Abstract

Electronic nematicity is often found in unconventional superconductors, suggesting its relevance for electronic pairing. In the strongly hole-doped iron-based superconductors, the symmetry channel and strength of the nematic fluctuations, as well as the possible presence of long-range nematic order, remain controversial. Here, we address these questions using transport measurements under elastic strain. By decomposing the strain response into the appropriate symmetry channels, we demonstrate the emergence of a giant in-plane symmetric contribution, associated with the growth of both strong electronic correlations and the sensitivity of these correlations to strain. We find weakened remnants of the nematic fluctuations that are present at optimal doping, but no change in the symmetry channel of nematic fluctuations with hole doping. Furthermore, we find no indication of a nematic-ordered state in the AFe2As2 (A = K, Rb, Cs) superconductors. These results revise the current understanding of nematicity in hole-doped iron-based superconductors.

Similar content being viewed by others

Introduction

Nematicity, the breaking of rotational symmetry by electronic interactions, has by now been observed in a variety of unconventional superconductors. In addition to iron-based superconductors with almost ubiquitous nematicity1,2, nematicity is discussed in the context of cuprate high-Tc superconductors3,4,5,6,7,8,9,10,11,12, heavy-fermion superconductors13,14, intercalated Bi2Se3 topological superconductors15,16,17,18, and even twisted bilayer graphene19. Furthermore, it has been theoretically suggested that nematic fluctuations may enhance pairing and therefore be an important ingredient for high-Tc superconductivity20,21,22,23.

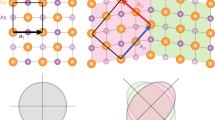

In iron-based superconductors, nematicity has been intensively studied in the vicinity of the parent compound BaFe2As2 because the stripe-type antiferromagnetic ground state inherently breaks the C4 rotational symmetry of the high-temperature tetragonal phase1,2,24,25, corresponding to a nematic degree of freedom. The accompanying structural distortion is in the B2g channel of the tetragonal D4h point group. In electron-doped BaFe2As2, the structural distortion occurs at a higher temperature than the antiferromagnetic state, creating a long-range, nematic-ordered phase. Nematic fluctuations of B2g symmetry are observed near optimal doping in both hole- and electron-doped BaFe2As226,27. Such fluctuations have frequently been studied using elastoresistance, the strain dependence of electrical resistivity1,28,29.

The parent compound BaFe2As2 nominally has a 3d6 Fe configuration. With hole doping the Fe electron configuration begins to approach the half-filled 3d5, where a Mott insulating state is expected theoretically30,31,32. Indeed, signatures of strong electronic correlations and orbital-selective Mott behavior have been observed in the isoelectronic 3d5.5 series AFe2As2 (A = K, Rb, Cs), including an enhanced Sommerfeld coefficient and signs of a coherence–incoherence crossover33,34,35. On the basis of the strong increase of electronic correlations with increasing alkali ion size in AFe2As2 (A = K, Rb, Cs), it has further been proposed that these compounds lie near a quantum critical point (QCP) associated with the suppression of a (thus far unobserved) ordered phase, possibly related to the 3d5 Mott insulator36,37. Furthermore, the electronic correlations in AFe2As2 have been found to be highly sensitive to in-plane strain34,36.

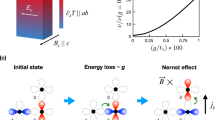

The fate of nematicity in the strongly hole-doped iron-based superconductors remains controversial. In the Ba1−xKxFe2As2 series, the elastic softening associated with the B2g nematic fluctuations decreases with hole doping and is no longer observed for x ≥ 0.8227. Several recent studies have suggested a change to nematic fluctuations of B1g symmetry in the 3d5.5 compounds, in contrast to the pervasive B2g nematic fluctuations observed at optimal doping38,39,40,41,42,43,44. Furthermore, an ordered B1g nematic phase has been proposed in RbFe2As2 based on a maximum in the elastoresistance39 and an anomaly in the zero-field nuclear spin lattice relaxation rate at a similar temperature44. In addition, asymmetries were observed in STM at low temperature40. However, the study of nematic fluctuations in these compounds is complicated by the emergence of the strong electronic correlations, which are sensitive to in-plane symmetric A1g strain45. In such a case, it is essential to properly decompose the contributions in different symmetry channels45,46,47. This symmetry decomposition was not performed in previous elastoresistance measurements on the strongly hole-doped iron-based superconductors39. In addition, the extreme thermal expansion of these samples (Fig. 1b) poses an experimental challenge for controlled measurements under elastic strain45.

a Normalized electrical resistance as a function of temperature. Inset: zoom of superconducting transitions. b In-plane sample length changes as a function of temperature34. Titanium and BaFe2As251 are shown for comparison. c Sketch of the deformations in the Fe plane corresponding to the indicated irreducible representations. d Photograph of a RbFe2As2 sample mounted between titanium plates in the strain cell. The uniaxial stress axis is defined to be x. In this example, strain is applied along [110] and the sample experiences A1g + B2g strain. ν is the in-plane Poisson ratio of the sample. e, f Longitudinal and transverse elastoresistance curves at indicated temperatures. Lines are linear fits.

In this work, we present comprehensive elastoresistance measurements on the hole-doped iron-based superconductors Ba0.4K0.6Fe2As2 and AFe2As2 (A = K, Rb, Cs) carried out in a piezoelectric-based strain cell capable of full control over the strain state of the sample. We find a monotonic increase of the A1g response with hole doping and increasing alkali ion size. In contrast, the B2g elastoresistance, a measure of the B2g nematic susceptibility, weakens with hole doping. The B1g elastoresistance shows no sign of divergence, and there is no indication of the emergence of a B1g-type nematic instability with increasing hole doping. Furthermore, we find a clear correspondence between the low-temperature elastoresistance and the electronic Grüneisen parameter if the elastoresistance coefficient is defined based only on the temperature-dependent part of the resistance.

Results

Elastoresistance measurements

The freestanding electrical resistance of our samples is displayed in Fig. 1a. For elastoresistance measurements, the sample is mounted in a strain cell composed of titanium (Fig. 1d). Figure 1b displays the length of the samples as a function of temperature, along with titanium for comparison. We see that the hole-doped samples shrink much more than the titanium apparatus on cooling. Thus, the samples can be maintained near neutral strain on cooling by adjusting the distance between the sample mounting plates in the strain cell based on the thermal expansion difference between the sample and titanium (see “Methods”). We place eight electrical contacts on the sample so that both longitudinal and transverse elastoresistance can be measured in the same experimental run (Fig. 1d). Raw elastoresistance data on RbFe2As2 obtained in this way are shown in Fig. 1e and f as an example.

In Fig. 2a–h, we present the longitudinal and transverse elastoresistance for all samples. Here, the elastoresistance is defined, for the moment, simply as mii,xx = (1/Rii)dRii/dϵxx, where i = x corresponds to the longitudinal and i = y corresponds to the transverse elastoresistance. The strain is applied along x∥[100] (Fig. 2a–d) or x∥[110] (Fig. 2e–h). In one configuration, we have reproduced our result by the usual method28 of gluing the sample directly onto a piezoelectric stack (Fig. 2c, inset). These results are in conflict with previous measurements39. When strain is applied along [100], the transverse elastoresistance is larger than the longitudinal over most of the temperature range for all samples. In contrast, for strain applied along [110], we observe that the longitudinal and transverse elastoresistance are equal at high temperature, while the longitudinal becomes larger at low temperature, for all samples. In the case of Ba0.4K0.6Fe2As2 with strain along [110] (Fig. 2e), the longitudinal and transverse elastoresistance have opposite sign. This is the expected behavior for dominant B2g nematic fluctuations46. In contrast, in the 3d5.5 superconductors AFe2As2 (A = K, Rb, Cs), both the longitudinal and transverse elastoresistance are positive at all temperatures.

Longitudinal and transverse elastoresistance with the strain direction ϵxx∥[100] (a–d) and ϵxx∥[110] (e–h) for indicated samples arranged by column. Error bars indicate one standard deviation of a linear fit. The inset of c shows a comparison of strain-cell-based and piezoelectric stack-based longitudinal elastoresistivity measurements for RbFe2As2 with ϵxx∥[100]. The strain-cell data have been scaled to account for strain relaxation in the epoxy (see “Methods” and Supplementary Fig. 1).

We note significant drops in the elastoresistance on decreasing temperature below ~15 K for both transverse and longitudinal, most notably in KFe2As2 and RbFe2As2 (Fig. 2b, c, f, g). We do not associate these anomalies with a phase transition, since no hint of a phase transition is seen in either R(T) or the thermal expansion L(T) (Fig. 1), nor indeed in the respective temperature-derivatives dR(T)/dT and dL(T)/dT (Supplementary Fig. 3). Rather, as explained below, the drop in elastoresistance results from the sample’s resistance becoming comparable to its residual resistance. Note, however, that the broad peak in CsFe2As2 at ~35 K is a pronounced manifestation of the coherence–incoherence crossover in this material.

Physical mechanism for strain dependence of resistance

To obtain a better physical understanding of elastoresistance, it is useful to take a complementary view and study the resistance as a function of temperature at a fixed strain. This is shown in Fig. 3a, taking KFe2As2 as an example. At low temperatures, the data can be fit to the standard Fermi liquid form R = R0 + AT2. The coefficient A is a measure of electronic correlations and effective mass, as given by the Kadowaki–Woods relation for a Fermi liquid A ∝ γ2, where γ is the Sommerfeld coefficient. The fit parameters R0 and A are shown as a function of strain in Fig. 3b and c. We observe that the coefficient A increases linearly with strain, while the residual resistance R0 is strain independent within experimental uncertainty. We have similarly confirmed that R0 is also strain-independent in CsFe2As2.

a Normalized resistance of KFe2As2 as a function of temperature at fixed strains, along with fits to the indicated fitting function. Inset: zoom of superconducting transitions. b Strain dependence of the fit parameter A, measuring electronic correlations and effective mass. c Strain dependence of the fit parameter R0, the residual resistance. Lines in b, c are linear fits. Error bars represent the standard error of the fits.

From the Kadowaki–Woods relation, the increase of A with strain is quantitatively consistent with the large positive dγ/dϵ inferred from thermal expansion measurements34,36 (see Supplementary Note 2) and LDA+DMFT calculations48. Consistently, hydrostatic pressure reduces A in KFe2As249. Furthermore, we observe that Tc increases with tensile strain. The strain dependence of Tc is in rough quantitative agreement with inferences based on thermodynamic measurements36 (see “Methods”).

In RbFe2As2 and CsFe2As2, we find that the resistance at low temperature can be fit to R = R0 + ATn, but with an exponent n < 2 (Fig. 4a). This is consistent with the non-Fermi liquid behavior seen at low temperature in these samples by NMR37. In Fig. 4b, we show the derivative dR/dϵ as a function of temperature for the case of RbFe2As2 with strain ∥[110] as a representative example. Taking R0 to be independent of strain, dR/dϵ = (dA/dϵ)Tn. Consistently, we find that dR/dϵ can be fit to B + CTn with the same exponent n as the resistance and an intercept B consistent with zero. In this situation, if the elastoresistance is simply defined as m = (1/R)dR/dϵ as is commonly done (see Fig. 2), we obtain m = (dA/dϵ)Tn/(R0 + ATn). Clearly, m → 0 as T → 0, as shown in Fig. 4c. As a consequence, the elastoresistance starts to drop on cooling when the residual resistance becomes a significant fraction of the total resistance below 15 K, as noted earlier (Fig. 2). If instead the elastoresistance is redefined based on only the temperature-dependent contribution to the resistance as \(\bar{m}=[1/(R-{R}_{0})]{{{{{\mathrm{d}}}}}}R/{{{{{\mathrm{d}}}}}}\epsilon\), we obtain \(\bar{m}\to ({{{{{\mathrm{d}}}}}}A/{{{{{\mathrm{d}}}}}}\epsilon )/A\) at low temperature (Fig. 4c). Note that these arguments are valid for any n. A similar approach has been applied in the analysis of elastoresistance data in YbRu2Ge250.

a The resistance of a particular RbFe2As2 crystal at temperatures where elastoresistance was measured. The solid line is a fit of these points to R = R0 + ATn (here n = 1.84). The dashed line represents the residual resistance R0. b The strain derivative of the sample resistance at selected temperatures. The solid line is a fit of these points to dR/dϵ = B + CTn (again n = 1.84). B is consistent with zero within uncertainty. The dashed line gives an upper limit on B, from the fit uncertainty. c Elastoresistance calculated as m = (1/R)dR/dϵ (black) and \(\bar{m}=[1/(R-{R}_{0})]{{{{{\mathrm{d}}}}}}R/{{{{{\mathrm{d}}}}}}\epsilon\) (green). The error bars on [1/(R − R0)]dR/dϵ reflect the uncertainty in the estimation of R0. The solid lines show the same quantities instead calculated from the fitted functions in (a, b).

The redefined elastoresistance \(\bar{m}\) produces more physically meaningful results at low temperature. For example, in the special case of n = 2 where A ∝ γ2, \(\bar{m}(T\to 0)\) is given by (dA/dϵ)/A = (dγ2/dϵ)/γ2 = 2(dγ/dϵ)/γ, which is proportional to the Grüneisen parameter Γ ≡ (dγ/dϵ)/γ for the Sommerfeld coefficient γ. Γ is a measure of the strain dependence of an energy scale. Its divergence is a central characteristic of a strain-tuned QCP51,52,53, as previously discussed in these materials36.

Having understood the longitudinal and transverse elastoresistance data, we now calculate the symmetry-decomposed elastoresistance coefficients \({\bar{m}}_{\alpha }\), where α represents the irreducible representation of the tetragonal D4h point group. These coefficients determine the resistance changes associated with the pure symmetric strains illustrated schematically in Fig. 1c. In terms of the experimental data, \({\bar{m}}_{{A}_{1g}}\) is proportional to the sum of the longitudinal and transverse elastoresistance, while \({\bar{m}}_{{B}_{1g}}\) (\({\bar{m}}_{{B}_{2g}}\)) is proportional to the difference when ϵ∥[100] (ϵ∥[110]) (see “Methods”). The resulting symmetry-decomposed elastoresistance coefficients are shown in Fig. 5. The in-plane symmetric coefficient \({\bar{m}}_{{A}_{1g}}\) (Fig. 5a) strongly increases in magnitude with hole doping from Ba0.4K0.6Fe2As2 to KFe2As2 and further with chemical substitution from KFe2As2 to CsFe2As2. Furthermore, \({\bar{m}}_{{A}_{1g}}\) of CsFe2As2 has strong temperature dependence, with an increase on cooling and a broad peak near 30 K. This temperature dependence is reminiscent of the coherence–incoherence crossover observed in the thermal expansion coefficient of this material34,45. The coefficients \({\bar{m}}_{{B}_{2g}}\) (Fig. 5b) and \({\bar{m}}_{{B}_{1g}}\) (Fig. 5c) are significantly smaller in magnitude than \({\bar{m}}_{{A}_{1g}}\), except for the case of \({\bar{m}}_{{B}_{2g}}\) in Ba0.4K0.6Fe2As2. For all samples, \({\bar{m}}_{{B}_{2g}}\) is near zero at high temperature and displays a divergent increase on cooling. The positive sign of \({\bar{m}}_{{B}_{2g}}\) is opposite to that of BaFe2As2, consistent with the observed sign change of resistivity anisotropy upon K substitution in Ba1−xKxFe2As254. We also note that both \({\bar{m}}_{{B}_{1g}}\) and \({\bar{m}}_{{B}_{2g}}\) of Ba0.6K0.4Fe2As2 are similar in magnitude and sign to CaKFe4As4, which is isoelectronic to Ba0.5K0.5Fe2As255,56. The coefficient \({\bar{m}}_{{B}_{1g}}\) is nonzero at high temperature and decreases roughly linearly on cooling in RbFe2As2 and KFe2As2. In CsFe2As2 and Ba0.4K0.6Fe2As2, we observe an upturn at low temperature. The temperature dependence of \({\bar{m}}_{{B}_{1g}}\) shows no sign of divergence in any of our samples.

Calculated with the redefined \({\bar{m}}_{\alpha }\) (see text). a \({\bar{m}}_{{A}_{1g}}\) calculated from ϵxx∥[110] data. b \({\bar{m}}_{{B}_{2g}}\). c \({\bar{m}}_{{B}_{1g}}\). The strain symmetry channels are illustrated in the upper right of each panel. The insets in panels b and c show a zoomed view. The error bars take into account the uncertainty in R0. Due to large uncertainties in R0 for the high-Tc sample Ba0.4K0.6, we have plotted mα instead of \({\bar{m}}_{\alpha }\) for this sample (points with thick edges).

Discussion

We discuss first the in-plane symmetric coefficient \({\bar{m}}_{{A}_{1g}}\) (Fig. 5a). Since the resistance reflects the electronic entropy and correlations in these materials35,45, the increase of \({\bar{m}}_{{A}_{1g}}\) from KFe2As2 to CsFe2As2 indicates that the strain sensitivity of the electronic correlations increases as a result of this chemical substitution. This is consistent with the increase in the strain derivative of the Sommerfeld coefficient ∂γ/∂ϵ observed in thermodynamic measurements34,36. Therefore, the origin of the large A1g elastoresistance is the high-strain sensitivity of the electron correlations associated with the orbital-selective Mott behavior. As a consequence, the temperature and substitution dependence of the A1g coefficient show a strong similarity to that of the thermal expansion coefficient34,45 (Supplementary Note 3). We note that the heavy-fermion superconductor URu2Si2 has also recently been shown to have a large symmetric elastoresistance57.

We turn now to the coefficients \({\bar{m}}_{{B}_{2g}}\) (Fig. 5b) and \({\bar{m}}_{{B}_{1g}}\) (Fig. 5c) corresponding to symmetry-breaking strain. They are proportional to the nematic susceptibility in the respective symmetry channels1, though the proportionality constant may become temperature and material dependent55. Note that the underdoped BaFe2As2 compounds are characterized by a diverging \({\bar{m}}_{{B}_{2g}}\). For all samples, \({\bar{m}}_{{B}_{2g}}\) is near zero at high temperature and displays a divergent increase on cooling. In AFe2As2 (A = K, Rb, Cs), \({\bar{m}}_{{B}_{2g}}\) is smaller than in Ba0.4K0.6Fe2As2 but has a similar temperature dependence, strongly suggesting that we are observing the remnants of the B2g nematic fluctuations found in lightly doped BaFe2As2. The temperature dependence of the coefficient \({\bar{m}}_{{B}_{1g}}\) does not show a divergence with decreasing temperature, an indication that the AFe2As2 (A = K, Rb, Cs) compounds are not near a B1g nematic instability. The evolution of \({\bar{m}}_{{B}_{1g}}\) and \({\bar{m}}_{{B}_{2g}}\) show no indication of a change from B2g to B1g nematic fluctuations in hole-doped iron-based superconductors, in contrast to previous studies39,40,41,42,43. Further, nematic fluctuations of XY, as opposed to Ising, character have been proposed in the Ba1−xRbxFe2As2 series in the 0.6 < x < 0.8 doping range39. Whereas we do find that \({\bar{m}}_{{B}_{1g}}\) and \({\bar{m}}_{{B}_{2g}}\) have similar magnitude in this doping range (in Ba0.4K0.6Fe2As2 in our case), their distinct temperature dependence is inconsistent with XY nematic fluctuations.

A phase transition to a long-range ordered B1g nematic-ordered phase below 40 K has been proposed in RbFe2As2 based on a maximum in the longitudinal elastoresistance measured along [100]39. The symmetry decomposition of the elastoresistance reveals that such a maximum occurs in the A1g channel, which we associate with the coherence/incoherence crossover and not a phase transition. Consistently, the resistance and thermal expansion34 data show no sign of a phase transition in RbFe2As2 (Fig. 1a and Supplementary Fig. 3).

Our results are summarized in Fig. 6. In this phase diagram, we plot the values of the elastoresistance coefficients at 40 K as a function of substitution, with both the hole-doped series Ba1−xKxFe2As2 and the isoelectronic 3d5.5 series AFe2As2 (A = K, Rb, Cs) on the same horizontal axis. In all, 40 K is chosen so that the high-Tc sample can be included. The hashed region 0.6 < x < 0.8 denotes the doping range where a significant change of behavior has been observed, including a Lifshitz transition58,59,60,61 and proposed broken time-reversal symmetry in the superconducting state62,63,64, as well as the proposed XY nematic state in the Rb-doped series (Ba1−xRbxFe2As2)39. Our results suggest that this doping range coincides with the emergence of an enhanced A1g elastoresistance. Recalling that \({\bar{m}}_{{A}_{1g}}\) is expected to reflect the in-plane Grüneisen parameter Γa at low temperature, we plot Γa alongside \({\bar{m}}_{{A}_{1g}}\) (40 K) in Fig. 6. The agreement confirms that the \({\bar{m}}_{{A}_{1g}}\) component of the elastoresistance is associated with the strong electronic correlations observed in thermodynamic measurements.

a Phase diagram of the hole-doped series Ba1−xKxFe2As2 for x > 0.5 and the isoelectronic series 3d5.5 series AFe2As2 (A = K, Rb, Cs) on the same horizontal axis. The hashed area denotes the doping range of a Lifshitz transition58,59,60,61 and proposed broken time-reversal symmetry in the SC state62,63,64. XY-type nematic fluctuations were suggested in the same doping range in the related system Ba1−xRbxFe2As239. Inset: full thermodynamic phase diagram of Ba1−xKxFe2As2. b Value of the elastoresistance coefficients \({\bar{m}}_{\alpha }\) at 40 K as a function of doping, for the three symmetry channels. The black triangles (right axis) represent the in-plane electronic Grüneisen parameter Γ, for comparison with \({\bar{m}}_{{A}_{1g}}\). Note the experimental definition34,51\({{{\Gamma }}}_{a}\equiv {\alpha }_{a}^{{{{{{{{\rm{elec}}}}}}}}}/{C}^{{{{{{{{\rm{elec}}}}}}}}}=-(d\gamma /d{p}_{a})/\gamma\) where pa is the in-plane uniaxial pressure.

We stress that we observe, nevertheless, the remnant of the B2g nematic fluctuations of the optimally doped regime even in fully substituted samples with 3d5.5 electronic configuration. We also observe signatures of possible weak nematic fluctuations in the B1g channel, but we do not observe a change from B2g-dominant to B1g-dominant nematic fluctuations with doping and we find no evidence for a bulk nematic state in any of our samples. These results revise the current understanding of nematicity in hole-doped iron-based superconductors and raise some new points. First, neither B1g nor B2g nematic fluctuations depend strongly on the alkali ion size in AFe2As2 (A = K, Rb, Cs). In contrast, the strong correlations related to the orbital-selective Mott behavior seen in the A1g channel increase dramatically with increasing alkali ion size. The contrasting behavior indicates that the orbital-selective Mott physics does not cause the nematic fluctuations. Second, we find that the B2g nematic fluctuations are surprisingly robust, persisting at high hole doping even beyond the Lifshitz transition where the electron pocket of the Fermi surface and the corresponding nesting properties are lost, and magnetic fluctuations become incommensurate.

To conclude, we reflect on the different physical mechanisms responsible for the observed strain-induced resistance changes. In Ba0.4K0.6Fe2As2 with a sizeable nematic susceptibility, anisotropic strains change the measured resistance by favoring the resistance of one in-plane direction over the other, as nematic order causes a resistance anisotropy. In CsFe2As2, by contrast, symmetric strains directly modulate the strength of electron correlations and effective mass causing changes in average in-plane resistance.

Methods

Sample growth

Single crystals of CsFe2As2 were grown from solution using a Cs-rich self-flux in a sealed environment65. Cs, Fe, and As were weighted in molar ratio 8:1:11, respectively. All sample manipulations were performed in an argon glovebox (O2 content is < 0.5 ppm). Molten Cs together with a mixture of iron and arsenic powder were loaded into an alumina crucible. Typically 15–20 g of a mixture of Cs, Fe, and As were used for each crystal growth experiment. The alumina crucible with a lid was placed inside a stainless steel container and encapsulated. This was done by welding a stainless screw cap to one end of the container. This has the advantage that stainless steel does not corrode due to Cs vapor at high temperatures. The stainless steel container was placed in a tube furnace, which was evacuated at 5–10 mbar and slowly heated up to 200 °C. The sample was kept at this temperature for 10 h and subsequently heated up to 980 °C in 8 h. The furnace temperature was kept constant at 980 °C for 5 h and slowly cooled to 760 °C in 14 days, and then the furnace was canted to separate the excess flux. After cooling to room temperature, shiny plate-like crystals were easily removed from the remaining ingot. Refined crystallographic data have been presented elsewhere45. KFe2As2 and RbFe2As2 single crystals were obtained under similar conditions using an alkali metal/As-rich flux34.

High-quality single crystals of Ba0.4K0.6Fe2As2 were grown by a self-flux technique, using FeAs fluxes, in alumina crucibles sealed in iron cylinders using very slow cooling rates of 0.2–0.4 °C/h. The crystals were annealed in situ by further slow cooling to room temperature.

Elastoresistance measurements

Elastoresistance measurements were performed in a commercial strain cell (Razorbill Instruments CS-120). The samples were cut with edges along the tetragonal in-plane directions [100] or [110], with typical dimensions of 3.0 × 1.0 × 0.06 mm. The samples were fixed in the strain cell using DevCon 5 Minute Epoxy with an effective strained sample length of 2.0 mm. The epoxy thickness was controlled to be 50 μm below the sample and ~30 μm above the sample. Cigarette paper was used to ensure the electrical insulation of the sample from the titanium mounting plates. The sample strain was measured via a built-in capacitive displacement sensor and readout on an Andeen Hagerling 2550A capacitance bridge. Resistance was measured using a four-point method on a Lake Shore 372 resistance bridge. Hans Wolbring Leitsilber 200N was used to make the electrical contacts, as contacts made with DuPont 4929N silver paint were found to be mechanically unstable on strain application.

We note that the true strain experienced by a sample in the strain cell is less than the nominal strain read by the capacitance sensor66. From a comparison with established elastoresistance data on BaFe2As2, we estimate that the true strain is ~60% of the nominal strain in our setup, as shown in Supplementary Fig. 1. As all measurements are performed with very similar sample dimensions and sample mounting in the same cell, conversion of the elastoresistance from nominal to true strain can be performed by scaling them up by a factor of (1/0.6). Nevertheless, we report primarily nominal strain, the only exception being the inset of Fig. 2c where the scaling factor has been applied in order to compare with piezoelectric stack-based measurements.

Due to the large thermal expansion mismatch between our samples and the titanium body of the strain cell, the samples will experience tension on cooling (Fig. 1b). In the most extreme case of CsFe2As2, the sample is expected to experience ~0.7% tension at base temperature. In contrast, the parent compound BaFe2As2 has a thermal expansion nearly identical to titanium. This is also true for lightly doped compounds66. Elastoresistance has typically been measured by gluing the sample directly onto the side of a piezoelectric stack, which has a small thermal expansion, similar to titanium. The success of previous elastoresistance measurements on lightly doped BaFe2As2 samples thus depended on the fortunately similar thermal expansion of the piezoelectric stack and the sample. However, this method is unreliable for the 3d5.5 superconductors45.

To keep the sample in an unstrained state on cooling, we progressively reduce the distance between the sample mounting plates by an amount calculated based on the known thermal expansion difference between the sample and titanium, and the measurement of a titanium calibration sample45.

To express the elastoresistance in terms of the irreducible representations α of the D4h point group, we note that the symmetric strains ϵα are given in terms of ϵxx by \({\varepsilon }_{{A}_{1g}}=\frac{1}{2}({\varepsilon }_{[100]}+{\varepsilon }_{[010]})=\frac{1}{2}({\varepsilon }_{[110]}+{\varepsilon }_{[\bar{1}10]})\), \({\varepsilon }_{{B}_{1g}}=\frac{1}{2}({\varepsilon }_{[100]}-{\varepsilon }_{[010]})\) and \({\varepsilon }_{{B}_{2g}}=\frac{1}{2}({\varepsilon }_{[110]}-{\varepsilon }_{[\bar{1}10]})\), where we use the simplified notation εx ≡ εxx. Similar expressions apply relating Rα with Rxx. The symmetry-decomposed elastoresistance coefficients are then defined as mα = (1/Rα)dRα/dεα. In terms of the experimental data, these coefficients are given by

The quantity ν is the sample’s Poisson ratio, which relates the strain along different directions, ν[100] = − ε[010]/ε[100], and \({\nu }_{[110]}=-{\varepsilon }_{[\bar{1}10]}/{\varepsilon }_{[110]}\). In general, ν is sample and temperature-dependent and anisotropic (ν[100] ≠ ν[110]). The elastoresistance coefficients in the notation of irreducible representations are given in terms of the elastoresistance coefficients in the usual Voigt notation as

In the A1g channel, \({m}_{13}={m}_{{A}_{1g,2}}\) contributes and cannot be disentangled from \({m}_{11}+{m}_{12}={m}_{{A}_{1g,1}}\). Our measured elastoresistance coefficient \({m}_{{A}_{1g}}\) therefore includes the effect of c-axis compression (tension) which accompanies the symmetric in-plane biaxial tension (compression) because of the Poisson effect.

We note that the reported elastoresistance coefficients for CsFe2As2 are larger in this paper than in our previous work45. This results from a difference in the ratio between real and nominal strain in the two studies. Our previous work was conducted with a Razorbill CS-100 cell, which has a smaller maximum displacement than the CS-120 cell used here. According to the documentation provided with our strain cells by Razorbill Instruments, due to the deformation of the strain device itself by a stiff sample, the capacitance sensor will overread the applied displacement according to

where ks is the sample spring constant, and hs is the sample mounting height above the top of the apparatus. The remaining parameters are properties of the strain cell itself: kτ is the torsional spring constant, ha is the height of the top surface above the moving block rotation center, and hc is the height of the top surface above the center of the capacitor. The parameters kτ, ha and hc are different between the two strain cells. In addition, the sample spring constants ks in this work were typically ~2 N/μm, compared with ~4 N/μm in our previous work. The smaller ks allows for a transmitted strain closer to the nominal value determined from the capacitance sensor, producing a greater measured elastoresistance in our current work. Due to these issues, we chose to re-measure CsFe2As2 in the CS-120 cell to make sure the results were comparable in all presented samples.

Calculation of Poisson ratios

The sample Poisson ratios νx = − ϵyy/ϵxx and \({\nu }_{x}^{\prime}=-{\epsilon }_{zz}/{\epsilon }_{xx}\) in terms of the elastic constants cij are given by

To obtain rough estimates of the elastic constants, we performed ab initio calculations in the framework of the generalized gradient approximation using a mixed-basis pseudopotential method36. The phonon dispersions and corresponding interatomic force constants were calculated via density functional perturbation theory and the elastic constants were then extracted via the method of long waves. For Ba0.4K0.6Fe2As2, we used values calculated for Ba0.5K0.5Fe2As2 in a virtual-crystal approximation. The numerical values of elastic constants and Poisson ratios calculated therefrom are given in Table 1. For the purposes of calculating the elastoresistance coefficients, the Poisson ratios were taken to be temperature independent.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Kuo, H.-H., Chu, J.-H., Palmstrom, J. C., Kivelson, S. A. & Fisher, I. R. Ubiquitous signatures of nematic quantum criticality in optimally doped Fe-based superconductors. Science 352, 958–962 (2016).

Fernandes, R. M., Chubukov, A. V. & Schmalian, J. What drives nematic order in iron-based superconductors? Nat. Phys. 10, 97–104 (2014).

Kivelson, S. A., Fradkin, E. & Emery, V. J. Electronic liquid-crystal phases of a doped Mott insulator. Nature 393, 550–553 (1998).

Hinkov, V. et al. Electronic liquid crystal state in the high-temperature superconductor YBa2Cu3O6.45. Science 319, 597–600 (2008).

Daou, R. et al. Broken rotational symmetry in the pseudogap phase of a high-Tc superconductor. Nature 463, 519–522 (2010).

Murayama, H. et al. Diagonal nematicity in the pseudogap phase of HgBa2CuO4+δ. Nat. Commun. 10, 1–7 (2019).

Sato, Y. et al. Thermodynamic evidence for a nematic phase transition at the onset of the pseudogap in YBa2Cu3Oy. Nat. Phys. 13, 1074–1078 (2017).

Achkar, A. J. et al. Nematicity in stripe-ordered cuprates probed via resonant X-ray scattering. Science 351, 576–578 (2016).

Cyr-Choinière, O. et al. Two types of nematicity in the phase diagram of the cuprate superconductor YBa2Cu3Oy. Phys. Rev. B 92, 224502 (2015).

Lawler, M. J. et al. Intra-unit-cell electronic nematicity of the high-Tc copper-oxide pseudogap states. Nature 466, 347–351 (2010).

Vojta, M. Lattice symmetry breaking in cuprate superconductors: stripes, nematics, and superconductivity. Adv. Phys. 58, 699–820 (2009).

Auvray, N. et al. Nematic fluctuations in the cuprate superconductor Bi2Sr2CaCu2O8+δ. Nat. Commun. 10, 1–7 (2019).

Ronning, F. et al. Electronic in-plane symmetry breaking at field-tuned quantum criticality in CeRhIn5. Nature 548, 313–317 (2017).

Helm, T. et al. Non-monotonic pressure dependence of high-field nematicity and magnetism in CeRhIn5. Nat. Commun. 11, 1–10 (2020).

Yonezawa, S. et al. Thermodynamic evidence for nematic superconductivity in CuxBi2Se3. Nat. Phys. 13, 123–126 (2016).

Shen, J. et al. Nematic topological superconducting phase in Nb-doped Bi2Se3. npj Quant. Mater. 2, https://doi.org/10.1038/s41535-017-0064-1 (2017).

Hecker, M. & Schmalian, J. Vestigial nematic order and superconductivity in the doped topological insulator CuxBi2Se3. npj Quant. Mater. 3, https://doi.org/10.1038/s41535-018-0098-z (2018).

woo Cho, C. et al. Z3-vestigial nematic order due to superconducting fluctuations in the doped topological insulators NbxBi2Se3 and CuxBi2Se3. Nat. Commun. 11, https://doi.org/10.1038/s41467-020-16871-9 (2020).

Cao, Y. et al. Nematicity and competing orders in superconducting magic-angle graphene. Science 372, 264–271 (2020).

Eckberg, C. et al. Sixfold enhancement of superconductivity in a tunable electronic nematic system. Nat. Phys. 16, 346–350 (2019).

Malinowski, P. et al. Suppression of superconductivity by anisotropic strain near a nematic quantum critical point. Nat. Phys. 16, 1189–1193 (2020).

Lederer, S., Schattner, Y., Berg, E. & Kivelson, S. A. Enhancement of superconductivity near a nematic quantum critical point. Phys. Rev. Lett. 114, 097001 (2015).

Lederer, S., Schattner, Y., Berg, E. & Kivelson, S. A. Superconductivity and non-Fermi liquid behavior near a nematic quantum critical point. Proc. Natl Acad. Sci. USA 114, 4905–4910 (2017).

Nandi, S. et al. Anomalous suppression of the orthorhombic lattice distortion in superconducting Ba(Fe1−xCox)2As2 single crystals. Phys. Rev. Lett. 104, 057006 (2010).

Chu, J.-H., Kuo, H.-H., Analytis, J. G. & Fisher, I. R. Divergent nematic susceptibility in an iron arsenide superconductor. Science 337, 710–712 (2012).

Gallais, Y. et al. Observation of incipient charge nematicity in Ba(Fe1−xCox)2As2. Phys. Rev. Lett. 111, 267001 (2013).

Böhmer, A. et al. Nematic susceptibility of hole-doped and electron-doped BaFe2As2 iron-based superconductors from shear modulus measurements. Phys. Rev. Lett. 112, 047001 (2014).

Chu, J.-H., Kuo, H.-H., Analytis, J. G. & Fisher, I. R. Divergent nematic susceptibility in an iron arsenide superconductor. Science 337, 710–712 (2012).

Ikeda, M. S. et al. Elastocaloric signature of nematic fluctuations. Preprint at https://arxiv.org/abs/2101.00080 (2020).

de’ Medici, L., Hassan, S. R., Capone, M. & Dai, X. Orbital-selective Mott transition out of band degeneracy lifting. Phys. Rev. Lett. 102, 126401 (2009).

Misawa, T., Nakamura, K. & Imada, M. Ab initio evidence for strong correlation associated with Mott proximity in iron-based superconductors. Phys. Rev. Lett. 108, 177007 (2012).

de’ Medici, L., Giovannetti, G. & Capone, M. Selective Mott physics as a key to iron superconductors. Phys. Rev. Lett. 112, 177001 (2014).

Hardy, F. et al. Evidence of strong correlations and coherence-incoherence crossover in the iron pnictide superconductor KFe2As2. Phys. Rev. Lett. 111, 027002 (2013).

Hardy, F. et al. Strong correlations, strong coupling, and s-wave superconductivity in hole-doped BaFe2As2 single crystals. Phys. Rev. B 94, 205113 (2016).

Wu, Y. et al. Emergent Kondo lattice behavior in iron-based superconductors AFe2As2 (A = K, Rb, Cs). Phys. Rev. Lett. 116, 147001 (2016).

Eilers, F. et al. Strain-driven approach to quantum criticality in AFe2As2 with A = K, Rb, and Cs. Phys. Rev. Lett. 116, 237003 (2016).

Zhang, Z. T. et al. Increasing stripe-type fluctuations in AFe2As2 (A = K, Rb, Cs) superconductors probed by 75As NMR spectroscopy. Phys. Rev. B 97, 115110 (2018).

Li, J. et al. Reemergeing electronic nematicity in heavily hole-doped Fe-based superconductors. Preprint at https://arxiv.org/abs/1611.04694 (2016).

Ishida, K. et al. Novel electronic nematicity in heavily hole-doped iron pnictide superconductors. Proc. Natl Acad. Sci. USA 117, 6424–6429 (2020).

Liu, X. et al. Evidence of nematic order and nodal superconducting gap along [110] direction in RbFe2As2. Nat. Commun. 10, https://doi.org/10.1038/s41467-019-08962-z (2019).

Onari, S. & Kontani, H. Origin of diverse nematic orders in Fe-based superconductors: 45∘ rotated nematicity in AFe2As2(A = Cs, Rb). Phys. Rev. B 100, 020507 (2019).

Wang, Y., Hu, W., Yu, R. & Si, Q. Broken mirror symmetry, incommensurate spin correlations, and B2g nematic order in iron pnictides. Phys. Rev. B 100, 100502 (2019).

Borisov, V., Fernandes, R. M. & Valentí, R. Evolution from B2g nematics to B1g nematics in heavily hole-doped iron-based superconductors. Phys. Rev. Lett. 123, 146402 (2019).

Moroni, M. et al. Charge and nematic orders in AFe2As2 (A = Rb, Cs) superconductors. Phys. Rev. B 99, 235147 (2019).

Wiecki, P. et al. Dominant in-plane symmetric elastoresistance in CsFe2As2. Phys. Rev. Lett. 125, 187001 (2020).

Kuo, H.-H., Shapiro, M. C., Riggs, S. C. & Fisher, I. R. Measurement of the elastoresistivity coefficients of the underdoped iron arsenide Ba(Fe0.975Co0.025)2As2. Phys. Rev. B 88, 085113 (2013).

Palmstrom, J. C., Hristov, A. T., Kivelson, S. A., Chu, J.-H. & Fisher, I. R. Critical divergence of the symmetric (A1g) nonlinear elastoresistance near the nematic transition in an iron-based superconductor. Phys. Rev. B 96, 205133 (2017).

Backes, S., Jeschke, H. O. & Valentí, R. Microscopic nature of correlations in multiorbital AFe2As2(A = K, Rb, Cs): Hund’s coupling versus coulomb repulsion. Phys. Rev. B 92, 195128 (2015).

Taufour, V. et al. Upper critical field of KFe2As2 under pressure: a test for the change in the superconducting gap structure. Phys. Rev. B 89, 220509 (2014).

Rosenberg, E. W., Chu, J.-H., Ruff, J. P. C., Hristov, A. T. & Fisher, I. R. Divergence of the quadrupole-strain susceptibility of the electronic nematic system YbRu2Ge2. Proc. Natl Acad. Sci. USA 116, 7232–7237 (2019).

Meingast, C. et al. Thermal expansion and Grüneisen parameters of Ba(Fe1−xCox)2As2: a thermodynamic quest for quantum criticality. Phys. Rev. Lett. 108, 177004 (2012).

Küchler, R. et al. Grüneisen ratio divergence at the quantum critical point in CeCu6−xAgx. Phys. Rev. Lett. 93, 096402 (2004).

Garst, M. & Rosch, A. Sign change of the Grüneisen parameter and magnetocaloric effect near quantum critical points. Phys. Rev. B 72, 205129 (2005).

Blomberg, E. C. et al. Sign-reversal of the in-plane resistivity anisotropy in hole-doped iron pnictides. Nat. Commun. 4, https://doi.org/10.1038/ncomms2933 (2013).

Böhmer, A. E. et al. Evolution of nematic fluctuations in CaK(Fe1−xNix)4As4 with spin-vortex crystal magnetic order. Preprint at https://arxiv.org/abs/2011.13207 (2020).

Terashima, T. et al. Elastoresistance measurements on CaKFe4As4 and KCa2Fe4As4F2 with the Fe site of C2v symmetry. Phys. Rev. B 102, 054511 (2020).

Wang, L. et al. Electronic nematicity in URu2Si2 revisited. Phys. Rev. Lett. 124, 257601 (2020).

Xu, N. et al. Possible nodal superconducting gap and Lifshitz transition in heavily hole-doped Ba0.1K0.9Fe2As2. Phys. Rev. B 88, 220508 (2013).

Malaeb, W. et al. Abrupt change in the energy gap of superconducting Ba1−xKxFe2As2 single crystals with hole doping. Phys. Rev. B 86, 165117 (2012).

Liu, Y. & Lograsso, T. A. Crossover in the magnetic response of single-crystalline Ba1−xKxFe2As2 and Lifshitz critical point evidenced by Hall effect measurements. Phys. Rev. B 90, 224508 (2014).

Hodovanets, H. et al. Fermi surface reconstruction in (Ba1−xKx)Fe2As2(0.44 ≤ x ≤ 1) probed by thermoelectric power measurements. Phys. Rev. B 89, 224517 (2014).

Maiti, S. & Chubukov, A. V. s + is state with broken time-reversal symmetry in Fe-based superconductors. Phys. Rev. B 87, 144511 (2013).

Böker, J., Volkov, P. A., Efetov, K. B. & Eremin, I. s + is superconductivity with incipient bands: doping dependence and STM signatures. Phys. Rev. B 96, 014517 (2017).

Grinenko, V. et al. Superconductivity with broken time-reversal symmetry inside a superconducting s-wave state. Nat. Phys. 16, 789–794 (2020).

Wang, A. F. et al. Calorimetric study of single-crystal CsFe2As2. Phys. Rev. B 87, 214509 (2013).

Ikeda, M. S. et al. Symmetric and antisymmetric strain as continuous tuning parameters for electronic nematic order. Phys. Rev. B 98, 245133 (2018).

Acknowledgements

We thank I.R. Fisher and K. Grube for valuable discussions. We acknowledge support by the Helmholtz Association under Contract No. VH-NG-1242. This work was also supported by the German Research Foundation (DFG) under CRC/TRR 288 (Project A02).

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

P.W. and A.E.B. initiated the project. A.A.H. and T.W. grew single-crystal samples. P.W., A.E.B., and M.F. performed the experiments. R.H. performed DFT calculations of elastic constants. P.W. analyzed the data and P.W., C.M., and A.E.B. developed the interpretations. A.E.B. guided the project. P.W. and A.E.B. wrote the manuscript with input from all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wiecki, P., Frachet, M., Haghighirad, AA. et al. Emerging symmetric strain response and weakening nematic fluctuations in strongly hole-doped iron-based superconductors. Nat Commun 12, 4824 (2021). https://doi.org/10.1038/s41467-021-25121-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-021-25121-5

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.