-grade (>99.95%) C2H4 in just one step. We attribute this performance to the unusual pore environment in Zn-atz-oba, which enables roughly equal affinity towards C2H2, C2H6, and CO2 over C2H4. Future studies will focus upon crystal engineering of second-generation variants to further improve the purification performances of other gas mixtures of industrial relevance.

Methods

General

All reagents were obtained from vendors and used as received without further purification. Powder X-ray diffraction (PXRD) data were collected with a Rigaku-Miniflex-600 diffractometer at a scanning rate of 5° min−1 using Cu Kα radiation. Thermogravimetric analysis (TGA) data were obtained using Mettler TG DSC 3+ Thermogravimetric Analyzer. In TGA measurements, the sample was heated from 298 K to 1073 K under Ar atmosphere at a heating rate of 10 K min−1. The morphology was examined using scanning electron microscopy (FESEM, Verios G4, FEI).

Synthesis of Zn-atz-oba

A mixture of Zn(NO3)2·6H2O (10 mmol, 2.98 g), H2oba (5 mmol, 1.29 g), Hatz (10 mmol, 0.84 g), DMF (40 mL), MeOH (40 mL), and H2O (20 mL) was sealed in a 250 ml borosilicate bottle and sonicated for five minutes. The reaction mixture was then solvothermally treated at 403 K for 3 days before naturally cooling it to room temperature. The as-synthesized sample Zn-atz-oba was washed with fresh DMF, MeOH, and H2O, and exchanged with MeOH three times daily for three days and then activated at 353 K in vacuum for 12 h.

Single-component gas sorption experiments

A Micromeritics 3Flex was used for recording all gas sorption isotherms, N2 (77 K), C2H2, C2H4, C2H6, and CO2 (each, 273 and 298 K). For N2 adsorption isotherms, the temperature was controlled at 77 K using a Dewar containing 4 L liquid N2. Precise control of 273 and 298 K temperatures was implemented by a dc-2006 from Ningbo Scientz Biotechnology, which contained a cyclic control system of ethylene glycol and water mixture (v/v = 1:1). Zn-atz-oba was degassed at 298 K under high vacuum for 4 h to regenerate in between consecutive isotherm measurements.

Dynamic gas breakthrough experiments

Breakthrough curves were recorded by an in-house custom-built rig (Supplementary Fig. 22). Equimolar C2H6/C2H4 (1:1), C2H2/C2H4/C2H6 (1:1:1) and C2H2/C2H4/C2H6/CO2 (1:1:1:1) gas mixtures (total gas pressure and flow: 100 kPa and 1.4, 2.1, and 2.8 cm3 min−1, respectively) were subjected through the Zn-atz-oba packed column (6.3 g) at 298 K, and the outlet gas concentrations and composition were monitored by a gas chromatography analyzer (Carrier gas: He, TCD-Thermal Conductivity Detector, detection limit 0.1 ppm). During gas breakthrough cycling tests, Zn-atz-oba packed in the column was regenerated under He flow of 30 cm3 min−1 at 333 K for 2 h, after each breakthrough experiment.

Data availability

The sorption data; molecular simulations and breakthrough data generated in this study are provided in the Supplementary Information/Source Data file52.

Code availability

The codes used to analyse all the data generated in this study are provided in the Supplementary Information (Supplementary Note 1: Calculations, Supplementary Note 2: Adsorption enthalpy calculation and Supplementary Note 3: Modeling Study) and/or the Source Data file52.

References

Ethylene (ET): 2019 World Market Outlook and Forecast up to 2023. https://www.researchandmarkets.com/ (retrieved Jan 2019).

Sholl, D. S. & Lively, R. P. Seven chemical separations to change the world. Nature 532, 435–437 (2016).

Sadrameli, S. M. Thermal/catalytic cracking of hydrocarbons for the production of olefins: a state-of-the-art review I: thermal cracking review. Fuel 140, 102–115 (2015).

Safarik, D. J. & Eldridge, R. B. Olefin/paraffin separations by reactive absorption: a review. Ind. Eng. Chem. Res. 37, 2571–2581 (1998).

Ren, T., Patel, M. & Blok, K. Olefins from conventional and heavy feedstocks: energy use in steam cracking and alternative processes. Energy 31, 425–451 (2006).

P. A. Angelini, T et al. Materials for Separation Technologies: Energy and Emission Reduction Opportunities. Oak Ridge, TN (United States): Oak Ridge National Lab. (ORNL); 2005.

Wang, H., Liu, Y. & Li, J. Hydrocarbon separation: designer metal-organic frameworks for size-exclusion-based hydrocarbon separations: progress and challenges. Adv. Mater. 32, 2002603 (2020).

Li, J., Kuppler, R. J. & Zhou, H. Selective gas adsorption and separation in metal-organic frameworks. Chem. Soc. Rev. 38, 1477–1504 (2009).

Perry, J. J., Perman, J. A. & Zaworotko, M. J. Design and synthesis of metal-organic frameworks using metal-organic polyhedra as supermolecular building blocks. Chem. Soc. Rev. 38, 1400–1417 (2009).

MacGillivray L.-R. Metal-Organic Frameworks: Design and Application (ed. MacGillivray, L.-R.) (Wiley, Hoboken, NJ, 2010).

Furukawa, H., Cordova, K. E., O’Keeffe, M. & Yaghi, O. M. The chemistry and applications of metal-organic frameworks. Science 341, 1230444 (2013).

Kitagawa, S., Kitaura, R. & Noro, S. Functional porous coordination polymers. Angew. Chem. Int. Ed. 43, 2334–2375 (2004).

Mukherjee, S., Sensharma, D., Chen, K. & Zaworotko, M. J. Crystal engineering of porous coordination networks to enable separation of C2 hydrocarbons. Chem. Commun. 56, 10419–10441 (2020).

Yang, H. et al. Pore-Space-Partition-Enabled exceptional ethane uptake and ethane-selective ethane-ethylene separation. J. Am. Chem. Soc. 142, 2222–2227 (2020).

Liao, P., Zhang, W., Zhang, J. & Chen, X. Efficient purification of ethene by an ethane-trapping metal-organic framework. Nat. Commun. 6, 8697 (2015).

Qazvini, O. T., Babarao, R., Shi, Z., Zhang, Y. & Telfer, S. G. A robust ethane-trapping metal-organic framework with a high capacity for ethylene purification. J. Am. Chem. Soc. 141, 5014–5020 (2019).

Sun, F. et al. Microporous metal-organic framework with a completely reversed adsorption relationship for C2 hydrocarbons at room temperature. ACS Appl. Mater. Interfaces 12, 6105–6111 (2020).

Li, L. et al. Ethane/ethylene separation in a metal-organic framework with iron-peroxo sites. Science 362, 443–446 (2018).

Zeng, H. et al. Cage-Interconnected metal-organic framework with tailored apertures for efficient C2H6/C2H4 separation under humid conditions. J. Am. Chem. Soc. 141, 20390–20396 (2019).

Gücüyener, C., van den Bergh, J., Gascon, J. & Kapteijn, F. Ethane/Ethene separation turned on its head: Selective ethane adsorption on the metal-organic framework ZIF-7 through a gate-opening mechanism. J. Am. Chem. Soc. 132, 17704–17706 (2010).

Lysova, A. A. et al. A series of mesoporous metal-organic frameworks with tunable windows sizes and exceptionally high ethane over ethylene adsorption selectivity. Angew. Chem. Int. Ed. 59, 20561–20567 (2020).

Bloch, E. D. et al. Hydrocarbon separations in a metal-organic framework with open iron (II) coordination sites. Science 335, 1606–1610 (2012).

Zhang, Z. et al. Efficient trapping of trace acetylene from ethylene in an ultramicroporous metal-organic framework: synergistic effect of high-density open metal and electronegative sites. Angew. Chem. Int. Ed. 59, 18927–18932 (2020).

Cui, X. et al. Pore chemistry and size control in hybrid porous materials for acetylene capture from ethylene. Science 353, 141–144 (2016).

Li, B. et al. An ideal molecular sieve for acetylene removal from ethylene with record selectivity and productivity. Adv. Mater. 29, 1704210 (2017).

Chen, K. et al. Benchmark C2H2/CO2 and CO2/C2H2 separation by two closely related hybrid ultramicroporous materials. Chem 1, 753–765 (2016).

Yang, S. et al. Supramolecular binding and separation of hydrocarbons within a functionalized porous metal-organic framework. Nat. Chem. 7, 121–129 (2015).

Wang, J. et al. Optimizing pore space for flexible-robust metal-organic framework to boost trace acetylene removal. J. Am. Chem. Soc. 142, 9744–9751 (2020).

Qazvini, O. T., Babarao, R. & Telfer, S. G. Multipurpose metal-organic framework for the adsorption of acetylene: ethylene purification and carbon dioxide removal. Chem. Mater. 31, 4919–4926 (2019).

He, T., Xiao, Y., Zhao, Q., Zhou, M. & He, G. Ultramicroporous metal-organic framework Qc-5-Cu for highly selective adsorption of CO2 from C2H4 stream. Ind. Eng. Chem. Res. 59, 3153–3161 (2020).

Horike, S. et al. Dense coordination network capable of selective CO2 capture from C1 and C2 hydrocarbons. J. Am. Chem. Soc. 134, 9852–9855 (2012).

Qazvini, O. T., Babarao, R. & Telfer, S. G. Selective capture of carbon dioxide from hydrocarbons using a metal-organic framework. Nat. Commun. 12, 197 (2021).

Mukherjee, S. & Zaworotko, M. J. Crystal engineering of hybrid coordination networks: from form to function. Trends Chem. 2, 506–518 (2020).

Liu, S. et al. Efficient separation of acetylene and carbon dioxide in a decorated zeolite. Angew. Chem. Int. Ed. 60, 6526–6532 (2021).

Hao, H. G. et al. Simultaneous trapping of C2H2 and C2H6 from a ternary mixture of C2H2/C2H4/C2H6 in a robust metal-organic framework for the purification of C2H4. Angew. Chem. Int. Ed. 57, 16067–16071 (2018).

Xu, Z. et al. A robust Th-azole framework for highly efficient purification of C2H4 from a C2H4/C2H2/C2H6 mixture. Nat. Commun. 11, 3163 (2020).

Dong, Q. et al. Tuning gate-opening of a flexible metal-organic framework for ternary gas sieving separation. Angew. Chem. Int. Ed. 59, 22756–22762 (2020).

Yang, S. et al. Efficient purification of ethylene from C2 hydrocarbons with an C2H6/C2H2-selective metal-organic framework. ACS Appl. Mater. Interfaces 13, 962–969 (2021).

Zhu, B. et al. Pore engineering for one-step ethylene purification from a three-component hydrocarbon mixture. J. Am. Chem. Soc. 143, 1485–1492 (2021).

Mukherjee, S. et al. Amino-Functionalised hybrid ultramicroporous materials that enable single-step ethylene purification from a ternary mixture. Angew. Chem. Int. Ed. 60, 10902–10909 (2021).

Wang, Y. et al. One-step ethylene purification from an acetylene/ethylene/ethane ternary mixture by cyclopentadiene cobalt-functionalized metal-organic frameworks. Angew. Chem. Int. Ed. 60, 11350–11358 (2021).

O’ Hearn, D. J., Bajpai, A. & Zaworotko, M. J. The “Chemistree” of porous coordination networks: taxonomic classification of porous solids to guide crystal engineering studies. Small 2006351 (2021).

Nugent, P. et al. Porous materials with optimal adsorption thermodynamics and kinetics for CO2 separation. Nature 495, 80–84 (2013).

Lin, R. et al. Molecular sieving of ethylene from ethane using a rigid metal-organic framework. Nat. Mater. 17, 1128–1133 (2018).

Liao, P., Huang, N., Zhang, W., Zhang, J. & Chen, X. Controlling guest conformation for efficient purification of butadiene. Science 356, 1193–1196 (2017).

Chen, K. et al. Synergistic sorbent separation for one-step ethylene purification from a four-component mixture. Science 366, 241–246 (2019).

Chen, K. et al. New Zn-aminotriazolate-dicarboxylate frameworks: synthesis, structures, and adsorption properties. Cryst. Growth Des. 13, 2118–2123 (2013).

Spek, A. L. Structure validation in chemical crystallography. Acta Cryst. D65, 148–155 (2009).

Myers, A. L. & Prausnitz, J. M. Thermodynamics of mixed-gas adsorption. AIChE J. 11, 121–127 (1965).

Bao, Z. et al. Potential of microporous metal-organic frameworks for separation of hydrocarbon mixtures. Energy Environ. Sci. 9, 3612–3641 (2016).

Yancheshmeh, M. S. S. et al. Modeling of ethane pyrolysis process: a study on effects of steam and carbon dioxide on ethylene and hydrogen productions. Chem. Eng. J. 215-216, 550–560 (2013).

Jian-Wei, C. (2021): Zn-atz-oba gas sorption data (Exp. and Sim.) is provided as a Figshare dataset: https://doi.org/10.6084/m9.figshare.16571151.v1.

Acknowledgements

K.J.C. acknowledges the National Natural Science Foundation of China (grant number 22071195, 21805227) and Fundamental Research Funds for the Central Universities (grant number 3102017jc01001). T.W. acknowledges the National Natural Science Foundation of China (grant number 21905229). M.J.Z. acknowledges the Science Foundation Ireland (awards 13/RP/B2549, 16/IA/4624) and the European Research Council (award ADG 885695). S.M. acknowledges the Alexander von Humboldt Foundation for the award of a postdoctoral research fellowship. We would like to thank the Analytical & Testing Center of Northwestern Polytechnical University and eceshi (www.eceshi.com) for SEM and TGA testing, respectively. T.P., K.A.F., and B.S. acknowledge the National Science Foundation (Award No. DMR-1607989), including support from the Major Research Instrumentation Program (Award No. CHE-1531590). Computational resources were made available by a XSEDE Grant (No. TG-DMR090028) and by Research Computing at the University of South Florida.

Author information

Authors and Affiliations

Contributions

K.J.C. and M.J.Z. designed the project. J.W.C. and H.J.T synthesized the compounds. J.W.C. collected and analyzed all adsorption data. T.Z. and T.W. collected and analyzed the power X-ray diffraction. T.P., K.A.F., and B.S. performed the classical molecular simulations. J.W.C., S.M., and X.J. collected the experimental breakthrough data. S.M. and Y.W contributed to formal analysis and data curation. J.W.C., S.M., and K.J.C. wrote the paper, and all authors contributed to revise the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cao, JW., Mukherjee, S., Pham, T. et al. One-step ethylene production from a four-component gas mixture by a single physisorbent. Nat Commun 12, 6507 (2021). https://doi.org/10.1038/s41467-021-26473-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-021-26473-8

This article is cited by

-

Hydrogen bond unlocking-driven pore structure control for shifting multi-component gas separation function

Nature Communications (2024)

-

Benchmark single-step ethylene purification from ternary mixtures by a customized fluorinated anion-embedded MOF

Nature Communications (2023)

-

Water boosted CO2/C2H2 separation in L-arginine functionalized metal—organic framework

Nano Research (2023)

-

Ultramicroporous material based parallel and extended paraffin nano-trap for benchmark olefin purification

Nature Communications (2022)

-

Catalytic ozone decomposition and adsorptive VOCs removal in bimetallic metal-organic frameworks

Nature Communications (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.